Photostability Chamber, R&D Laboratory Equipment | Stability Chamber Manufacturer India

-

Upload

compusoft-compusoft-compusoft -

Category

Documents

-

view

219 -

download

0

Transcript of Photostability Chamber, R&D Laboratory Equipment | Stability Chamber Manufacturer India

-

7/28/2019 Photostability Chamber, R&D Laboratory Equipment | Stability Chamber Manufacturer India

1/12

AutoclaveSteam Sterilizer

R

OSWORLDExperiment With The Truth

-

7/28/2019 Photostability Chamber, R&D Laboratory Equipment | Stability Chamber Manufacturer India

2/12

CONTENTS

Osworld Timeline

What Is An Autoclave?

Autoclave Sterilization Graph

Autoclave Steam Sterilizer

Osworld Portable Autoclave: Model No OAT-P

Osworld Standard Model Autoclave: Model OAT S Wingnut Type

Osworld Fully Automatic Or Gmp Model Autoclave Model OAT E/S

Osworld Premium Model Autoclave Single Handle Internal/external Reservoir Model OAT SHI/SHE

Osworld Horizontal Autoclave Model OAT H

Osworld Range of Products

Clientele

03

04

05

06

07

08

09

10

11

06

06

R

OSWORLDExperiment With The Truth

-

7/28/2019 Photostability Chamber, R&D Laboratory Equipment | Stability Chamber Manufacturer India

3/12

At Osworld,Perseverance is the hard work

we do after we get tired of doing the

hard work we already did

PROFILEPROFILE

OSWORLD TIMELINE

1972:

1988:

1990:

1994:

1997:

2000:

2003:

2004:

2007:

2008:

2010

Character in Osworld is not automatic,

it has been worked at. The benefit however is well worth the time and effor t invested.

Joseph DSouza founded the business, and started by manufacturing andselling Oven, Incubator, Heating Mantle, Water Bath, and Hot Plate during the firstyears. The key factors behind company growth and continuance is his persistence anda strong sense of determination. As the organizations founder he values high moralsand injected them strategically in to the ground work.

Osbert DSouza his son joins the business; the product range is furtherincreased with additional products such as Autoclaves, Stability Chamber, BODIncubator, Cooling Incubator and Vacuum Oven.

Osworld executes its first expor t order of 50 Water baths and 30 Autoclaves.

Oswin DSouza his youngest son joins business. In the following year Osworld

for the first time participates in a trade exhibition and displays its products at theChemtech exhibition held at Nehru Centre, Mumbai.

With the enforcement of GMP regulatory compliance in the pharmaceuticalsector. Osworld takes proactive steps in implementing the guidelines to comply to theprovisions of the new ruling 21 CFR Part 11 from the Food & Drug Administration(FDA).

Company moves its registered office and assembly area to a new location inview of increased admin staff and marketing executives.

A new manufacturing facility with increased production capabilities is built. Theadditional space with sophisticated machinery provides for increased production tocope with the sales demand.

ISO 9000: 2000 quality assurance system is adopted, with Bureau Veritas,(formerly BVQI), worlds leading cer tifying body as the auditing agency.

CE certification for Stability Chamber and BOD Incubator was effectivelycompleted. This involves compliance to safety electrical requirements which were

tested and assessed by a regulatory governing institute.

The essential stringent compliance to the provisions of ruling 21 CFR Part 11and its firm enforcement by the FDA led to Osworld outsourcing the development ofnew data storage software. Godrej & Boyce Mfg. Co. Ltd, one of Indias most trusted,reputed brands, having entered in to an agreement with Osworld, took over the task ofdeveloping the 21 CFR Part 11 software. A reliable well equipped software team atGodrej ensured the sof tware was developed in a compliant way.

Osworld filed its first Patent (Patent Pending Application No. 2075/MUM/2010) forOslog Data Storage Device, a device used to interface varous Osworld equipments to a

PC using Oslog 21 CFR Part 11 compliant software.Osworld also launched its Premium Model Autoclave Steam Sterilizer.

ISO 9001:2000 certification was enhanced to ISO 9001:2008 certification.

