Partnership between Domino’s, DMI still strong after fi ve ...

Transcript of Partnership between Domino’s, DMI still strong after fi ve ...

Reprinted with permission from the Nov. 8, 2013, edition of CHEESE MARKET NEWS® © Copyright 2013 Quarne Publishing LLC; PH: (509) 962-4026; www.cheesemarketnews.com

U.S. cheese production up 2.3 percent in SeptemberWASHINGTON — Total U.S. cheese production in September, excluding cottage cheese, totaled 891.8 million pounds, accord-ing to data released this week by USDA’s National Agricultural Statistics Service (NASS). (All fi gures are rounded. Please see CMN’s Dairy Production chart on page 10.)

This was up 2.3 percent from September 2012’s 871.5 million pounds but down 1.5 percent, adjusted for an average daily basis, from August 2013’s 935.6 million pounds.

Total Italian-type cheese production was 385.0 million pounds in September, up 4.5 percent from a year earlier. Mozzarella, the largest component of Italian-type production and the most-produced cheese in the United States, experienced a 4.7-percent increase in production from a year earlier to 300.0 million pounds.

NASS reports American-type cheese production was 347.1

Plourd: Convergence in dairy trade isn’t around the corner By Kate Sander

CHICAGO — While U.S. dairy exports continue to rise, and the world appears to become a smaller place with more and more international trade, there are many factors still at play that will defi ne the future, Phil Plourd, president & CEO, Blimling and Associates, Madison, Wis., told attendees at an educational session at this week’s International Dairy Show.

“As we think about global markets and dairy, there’s a lot of things that are assumed or presumed or that we think exist that may not exist,” Plourd says.

His session, “Convergence: Fleeting or Forever,” explored market structure and barriers to convergence, a.k.a. that time when specifi c dairy prices are essentially the same worldwide.

One obvious hindrance to convergence, Plourd notes, is there are not one or two but at least 11 easily identifi able ways to price nonfat dry milk/skim milk powder (NDM/SMP)worldwide. These include the Chicago Mercantile Exchange, the National Dairy Products Sales Re-port, GlobalDairy Trade and NZX, just to name a few. That’s in sharp contrast to corn, coffee, sugar and crude oil — which each have only one or two major markets. While milk powder markets usually track each other to some extent, Plourd says a closer examination reveals prices that are hardly uniform — including just this past May when milk powder prices were tracking as much as a $1 apart per pound.

Another important issue affecting convergence is that the United States and the rest of the world don’t trade the same basic products.

The United States primarily makes NDM while other countries market SMP. The United States makes 80 percent salted butter; the majority of the world makes 82 percent unsalted butter. U.S. markets focus on Cheddar and Mozzarella prices; other markets focus on Gouda.

Volume 33 November 8, 2013 Number 42

By Alyssa Sowerwine

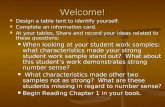

ROSEMONT, Ill. — Five years ago, a well-known national pizza brand was looking to enhance its product line. At the same time, the U.S. dairy industry was looking to address a decline in consumption of cheese on pizzas.

Out of this mutual need for change, a partnership between Domino’s Pizza and Dairy Management Inc. (DMI) was formed.

DMI is funded by America’s nearly 49,000 dairy farmers, as well as dairy importers. Created to help increase sales and de-mand for dairy products, DMI and its related organizations work to increase demand for

Partnership between Domino’s, DMI still strong after fi ve years

dairy through research, edu-cation and innovation, and to maintain confi dence in dairy foods, farms and businesses.

Dairy farmers pay 15 cents and dairy importers pay 7.5 cents for every 100 pounds of milk (or the equivalent thereof) they sell or import into a ge-neric dairy product promotion fund called the “dairy checkoff” that DMI manages along with state and regional promotion groups. That money, with USDA oversight, is used to fund programs aimed at promoting dairy consumption and protect-ing the positive image of dairy farmers, dairy products and the dairy industry.

“When we entered into this partnership with Domino’s in 2009, our objective was to revitalize pizza as it relates to cheese,” says Tom Gallagher, CEO, DMI. “Demand for cheese had been slowing down in the last fi ve years, and the amount of cheese used on pizza, for a number of reasons, had been declining.”

Gallagher notes that at the time, many pizza companies were adding pasta and sand-wiches to their menus, moving away from focusing on their core product as well as away from products that featured

more dairy.With the escalation of

commodity costs, many pizza companies tried to compensate by taking cheese off pizzas or reducing the quality, but as a result, consumers were mov-ing into other categories to meet their in-restaurant eating needs, he adds.

“Realizing we needed to start somewhere rather than do many things with many people, we thought, let’s get a stake in the ground. We chose Domino’s, although we wanted it to be a stimulation across the pizza category for cheese sales, from other national brands to mom and pop shops,” Gallagher says.

In selecting promotional partners, DMI looks for orga-nizations that share common values with the dairy industry — such as integrity and indus-try leadership, Gallagher notes. Partners also should want to work together to expand the reach of nutrient-rich dairy products and ingredients, and bring to the table many addi-tional resources in advancing dairy product innovation, he says.

In Domino’s, DMI found a group of friendly people with an eagerness to learn about formulations for cheese on

pizzas as well as information about consumers related to dairy consumption.

Early on in the partner-ship, new product marketing staff and culinary staff from Domino’s spent a week at the Center for Dairy Research in Madison, Wis., learning more about cheese and its various uses. The group also toured independent pizza restaurants in the Madison area to gain additional ideas.

Patrick Doyle, CEO, Domi-no’s Pizza, notes the partner-ship began with specifi c prod-uct promotion and new product development, starting with the launch of a new American Legends line of specialty piz-zas featuring 40 percent more cheese than Domino’s standard pies. The line featured several varieties of cheeses on the piz-zas, ranging from Mozzarella to Cheddar to Feta.

The launch proved success-ful in the following years, lead-ing to the continuation of the partnership and diversifi cation of marketing efforts.

“We’ve seen higher con-sumer acceptance and liking of our pizzas since we added more cheese,” says Joe Jordan, vice president of marketing

Relco awarded $22.7 million in case against CFR

A

INSIDE

Turn to PIZZA, page 14 a

Turn to SEPTEMBER, page 10 a

MINNEAPOLIS — Relco LLC, Wilmar, Minn., re-cently won a $22.7 million jury verdict in a case of misappropriation of con-fi dential business infor-mation. The verdict was rendered on Oct. 25 in Kandiyohi County (Minn.) District Court following a nine-day trial.

The jury found that two former employees of Relco

Turn to RELCO, page 9 aTurn to PLOURD, page 10 a

Scan this code

for breaking

news and the

latest markets!

✦ Guest column: ‘Another step closer to a one-stop shop.’ For details, see page 4.

✦ Tasting seminar looks at histories behind Wisconsin, European cheeses. For details, see page 6.

✦ Lawmakers prepare for farm bill talks to resume. For details, see page 8.

✦ September U.S. milk production up 1 percent. For details, see page 15.

Reprinted with permission from the Nov. 8, 2013, edition of CHEESE MARKET NEWS® © Copyright 2013 Quarne Publishing LLC; PH: (509) 962-4026; www.cheesemarketnews.com

MARKET INDICATORS

2 CHEESE MARKET NEWS® — November 8, 2013

DISCLAIMER: Cheese Market News® has made every effort to provide accurate current as well as historical market information. However, we do not guarantee the accuracy of these data and do not assume liability for errors or omissions.

STAFF SUBSCRIPTION INFORMATION

POSTMASTER: Send address changes to Cheese Market News®, Subscriber Services, P. O. Box 628254, Middleton, WI 53562; Form 3579 requested; or call direct at 608/831-6002.

Subscriptions:

Susan Quarne, (PH 608/831-6002; FAX 608/831-1004)

e-mail: [email protected] Kate Sander, (PH 509/962-4026; FAX 509/962-4027)

e-mail: [email protected] Sowerwine, (PH 608/288-9090; FAX 608/288-9093) e-mail: [email protected]

Rena Archwamety, (PH 608/288-9090; FAX 608/288-9093) e-mail: [email protected]

Aaron Martin, (PH 608/288-9090; FAX 608/288-9093) e-mail: [email protected]

REGULAR CONTRIBUTORSJohn Umhoefer, Downes-O'Neill LLC, International Dairy Foods Association, National Milk Producers Federation

SUBSCRIPTIONS & BUSINESS STAFFSubscription/advertising rates available upon requestContact: Susan Quarne - PublisherP.O. Box 628254, Middleton, WI 53562PHONE 608/831-6002 • FAX 608/831-1004

WEBSITE: www.cheesemarketnews.com

CLASS III PRICE (Dollars per hundredweight, 3.5% butterfat test)

YEAR2007200820092010201120122013

JAN13.5619.3210.7814.5013.4817.0518.14

FEB14.18 17.03 9.31 14.2817.0016.0617.25

MAR15.0918.0010.4412.7819.4015.7216.93

APR16.0916.7610.7812.9216.8715.7217.59

MAY17.6018.18 9.8413.3816.5215.2318.52

JUN20.1720.25 9.9713.6219.1115.6318.02

JUL21.3818.24 9.9713.7421.3916.6817.38

AUG19.8317.3211.2015.1821.6717.7317.91

SEP20.0716.2812.1116.2619.0719.0018.14

OCT18.7017.0612.8216.9418.0321.02 18.22

NOV19.2215.5114.0815.4419.0720.83

DEC20.6015.2814.9813.8318.7718.66

(These data, which include government stocks and are reported in thousands of pounds, are based on reports from a limited sample of cold storage centers across the country. This chart is designed to help the dairy industry see the trends in cold storage between the release of the National Agricultural Statistics Service’s monthly cold storage reports.)*Numbers unavailable due to the government shutdown.

