microbiological evaluation of portable laminar air flow isolation ...

Portable Laminar Air Flow Cabinet (STERIFLOW™)nopr.niscair.res.in/bitstream/123456789/17643/1/JSIR...

Transcript of Portable Laminar Air Flow Cabinet (STERIFLOW™)nopr.niscair.res.in/bitstream/123456789/17643/1/JSIR...

Journal of Scientific & Industrial Research

Vol. 62, December 2003, pp 1158-1163

Portable Laminar Air Flow Cabinet (STERIFLOW™)

Rajesh Thakur, Anil Sood* and P S Ahuja

Biotechnology Division , In stitute of Himal ayan Bioresource Technology, PO Box 6, Pal ampur, Himachal Pradesh 176061

Received: 20 May 2003 ; accepted : 15 September 2003

The development of a portable lamin ar air flow cabinet christened as STERIFLOWT

" was prompted by the need to perform aseptic manipulati ons in places o ther than establi shed laboratories, where conventional laminar air now hoods are not avail ab le. STERIFLOW"" is based on the principle of a regul ar Laminar Air Flow, whereby an electrically operated propeller fan sucks in ai r th rough a prefilter and drives it through a HEPA filter to generate a continuous stream of ster ile air in the working zone. The Laminar is equipped wi th a UV lamp for ensuring initial disinfection of the working space. Besides being affordabl e, its small size and li ght weight allows it to be taken along on biological sample coll ection tours. Moreover, a removable base enables its u ~e along with instrumel1.ts like, a di ssection microscope fo r manipulati on and pre paration of biological samples under aseptic conditions. Its performance was compared with that of a standard Laminar Flow Hood and the result s were found to be co mparable. Due to a combination of cost-effectiveness and portability, STERIFLOW '" has many potential applications.

Keywords: Portable laminar air fl ow, Asepti c environment , Steriflow

Introduction

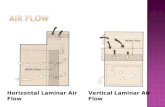

Laminar air flow instruments used in 1950s were e laborate structures having a series of appliances connected to each other for providing purified air in the work chamber I . With time, various refinements and modifications were incorporated in the apparatus to improve its effici ency and ve rsatilit /·21

. All these in st ruments are, however, des igned to provide a large aseptic workbench fo r industrial applications. These horizonta l and vertical ste ril e laminar air flow systems have the di sadvantages of be ing heavy, bulky , and expensive in terms of cost and maintenance, and hence unsuitable for low end applications, where steril e e nvironment is not required inte nsive ly , and more often a high infrastruc tural cost is unaffordable.

Es tabli shment of aseptic cultures of the rare biological specimens from remote areas has always been a problem for biologi sts. By the time they re turn

* Author for correspondence E- mail address: kuki sood @yahoo.co.in

"I" IHBT Publicati on No : 273, Dated: April 16,2003 ; Its patent has hecn li leel in Indi a, USA. pe T , Britain, Australi a, Brazil , Malays i ~l , New Zeu lanel , Singapo re. Zambi a (LJS No . 601273653. Filin g da te 05 .03.200 I)

back to their laboratories after co llecting the plant/microbial samples from far off places, the materials had already undergone treme ndous amount of stress both due to environmental variations and due to contaminating microorgani sms. Thi s results in poor survival of in vitro cultures, causing frustration to the person who spent time and effort s in its co ll ect ion. Commercial micropropagati on has al so remained restricted, since the cost of standard laminar flow in the Indian market is at least Rs 30 ,000 to 40,000 which becomes the limiting factor fo r many small entrepreneurs who wish to set up the ir own production centers at domestic levels .

It was thus realised that deve lopment of a portable model of the instrument would enable both the scientists and small scale entrepreneurs to take advantage of the affordability, portabil ity , and ease of operation of the new instrument. Further, biotechnology has been included as a part of the revised curriculum of the CBSE, and STERIFLOW'M can fill the gap as a handy teaching aid in the schoo l laboratories for the, students at a fraction of the usual cost. The development process went through des igning, fabrication and testing of va ri ous mode ls before specific des ign parameters were standard ized.

THAKUR el at.: PORTABLE AIR FLOW CABINET 1159

Design of the Apparatus.

The entire vo lume is di vided into three chambers. These are: sucti on zone with a prefilter at its inlet, a compress ion zone wi th a prope ller fan at its interface with the suction zone, and the working zone with a HEPA filter at its interface with the compress ion zone (Figure I). The propeller fan generates a stream of air that is sucked through the prefilter, and then driven through the HEPA filter to generate an aseptic environment in the working zone.