R

OSWORLDExperiment With The Truth

ISO 9001: 2008Certified Organization

Recognition in the form of Lifetime

Achievement Award received byFounder of Osworld group, Mr. JosephDSouza from his Excellency, Governor

of Maharashtra at the Pharmaceutical

Leadership Summit 2010 held on 26th

June 2010 at Mumbai, India.

-

7/28/2019 Photostability Chamber, R&D Laboratory Equipment | Stability Chamber Manufacturer India

4/12

An autoclave is a device to sterilize equipment and supplies by subjecting them to high pressure saturated steam at 121 C ormore, typically for 15-20 minutes.

In its most basic form the autoclave is a pressure cooker. Water is heated in a pressurized environment to create steam. Usingpressure makes it possible to heat to higher temperatures with less energy. Autoclaves are usually made of steel and havevarious configurations for removing air prior to pressurization. Downward displacement autoclaves use gravity to remove air.Steam pulsing autoclaves use pulses of steam along with pressurizing and depressurizing to reach optimum pressure. Vacuumpump autoclaves suck air out for pressurization. Superatmospheric autoclaves are a combination of steam pulsing and vacuumpump techniques.

Autoclaves are widely used in microbiology, medicine, tattooing, body piercing, veterinary science, mycology, dentistry,chiropody and prosthetic fabrication.

Typical loads include laboratory glassware, surgical instruments, medical waste, patient care utensils, animal cage bedding,and Lysogeny broth.

A notable growing application of autoclaves is in the pre-disposal treatment and sterilization of waste material, such aspathogenic hospital waste. Machines in this category largely operate under the same principles as the original autoclave in that

they are able to neutralize potentially infectious agents by utilizing pressurized steam and superheated water.

How Does an Autoclave Work?

What Does an Autoclave Kill?

Air Removal

An autoclave sterilizes items by heating them with steam to a very high temperature. Some common temperatures at whichautoclaves operate are: 115 degrees C/10 p.s.i., 121 degrees C/15 p.s.i., and 134 degrees C/30 p.s.i. (p.s.i.=pounds persquare inch). The temperature, pressure and time of operation depend on the degree of sterilization needed.

An autoclave using standard settings can kill most bacteria, spores, viruses and fungi (all models of Osworld Autoclaves). Mostdoctor's offices, tattoo parlors, dentist offices and other places where instruments might come in contact with contaminantshave a small autoclave on site for disinfection (Osworld Por table Autoclave). Hospitals use larger autoclaves that look similar toindustrial dishwashers to sterilize many items at once (Osworld Rectangular/Cylindrical Horizontal Autoclave).Heat kills microorganisms by causing vital proteins to coagulate. The proteins stick together causing fatal damage to themicroorganism. An autoclave cooks microorganisms in the same way a pressure cooker cooks food, but at a higher

temperature. Autoclaves use steam instead of dry heat because steam can more effectively transmit heat to themicroorganisms.

It is very impor tant to ensure that all of the trapped air is removed, as hot air is very poor at achieving sterility. Steam at 134 Ccan achieve in 3 minutes the same sterility that hot air at 160 C takes two hours to achieve. Methods of achieving air removalinclude:

Downward displacement (or gravity type) - As steam enters the chamber, it fills the upper areas as it is less dense than air. Thiscompresses the air to the bottom, forcing it out through a drain. Often a temperature sensing device is placed in the drain. Onlywhen air evacuation is complete should the discharge stop. Flow is usually controlled through the use of a steam trap or asolenoid valve, but bleed holes are sometimes used, often in conjunction with a solenoid valve. As the steam and air mix it is also

possible to force out the mixture from locations in the chamber other than the bottom.

Steam pulsing - Air dilution by using a series of steam pulses, in which the chamber is alternately pressurized and thendepressurized to near atmospheric pressure.

Vacuum pumps - Vacuum pumps to suck air or air/steam mixtures from the chamber.

What is an Autoclave?