ButterCheese

11,854105,409

-860-3,439

9,226120,969

-172-688

+2,628-15,560

-1 -1

Weekly Cold Storage Holdings November 4, 2013 On hand Week Change since Nov. 1 Last Year Monday Change Pounds Percent Pounds Change

Class 4aClass 4b

Butterfat$ 1.6121/lb.$ 1.6121/lb.

SNF$ 1.6506/lb.$ 1.2851/lb.

Equivalent $ 20.00/cwt.$ 16.82/cwt.

California Minimum PricesReleased November 1, 2013

Dry Products* November 8, 2013

DRY BUTTERMILK(FOB)Central & East: $1.7500(+7)-$1.8500(+6).(FOB) West: $1.7200(+4)-$1.8500(+7); mostly $1.7400(+1)-$1.7500.

EDIBLE LACTOSE(FOB)Central and West: $.4500(-3)-$.7400(-26); mostly $.5700(-1)-$.7200.

NONFAT DRY MILKCentral & East: low/medium heat $1.8800(+4)-$1.9700(+2); mostly $1.8900(+1 1/2)-$1.9300. high heat $1.9600(+3)-$1.9825.West: low/medium heat $1.8200(+2)-$1.9500(+1); mostly $1.8800(+2)-$1.9100(+1). high heat $1.9450(+3 1/2)-$1.9950(+1 1/2).Calif. manufacturing plants: extra grade/grade A weighted ave. $1.8390(+.0171) based on 7,501,460 lbs. Sales to CCC: 0 lbs.

WHOLE MILK POWDER (National): $1.9000-$2.0700(-4).

DRY WHEYCentral: nonhygroscopic $.4700-$.6100(-1); mostly $.5200-$.5600.West: nonhygroscopic $.5200(-1)-$.5925; mostly $.5400-$.5900(+1/2).(FOB) Northeast: extra grade/grade A $.5400(+1)-$.6100(-1).

ANIMAL FEED (Central): Whey spray milk replacer $.4050(+4 1/2)-$.5200.

WHEY PROTEIN CONCENTRATE (34 percent): $1.4500(+10)-$1.7050(+1/2); mostly $1.5250(+2)-$1.6250(+2).

CASEIN: Rennet $4.7000-$5.0000; Acid $4.8000-$5.4000.

*Source: USDA’s Dairy Market News

Total Contracts Traded/Open Interest

NOV13DEC 13JAN14FEB14MAR14APR 14MAY14JUN14JUL14AUG14SEP14OCT14NOV14DEC14

DRY WHEY FUTURES for the week ended November 7, 2013 (Listings for each day by month, settling price and open interest)

56.5056.7556.2556.0355.5355.0054.7553.9053.0053.0051.0051.0050.5050.00

265280241237275178183219104

7756344554

69/2,248Daily market prices are available by visiting CME’s online statistics sites at http://www.cmegroup.com.

Fri., Nov. 1 Mon., Nov. 4 Tues., Nov. 5 Wed., Nov. 6 Thurs., Nov. 7

10/2,206

57.2357.2057.0057.0055.7555.0054.7553.9053.0053.0051.0051.0050.5050.00

265280242238275178183219104

7856344554

6/2,251

56.5056.7556.2556.0355.5055.0054.7553.9053.0053.0051.0051.5050.5050.00

261278240236275178182219106

7849274655

57.0057.9057.5057.0056.0055.5054.4053.9053.0052.5051.0051.5050.5049.75

260273241229273171178219107

7849274655

103/2,230

56.5057.5057.5056.5056.0055.5054.4053.9053.0052.5051.0051.5050.5049.75

260277241230273171178219107

7849274655

12/2,211

Total Contracts Traded/Open Interest Daily market prices are available by visiting CME’s online statistics sites at http://www.cmegroup.com.

NOV13DEC13JAN14FEB14MAR14APR14MAY14JUN14JUL14AUG14SEP14OCT14NOV14DEC14

CHEESE FUTURES for the week ended November 7, 2013 (Listings for each day by month, settling price and open interest)

1.8631.7641.6901.6761.6681.6671.6641.6841.7201.7261.7351.7301.7311.725

1,4941,511

901696736607588551253262263249254229

114/8,594

Fri., Nov. 1 Mon., Nov. 4 Tues., Nov. 5 Wed., Nov. 6 Thurs., Nov. 7

1.8771.7911.7101.6811.6761.6671.6671.6841.7201.7261.7351.7301.7311.725

1,4921,514

896692728603580546253262263249254229

54/8,561

1.8651.7701.6921.6761.6681.6671.6641.6841.7201.7261.7351.7301.7311.725

1,4941,512

911709737611597560254271263251256231

118/8,657

1.8761.8141.7221.6811.6661.6631.6651.6851.7151.7261.7351.7301.7311.725

1,4741,500

882679706600578542253262263249254229

47/8,471

1.8771.7931.7101.6881.6761.6631.6701.6901.7201.7261.7351.7301.7311.725

1,4921,509

888685727600579543253262263249254229

69/8,533

Monday Tuesday Wednesday Thursday Friday

Chicago Mercantile Exchange

Nov. 4 Nov. 5 Nov. 6 Nov. 7 Nov. 8

Weekly average (Nov. 4-8): Barrels: $1.8230(-.0130); 40-lb. Blocks: $1.8865(+.0030).Weekly ave. one year ago (Nov. 5-9, 2012): Barrels: $1.9610; 40-lb. Blocks: $2.0240.

Cheese BarrelsPriceChange

Cheese 40-lb. blockPriceChange

Extra Grade NDMPriceChange

Grade A NDMPriceChange

Weekly average (Nov. 4-8): Extra Grade: $1.8620(+.0120); Grade A: $1.9200(+.0160).

Grade AA ButterPriceChange

Class II Cream (Major Northeast Cities): 2.0203(+.0625)–2.1250(+.0348).

Weekly average (Nov. 4-8): Grade AA: $1.5570(+.0605).

$1.5600NC

Sign up for our daily fax or e-mail service for just $104 a year. Call us at 608-288-9090.

Cash prices for the week ended November 8, 2013

$1.8700 NC

$1.9025 NC

$1.8600+1

$1.9100NC

$1.5600+1 1/2

$1.7950 -1/4

$1.9025 NC

$1.5600NC

$1.8700 +1

$1.9325+1 3/4

$1.5600NC

$1.8700 NC

$1.9325NC

$1.7825 -1 1/4

$1.8225 -8

$1.7975 -7 1/4

$1.9025 NC

$1.8600 NC

$1.9150 +1/2

$1.8700 NC

$1.9025 NC

$1.8500NC

$1.9100NC

$1.5450+1 1/4

Reprinted with permission from the Nov. 8, 2013, edition of CHEESE MARKET NEWS® © Copyright 2013 Quarne Publishing LLC; PH: (509) 962-4026; www.cheesemarketnews.com

November 8, 2013 — CHEESE MARKET NEWS® 3

DISCLAIMER: Cheese Market News® has made every effort to provide accurate current as well as historical market information. However, we do not guarantee the accuracy of these data and do not assume liability for errors or omissions.

For more information please visit www.devilletechnologies.com

NEWS/BUSINESS MARKET INDICATORS

KANSAS CITY, Mo. — USDA’s Kansas City Commodity Offi ce (KCCO) this week announced the award of contracts for the government of purchase of process cheese and Mozzarella in 2014. In addi-tion, KCCO this week issued a solicitation for 831,602 pounds of String cheese.

KCCO will purchase up to 53.7 mil-lion pounds of process cheese in various formats from Bongards’ Creameries and Land O’Lakes. The purchase price for each delivery period is the accepted differential price per pound indicated plus the applicable previous month’s average of the Chicago Mercantile Exchange cash market price for barrel cheese trading as reported by USDA’s Dairy Market News.

Up to 75 percent of the acquisition quantity for process cheese was awarded to small business under Small Business Administration (SBA) set-aside provi-sions.

• Bongards’ Creameries, up to 37.2 million pounds, with differentials rang-ing from $-0.0599 to $0.5200.

• Land O’Lakes, up to 16.5 million pounds, with differentials ranging from $-0.0810-$0.2399.

