Performance and Rotor-Based Control of a Shrouded Rotor MAV in Edgewise Flow

description

Transcript of Performance and Rotor-Based Control of a Shrouded Rotor MAV in Edgewise Flow

Alfred Gessow Rotorcraft CenterUniversity of Maryland

Performance and Rotor-Based Control of a Shrouded Rotor MAV

in Edgewise Flow

Vikram Hrishikeshavan

Graduate Research Assistant

Inderjit Chopra

Alfred Gessow Professor and Director

AHS International Specialists’ Meeting on Unmanned Rotorcraft and Network Centric Operations,Tempe, AZ, Jan 25-27, 2011

MotivationPerimeter surveillance, building searches

Rotor based MAVs - Hover capability

- Maneuverability within confined spaces- Handle gust disturbances

Need to study vehicle performance in adverse flow conditions and enable sufficient contrallability

Low Reynolds Number Effects

Main Vortex

Vortex Sheet

Rotor Plane

Wake Obstruction

MainVortex

Low Re aerodynamics limits rotor performance

Re = 10,000-100,000

Increased profile drag

Strong tip vortex

Increased tip losses

Performance Improvement : Shrouded Rotor

•Reduces tip loss effects•Improves power loading•Protects rotor•Sturdy structure

Shrouded Rotor Performance

0 50 100 150 200 250 3000

5

10

15

20

25

Thrust (g)

Mechanical Power (W)

No shroud

Shroud

More thrustfor samepower

122 mm unshrouded rotor(FM ~0.6)

Shrouded Rotor Vehicles

ISTAR TiShrovCypher GTSpy

115 KgWeight

2 Kg 1.8 Kg 0.3 Kg

2.2 mRotor diameter

0.25 m

TiShrov – Shrouded Rotor MAV

Shroud (45 g)Carbon /epoxy

Hingeless rotor(245 mm dia)

Circular camber, sharp LE carbon/epoxyDriven by 75 W brushless outrunner motor

Vanes for anti-torqueTwo deflectable flaps for yaw control

Battery3 cell 800mAH 20C LiPo

IMUComplimentary filter gyro and acc input

for pitch and roll attitude

Weight300 g

Flight in Hover

Flybar Flybarless

Adverse pitch up tendency

Response to Edgewise Flow

Outline

• Performance in edgewise flow

• Strategies to improve controllability of shrouded rotor in edgewise flow

• Flight tests

Shroud Design

lipr

Circular inlet

lipr

lip2r

Elliptic inlet

Elliptic inlet shroud – more hover efficient(Lakshminarayan,Baeder (2010)) - CFD

Hover Performance Measurement

2% thickness (t/c)8-13% circular camber

Sharpened leading edge

2: 1 Taper @ 80%R

Hover Performance

0 50 100 150 200 2500

2

4

6

8

10

12

Thrust (g)

Mec

hani

cal P

ower

(W)

Circular inletshrouded rotor

Elliptic inletshrouded rotor

10% improvement in power loading with elliptic inlet shroud

3%R tip clearance

Performance in Edgewise Flow

Edgewise Flow: Asymmetric Pressure Distribution

Hover, no gusts Hover, edgewise gust

Edgewise Flow: Momentum Drag

Thrust

Forces in Edgewise Flow

Drag

Pitching moment

Measurement of Forces in Wind tunnel

1) Unshrouded (open) rotor

2) Circular inlet shrouded rotor

3) Elliptical inlet shrouded rotor

Pitching Moment Measurement

Bearings

Open jet Wind tunnel

Drag load cell

Pitching momentmeasurement

Drag MeasurementEdgewise flow

Drag load cell

Linear bearing

Thrust: Open Rotor

1500 2000 2500 3000 35000

50

100

150

200

250

RPM

Thrust (g)

0 m/s

1500 2000 2500 3000 35000

50

100

150

200

250

RPM

Thrust (g)

0 m/s2 m/s 24 deg

collective

No change in thrust

Thrust: Circular Inlet Shrouded Rotor

1500 2000 2500 3000 350050

100

150

200

250

RPM

Thrust (g)

0 m/s2 m/s

Thrust: Elliptical Inlet Shrouded Rotor

1500 2000 2500 3000 350050

100

150

200

250

RPM

Thrust (g)

0 m/s2 m/s

Thrust for each rotor relatively unaffected by low edgewise flow

Drag: Open Rotor

1500 2000 2500 3000 3500 40000

10

20

30

40

50

60

RPM

1 m/s

2 m/sDrag (g)

Drag: Circular Inlet Shroud

1500 2000 2500 3000 3500 40000

10

20

30

40

50

60

RPM

1 m/s

1.3 m/s

1.7 m/s

2 m/sDrag (g)

Drag: Elliptic Inlet Shroud

1500 2000 2500 3000 3500 400010

20

30

40

50

60

RPM

1 m/s

1.3 m/s

1.7 m/s

2 m/s

Drag (g)

Drag: Comparison

Shrouded rotor drag-speed slope is much higher than open rotor

0 0.5 1 1.5 2 2.50

10

20

30

40

50

60

Wind speed (m/s)