R

OSWORLDExperiment With The Truth

-

7/28/2019 Photostability Chamber, R&D Laboratory Equipment | Stability Chamber Manufacturer India

5/12

Autoclave Quality Assurance

physical, chemical biological indicators temperature

time

Chemical indicators medical packaging autoclave tape color

sterilization

Types of Sterilizersa) Clinical Sterilizer:

b) Laboratory Sterilizers:

Sterilants:

Sterilization bags/pads often have a "sterilization indicator mark" that typically darkens when the bag/pad has been processed.

Comparing the mark on an unprocessed bag to a bag that has been properly cycled will show an obvious visual difference.There are , and that can be used to ensure an autoclave reaches the correct for the

correct amount of .

can be found on and , and these change once the correct conditions have

been met. This color change indicates that the object inside the package, or under the tape, has been processed.Some computer-controlled autoclaves use an F0 (F-nought) value to control the cycle. F0 values are set as the number of

minutes of equivalent sterilization at 121 C (250 F) at 15 psi (100 kPa) above atmospheric pressure for 15 minutes . Since exact

temperature control is difficult, the temperature is monitored, and the sterilization time adjusted accordingly.

Designed to process medical devices or medicinal products.

are designed to process laboratory goods and materials that are neither medical devices normedicinal products and are not intended for use in the clinical care of patients.

Sterilizers can also be classified according to the sterilant used to effect sterilization. The commonly used sterilants are:a) high-temperature steam.b) dry heat (hot air).c) low-temperature steam and formaldehyde (LTSF).d) ethylene oxide (EO).

The High-Temperature Steam is the sterilant of choice because of its superior sterilizing qualities. The various High Temperature Steam

Sterilizers that Osworld manufactures is shown herein.

R

OSWORLDExperiment With The Truth

Autoclave Sterilization Graph

Cham

ber-vePressure(mbar)

+veChamberPressure(mbar)

x

Sterilization Exhaust PostVac

DryingCycle

Auto Exhaust& cycle complete

End Cycle Buzer ON& Cooling Cycles ON

+ve PressurePulsing

-ve PressurePulsing

PrevacDryingCycle

-

7/28/2019 Photostability Chamber, R&D Laboratory Equipment | Stability Chamber Manufacturer India

6/12

R

OSWORLDExperiment With The Truth

Osworld offers various types of Autoclaves (High Temperature Steam Sterilizers):

Vertical Top Loading Autoclaves Standard model Autoclave Wingnut type Fully Automatic Autoclave Wingnut type (available only in GMP Model) Premium Model Single Handle Autoclave with Internal Reservoir (Available in Standard as well as GMP model) Premium Model Single Handle Autoclave with External Reservoir (Available in Standard as well as GMP model)

Horizontal Front Loading Autoclaves Horizontal Autoclave Cylindrical or Rectangular Autoclaves (Available in Standard as well as GMP model)

Portable Autoclave small desktop autoclave

Autoclave Steam Sterilizer

Vertical Top Loading Autoclaves

Osworld Portable Autoclave: Model No OAT-P

Desktop Autoclave, available in small capacities of 21 litres.

Single Drum with heater and stand inside.

Entirely made of Stainless Steel 304 grade, mirror finish.

Standard size available: 300mm dia x 300 mm height.

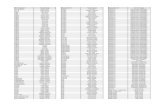

Osworld Standard Model Autoclave: Model OAT S Wingnut Type

Application: For use in Microbiology, QC & Research laboratories - Pharma Industry.

Vertical type, Double wall design has single chamber for steam and water.

Inner chamber/Outer cover made of SS 304 grade.

Lid, flange & bottom sheet also made of stainless steel. All joints argon welded.

Pressure range: 15 PSI. Temperature Range: 121C to 125C.

Lid fitted pressure gauge, safety spring loaded pressure valve, and steam release valve.

Electrical: 230V / 15A / 50 Hz.

Temperature Control: controls pressure and temperature with digital temperature indication,factory set at 121C (15 PSI), along with built in adjustable digital timer for maintainingsterilization cycle time with auto cut off.