Key Features/Specifications

Working space

Working sur face

Ex t. Dimensions

Weight

Prefilte r e ffic iency

HEPA filter effic iency

Body

Portability

UV Lamp

Power suppl y

Power consumpti on

Operati on

H x W x D = 27 em x 32ern x

23ern

G lossy sta inless steel

H x W x D = 55cm x 36cm x 25 cm

14.5 kg

99 per cent down to 5J..1

99.97 per cent down to 0.3 J..1

Medium density fibre body with sunmica fini sh (interi or and ex teri or)

Acrylic doors on front and sides, front door height adjustable.

Removable base plate

Handle and shoulder strap

9W germicidal UV-Iamp

50 Hz 220V AC Voltage

200W

No ise less and effic ient bl owers with a speed regul ator

Specifications are subj ect to change as and when required , in order to incorporate improvements in the stated instrument.

Maintenance is negli gible, except fo r care to keep it covered when not in use to protect from du st.

Details of the Individual Parts of the STERIFLOW'" (Figure 1)

(A) Handle - Swing type handle, centrally located at the top of the body such that it does not come into the way of the air inlet.

(B) Prefilter - A fibrou s washable filter sheet with large pore size and folded set up for hi gh surface area to fi Iter restrict the intake of suspended dust part ic les. Its filtration effi ciency is 99 per cent down to 5/1 .

(C) Body - A wooden cabinet made of med ium density fibre body with sunmica finish (interior and exterior) with outer dimensions 36 x 25 x 55 c m: W x D x H and wall thickness 2 cm di vided into upper and lower chambers. The internal dimensions of the upper chamber are: 32 x 23 x 2 1 cm : W x D x H. It has a removable pane l (D) at the front for access to the internal components, a filtrati on member (B) at the top, a motor (T) with a prope ller fan (S), HEPA fi lter (U) at the bottom, a partition (R) that compartmentalizes it into a suction channe l th rough the prefilter (B) and the exhaust c hanne l through the HEPA filter (U). The interna l dimensions of the lower

chamber are 32 x 23 x 27 cm: W x D x H. It has transparent panels (L,P) on sides with hinge j oin ts (K) along the rear vertical axi s, and a front pane l (M) which can be opened by sliding movement in vertical pl ane along the vertical groove (Q) in the body, through a hori zontal slot (Y) at the front, above the lower chamber. Fibrous mat packing fi xed to the edges of the s lot (Y) prevents free movement of unfiltered air from outside . Provi sion for opening or clos ing the front and the side panels, make manipulations inside the sterile zone w ithin the lower chamber possible from any direction as per convel1lence.

(D) Upper Front Panel - A removable wooden pane l, approximate ly 6 mm in thickness, fixed in fro nt of the upper chamber with screws, a ll ows access to the internal components for servic ing.

(E) Regulator - An e lectronic fa n regul ator th at operates at 240V AC 50 Hz e lec tric ity suppl y, to regul ate the speed of the motor, turbo fan and hence the speed of the air fl ow.

(G) Notches - The front transparent po lycarbonate sheet has notches at regular intervals to fac il itate ho lding the sheet at des ired he ights .

(H) Indica tor Switches - T wo ind ica tor sw itc hes, operable at 250 V AC, placed on the side of the body (C) to fac ilitate the switching on and off the motor (T) and the germicidal UV lamp (1).

(I) Ball, Spring and Screw System - Prov ided in the lower front pane l to ho ld the transparent sheet at des ired heights.

1160 J SC I I 0 RES VOL 62 DECEMBER 2003

& & & &

Di mensions in em

1I+1H1--@

-@

(A) Hand le; (13) Prelilter; (C) Body; (D) Upper Front Panel; (E) Regulator; (G) Notches; (H) Indicator Switches; (I) Bal i, sp ring and screw systelll: (J ) Gerillicidal UV Lalllp; (K) Hinge; (L) Lower ri gh t side Panel ; (M) Lower Front Panel ; (N) Stainless steel plate; (0) Rubberized legs : (P) Luwer left side panel; (Q) Vert ical groove; (R) Partition wall; (S) Propeller fan ; (T) The fan motor; (U) HEPA lilter modu le;

(V) Spongy rubber strip ; (W) Buckle; (X) Remov"ble basal plate; (Y) Horizontal slot; (Z) Rotating door lock.

Figure I - Clockwise - Picture; Is metric view - whole; Isometric view - Vertical cut section - Air currents - schemati c diagram ; Isometric view - front upper panel removed.