KCCO awarded contracts for the purchase of up to 82.4 million pounds of lite Mozzarella and low-moisture,

KCCO awards contracts, seeks String cheesepart-skim Mozzarella in various formats. The purchase price for each delivery period is the accepted differential price per pound plus the applicable previous week’s average of the Chicago Mercan-tile Exchange cash market for block cheese trade as reported by USDA’s Dairy Market News. Up to 35 percent of the acquisition quantity was awarded to small business under SBA set-aside provisions.

• Dairy Farmers of America, up to 17.9 million pounds, with differentials ranging from $0.0348-$0.1163.

• Leprino Foods, up to 33.4 million pounds, with differentials ranging from $-0.0717-$0.2045.

• Masters Gallery Foods, up to 2.8 million pounds, with differentials rang-ing from $0.2012-$0.2894.

• Miceli Dairy Products Co., up to 19.7 million pounds, with differentials ranging from $0.0324-$0.2368.

• Saputo Cheese USA Inc., up to 8.7 million pounds, with differentials rang-ing from $-0.0193-$0.2281.

Meanwhile offers to provide the government with String cheese under this week’s solicitation are due by 9 a.m. Nov. 18 in Kansas City. For more information, visit https://portal.wbscm.usda.gov/publicprocurement. CMN

International Dairy Markets November 8, 2013

Oceania Butter: 82 percent butterfat $3,500(-250)-$4,500. Cheddar Cheese: 39 percent maximum moisture $4,400(+100)-$4,700(+200).Skim Milk Powder: 1.25 percent butterfat $4,450(+100)-$4,850(+175).Whole Milk Powder: 26 percent butterfat $4,825(-125)-$5,100(-200).Source: Dairy Market News. Prices reported in U.S. dollars per metric ton, F.O.B. port. To convert to price per pound: divide price by 2,204.6 pounds.

Western Europe Butter: 82 percent butterfat $5,300(-125)-$5,750(-175).Butteroil: 99 percent butterfat $6,300-$6,950(-150).Skim Milk Powder: 1.25 percent butterfat $4,000(+100)-$4,500.Whole Milk Powder: 26 percent butterfat $4,850(-25)-$5,075(-125).Whey Powder: Nonhygroscopic $1,225(-25)-$1,1475(-25).

National Dairy Products Sales Report

Cheese 40-lb. Blocks:

**/Numbers not available due to government shutdown. 1/Prices weighted by volumes reported. 2/Sales as reported by participating manufacturers. Reported in pounds. More information is available by

calling AMS at 202-720-4392.

Average price1 Sales volume2

Cheese 500-lb. Barrels:Average price1

Adj. price to 38% moistureSales volume2

Moisture content Butter:

Average price1

Sales volume2 Nonfat Dry Milk:

Average price1 Sales volume2

Dry Whey:Average price1 Sales volume2

For the week ended: 10/19/13

$1.788910,861,148

$1.8509$1.7692

10,163,62335.14

$1.56773,537,562

$1.8432*15,790,269

$0.57136,998,738

*$1.7976*12,408,028

*$1.8820*$1.7999

9,700,01135.17

$1.52392,183,772

*$1.8455*15,482,888

$0.5604*8,834,536

10/26/13 10/12/13

$1.7890**

**$1.7697

****

$1.5425**

$1.8284**

$0.5802**

$1.824811,392,640

$1.9035$1.8203

9,523,77335.17

$1.49492,718,739

$1.861611,407,507

$0.57966,216,542

11/2/13

Daily market prices are available by visiting CME’s online statistics sites at http://www.cmegroup.com. *Total Contracts Traded/Open Interest reflect additional months not included in this chart.

Total Contracts Traded/Open Interest

Cash-Settled NDM*

NOV13DEC13JAN14FEB14MAR14APR14MAY14JUN14JUL14AUG14SEP14

NOV13DEC13JAN14FEB14MAR14APR14MAY14JUN14JUL14AUG14

Total Contracts Traded/Open Interest

187.25186.73179.00173.23171.00163.03163.50163.00159.50158.83159.00

57/2,440

154.00150.15149.50148.50150.30151.00151.75154.45155.00155.00

56/4,353

Fri., Nov. 1 Mon., Nov. 4 Tues., Nov. 5 Wed., Nov. 6 Thurs., Nov. 7

Total Contracts Traded/Open Interest

Fri., Nov. 1 Mon., Nov. 4 Tues., Nov. 5 Wed., Nov. 6 Thurs., Nov. 7NOV13DEC13JAN14FEB14MAR14APR14MAY14JUN14 JUL14AUG14SEP14OCT14NOV14DEC14JAN15

Class III Milk

18.7617.8617.1016.8816.8216.7216.7016.8717.1017.1317.2017.2217.1017.0016.27

1,833/21,718

Total Contracts Traded/Open Interest

Class IV Milk

NOV13DEC13JAN14FEB14MAR14APR14MAY14JUN14JUL14AUG14SEP14OCT14NOV14DEC14

20.4920.3219.5218.9518.8318.2518.3318.4017.9517.9418.0518.0418.0018.00

84/4,961

CME FUTURES for the week ended November 7, 2013

Fri., Nov. 1 Mon., Nov. 4 Tues., Nov. 5 Wed., Nov. 6 Thurs., Nov. 7

350370404342234175172166

423645

1,198832508442302297233216

9671

708745790709471328352312130103102

756967

Fri., Nov. 1 Mon., Nov. 4 Tues., Nov. 5 Wed., Nov. 6 Thurs., Nov. 7

Cash-Settled Butter*

4,4154,1012,1711,7941,6121,3281,3381,145

658665700565508452

1

18.8918.1317.2516.9716.8516.7516.7016.8717.1017.1017.1617.1617.0616.9416.26

20.4920.3119.5018.9518.8418.2518.3318.4018.1017.9418.0518.0418.0018.00

710741769685456328352312126102102

726767

187.25186.75179.00173.23171.20163.00163.50163.00159.50158.83159.00

350369392331227174169165

423745

154.00150.15150.00148.75150.03150.95151.50154.45155.00155.00

1,202832498434306292233216

9671

1,088/21,453

150/4,889

34/2,405

35/4,331

4,4583,9642,0541,6811,5111,2751,3121,120

642646673540485

441

18.8418.2717.3116.9016.7516.6816.6916.8517.0817.0817.1417.0817.0316.9616.26

1,039/20,806

20.4920.3119.6719.1518.9518.4018.4018.5218.1117.9418.1018.0418.0018.00

710741752655439327341311126102

97726767

100/4,807

187.50186.75180.00174.00172.00165.50165.00164.00161.48158.83159.00

350369382318223170170165

423745

47/2,375

153.50150.50150.00149.98150.05150.50152.00154.50152.60154.50

1,202825497432294284231216

9470

75/4,295

810/21,927

4,4014,0902,2161,8391,6391,3741,3921,189

713723738579543480

11

20.4920.3219.6219.0518.8718.3018.3318.4018.0017.9018.1018.0418.0018.00

297/5,197

708756822744528348384326133105111

827674

187.50187.50180.30175.00171.73163.53163.50163.00159.48158.83159.60

82/2,470

342371406354252176176166

423645

154.00150.23150.00148.50149.65151.00151.75154.45155.03155.50

91/4,403

1,198832515455318299235216

9673

4,4094,0822,1971,8351,6231,3511,3741,170

682685724571533471

11

4,4304,0522,1321,7481,5721,3061,3211,126

649655682553491441

1

18.8518.0817.2416.9716.8516.7516.7316.8917.1317.1517.1417.1517.0616.9416.26

1,279/21,159

20.4920.3119.6019.0018.9218.4018.4018.4918.1117.9418.1018.0418.0018.00

710741753662439327341311126102

97726767

9/4,815

187.50186.75179.80173.50171.88164.00164.50163.75161.00158.83159.00

350369388328223173172165

423745

32/2,396

154.00150.43149.80149.98150.05150.50151.98154.50154.50155.00

1,202829496434305284231217

9671

65/4,315

18.8217.9017.1616.9216.8516.7016.6816.8617.0917.1517.1417.1417.0716.9716.28

Reprinted with permission from the Nov. 8, 2013, edition of CHEESE MARKET NEWS® © Copyright 2013 Quarne Publishing LLC; PH: (509) 962-4026; www.cheesemarketnews.com

4 CHEESE MARKET NEWS® — November 8, 2013

Tom Suber is president of the U.S. Dairy Export Council. He contributes this column exclusively for Cheese Market News®.

Perspective:Export Expertise

Another step closer to a one-stop shopIn 2007, after conducting an in-

depth study of international gouda trade, the U.S. Dairy Export Council (USDEC) launched its “Gouda Initia-tive.” The initiative, based on oppor-tunities outlined by the research, fo-cused on developing U.S. capabilities to supply bulk gouda to customers in Mexico, which at the time was buying more than 70 million pounds of gouda per year — virtually none from the United States.