Optional Accessoriesoffered by Standard model:

Basket, Printer Interface, High Temp Safety Controller

Size of UseableChamber

in cmsDia x Ht

30 x 50

35 x 55

45 x 60

45 x 75

55 x 75

Rating

KW

2.0

3.0

4.0

4.0

3.0x2

Model No

StandardModel

OAT S 35

OAT S 52

OAT S 95

OAT S 125

OAT S 175

Foot LiftingArrangement

To Lift Lid

No

No

Yes

Yes

Yes

OverallDimension

in cmsL x W x H

45 x 66 x 106

51 x 71 x 117

72 x 78 x 122

72 x 78 x 137

82 x 92 x 135

Capacity

Litres

35

52

95

125

175

-

7/28/2019 Photostability Chamber, R&D Laboratory Equipment | Stability Chamber Manufacturer India

7/12

Optional Accessoriesoffered by Fully Automatic model:

Basket

Printer Interface (1 Temp + 1 Pressureprinting or 3 Temp + 1 PressurePrinting)

High Temp Safety Controller

Fo printing

PC software 21CFR Part 11 compliant

Basket

PC SoftwarePrinter Interface

PLC Based System

R

OSWORLDExperiment With The Truth

Application: For use in Microbiology, QC & Research laboratory Pharma Industry.?

Double wall design has single chamber for steam and water.

Fully Automatic operation; cycle begins by press of the START button. Initial air purging cycle; at the beginning air is automatically removed from the chamber.

Microprocessor based Digital Temperature Indicator Controller.

Controls temperature / pressure precisely at set value.

In built adjusted digital timer; programmable as per sterilization load requirement.

Automatic steam exhaust at the end of cycle.

Electrical Low water level heater safeguard.

All parts of stainless steel 304 grade. All joints argon welded.

Jointless silicon gasket. Heavy duty industrial flange heater.

Pressure range: 15 PSI. Temperature Range: 121C to 125C.

Lid fitting pressure gauge, safety spring loaded pressure valve, steam release valve. Hydraulically tested at 60PSI.

Foot lifting arrangement included for capacity 95ltrs and above.

Electrical: 230V / 15A / 50 Hz.

Calibration certificate by ERTL Mumbai with traceability to NPL New Delhi.

Provided with DQ, IQ, OQ, documentation.

Vertical Top Loading Autoclaves

Osworld Fully Automatic or GMP Model Autoclave Model OAT E/S

Size of UseableChamber

in cms

Dia x Ht30 x 50

35 x 55

45 x 60

45 x 75

55 x 75

Capacity

Litres

35

52

95

125

175

Rating

KW

2.0

3.0

4.0

4.0

3.0x2

Model No

GMP

OAT G - 35

OAT G - 52

OAT G - 95

OAT G 125

OAT G 175

Foot LiftingArrangement

To Lift Lid

No

No

Yes

Yes

Yes

OverallDimension

in cms

L x W x H45 x 64 x 92

51 x 69 x 102

62 x 73 x 110

62 x 73 x 125

82 x 92 x 125

-

7/28/2019 Photostability Chamber, R&D Laboratory Equipment | Stability Chamber Manufacturer India

8/12

Double wall type design however has inner chamber for steam, outer as cover. Choose from 2 models Internal Reservoir or External Reservoir. Fully Automatic operation; cycle begins by press of the START button. Initial air purging cycle; at the beginning air is automatically removed from the chamber. Microprocessor based Digital Temperature Indicator Controller Controls temperature / pressure precisely at set value. Temperature Sensor: PT 100. In built digital timer; timer can be adjusted as per sterilization load requirement, 1 to 99minutes. Automatic steam exhaust at the end of cycle. Low water level heater safeguard. Safety high pressure release valve. Safety high temperature cut off. Working chamber made of stainless steel LM 304 grade.

Outer cover made of Mild Steel for Standard model duly powder coated and stainless steel 1mm thick for GMP model, however,inner frame structure of solid chrome plated finish. Lid, flange & bottom sheet also made of stainless steel SS 304. All joints argon welded. Silicon gasket. Heavy duty industrial flange heater. Pressure range: 15 to 30 PSI, factory set at 15 PSI, 15 minutes ster. Cycle time. Temperature Range: 121C to 134C. Temperature Resolution: 0.1C / Temperature Accuracy: 0.5C. Pressure gauge 0-50 PSI, safety spring loaded pressure valve, steam release valve. Hydraulically tested at 75PSI. Additional Safety:

i) Pressure Switch made in Europe, CE certified for additional safety. Factory set at 30PSI.ii) Vacuum breaker cum lid locking arrangement for locking lid above 80degC.

iii) Multiple micro-switches to sense lid closure, lid proper latching such that heating won't start if parameters not satisfied.