THAKUR el al. : PORTABLE AIR FLOW CABINET 1161

(.J) Germicidal UV Lamp - A Sankyo Denki , Japan brand 2 1 cm long, 9 W short-wave germicidal UV lamp placed at the rear s ide, below the roof of lower chamber to evenl y illuminate the working area and any objects kept on the working platform (N).

(K) Hinge - Provided to faci litate opening and closing of side pane ls.

(L) and (P) Lower Side Panels - Transparent openable panel s on the sides provide access to the working platform when required .

(M) Lower Front Panel - A 4 mm thick rectangula r UV stabilized transparent polycarbonate plate of

dimensions 32 x 27 cm: W x H, the left and right marg in s of which are notched (G) at regul ar inte rva ls, whi ch when obs tructed by the ball , spring and sc rew sys tem (1) prov ide a mechani sm of ho lding it at desired he ights. The lower edge is partially trimmed at both ends in an obi ique manner to avo id obstruct ion by the ba ll , spring sc rew system (I) during its initi a l in sertion in to the vertical groove (Q). Its shape and s ize are such that upon compl ete c losure it does not obstruct the removal of the upper front pane l (D). It has a handl e (F) fixed to it as a site for gripping with hand , to faci I itate its vertica l movement.

(N) Stainless Steel Plate - A removable stainless stee l plate , with such shape that it fit s we ll into the working p latform (X) . It may have perfo rat ions to fac ilitate parti a l vertica lly downwards fl ow of the steril e air.

(0 ) Rubberized Legs - 2 cm ta ll rubberized legs that keep the working platform (X) ra ised above the surface. It dampens the vibrati ons in the body due to activity of the motor (T) , resulting in a smoother operati on.

(Q ) Vertical Groove - Provided on the s ides in which the fro nt transparent panel's movement IS

mate riali zed.

(R) Partition Wall - Partitions the upper chamber inlerna ll y into an upper partition fO fmin g the sucti on channe l through the pre fi Ite r(B), and a lower partition hous ing HEPA filter unit.

(S) Propeller Fan - This fan sucks a ir through the prefilter (B) and drives it through the HEPA filt er (U) to generate a continuous stream of ste ril e a ir in the lower chamber.

(T) The Fan Motor has the following specificat ions:

( i) Power : 200 W , (0.003 units/min)

( ii) Operation vo ltage : 230V AC, 50 Hz

(iii ) Current : 0 .95 A

(iv) Suction strength : 650 mm wate r co lumn

(v) Speed : 15500 - 16000 rpm

Motors of othe r configurat ions and spec ificati ons can a lso be used , with des ign modified suitab ly to enable forced movement of a ir in orde r to generate a stream of steril e a ir upon the worki ng platform at sufficient velocity.

(U) HEPA Filter Module - A set up of fo lded f ilte r membrane for high surface area, with a cut off pore size of 0.2 /l located at the end of the ex haust channe l in the upper chamber. It retains all the potent bi o logica l contaminants such as , bacterial and fu nga l spores, when the a ir pressuri zed by the prope lle r fan passes through it. Thi s gene rates a ve rt ica ll y downwards uniform strea m of s te ril e a ir into the lower chamber, the reby c reating a sterile environment above the work ing platform eX).

(V) Spongy Rubber Strip - A strip of spongy rubber is sandwiched a long the c ircumfere nce of the HEPA module, between the HEPA module and the lower wall of the upper chamber of the body (C) to which the HEPA module is fi xed, to avo id any air leakage from the upper chamber into the lower chamber except th rough the HEPA fi Ite r.

(W) Buckle - Site for attachment of shoulder strap , which enab les conveni ent portability of the in strument.

(X) Removable Basal Plate - Its removal a ll ows placement of an in strument such as a di ssect ion microscope for carrying ou t aseptic di ssec ti on works.

(Y) Horizontal Slot - This fac ilitates movement of the lower front panel in a desired ori en tati on.

(Z) Rotating Door Lock - This is a ro tating lock for the s ide doors placed on the inside of the door, w ith a knob on the outside. Turning the knob turns the lock pl ate and engages it into the cavity in the ve rtica l pillar, and prevents opening of the door.

Materials and Methods

The working of the present inventi on for obtaining a continuous flow of clean air at the perforated bench area is di scussed subsequentl y: The STERIFLOW'" is switched on so that the air is sucked into the upper chamber because of the fan and is filtered through the filter B re taining the dust particles. Soon the pressure builds up within the upper chamber and the a ir is then forced through the HEPA

1162 J SCIIND RES VOL 62 DECEMBER 2003

f ilter which takes care of the remaining suspended parti c les, both biological and abiological. Clean air flows as continuous and uni fo rm stream upon the working area, which a lso gets c leared of any suspended parti c les and after LO-12 min, the same can be used for sterile operati ons. In the case of biological operat ions, the pri or use of UV light for at least 10- 15 min is recommended to kill already ex isting contaminants . A spi rit lamp or a gas burner should be used to flame sterili ze the mouths of the culture vesse ls before carrying out operations in vo lving live biological materia l.