The initiative came at a time when the U.S. dairy sector was fighting a reputation as a casual participant in global markets — unwilling or unable to provide many of the products in demand overseas. Through coopera-tive work between checkoff-funded USDEC, Mexican buyers and U.S. manufacturers, the Gouda Initiative cultivated partnerships that helped raise the U.S. share of Mexican gouda imports from about 1 percent in 2009 to nearly 30 percent in the first seven months of 2013. Gouda volume rose from less than 1 million pounds in

2009 to nearly 18 million pounds from January-July 2013.

It quickly made the United States a competitive supplier not only in Mexico, but also to other major gouda markets worldwide, including Japan. Most importantly, it provided a valuable lesson: When U.S. suppli-ers expand their export offerings and go after “new” product sectors, it not only provides commercially valuable growth, it enriches the United States’ reputation as a serious, commit-ted global dairy player and lays the groundwork for future expansion.

The challenge is identifying the gaps in the U.S. dairy export portfolio and taking the steps necessary to close those that are viable to address. Since gouda, U.S. suppliers have done a good job of branching out, moving to provide high-spec nonfat dry milk/skim milk powder (NDM/SMP), milk protein concentrate (MPC) and, most recently, whole milk powder (WMP). The latest research from USDEC points to the next opportunity in our

national portfolio: ultra high tempera-ture (UHT) milk.

UHT milk is milk heat-treated and packaged to provide a 9-12-month shelf life without refrigeration.

The UHT report focused spe-cifically on China, the world’s largest UHT milk buyer. Chinese demand for imported UHT milk is soaring. Consumption jumped from nearly 18 million pounds in 2010 to a forecast 331 million pounds this year. Demand scenarios suggest China’s appetite for imported UHT milk could grow four-fold to more than 1.3 billion pounds by 2020, spurred by economic growth and the resultant drive to consume more and better food.

China is drinking more UHT milk than it can produce on its own, and imported brands are flying off the shelves. Due in part to past food safety scares, Chinese consumers have shown they are willing to pay two-to-three times the price of local labels.

Urbanization and middle class expansion are creating an ever-larger consumer pool. Urbanization is particularly important because dairy consumption in rural areas is negligible, meaning there is huge room for growth as those rural dwell-ers move to cities. About 300 million more people — a mass nearly the size of the entire United States — will move to Chinese cities over the next 17 years, encouraged by government programs aimed at shifting China’s economic model to one based more on internal consumption rather than exports.

U.S. suppliers have a reputation for high-quality food and have established dairy trade routes with China over the past decade. Chinese buyers have con-sequently expressed interest in U.S. UHT milk to meet spiraling demand.

The decision U.S. suppliers will have to make is whether they want to play a role in meeting that demand. Like past experiences with gouda, NDM/SMP, MPC and WMP, capitalizing on the opportunity requires flexibility and commitment.

That means making product in package sizes (1-liter) preferred by Chinese consumers, adding nothing, not even vitamins, during processing.

Capacity expansion projects tar-geting Asian UHT milk demand have been proposed or are underway in Oceania. But even if all that capacity comes online, it will still be insuffi-cient to supply all of China’s needs, particularly in light of Oceania’s desire to supply other regions.

The potential payback is greater than simply the Chinese milk market. USDEC sees opportunity in other Asian markets, including the Philip-pines, and for additional products such as UHT cream and lactic acid beverages.

Expanding into global in-demand product categories lifts the entire dairy trade endeavor, while making the United States a better, more trusted, more desirable global sup-plier as global demand continues to grow faster than supply. CMN

Note: The U.S. Dairy Export Council is primarily supported by Dairy Management Inc. (DMI) through the producer checkoff that builds on collaborative industry partnerships with processors, trading companies and others to build global demand for U.S. dairy products.

The views expressed by CMN’s guest columnists are their own opin-ions and do not necessarily reflect those of Cheese Market News®.

E X P O R T T O O L K I T C M N E x c l u s i v e !

NEWS/BUSINESS

ROSEMONT, Ill. — National Football League (NFL) players Alfred Morris of the Washington Redskins, Corey Wootton of the Chicago Bears, and Steve Smith and Luke Kuechly of the Carolina Panthers have teamed up with Fuel Up to Play 60 to launch “Make Your Move” — a campaign to inspire students, teachers, parents and com-munity members to get active.

Make Your Move offers several ideas to help kids get 60 minutes of play a day, with a focus on dance-themed ac-tivities from dance-a-thons to in-class dance breaks. A “playbook” of tips and suggestions is available at www.FuelUpToPlay60.com. To kick off the campaign, the NFL players and Fuel Up to Play 60 student ambassadors battled it out on camera to see who has the ultimate “moves.” Andrew Luck of the Indianapolis Colts and spokesperson

NFL players join Fuel Up to Play 60 in new campaign to encourage students to get activefor the Quaker Oats Co., a subsidiary of PepsiCo Inc., also made a special appearance in the video.

Make Your Move runs through the end of this month. Student and teacher participants who register can earn points and win NFL prizes and grants for tracking their Make Your Move activi-ties. Parents and teachers can submit on behalf of a school a short video of their kids and students moving and getting active into the Quaker and Fuel Up to Play 60 Make Your Move Video Contest. Schools will have a chance to win one of fi ve $15,000 grants or one of ten $2,500 grants.

Through Nov. 27, video entries can be uploaded at http://QuakerOats.com/makeyourmove, which also includes offi cial contest rules, entry forms and more information. Andrew Luck will be serving as a guest judge and helping to

select the winning schools. Additionally, Make Your Move rallies were held Oct. 29 and Oct. 30 in schools around the country, hosted by the participating NFL players.

Fuel Up to Play 60 is an in-school nutrition and physical activity program launched by NFL and National Dairy Council (NDC), which is funded by America’s dairy farmers in collaboration with USDA. It is the nation’s largest in-school wellness program, reaching more than 73,000 schools.

“With research showing that im-proved nutrition paired with physical activity leads to improved academic achievement, America’s dairy farm-ers are committed to childhood health and wellness through pro-grams like Fuel Up to Play 60,” says Jean Ragalie, registered dietician and president of NDC. “We look for-ward to seeing how Fuel Up to Play 60 schools and students get active with Make Your Move and create lasting, healthy change.” CMN

WASHINGTON — FDA recently an-nounced it has introduced a new Twitter feed to aid in disseminating the agency’s updates on food, nutrition, food addi-tives, dietary supplements and the FDA Food Safety Modernization Act (FSMA).

FDA introduces Twitter feed to share updatesAnyone with an active Twitter ac-

count can follow the feed. To follow the feed, users can search “@FDAFood” using their Twitter accounts and then click “follow.” FDA’s privacy policy can be found at www.fda.gov/privacy. CMN

Reprinted with permission from the Nov. 8, 2013, edition of CHEESE MARKET NEWS® © Copyright 2013 Quarne Publishing LLC; PH: (509) 962-4026; www.cheesemarketnews.com

NEWS/BUSINESSNovember 8, 2013 — CHEESE MARKET NEWS® 5

For more information please visit www.johnsonindint.com

FOR MORE INFORMATION, VISIT US ON THE WEB AT

www.johnsonindint.com

From one-way, two-way, and three-way cutting machines to custom cutting systems designed for unique applications, Johnson Industries has delivered exceptional reduction equipment for over three decades.

Robust and reliable cuttersdesigned to suit your production

CUTTINGSYSTEMS

Opportunities abroad

DUBAI, United Arab Emirates — U.S. dairy industry representatives visited Dubai, United Arab Emirates, this week to learn more about the growing opportunities for U.S. dairy in the Middle East and North Africa region. Participants toured Emirates Flight Catering and the Jebel Ali Free Zone, met with key Middle East dairy contacts and took part in the fi rst U.S. Dairy Business Conference on Wednesday, sponsored by the U.S. Dairy Export Council (USDEC). Pictured are, from left: Dairy Management Inc. (DMI) board members Ray Prock, Jr.; and Larry Shover; Corey Geiger, managing editor, Hoard’s Dairyman; DMI board members Jim Reid; and Glen Easter; Alyssa Sowerwine, senior editor, Cheese Market News; Mark O’Keefe, vice president, edito-rial services, USDEC; and USDEC Middle East Director Nina Bakht Halal. CMN

MONETT, Mo. — Dairy Farmers of America (DFA) ceased operations Oct. 31 at a dairy processing plant in Monett, Mo., where it leased space from Schreiber Foods.

The facility, which DFA oper-ated for many years, had been used to manufacture American cheese curd for Schreiber Foods as well as liquid whey.

DFA on March 6 announced its deci-sion to cease operations at the facility, where it employed 86 people. The deci-sion was based on the plant’s fi nancial losses due to a defi cit milk market and its inability to run at full volume. (See “DFA to shutter dairy plant in Monett, Mo.,” in the March 8, 2013, issue of Cheese Market News.)