Electrical: 230V / 15A / 50 Hz. Calibration certificate by ERTL Mumbai with traceability to NPL New Delhi. Provided with DQ, IQ, OQ, documentation.

Application: For use in Microbiology, QC & Research laboratory Pharma Industry

* I/E for Internal or External Reservoir model Optional Accessories offered by Premium Model:

PLC based system with 5.7 HMI Touch Screen display:

BasketPrinter Interface (1 Temp + 1 Pressure printing or 3 Temp + 1 PressurePrinting).High Temp Safety Controller.Fo printing.PC software 21CFR Part 11 compliant.Electrical actuator to ensure lid doesn't open under pressure.Electromagnetic door lock for locking lid under pressure. Imported from

Europe, patented design, CE marked. Can keep door locked upto 300Newton pressure.

Osworld Premium Model Autoclave

Single Handle Internal / External Reservoir Model OAT SHI / SHE

Vertical Top Loading Autoclaves

R

OSWORLDExperiment With The Truth

Size of UseableChamber

in cmsDia x Ht

35 x 55

35 x 66

35 x 75

45 x 60

45 x 75

55 x 75

Capacity

Litres

52

65

75

95

125

175

Rating

KW

3.0

3.0

4.0

4.0

3.0x2

4.0

Complete Unit ofSS 304 Grade

Model NoFor GMP Model

OAT SHI/E*-/G 52

OAT SHI/E*-/G 65

OAT SHI/E*-/G 75

OAT SHI/E*-/G 125

OAT SHI/E*-/G 175

OAT SHI/E*-/G 95

Model NoFor Standard Model

Outer Mild Steeland Inner S.S.

OAT SHI/E*-S 52

OAT SHI/E*-S 65

OAT SHI/E*-S 75

OAT SHI/E*-S 125

OAT SHI/E*-S 175

OAT SHI/E*-S 95

OverallDimension

in cmsL x W x H

45 x 64 x 92

51 x 69 x 102

62 x 73 x 110

62 x 73 x 125

82 x 92 x 125

62 x 73 x 115

- Pressure Pulsing: both +ve and ve pressure pulsing is programmable.- Assisted Air Cooling: for quick cooling of chamber.- Vacuum Pump system for automatic pre/post vacuuming with pulsing.- Drying cycle.- Automatic Water Fill automatic water filling in reservoir.

-

7/28/2019 Photostability Chamber, R&D Laboratory Equipment | Stability Chamber Manufacturer India

9/12

Osworld Horizontal Autoclave Front Loading Cylindrical / Rectangular Model

Model OAT-H

Opening: Front opening2Working pressure: 1.2 to 1.7 kgf / cm g

Working temperature: 121C to 134C

Material of Construction: Inner and outer

Inner working chamber: Stainless steel 316 grade of 6mm thickness

Chamber flange: Stainless steel 304 grade of 10mm thickness

Steam jacket: MS Boiler / SS 304 of 10 mm thickness

Door :Thick Stainless Steel door of 15mm thickFor Double Door Option: two thick SS doors of 15mm thickness, one opening insterile area and the other opening in non sterile area

Outer cabinet: Stainless steel 304 grade of 1mm thick - mirror finish

Other fittings:

Piping: Stainless steel 316 grade good quality seamless

Fittings: Stainless steel 316 grade with B.S.P thread

Radial locking assembly: MS chrome plated or SS with CI lock with radial arm orSliding Door arrangement.

Stand: MS / SS round pipe

Insulation: Rock wool slabs 50mm thick

Gasket: Silicon jointless

Optional Accessories :

S.S. Loading carriage (1 no.) & S.S. Transfer trolley (2 Nos).

Vacuum Pump water immersion type.