Experiment 1 - Testingfor Sterility E..rposing Nutrient Medium Alone

The UV li ght in the ST ERIFLOW™ was turned on fo r I 5 min , and thereafter, its blower was kept running for another I 0 min . Then pre-ste rilized petriplates were fi rst kept in the working platform for 10 min , a long the arms of a cross-stretching across the corners of the working platform and then, still hot, yet to solidify ste rilized liquid MS med ium containing sucrose (3.0 per cent w/v), vitamins and agar (0.8 per cent w/v) for solidification, was poured into them and allowed to solidify for J 5 min . The petri-pl ates were then covered and sealed with parafilm M (Mis Sigma, USA) and incubated to check for any contamination for 3 weeks.

Experiment 2 - Testingfor Sterility During In oculation Process

STERIFLOW '" was used for rai sing aseptic cultures of the nodal exp lants of a bamboo plant, Den.drocalamus hamiltonii. The nodal exp lants after surface ste rili zation with 0.04 per cent solution of HgClz (w/v) containing a drop of liquid detergent and subsequent rinsing with sterile water. These were rhen transferred to aga r (0.8 per cent wi v) solidified nutrient medium in j am bottles and incubated in growth room maintained at 25 ± 2°C and with a 12 h photoperiod.

Results and Discussions

No contamination 111 the petri-plates 111

Experiment-I confirmed the proper working of STERIFLOW '" Moreover, in Experiment-2, there was no contamination of cultures because of any bacteria or fu ngi even after three weeks of incubation period, affirmi ng that the STERIFLOW'>I is working in the desired manner and can be Ll sed for carrying out highly sensit ive, aseptic activities such as, plant ti ssue culture.

Following are some of the pote nti a l uses of this instrument:

(a) Promotion of Micropropagarion as Cottage Industry - The instrument is sma ll and does not require dedicated space for keeping. Be ing cheap. it is much more affordable .

(b) Collection of Biological Samples - It can be taken along for an on site es tab li shment of asep ti c cultures during collection of rare biologica l samples from pl aces away from laboratory;

(c) EducationaL Aid - Be ing small and cheap, it can be widely used as an aid for demonstrati on of plant ti ssue culture technology in schoo ls and co lleges ;

(d) MicrobioLogical Works - Microbiology work mostly involves use of small culture vessels and thi s instrument may serve as just suffic ient means fo r such work, instead of procuring standard laminar flow hood.

(e) Use with Bioreactor Systems - It is not practical to carry components of bioreactor sys tem to the larn.inar flow for conducting aseptic activities such as , addition of the inoculum or aseptic connection or disconnection of tubings . STERIFLOW'>I can be he lpful fo r carryi ng out such activities , by generat ing a localized aseptic environment.

(f) Integration with Other Devices - The working platform be ing partially removable, the sys tem can be integrated with other devices that may at times require ste ril e environment such as, a di ssection microscope, thus increas ing the versatility of app licatio ns.

Guidelines for Proper Functioning of STERIFLOW'>I

(i ) Keep the STERIFLOW'>I preferably in a c lean enclosed area without direct stream of ai r. .

( ii ) Use UV light for at leas t IS min before use.

(iii ) Clean the prefilte r periodically for effic ient functioning.

( iv) Operate with absolutely c lean hands and wi th a face mask and head gear.

General Information

•

•

Its patent has been filed in India, USA, PCT, Britain, Australia, Brazil , Malaysia, New Zealand , Singapore, Zambia (US No. 60/273653, Fi ling date 05.03 .2001).

This mUltipurpose instrume nt costs just Rs 10,000, whereas other low-end Laminar Flow

THAKUR el al. : PORTABLE AIR FLOW CABINET 1163

•

•

Hoods would cost at least Rs 30,000 to 40,000 in the Indian market and upper end model s, over Rs 1.0Iakh .

M s Rescholar Equipments Pvt Ltd, 85, HSIDC, Industrial Estate, Ambala Cantt 136 006, Haryana, India. (Tel. 0171-699883, Fax . 0171-699 169, E-mail: [email protected]) had been licensed for its commerc ial production .

Many trade inquiries have been received both from India and abroad.