“The majority of our 86 employees have secured future plans through new jobs, retirement or other personal

DFA ceases operations at Monett, Mo., plantendeavors,” says Kristi Dale, director of media relations, DFA. “We are grateful to our industry partners and business lead-ers in the community who have assisted us in hosting job fairs and employee meetings for our dedicated workers.”

Dale adds that DFA members whose milk was supplying the plant will con-tinue to have a market for their milk at alternate processing facilities.

Schreiber Foods says it has no cur-rent plans for what it will do with the part of the building formerly occupied by DFA.

“They were a longtime partner and we hated to see them go, but for us it’s business as usual,” says Andrew Tobisch, director of communications, Schreiber Foods, adding that Schreiber has found a new source for the product DFA previously supplied. CMN

LOUISVILLE, Ohio — Biery Cheese Co. has acquired Kickapoo Valley Cheese (KVC), Milladore, Wis., effec-tive Nov. 1 and will operate it under the Biery Cheese Co. brand.

“We are excited about being able to bring on the KVC facility into the Biery Cheese family. Both organiza-tions share in the belief of service and innovation of packaging, coupled with generations of experience,” says Ben Biery, CEO, Biery Cheese Co. “Continu-ing with our tradition of growth, this addition will help us strategically posi-tion our company to service our existing customers along with developing new customers.”

Biery Cheese Co. was started in 1929 by Norman F. Biery, who started out making Swiss cheese in Louisville, Ohio. The company has evolved from a manufacturing

Biery Cheese acquires Kickapoo Valley Cheese, will operate under Biery brand

company to a packaging, processing and distributing company providing chunks, shreds, slices, diced, cubes and snacking cheeses to its customers.

“It is with confi dence and a clear conscious that I transfer the ownership of Kickapoo Valley Cheese to Biery Cheese Co. Biery Cheese meets every criteria I have for a buyer,” says Jim Leytus, former owner, Kickapoo Val-ley Cheese.“They are a fi ne company with an impressive growth curve, an excellent reputation and a desire to participate in the Wisconsin dairy industry. It was of paramount impor-tance to me to fi nd a willing, qualifi ed buyer that would carry on the work and tradition of Kickapoo Valley and, where possible, retain the current employees, take care of our loyal customers, and give priority consideration to our sup-pliers and service providers.” CMN

CONCORD, Mass. — The Massachu-setts Cheese Guild was launched on Oct. 29 with a gala at Verrill Farm located here.

Based in Westport Point, Mass., the guild has 50 founding members and has applied for not-for-profi t status.

The guild will work to educate its members, consumers, retailers and distributors; encourage and support the production of farmstead and artisanal cheeses and cultured dairy products made from Massachusetts milk; help ar-tisan cheesemakers promote products and accomplishments; and make the public aware of the varieties of cheese available throughout the state.

Guild president is Barbara Hanley, who is a partner at Shy Brothers Farm in Westport.

Guild charter artisan members are Appleton Farms in Ipswich; Berkshire

New Massachusetts Cheese Guild aims to help promote artisan, farmstead cheeses

Blue in Dalton; Chase Hill Farm in Warwick; Cricket Creek Farm in Wil-liamstown; Crystal Brook Farm in Sterling; Fiore di Nonno in Somerville; Foxboro Cheese Co. in Foxboro; Great Hill Dairy in Marion; Grey Barn and Farm in Chilmark; Hillman Farm in Colrain; Mermaid Farm in Chilmark; Mozzarella House in Peabody; Rawson Brook Farm in Montere; Robinson Farm in Hardwick; Ruggles Hill Creamery in Hardwick; Shy Brothers Farm in West-port; Sidehill Farm in Hawley; Smith’s Country Cheese in Winchendon; Valley View Farm in Topsfi eld; and Westfi eld Farm in Hubbardston.

Guild charter sponsors are The Cheese Shop of Concord, Shubie’s Mar-ket and Seacrest Foods International.

F o r m o r e i n f o r m a -tion, visit the guild’s website at www.macheesegui ld .org . CMN

Reprinted with permission from the Nov. 8, 2013, edition of CHEESE MARKET NEWS® © Copyright 2013 Quarne Publishing LLC; PH: (509) 962-4026; www.cheesemarketnews.com

6 CHEESE MARKET NEWS® — November 8, 2013

For more information please visit www.ivarsoninc.com

NEWS/BUSINESS

Photo by Jane Burns

By Rena Archwamety

MADISON, Wis. — The fi fth annual Wisconsin Cheese Originals Festival, held here last weekend, drew a record attendance of about 1,000 people who dined and mingled with cheesemakers, toured creameries and farms, and at-tended tasting seminars that featured cheeses from Wisconsin and around the world.

One of the Saturday afternoon seminars, “European Traditionals vs. Wisconsin Originals,” highlighted four traditional-style village dairy cheeses from Germany and Switzerland, fi ve relatively new cheese creations from Wisconsin artisans, and the stories of the cheesemakers behind these new and traditional cheeses.• European Traditionals

The four European cheeses were se-lected and presented by Jonathan Rich-ardson of the New York-based importer Columbia Cheese and included: Gruyere 1655 by cheesemaker Jean-Marie Du-nand at Fromagerie Le Cret (affi nage at Fromage Guryere SA), Switzerland; Ur-Bergkase by cheesemaker Evelyn Wild at Kaeskuche Isny, Germany; Nufenen by cheesemaker Christian Schumacher at Sennerei Nufenen Coop-erative, Switzerland; and Challerhocker by cheesemaker Walter Rass at Kaserei Tufertschwil, Switzerland.

Richardson explained in his presen-tation that due in part to international demand and the rise of cheesemaking associations in the 20th century, most cheese production in Austria and Switzerland is Gruyere, Emmentaler, Appenzeller and a few other major AOC cheeses.

For these AOC or controlled designa-tion of origin cheeses, the cheesemak-

Tasting seminar looks at the histories behind cheeses of Wisconsin, Germany, Switzerland

ing practices as well as milk prices are heavily structured and regulated to produce a consistent product and market for the product, Richardson says. Advantages of this system are that milk producers and cheesemakers who follow the quotas and mandates make a good, steady living practicing their craft. The system, set up to promote these cheese brands, also is able to fulfi ll consumers’ expectations of quality and hygiene.

Downsides, however, include brand promotion at the expense of a chance for the best producers to excel and gain recognition for their product, as producers are treated as contract manufacturers for cheeses that meet a set standard.

“When they are all encouraged to hit the middle, it creates anonymity,” Richardson says. “There is less oppor-tunity for an individual dairy to control their business.”

Despite a dominance of AOC cheeses, recently some cheesemakers in this region have resurrected lesser-known traditional village cheese varieties or created unique cheeses based on tradi-tional ones. For example, Rass’ Challer-hocker, which Richardson describes as a “reboot” or “creative deviation” of Ap-penzeller, is made from unskimmed milk and house-made starter cultures and features a creamier density and brighter fl avor than the traditional cheese. Rich-ardson notes that by 2015, Tufertschwil Dairy will produce more Challerhocker than Appenzeller for the fi rst time in its nearly 120-year history, giving Rass and his farmers a scalable opportunity to control their fi nancial destiny.• Wisconsin Originals

Jeanne Carpenter, executive direc-tor of Wisconsin Cheese Originals and organizer of the festival, called Wiscon-

sin the “specialty cheese capital of the United States” with almost 50 percent of the nation’s specialty cheese production coming from the state.

“Wisconsin really is a story of the power of cheese,” Carpenter told semi-nar attendees. “It also is about bringing together three components: the farmer, the processor and marketer, and the community.”

Moving away from a system that favored either the farmers or the chee-

semakers, she says the focus on artisan cheeses has allowed artisans and milk producers to work together on unique cheeses that can retail for a premium and support both parts of the industry.

Carpenter presented fi ve Wisconsin cheeses: Gran Canaria by cheesemaker Sid Cook of Carr Valley Cheese; Pasto-rale by cheesemaker Mike Matucheski of Sartori Co.; Red Rock by cheesemaker Chris Roelli or Roelli Cheese; Water Buffalo Taleggio by cheesemaker Anna Landmark of Landmark Creamery; and EWE CALF to be KIDding by cheese-maker Tony Hook of Hook’s Cheese.

She highlighted cheesemakers, such as Roelli and Cook, who came from traditions of commodity Cheddar production and switched or diversifi ed into more specialty varieties, launching their family legacies of cheesemaking into a new and profi table direction for the future.

Among the more experienced chee-semakers, Carpenter also included new cheesemaker Anna Landmark, winner of the 2012 Wisconsin Cheese Originals Beginning Cheesemaker Scholarship. The seminar attendees sampled her soft, washed-rind Water Buffalo Taleggio that she is expecting to release in limited supply around December.

While stressing that the tasting was not a direct comparison or battle of Wisconsin vs. European cheeses but rather an appreciation for two different traditions, Carpenter couldn’t resist some lighthearted boasting.