Semi-Automatic model with Printing facility (date, time, temperature and pressure)

on EPSON 80 column dot matrix printer (printer not supplied).

Datalogger: 8 channel with Printer Interface/PC software.

Thermograph Circular type, single channel.

Interlocking system for Double Door models: When one door opened the other

cannot be opened. Flush mounting system: Increases the aesthetics of the equipment by having a

Stainless Steel Sheet on the Sterile side of the equipment flushed with the wall.

Fully automatic cycle through PLC (PLC with computer based system with Printer).

Technical Details: The system is equipped with a PC based Controlled Process Management System. The process isprogrammable for selecting:

- Number of pulses, vacuum strength for pulse, sterilization time, operating temperature & pressure, drying time & postvacuum strength- all these parameters selectable & programmable as per requirement.

- Fully Automatic operation.

- Self diagnostic system is incorporated in microprocessor programming & fault / error message with indication & alarm onsystem failure.

- Manual operating arrangement is also provided in case of auto system failure for emergency use.- Equipped with a printer for printing key process parameters like name of organization, batch no., date, time, no. of pulsingtime of pulsing, temperature sterilization holding period, pressure, post vacuum & cycle over for every sterilization processand periodically at an interval of one minutes (variable) using a dot-matrix printer.

Osworld Horizontal Autoclave

R

OSWORLDExperiment With The Truth

Horizontal cylindricalsterilizer with an electricsteam generator resting on arobust stand

Stainless steel carriage beinghalf way in the rectangularsterilizer with easilymaneuverable trolley

-

7/28/2019 Photostability Chamber, R&D Laboratory Equipment | Stability Chamber Manufacturer India

10/12

Osworld Range of Products

i bWalk- n-Staility

Sta itybil Chamber

OD ubatorB Inc

Oven Gravity Convection

R

OSWORLDExperiment With The Truth

Autoclave Steam SterilizerBacteriological Incubator

BOD IncubatorCooling Incubator

Deep Freezer

Muffle Furnace

Oven

Photostability Chamber

Stability ChamberVacuum Oven

Walk in Stability Chamber ISO 9001: 2008Certified Organization

-

7/28/2019 Photostability Chamber, R&D Laboratory Equipment | Stability Chamber Manufacturer India

11/12

Access Industrial Systems Pvt. Ltd., Sri Lanka Al Bayan Technical Equipment Est., U.A.E Al Razi ChemicalInds Trading LLC, U.A.E Alco Pharmaceuticals Ltd., Bangladesh Alive Pharmaceuticals Pvt. Ltd., Nepal Amulet Pharmaceuticals Ltd., Bangladesh Apex Pharmaceuticals Pvt. Ltd., Nepal Asian Pharmaceuticals Pvt. Ltd., Nepal Bio Pharm Industries, Algerie Chemi Drug Industries Pvt. Ltd., Nepal Consolidated Pharma Industries, Sudan Crystal Pharmaceuticals, Bangladesh

CTL Pharmaceuticals , Nepal Curex Pharmaceuticals Pvt. Ltd., Nepal Deurali Janta Pharmaceuticals Pvt. Ltd., Nepal Delta Pharmaceuticals Ltd., Bangladesh Elder Universal Pharmaceuticals (Nepal) Pvt. Ltd., Nepal Eskay Therapeutics Ltd., Ghana Everest Pharmaceuticals Pvt. Ltd., Nepal G D Pharmaceuticals Pvt. Ltd., Nepal

Domestic Clients

Alkem Laboratories Ltd., Mumbai

Aurobindo Pharma Ltd., Hyderabad Bhabha Automic Research Centre, Mumbai Cadila Healthcare Ltd., Ahmedabad, Sikkim Central Drug Testing Laboratory, Mumbai Cipla Ltd., Mumbai Concept Pharmaceuticals Ltd., Aurangabad Defence Research & Development Estt, Gwalior Dr. D.Y. Patil Institute, Mumbai Dr. Reddy's Laboratories Ltd., Hyderabad Dr. Sabharwal's Wound Care, Baddi E.I. Dupont Ltd., Hyderabad Fritolay India Ltd., Pune