Conclusions

The laminar air flow instrument deve loped by the authors, offers to the user at low initial costs, portabi lity, freedom from arranging for a dedicated space fo r the laminar fl ow, without compromi sing on the funct ionality as a laminar fl ow. Thi s instrument provides a special opportunity for the authorities in schools and co lleges to arrange for demonstration of tissue culture technology to the ir students at afford ab le costs . It a lso provides the sc ienti sts/ researchers an effici ent means for on-site collection of biological specimens in remote places in the form of aseptic cultures. Thus the instrument wi ll find great utility in di verse app lications, where there is a need for an environment which is steri le and dirt-free.

Acknowledgments

The authors are grateful to The Institute of Himal ayan Bioresource Technology (CSIR), Palampur, for provision of the R&D facilities. Rajesh Thakur is grateful to Counci l of Scientific and Industri al Research for financial ass istance.

References

Baker Arthur K, Work tables, US Pat 2709954, 07 June 1955.

2 Au stin Phil ip R, Clean air workbench, US Pal 4,0 16,809 (to COnlamin ati on Co ntrol Laboratories, Inc., Livoni a, Mi ch.) 12 Apri l 1977.

3 Deckas P C. Clean air wo rk stati on, US Pal 3494 1 12 (to Dexo n, Inc., Minneapo li s, Minn ., a corporation of Min nesota) 10 February 1970.

4 Di cciani A M, Fil tering de vice, US PUI 3729905 (to Lamin ar Flow, Inc. , Canshohacken, Pal 0 I May 1973.

5 Duym A, Energy conserving fume hood , US Pal 4, 142,458, 06 March 1979 .

6 Fowler J M, Contamination control apparatus, US Pal 3811250 (to Becton , Dickinson and Company, East Rutherford, N J) 21 May 1974 .

7 Frickel E & WaJter G, Laboratory workbench , US Pal 5,997,397 (to Kendro Laboratory Products GmbH , Hanua, Germany) 07 December 1999.

8 Howard H D & Robert D S, Anticontaminant work bench, US Pal 3301167 (to Ray Products Company, Inc, Alhambra, Cal if) 3 1 Janu ary 1967 .

9 Hunter J, Gilkison K, Nelson L, Rhea B, O'Dell J , Krueger G, Roepke G, Knutson G W & Kennedy M E, Biological safety cabinet with improved air fl ow, US Pal 6,368,206 (to Labconco Corporation, Kansas City, MO, US) 09 April 2002.

10 Kertesz T , Fari M, Altman A & Ziv M, Rationali zation of micropropagation bench : a novel initi ative to improve the efficiency of the explant manipul ation, Acta Horticull, 447 ( 1997) 139- 14 1.

II Landy J J , Total ex haust laminar Ilow biological fume hood safety cabinet and method , US Pal 4,098, 174,04 July 1978.

12 Larigaldie S & Tai llet J, Laminar now hood with static electricity e liminator, US Pal 4,864,459 (to Office National D'Etudes Et De Recherches Aerospatia les , France) 05 September 1989 .

13 Leavey J A & Feikert D S, Ultra-clean transport carrier, US Pat 5,843, 196 (to International Business Machi nes Corporati on, Armonk, NY) 0 I December 1998 .

14 Marsh R C, Laminar flo w work bench , US Pal 3,6 16,624 (to Becton , Dickinson and Company, East Rutherford , J) 02 November I 97 I .

15 Mears E L & Jennings R E, Horizontal laminar air fl ow work station, US Pat 4,927,438 (to Vari an Associates , Inc. , Palo Alto, Cali f.) 22 May 1990.

16 Messina A J , Ultraclean work station , US Pal 3336855 (to Atmos-Tech Corporati on, USA) 22 August 1967.

17 Norton R 0 , Convertibl e, laminar fl ow bio logical sa fety cabinet apparatus. US Pal 4,100,847 (to Labconco Corporati on , K,lI1 sas C ity , Mo, USA) 18 Jul y 1978.

18 Orii K & Kawakami T , Clean bench. US Pal 4,557,184 (to Yamato Scientifi c Co. , Ltd., Japan) 10 December 1985 .

19 Peters M D, Clean air cabinet, US Pal 4,832,717 (to Nu Ai re. Inc. , Pl ymouth, Minn .) 23 May 1989 .

20 Peters M D, Peters G D & Henderson T L, Clean air cabinet with valved ex haust, US Pat 5,665.128 (to Nu Aire, Inc., Pl ymouth , Minn .) 09 September 1997 .

2 1 Zytka D J , Madden P G & Eglinton R B, Minienvi ron ment for materi al handling, US Pal 5,487, 768, 30 January 1996.