“Wisconsin cheeses fi nally have come into their own,” she says. “I think we can fi nally rival European cheeses.” CMN

ORIGINAL, TRADITIONAL — A variety of original cheeses from Wisconsin, as well as traditional and newer cheeses from Switzerland and Germany, were served during the “European Traditionals vs. Wisconsin Originals” seminar Nov. 2 at the Wisconsin Cheese Originals Festival.

Reprinted with permission from the Nov. 8, 2013, edition of CHEESE MARKET NEWS® © Copyright 2013 Quarne Publishing LLC; PH: (509) 962-4026; www.cheesemarketnews.com

November 8, 2013 — CHEESE MARKET NEWS® 7

For more information please visit www.gea.com

NEWS/BUSINESS

FDA says it will ban artifi cial trans fats SILVER SPRING, Md. — FDA yester-day announced a preliminary determi-nation that partially hydrogenated oils (PHOs), the primary dietary source of artifi cal trans fat in processed foods, are not “generally recognized as safe” for use in food. FDA says its preliminary determination is based on available scientifi c evidence and the fi ndings of expert scientifi c panels.

The agency has opened a 60-day comment period on this preliminary determination to collect additional data and gain input on the time poten-tially needed for food manufacturers to reformulate products that currently contain artifi cial trans fat should this determination be fi nalized. Comments can be submitted at www.regulations.gov under docket No. FDA-2013-N-1317.

“While consumption of potentially harmful artifi cial trans fat has declined over the last two decades in the United States, current intake remains a signifi -cant public health concern,” says FDA Commissioner Margaret A. Hamburg. “Further reduction in the amount of trans fat in the American diet could prevent an additional 20,000 heart attacks and 7,000 deaths from heart disease each year — a critical step in the protection of Americans’ health.”

In recent years, many food manu-facturers and retailers have voluntarily decreased trans fat levels in many foods and products they sell. Trans fat can be found in some processed foods, such as certain desserts, microwave popcorn products, frozen pizzas, margarines and coffee creamers. Cheese and dairy products have some naturally-occurring trans fats, which are not considered a health risk and the proposed FDA ban does not include.

The Grocery Manufacturers As-sociation (GMA) issued a statement yesterday noting that since 2005, food manufacturers have voluntarily lowered the amounts of trans fats in their food products by more than 73 percent.

“Product safety is the No. 1 priority for America’s food and beverage compa-nies and we invest our reputations and resources to provide consumers with safe and nutritious products that meet their preferences and lifestyle needs,” GMA says in the statement. “Consum-ers can be confi dent that their food is safe and we look forward to working with the FDA to better understand their concerns and how our industry can better serve consumers.” CMN

AKRON, N.Y. — In honor of its 95th year in business, Perry’s Ice Cream is celebrating with the release of a limited-edition anniversary fl avor.

Sponge Candy features caramelized sugar swirls and sponge candy pieces. Similar to the chicken wing, sponge candy has a cult-like following among

Perry’s Ice Cream celebrates 95th anniversary with limited edition Sponge Candy fl avorthose living in western New York state.

“This summer we introduced Sponge Candy at our ice cream stands and the consumer response has been tremen-dous,” said Bob Denning, president and CEO, Perry’s Ice Cream. “When we began discussing a 95th fl avor, Sponge Candy was the top choice to honor both four generations of ice cream craftsmanship and our community that has supported us for almost a century.”

Perry’s Ice Cream’s humble begin-nings date back to 1918, a time when H. Morton Perry, a broom maker by trade, seized his American dream by purchasing a horse-drawn milk route in the village of Akron. On his fi rst day of business,

Morton delivered 29 gallons of farm fresh milk to the homes of his new customers.

During the Great Depression, Mor-ton was asked by the cafeteria manager at Akron Central School to supply ice cream to the children as a treat. Morton responded with his usual eagerness and entrepreneurial spirit. The fi rst batch of Perry’s Ice Cream was cooked on the kitchen stove using his mother’s family recipe. Morton, with the help of his 17 year-old son Marlo, would freeze the mix in a hand-churned ice and salt freezer. Marlo would deliver it when he went to school the next day.

“You never know until after it hap-pens, that moment that will create your

legacy,” says Brian Perry, executive vice president, vice chair and fourth genera-tion Perry Ice Cream leader. “For my great-grandfather that moment there at the kitchen stove would come to defi ne who we are, even in today’s fast-paced business world. He is known for saying “make sure we put enough of the ‘good’ stuff” in our products. Ninety-fi ve years later, that is still our company and my family’s promise for everything we do.”

Today, Perry’s is one of the larg-est ice cream producers in New York state. With more than 330 associates, the company makes approximately 500 different items totaling more than 12 million gallons per year. CMN

GEA Process Engineeringengineering for a better world

GEA Niro SANICIP™

1600 O‘Keefe Road, Hudson WI, 54016Phone: 1 715 386 9371, Fax: 1 715 386 [email protected], www.gea.com

Low pressure drop - reduces power consumption and noise emission

Reprinted with permission from the Nov. 8, 2013, edition of CHEESE MARKET NEWS® © Copyright 2013 Quarne Publishing LLC; PH: (509) 962-4026; www.cheesemarketnews.com

8 CHEESE MARKET NEWS® — November 8, 2013

For more information please visit www.mdvamilk.com

FromOur Farms toYour Products

Cream, Skim Condensed, ButtermilkCondensed, Non-fat Dry Milk, Buttermilk Powder, and Bulk Butter

Contact us today at 540-465-5113 or [email protected].

Fresh Ingredients from Maryland & Virginia!

Maryland & VirginiaMilk Producers Cooperative Association, Inc.

NEWS/BUSINESS

WASHINGTON — As the U.S. House prepares to return to Washington Tues-day, lawmakers appealed this week to top negotiators to include milk price reform in the fi nal farm bill.

Monday, Sens. Kirsten Gillibrand, D-N.Y., a member of the Senate Agriculture Committee, and Susan Collins, R-Maine, sent a letter urging leaders of the Senate Agriculture Committee to include their bipartisan measure in the fi nal farm bill to help stabilize milk prices.

The bipartisan Gillibrand-Collins proposal, known as the Dairy Pricing Reform Act, would require USDA to begin a pre-hearing process to restruc-

Lawmakers prepare for farm bill talks to resume, urge reform measures for milk pricesture the dairy pricing system and direct the Secretary of Agriculture to release the department’s recommendations to Congress. This builds on language Sen. Gillibrand secured in the Senate farm bill that requires USDA to study different methods of determining prices, includ-ing competitive pay pricing or shifting from a 4-class system to a 2-class system.

“It is our hope that insight gained by this process will lead to new solutions that stabilize the price of milk and pro-vide certainty for our dairy producers, so that they can grow their business and help strengthen our national rural economies,” the Nov. 4 letter says.

The top four farm bill negotiators: Senate Agriculture Committee Chair-woman Debbie Stabenow and Ranking Member Thad Chochran, and House Agriculture Committee Chairman

Frank D. Lucas and Ranking Member Collin C. Peterson, were expected to meet informally this week to resolve key points between the House and Sen-ate versions of the farm bill. CMN

Butter, WMP prices down in latest GDT AUCKLAND, New Zealand — The GlobalDairyTrade (GDT) price index was down 1.8 percent, led by drops in butter and whole milk powder Tuesday follow-ing the latest auction on GDT, Fonterra’s internet-based sales platform. Prices of other commodities rose in this latest trade event.

The average prices for each commod-ity and their percent change at the Nov. 5 auction are as follows:

• Milk protein concentrate: US$7,738 per metric ton FAS ($3.5099 per pound), up 4.6 percent.

• Buttermilk powder: US$4,524 per metric ton FAS ($2.0521 per pound), up 1.8 percent.

• Butter: US$3,529 per metric ton FAS ($1.6007 per pound), down 7.0 percent.

• Anhydrous milkfat: US$5,343 per metric ton FAS ($2.4236 per pound), up 6.9 percent.

• Cheddar: US$4,380 per metric ton FAS ($1.9868 per pound), up 1.2 percent.

• Skim milk powder: US$4,559 per metric ton FAS ($2.0679 per pound), up 0.5 percent.

• Whole milk powder: US$4,891 per metric ton FAS ($2.2185 per pound), down 3.7 percent.

• Rennet Casein: US$9,926 per met-ric ton FAS ($4.5024 per pound), up 0.5 percent.

• Lactose: US$1,622 per metric ton FAS ($0.7357 per pound), up 3.2 percent (relative to two trading events prior to the current event because no quantity was offered or sold in the preceding event).

The next trading event will be held Nov. 19. For more information, visit www.globaldairytrade.info. CMN

NASHVILLE, Tenn. — The Tennessee Department of Health (TDH) this week said at least eight cases of illnesses among children in East Tennessee likely are related to drinking raw milk. The investigation has identifi ed a specifi c strain of E. coli O157 as the cause of at least three of the illnesses.

Illnesses in Tennessee linked to raw milkThe Knox County Health Depart-

ment and the East Tennessee Regional Offi ce of TDH issued an alert following their investigation last week of a cluster of E. coli illnesses associated with raw milk consumption. All cases are known to have obtained raw milk from a local cow-share dairy.