3300 RPM

Elliptic inlet shroud

Circular inlet shroud

Open rotor

Drag (g)

lipr

lipr

Elliptic inlet has more projected surface area in direction of flow

Leads to more drag

Projected Surface Area

Pitching Moment

1500 2000 2500 3000 3500 40000

200

400

600

800

1000

1200

RPM

Pitching moment (g-cm)

Open rotor

2 m/s1 m/s

1500 2000 2500 3000 35000

200

400

600

800

1000

1200

RPM

Pitching moment (g-cm)

1 m/s

1.3 m/s

1.7 m/s

2 m/s

Circular inlet shroud

Pitching Moment

0 1000 2000 3000 40000

200

400

600

800

1000

1200

RPM

Pitching Moment (g-cm)

1 m/s

1.3 m/s

1.7 m/s

2 m/s

Elliptic inlet shroud

Pitching Moment: Comparison (3300 RPM)

0 0.5 1 1.5 2 2.50

200

400

600

800

1000

Wind speed(m/s)

Pitching moment (g-cm)

Elliptic inlet shroud

Open rotor

300-400% higher pitching moment than open rotor

Circular inlet shroud

Alleviate Pitching Moment

Vents

Flaps

- Increased weight (flap actuators)

- Structural integrity of shroud reduced

- Complex control in free flight

Use rotor with swashplate control

Rotor control authority in edgewise flow

Swashplate transfers cyclic(10 deg max)

Rotor generates nose-down moment

Hingeless, flybarless rotorForce response ~ 45 deg delay

Edgewise flow

Rotor Control

Control Authority: No Edgewise Flow

2000 2500 3000 3500 40000

500

1000

1500

2000

2500

RPM

Total Control Moment (g-cm)

180

220

280

Controlauthority dropsat higher collectives

Open Rotor

Total controlmoment (g-cm)

Control Authority: No Edgewise Flow

2000 2500 3000 3500 40000

500

1000

1500

2000

2500

RPM

Total Control Moment (g-cm)

2000 2500 3000 3500 40000

500

1000

1500

2000

2500

RPM

Total Control Moment (g-cm)

Circular inlet shroud Elliptic inlet shroud

180240

300

180

240

300

Control authority increases quadratically with RPMHigher operating RPM -> Higher control authority

Total control moment (g-cm) Total control moment (g-cm)

Comparison: No Edgewise Flow

2000 2500 3000 3500 40000

500

1000

1500

2000

2500

RPM

Total Control Moment (g-cm)

Elliptic inlet shroudCircular inletshroud

Open rotor

80-100 %

CFD study on MAV shrouded rotor (Lakshminarayan, Baeder 2010)

- Shroud thrust contribution increases as rotor collective increases- Most of shroud thrust at instant rotor passes a given azimuth

Rotor bladelocation

Ratio of shroud thrust to total thrust

Shrouded Rotor Control Authority

+ve cyclic -ve cyclic

Control Authority =Mrotor + MShroud

Shroud augments rotor control authority

Control Authority in Edgewise Flow

+ve cyclic -ve cyclic

M2 (Nose-down moment)

Control Authority in Edgewise Flow (2 m/s)

Collective Unshrouded Circular lipshroud

Elliptic lipshroud

(M2) (M2) (M2)20 0 -8% -5%22 0 -8% 024 +8% -19% +3%26 - -19% +3%

Operate rotor at lower collective to minimize control authority reduction

• Elliptic inlet shrouded rotor: Increase in adverse pitching moment not

equivalent to increase in control authority – more sensitive to edgewise flow

Only circular inlet shroud considered in following sections

What is the gust tolerance?

Open-jetwind tunnel

Pitot tube

Gimbal

Gust Disturbance Response

PID attitude control IMU

10 15 20 25 30 35 40 45-0.5

0

0.5

10 15 20 25 30 35 40 450

0.2

0.4

Pitch (rad)

Gust ~ 2 m/s

Gust Disturbance Response

Can the tolerance be increased ?

Increase Control Authority

L2L1

1) Increase cyclic pitch ()2) Increase differential lift for a given cyclic pitch ()

Cyclic Pitch Magnitude

100 150

old new

2000 2500 3000 3500 4000500

1000

1500

2000

2500

3000

RPM

Control Moment (g-cm)

Old 100

New 150

Cyclic Pitch Magnitude

Shrouded rotor

Differential Lift

L

Increase chord of the airfoil

More control moment - Increase L for a given

c

Does it depend on solidity and/or planform?

