Repair of impeller pumps with composite materials from ...

Transcript of Repair of impeller pumps with composite materials from ...

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Repair of impeller pumps with composite materials from Chester Molecular

New pumps New cast-iron pumps are covered with ceramic composite materials from Chester in order to prolong the period of their operation, increase efficiency, resistance to abrasion and the impact of the medium. Repair of casting defects leveling smoothening the surface Chester Metal Ceramic T, Chester Metal Super Protecting the surface against abrasion, increasing the pump's durability and efficiency Chester Metal Ceramic F /FSL, PROTECTOR CF Composite materials Chester Ceramic F and Chester Ceramic FSL are used for large pumps or when the air temperature exceeds 35oC. They come in two colors and two layers are usually applied with a brush with short bristle. Chester Protector CF has a slightly higher resistance to abrasion. It is applied in one color. The thicker the coating, the higher the durability.

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

a/ Protecting the body and the rotor - Chester Metal Ceramic F Photographs of completed applications

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Protecting the pump's internal surfaces against chemical aggression PROTECTOR E

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Protecting the pump's external surfaces: a/ against corrosion COATING D1, COATING D2, PROTECTOR D b/against chemical aggression COATING E1, COATING E2, COATING EHT, PROTECTOR E Increasing the pump's efficiency The application of ceramic composite materials in new pumps on the pumps' working surfaces provides their high smoothness and thus flow resistances are reduced.

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Research conducted at pump manufacturers indicated the fact that the application of protective coatings made from fluidized materials Chester Metal Ceramic F /FSL, PROTECTOR CF makes it possible to obtain: an increase in efficiency by 5-12% an increase in lifting height a decrease in the consumption of power

Efficiency features of a pump before and after the application of CHESTER MOLECULAR CERAMIK-F

Charakterystyka sprawności pompy przed i po zastosowaniu preparatu CHESTER MOLECULAR CERAMIK-F

Efficiency Sprawność

Before the application Przed zastosowaniem preparatu

After the application of CHESTER MOLECULAR CERAMIK-F

Po zastosowaniu preparatu CHESTER MOLECULAR CERAMIK-F

Efficiency (Q) filter/ min 1 Wydajność Q filtr/min1

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Toppings for pump sets - Chester EVY, Chester Quartz

Gluing bearings, pans - anaerobic adhesives, e.g. D 36 Sealing threaded connections - anaerobic adhesives, e.g. B 36 Used pumps The purpose of the repair is to restore full operational efficiency to the damaged pump. This may be achieved by replacing parts with new ones or by regenerating used elements. "Chester Molecular" offers high quality materials for modern technologies for the regeneration of pump subassemblies which bring specific economic benefits. Repairing a body or a rotor is cheaper than new elements. In the case of large pumps, you do not need to wait for the delivery of new parts) and operational (the resistance of composite materials to erosion and cavitation is comparable or better than cast iron). After using our materials, the cost of repair quickly pays off because the pump is restored to its primary efficiency Most often damage in pumps which may be repaired with materials from "Chester Molecular" Reconstruction and regeneration of pump bodies and rotors

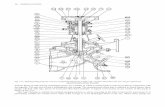

Impeller pumps are worn out due to erosion, cavitation and the chemical impact from the pumped medium.

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

This results in the increase of clearances between the rotor and the body, clear losses of the shape of the rotor, the body, covers which is reflected in the pump's reduced efficiency.

The wear may be so high that the casing is perforated.

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Materials with ceramic filling, very resistant to erosion as well as with good chemical resistance, are dedicated for the regeneration of this type of damage. These are: Chester Ceramic T, F, FSL, FHT as well as Chester Surface Protector B, C, CK, CF, E

First, degrease the regenerated parts using Chester Cleaner F-7. Then, clean the surfaces and give them an adequate profile. It is best to do this using abrasive

blasting to class S 21/2.

After secondary degreasing with the use of Chester Cleaner F-7 and drying the surface, start proper

works.

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Restore shape losses with a thixotropic material, most often Chester Metal Ceramic T, Chester

Surface Protector C, CK. When repairing large losses in the casing, use a reinforcing tape or fine metal netting previously

rubbing the regeneration material into them. This reinforcement may be additionally fixed by means of screws or rivets.

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Proceed with the casing's perforation damage in a similar manner.

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Degrease and roughen the external surface in the place of perforation – using abrasive blasting or using tools with a mechanical drive.

Cover the surface prepared in such manner with a fine layer of the composite material (thickness

approx. 1 mm). Then, apply the reinforcing tape, previously thoroughly rubbing the composite material into it. The reinforcement should be larger by approx. 40 mm than the damaged place. Cover the tape with a layer of the composite material, thickness approx. 4 mm. The layer's thickness on the edge of the tape should diminish and amount to approx. 1.5 mm in the

distance of 5 mm from its edges. After initial hardening, correct the shape in the repaired place by applying the composite material

onto the belt from the inside so as to reconstruct the primary outline of the surface as well as supplement other losses according to the guidelines specified previously.