“Out of an abundance of caution at this time, we advise people not to consume raw milk or dairy products from McBee Dairy Farm in Mascot, Tenn., due to possible contamination with E. coli O157,” the alert says. “We also recommend consumers dispose of any raw milk or dairy products they may currently have from McBee Dairy Farm.”

It is legal in Tennessee for in-dividuals to consume raw milk from their animals, including those under shared ownership. CMN

Reprinted with permission from the Nov. 8, 2013, edition of CHEESE MARKET NEWS® © Copyright 2013 Quarne Publishing LLC; PH: (509) 962-4026; www.cheesemarketnews.com

November 8, 2013 — CHEESE MARKET NEWS® 9

For more information please visit www.foremostfarms.com

NEWS/BUSINESS

Award-winning, all-natural cheese from certified Wisconsin Master Cheesemakers®, carefully crafted to provide outstanding flavor, color, texture and stretch.

Trust Foremost Farms premium-quality Wisconsin cheeses to deliver consistently exceptional pizza performance, pie after pie.

Call 800-362-9196 to learn more about the advantages of using premium quality Wisconsin cheese and dairy ingredients from Foremost Farms. www.foremostfarms.com

©2013 Foremost Farms USA Cooperative

Award-winning taste. Premium

performance.quality

took thousands of confi dential fi les before moving to work at Custom Fabri-cating & Repair Inc. (CFR), Marshfi eld, Wis. The jury also determined that CFR knowingly used the fi les to compete against Relco.

According to the judgment, CFR is responsible for approximately 90 percent of the total due to Relco. The two companies are seeking a resolu-tion of the legal proceedings that will minimize disruption to others in the industry, including customers, say Relco’s attorneys.

“It is very gratifying to see justice done in this case,” says Dean LeDoux, a principal at Minneapolis-based law fi rm Gray Plant Mooty, who led the Relco trial team. “Relco has become an industry leader through 30 years of innovation and integrity. The legal system worked as it should in protect-ing Relco’s rights to its confi dential and valuable technology.”

Calls to CFR requesting a com-ment on the verdict were not re-turned by press time. CMN

RELCOContinued from page 1

KANTVIK, Finland — DuPont Nutri-tion & Health says new clinical evi-dence on the impact of DuPont Danisco HOWARU Protect line of probiotics shows it helps maintain respiratory health for healthy adults.

DuPont Danisco HOWARU Protect line is designed for a range of ingre-dients that help provide enhanced bioprotection, an improved nutritional profi le as well as better taste and tex-ture with greater cost effi ciency and lower environmental impact for manu-facturers of dairy products and dietary supplements.

Investigated in a joint clinical study by Australian research institutes, two probiotic formulations reduced the risk of delayed the onset of respiratory ill-ness. It also improved the training load during physical exercise, according to a clinical study.

The study titled, “Probiotic Supple-mentation for Respiratory and Gastro-intestinal Illness Symptoms in Healthy Physically Active Individuals,” was just published in Clinical Nutrition journal.

Scientists from Griffi th University conducted the randomized, double-blind, placebo-controlled clinical trial in cooperation with the Australian In-stitute of Sport and other collaborating institutions. The 465 trial subjects were split into three groups, each receiving a daily dose of HOWARU Protect Adult, HOWARU Protect Sport or a placebo. All subjects were healthy adults who exercised for at least 30 minutes, three

Clinical study shows HOWARU Protect probiotics reduce risk of respiratory symptomstimes per week.

Daily supplementation with HOW-ARU Protect Adult produced the most notable result. In the healthy men and women who consumed a daily dose over the fi ve-month study period, the risk of upper respiratory tract illness was reduced by 27 percent, according to the study.

The results also indicate test sub-jects remained free of upper respiratory symptoms for several weeks longer, on average, than those in the placebo group.

“A signifi cant delay in the onset of symptoms indicates that this pro-

biotic strain may help active adults stay healthy longer,” says Allan Cripps, pro-vice chancellor of health,Griffi th University and the principal scientist of the study.

A tendency toward reduced respi-ratory illness episodes and signifi cant delay in the onset of symptoms also was observed among subjects who received the probiotic formulation HOWARU Protect Sport. The most notable fi nding in this group, however, was a signifi cantly higher level of physical activity, possibly due to the delayed time of symptoms.

“It is a known fact that physical

activity is reduced or may even stop when people are feeling the effects of respiratory symptoms,” says Da-vid Pyne, senior physiologist at the Australian Institute of Sport and lead investigator of the study. “So, these fi ndings are important, particularly for those who engage in competitive sports and need to maintain fi tness.”

Through the work of the global net-work of food scientists and technolo-gists in DuPont, the Danisco range is supported by a spectrum of know-how across applications and processing.

For more information on DuPont Danisco visit www.danisco.com. CMN

Reprinted with permission from the Nov. 8, 2013, edition of CHEESE MARKET NEWS® © Copyright 2013 Quarne Publishing LLC; PH: (509) 962-4026; www.cheesemarketnews.com

10 CHEESE MARKET NEWS® — November 8, 2013

NEWS/BUSINESS

million pounds in September, down 0.3 percent from a year earlier. Production of Cheddar, the largest component of American-type production, was down 1.2 percent from a year earlier to 240.6 million pounds.

Wisconsin led the nation’s cheese production with 229.8 million pounds produced in September, up 0.7 per-cent from its production a year earlier. California followed with 186.9 million pounds, a 9.8-percent increase from a year earlier.

The next four cheese-producing states in September were Idaho with 73.0 million pounds, down 1.7 percent from its production a year earlier; New York with 65.5 million pounds, up 5.9 percent; New Mexico with 56.8 million pounds, down 6.6 percent; and Min-nesota with 50.6 million pounds, up 5.4 percent.

NASS reports total U.S. butter production in September was 133.7 million pounds, down 1.9 percent from September 2012’s 136.3 million pounds but up 1.7 percent on an average daily basis from August 2013’s 135.9 million pounds.

U.S. production of nonfat dry milk suitable for human consump-tion totaled 76.4 million pounds in September, down 9.6 percent from September 2012 and down 26.2 percent from August 2013 when ad-justed to an average daily basis. CMN

SEPTEMBERContinued from page 1

And the fact of the matter is, no one really wants to say they sell a dairy commodity.

“Commodity markets can be spec-tacularly unsexy from a P&L perspec-tive,” Plourd says. “So we spend a lot of time saying, ‘Well, I know it’s skim milk powder, but it’s really better than skim milk powder.’ Or ‘my cheese is this, but it’s really better than that.’ We spend a lot of time talking about how we are occupying a quasi-commodity space, but we’re really reaching for differentiation. This obviously com-plicates standardized trade and the development of broadly relevant marketplaces.”

Also at play is whether trade is truly global or whether it’s more regional. Certainly there is global dairy trade occurring, but when one examines prominent trade relationships, the United States has signifi cant dairy trade with Mexico, the New Zealand has major exports to China, and a great deal of European Union product goes to Russia, Plourd notes.

There’s also the question of where China will play into world trade in the future.

“China was largely self-suffi cient in dairy until 2008, until the melamine

crisis,” Plourd says.The 2008 melamine scandal dealt a

serious blow to consumer confi dence and rippled back to the producer level in China, Plourd notes, and post-scandal powder imports took off as domestic supplies were left in tatters.

“I think it’s fair to wonder, if China was self-suffi cient once, will it be self-suffi cient again?” he says.

Five years post-melamine scandal, China isn’t close to self suffi ciency but that could change.

“I think it’s potentially dangerous to take for granted that China is going to be what it is today, forever,” he says.

And yet in many ways, Plourd says, it seems as though current global markets are turning on two key fac-tors: what New Zealand can make and what China can take. In terms of what New Zealand can make, the fact that New Zealand has a pasture-based dairy system means it can be subject to wide fl uctuations in milk production depending on weather.

In the United States, Plourd be-lieves the rewards of the export market are worth the risk, but if there were a hiccup in the world marketplace, it would compromise U.S. prices. Comparing the world dairy market to a basketball team, he suggests that while the United States is an important player, he doesn’t believe the nation is a starter.

“Exports are great, until they’re not,” he says.

So, does the U.S. dairy industry really want convergence?

“It’s very easy from an academic or economist perspective to stand up on high and say we should have transpar-ency and convergence,” Plourd says. “I think it’s even easy for industry people to say, ‘sign me up,’ and then when you go back home and look at your own P&L say, ‘then again, this is good for me … why would we want to change it?’

“There is a lot of money to be made in the shadows,” Plourd says, noting that when there are price spreads, there is money to be made in those gaps.

Looking at the corn market, which has single-point price discovery, Plourd notes that it is highly standardized and effi cient and has a large, concentrated, vertically-integrated merchant class.

“The question we have to ask our-selves as an industry is, ‘Are these goals we aspire to?’” Plourd says. “Because when you think about it … we have multiple price points, lots of small and medium merchants.”