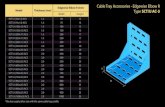

Blade Planforms

(a) Original planform

(b) Rectangular 0 1096.e 0 1322.e

0 1494.e 0 1784.e (c) Taper 140% chord (d) Rectangular 140% chord

Measure ΔThrustΔCollective instead of ΔL

Δθ

Tested with circular inlet shroud

CT vs Collective Circular inlet shrouded rotor

0 10 20 30 400

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0.09

Collective (deg)

CT

Original taper

140% taper

Rectangular140 % Rectangular

Stall

Expect higher L for a given for higher solidity rotor

Blade planform: Control Authority

2000 2500 3000 3500 40000

500

1000

1500

2000

2500

3000

3500

4000

RPM

Control Moment (g-cm)

Original taper

Rectangular

140 % Rectangular

Caution: Higher rotor should have lower collective for same RPM and thrust

Performance

0 10 20 30 40 500

2

4

6

8

10

12

14

16

Collective (deg)

Pow

er lo

adin

g (g

/W)

Original taper140% taper

Rectangular140 % Rectangular

Planform chosen based on performance at lower collective

Thrust : 300 g

Control Authority v/s Adverse Pitching Moment

0 100 200 300 400 5000

500

1000

1500

2000

2500

Thrust (g)

Moment (g-cm)

140

180

220

Adverse pitching momentat 2m/s edgewise flow

140

180 220

Nose-down control moment

Control margin gust tolerance can be increased

Rectangular planform rotor

Wind tunnel – attitude response

Gust tolerance increased to about 3 m/s

Flight Tests

VEHICLE

CAMERAS

TRACKINGMARKERS

VICON for attitude and position feedback control in gusts

Vicon flight tests

Station keeping hover Gust input from board

Experimental Set-up(MRI, Joppa, MD)

Flow straightener

CEP

X

Y

Measure the circular error probable as gust velocity increases

CEP

Greater error in position hold as gust velocity increases

0 0.5 1 1.5 2 2.5 3 3.50

500

1000

1500

2000

2500

3000

Wind speed (m/s)

Circ

ular

err

or p

roba

ble

(mm

)

Conclusions

• MAV shroud should be designed for high hover performance and low adverse pitching moment simultaneously

• Shrouded rotor - 30% higher power loading - 80% higher control authority (hingeless

rotor,swashplate) - can accept higher cyclic pitch range (stall

delay) - 300% higher adverse pitching moment • Adverse pitching moment of shrouded rotor not a

function of operating RPM or rotor collective

Conclusions (2)

• Control authority varies quadratically with RPM, (linearly with operating thrust)

• Improve control authority - Increase cyclic pitch range - High operating RPM, high rotor solidity and low

collective • Gust tolerance increased from 2 m/s to 3 m/s with

suggested changes (increased pitch and rectangular planform)

Shrouded rotor MAV viable platform for low gust environments

Future work

• Optimize rotor conditions to increase gust tolerance (incorporate collective control in swashplate)

• Onboard controller to increase controller bandwidth

• Inner and outer loop gain tuning (reduce overcorrection to disturbances)

Acknowledgements

This research was supported by the Army’s MAST CTA Center for Microsystem Mechanics with Dr. Joseph Mait (ARL) and Mr. Chris Kroninger(ARL-VTD) as Technical Monitors. The author wishes to thank Jay Baldwin from MRI, Joppa and Greg Gremillion, UMD for assistance with VICON tests. The author also wishes to thank Dr. Paul Samuel for technical advice.

0 10 20 30 400

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0.09

Collective (deg)

CT

OriginalRectangularTaper 140% chordRectangular 140% chord

0 10 20 30 400

0.1

0.2

0.3

0.4

0.5

Collective (deg)

CT/

e

OriginalRectangularTaper 140% chordRectangular 140% chord

Avionics and Telemetry

Pulse code

IMU records attitude change

Control box

generated

Servos respond

Bluetooth

2.4 GHzRadio signal

1

3

4

Pulse code

IMU records attitude change

Control box

generated

Servos respond

Bluetooth

4

22

1

3Pulse code

IMU records attitude change

Control box

generated

Servos respond

Bluetooth

Pulse code

IMU records attitude change

Control box

generated

Servos respond

Bluetooth

1

3

4

Sensor

1 tri-axis accelerometer3 rate gyros2 magnetometers

Communication: Bluetooth

Resolution: 10 Bit ADCSampling frequency: 200Hz

Input voltage: 5 V

Weight: 29 gInertial Measurement Unit

(IMU)

Latency and Bandwidth

BWdelay

0.37ω =τ

Closed loop bandwidth(Tischler 1989)

3.7 rad/s bandwidth sufficient for handling vehicle dynamics

ms

Inner Loop Control

Complementary filter to fuse gyro and accelerometer outputs – accurate attitude estimates

p – Roll rateq – Pitch rater – Yaw rateu – x velv – y velw – z vel

– Roll ang – Pitch ang – Yaw ang

Features:•LPC2138 ARM7 Processor•Freescale MMA7260Q triple-axis accelerometer, •2 Invensense IDG500 500 degree/second dual-axis gyros (total of 4 axis)•Honeywell HMC1052L and HMC1051Z magnetic sensors•Roving Networks Bluetooth Module•Tri-color status LED

2.8 m/s Edgewise Flow

10 15 20 25 30 35

0

0.2

0.4

10 15 20 25 30 35-1

-0.5

0

0.5

Time (s

Pitch(rad)

Control input(non dim)

Unable to return to hover attitude

Time (s)