Glaxo Smithkline Ltd., Hyderabad Glenmark Pharmaceutical Ltd., Mumbai, Pune, Nashik, Goa Godfrey Philips India Ltd., Mumbai Glochem Industries Ltd., Hyderabad/Vishakapatnam Haffkine Pharmaceuticals, Pune, Mumbai Hindustan Unilever Ltd., Mumbai Incozen Therapeutics Pvt. Ltd., Hyderabad Indian Drugs & Pharmaceuticals Ltd., Rishikesh Indian Institute of Technology, Mumbai Indoco Remedies Ltd., New Mumbai Ipca Laboratories Ltd., Silvassa, Ratlam, Indore Lilavati Hospital, Mumbai Lupin Ltd., Tarapur, Mumbai

Macleod Pharma Ltd., Mumbai Maneesh Pharmaceuticals Ltd, Baddi

Mark Formulations Pvt. Ltd., Nepal Maks Pharmaceuticals Ltd., Bangladesh Medivet Pharmaceuticals Pvt. Ltd., Nepal National Healthcare Pvt. Ltd., Nepal Nepal Pharmaceuticals Laboratory Pvt. Ltd., Nepal Product Proforma, Czech Republic Premier Pharmaceuticals Ltd., Bangladesh Quest Pharmaceuticals Pvt. Ltd., Nepal Red River Pharma, U.S.A S N Pharmaceuticals Ltd., Bangladesh S R Drugs Pvt. Ltd. , Nepal

Shiba Pharmaceuticals, Yemen Syarikat Bumi Sains, West Malaysia Time Pharmaceuticals Pvt. Ltd., Nepal Unimed Pharmaceuticals Ltd., Bangladesh Unique Pharmaceuticals (P) Ltd., Nepal Universal Pharmaceuticals Pvt. Ltd., Nepal Vijayadeep Laboratories Ltd., Nepal Yemen Egyptian Pharma, Yemen

IBN Sina Pharmaceuticals Ltd., Bangladesh

Manipal Accadimy of Higher Education, Mangalore

Merck Specialties Pvt. Ltd., Mumbai MSN Laboratories Ltd., Hyderabad Nicholas Piramal Ltd., Mumbai Orchid Chemicals & Pharmaceuticals Ltd., Chennai Orient Fans Ltd., Kolkata Parle Agro Pvt. Ltd., Mumbai Pfizer Ltd., New Mumbai Pharmasolve Specialities India Pvt. Ltd., Mumbai Pidilite Industries Ltd., Mumbai, Vapi Piramal Healthcare Ltd., Mumbai Ranbaxy Laboratories Ltd., Mumbai Raptakos Brett & Company Ltd., Mumbai

Reliance Life Sciences Pvt. Ltd., New Mumbai Richer Themis Ltd., Vapi S. Kant Healthcare Ltd., Vapi Sandoz Private Ltd., Thane Sarvotherm Healthcare Pvt. Ltd., Baddi Sun Pharmaceuticals Industries Ltd., Baroda Themis Medicare Ltd., Vapi Unichem Laboratories Ltd., Goa Unimark Remedies Ltd., Ahmedabad US Vitamin Ltd., Mumbai Vet India Pharmaceuticals, Hyderabad Wallace Pharmaceuticals Ltd., Goa, Baddi Wockhardt Ltd., Aurangabad, Baddi

Zydus Cadila Ltd., Ahmedabad, Goa Zenotech Laboratories Ltd., Hyderabad

R

OSWORLDExperiment With The Truth

ClientsInternational Clients

Ane Many More...

-

7/28/2019 Photostability Chamber, R&D Laboratory Equipment | Stability Chamber Manufacturer India

12/12

Olympus Industrial Estate, Off Layoff Road,Mahakali Caves Road, Andheri - (East),Mumbai - 400 093, India.

Factory:

Admin Office:

B-44, New Empire Industrial Premises, Kondivita Road, J.B. Nagar, Andheri (E), Mumbai - 400 059, India.Phone : +91-22-28320880 / 28390487, Fax : +91-22-66916595Email : [email protected] : www.osworldindia.com

R

OSWORLDExperiment With The Truth

ISO 9001: 2008Certified Organization