Instead of the reinforcing tape, you may use an adequately profiled piece of steel sheet which

should be absolutely covered with a ceramic material from the inside.

Repair cracks and local leaks of the body by applying Chester Metal Ceramic T or Chester Metal Super.

Description of repair of a pump body in which a hole was punched. A decision was made to repair the damaged body by gluing a steel sheet additionally screwed with screws on the external side. For this purpose, a patch was prepared from steel sheet, thickness 2 mm adequately larger than the hole and it was profiled. Then, openings, prepared for screws M8, were drilled in the body through the steel sheet. The openings were placed in the corners of the rectangular patch.

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

The surface of the body around the damaged place and the steel sheet were cleaned and roughened with sandpaper as well as degreased with the use of Chester Cleaner F-7. Surfaces prepared in this manner were lubricated with Chester Metal Ceramic T and were additionally connected by pressing with screws M8. The hole protected in this manner was filled with the composite material referred to above to obtain the necessary shape. The steel sheet was lubricated with Chester Metal Ceramic T from the outside, in particular on its edges.

Surface finishing and supplementing minor losses is most often made with the use of liquid material

Chester Ceramic F, FSL, Chester Surface Protector CF which give smoothness to the surface apart from increasing the resistance to wear.

Remember that the liquid material constituting the external layer may be applied only on thixotropic

material which is not completely hardened. Two layers of material are applied in special regenerations using the principle referred to above.

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

To facilitate the verification of the correctness of the application of the two layers, Chester Ceramic

F and FSL materials are produced in two colors. Liquid, fluidized materials are applied with stiff brushes with short bristle.

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Photographs of pump rotor 80 KW Left photograph - view of the rotor without protections, right photograph - view of the rotor in which shape losses were restored using Chester Metal Ceramic T and then the surface was protected with Protector CF. Both photographs after one year of operation. Damaged pump rotor from a sewage treatment plant. The rotor's screw shape was reconstructed using Chester Metal Ceramic T and Chester Metal Ceramic F Protection of a two-stage impeller pump against erosion and cavitation using Chester Metal Ceramic T and Chester Metal Ceramic F

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Restoring the pump's primary operation parameters, reducing the effects of cavitation and prolonging its life span - Chester Metal Ceramic T and Chester Metal Ceramic F

The type of medium often requires the use of thixotropic materials Chester Surface Protector B, C,

CK. The liquid material Chester Ceramic (F, FSL, FHT) or Protector CF is not always applied on these

materials as the finishing layer. For this reason, after initial hardening when it stops being sticky, smoothen it with a hand in a wet

rubber glove. After complete hardening giving smoothness using mechanical treatment is practically infeasible.

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Repaired pumps working with a non-aggressive medium can be put into operation after approx. 24

hours (in 20 o C). Full chemical resistance is obtained by Chester materials after 7 days. In order to raise the

resistance of the regenerated places, they can be heated up in the temperature of 80-100o C for 2-4 hours.

When using Chester Ceramic FHT material, absolutely perform the process of additional hardening

in increased temperatures described in the respective Technical Data Sheet. Correct performance of regeneration with the use of ceramic materials results in full recovery of

operation parameters of the pump. Thus increase in durability and improvement in general efficiency of pumps are obtained.

Damage to the shaft – Chester Super Metal , Chester Metal Super FE

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Repair of rubber lining in forwarding pumps, limewater in power plants – Chester Elastomer 75 T and Chester Elastomer 75 F A pump pumping water with sand in the mineral raw materials mine Regenerated places of the lining of the pump were made rough with abrasive paper and then degreased with Fast cleaner F 7. After evaporation of the Cleaner a primer was put on regenerated places under the elastomer on rubber surface EL -20 and then only Chester Elastomer 75 T

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

In pumps which work in difficult conditions (high erosion) the coating protecting against abrasion of can be made of Chester Elastomer 95 F. For restoration of original shapes Chester Metal Ceramic T or Chester Metal Ceramic F may be used. Non-tightness of screwed joints – anaerobic adhesive e.g.B 36

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

Repair of damaged surface of flange joints – Chester Metal Super Damaged sockets under rolling bearings – Chester Metal Super -Repair with the use of machining, or using the method of pasting as ready Excessive play of fitted joints (e.g.bearings graphite sleeves etc.) - anaerobic adhesive e.g.D-36 Repair of the damaged inlet groove - Chester Metal Super The selection of material for protection and repair of pumps is affected by many factors. The following have to be taken into consideration: -the cause for the damage: erosive, cavitation, chemical, corrosive, mechanical, cracks, pull -information about the medium-what is pumped, concentration of the medium, particles and their size -material from which the damaged element is made cast-iron colour metals Al alloys. Cu, -Materials improved with heat high-alloy materials, ceramic materials, rubber

Always before beginning work, it is necessary to familiarise with the information contained in the respective Technical Data Sheet (TDS). The sheets are at our representatives', on CDs with the presentation "Chester" and always available in our service www.chestermolecular.com

-temperature of operation -working time followed by detectable losses