Convergence, by its nature, means that prices would go up in some regions and down in others. It also likely means some industry players would consolidate. CMN

PLOURDContinued from page 1

Roehl Transport purchases Brock Cold Storage and Trucking operationsMARSHFIELD, Wis. — Roehl Trans-port has purchased Brock Cold Storage and Trucking effective Oct. 16. Roehl will operate the cold storage business as Roehl Cold Storage, and the trucking operation will become a part of Roehl Transport.

“We recognized the tremendous business and outstanding customer relationships built by the Brock family. We’re excited to enter the cold stor-age market and continue providing high levels of customer service to the customers that have been working with Brock,” says Rick Roehl, CEO, Roehl Transport.

The cold storage warehouses are in Vesper and Owen, Wis. The Owen loca-tion has 120,000 square feet of storage, and the Vesper warehouse is 38,000 square feet.

“We see new opportunities and synergies between the warehouse operations, our brokerage and our logistics services,” says Steve Elliott, vice president, Roehl Logistics.

Roehl has offered employment to for-mer Brock employees, and Brian Brock will stay on in a managerial role. CMN

Reprinted with permission from the Nov. 8, 2013, edition of CHEESE MARKET NEWS® © Copyright 2013 Quarne Publishing LLC; PH: (509) 962-4026; www.cheesemarketnews.com

November 8, 2013 — CHEESE MARKET NEWS® 11

For more information please visit www.relco.net

For more information please visit www.mctdairies.com

NEWS/BUSINESS

Block Formers

20 - 60 pound

flexibilityBlock Formers

Cheese Vats

Cottage Cheese Vats

Draining/Salting Belts

Curd Tables

Process Engineering

Block Formers

20 - 60 pound

flexibility

The Standard of Excellence in Cheesemaking Equipment

/ Innovative process solutions, engineered right. USA . The Netherlands . New Zealand +1 (320) 231-2210 www.relco.net

MADISON Wis. — The Wisconsin As-sociation of Food Protection (WAFP)recently honored Les Lamb, who has worked in the dairy industry for 35 years, with its meritorious achievement award.

Lamb began his dairy career as a dairy policy analyst with the Wisconsin Department of Agriculture in 1978. He joined the Wisconsin Milk Market-ing Board (WMMB) in 1984 and held various positions over 17 years with the organization.

In 2001, Lamb became deputy sec-retary of the Wisconsin Department of Agriculture, Trade and Consumer Protection. Then, in 2003, Lamb started his own consulting business assisting companies with intellectual property matters, food regulation and product traceability systems and software.

Lamb has served on WAFP’s board of directors for the last fi ve years. He is currently secretary and treasurer. CMN

Lamb receives Wis. Association of Food Protection award

Comings and goings … comings and goings

William Norman has been named president of rigid plastics packaging for foodservice, dairy, food and beverage, and industrial markets at Berry Plastics Group Inc., Evansville, Ind. In his new role, Norman will work to accelerate growth of the company’s rigid open top business while researching, designing and introducing innovative new prod-ucts. Norman joined Berry Plastics in 1993 and has held managerial and vice president positions.

Marc Benoit has been named execu-tive vice president of human resources at Danone, Paris. Benoit previously served as general manager at DIAM Group Europe and at Blédina. Benoit

succeeds Muriel Pénicaud.Brian McKeon has been named vice

president and chief fi nancial offi cer of IDEXX Laboratories Inc., Westbrook, Maine. McKeon previously served as executive vice president and chief fi nan-cial offi cer at Iron Mountain Co. and the Timberland Co. as well as vice president of fi nance at PepsiCo North America.

Daniel Smith has been named agri-cultural development administrator at the Wisconsin Department of Agricul-ture, Trade and Consumer Protection (WDATCP). Smith previously served as CEO of Midwestern BioAg and as an eco-nomic advisor at WDATCP. He also ran a dairy farm for more than 30 years. CMN

PEOPLE

PITTSBURGH — Harry Davis & Co. has announced it will hold an auction of the former Unilever margarine facility in Atlanta Nov. 19-20, and the former Kraft Foods/Churny Cheese packaging plant in Waupaca, Wis., Dec. 3. Both sales will take place on-site at the plants as well as via simultaneous online bidding at www.harrydavis.com.

The former Unilever plant in Atlanta is 140,000 square feet and features 84,000 square feet of produc-tion space, 42,000 square feet of cold storage space and a 14,000-square-foot office. The sale will include general plant equipment, including processing and packaging equipment, in addition to the facility on 11 acres of real estate.

“This auction is a must for anyone

Former Unilever, Kraft plants to be auctionedin need of premium equipment at a signifi cant cost savings,” says Leonard Davis, president, Harry Davis & Co.

The Kraft/Churny plant auction in December will feature cheese pack-aging and general plant equipment along with the 57,000-square-foot plant on 3.56 acres. The plant includes a warehouse, cold storage facilities and offi ce space.

“The Churny Cheese plant has been very well-maintained,” Davis says. “It would make an excellent investment for a company in need of space for food-grade production or packaging.”

Information about both auctions, in-cluding equipment photos, auction cata-log, registration and inspection infor-mation, is available at www.harrydavis.com or by calling 412-765-1170. CMN

Our Expertise in World Dairy Markets Makes MCT Your Global Partner for Successful Results

Could you use assistance in managing your supply chain? We have expanded our team to bring you unprecedented expertise and knowledge in today’s complex world markets.

MCT Dairies is the leading supplier of cheese and

dairy ingredients, offering innovative solutions

throughout the world.

Reprinted with permission from the Nov. 8, 2013, edition of CHEESE MARKET NEWS® © Copyright 2013 Quarne Publishing LLC; PH: (509) 962-4026; www.cheesemarketnews.com

12 CHEESE MARKET NEWS® — November 8, 2013

NEWS/BUSINESS

For more information please visit www.mdavisgrp.com

EQUIPMENT 1• EQUIPMENT 1•

C L A S S I F I E D A D V E R T I S I N G

CHEESE MARKET NEWS® is here to deliver original, straightforward, reliable news to help you run your business more efficiently and profitably. What better way to tap into the effectiveness of this one-stop news source than to advertise your products or services on our classified page or in the display section of our newspaper?

My job is to help you sell your equipment, ingredients or services or to find a qualified candidate to join your company, and I take my job seriously.

Getting results is as easy as picking up the phone or emailing me to discuss your needs. I am here to listen and help you achieve your goal. Please call me at (608) 831-6002 or email me at [email protected] and let me go to work for you today.

Say Cheese...Say CHEESE MARKET NEWS!

Susan Quarne Publisher The Weekly Newspaper Of The Nation's Cheese And Dairy/Deli Business

CHEESE MARKET NEWS®

For more information please visit www.ullmers-dairyequipment.com

CHEESE CUTTERSTHAT

BOOST PROFITS PHONE: FAX: 1-888-2-GENMAC 1-920-458-8316

E-MAIL: [email protected]

GENERAL MACHINERY CORPORATIONP.O. BOX 717

SHEBOYGAN, WI 53082-0717

Proudly Supplying theFood and Dairy Industry

for Over 70 Years!

1-800-MUELLER • www.paulmueller.com©2013 Paul Mueller Company 429-1

FOR MORE INFORMATION, PLEASE CONTACT:

NATIONAL SALES MANAGER – WESTMike Veatch • [email protected]

NATIONAL SALES MANAGER – EASTJim Hall • [email protected]

For more information please visit www.barrinc.com

For more information please visit www.genmac.com

For more information please visit www.paulmueller.com

©20

13 M

.Dav

isGr

oup,

LLC

The Leader in Food,Dairy & Beverage

Auctions(3) Dairy & (3) Food& Beverage Auctions(75+) Tanks, Silos, Mix Tanks & Assorted Vessels,NEW PROCESSORS, HTSTs,Homos, Separators, CaseHandling, (10+) Filling Lines, NEW LIKWIFIERS,Cheese Equipment, TortillaProduction Lines, MeatEquipment, Milk Receiving,CIPs, Material Handling,Lab, Refrigeration, GeneralPlant, Fleet, Office, REALESTATE!! FOR DETAILS:www.mdavisgrp.com11/14OAK FARMS DAIRYWaco, TX11/21TORTILLERIAEL MAIZALMarietta, GA12/5KEMPS FOODS FLUID MILKDuluth, MN12/12DFA BULK CHEESEMonett, MODATE TBDDEAN FOODSBuena Park, CADATE TBDBOB EVANS FARMSMEAT FACILITYBidwell, OH(3) OPERATING FACILITIES SOLD!!MORE IN Q1/2014!Buy. Sell. Appraise. Let M. Davis Group Help You.412.521.5751

Reprinted with permission from the Nov. 8, 2013, edition of CHEESE MARKET NEWS® © Copyright 2013 Quarne Publishing LLC; PH: (509) 962-4026; www.cheesemarketnews.com

November 8, 2013 — CHEESE MARKET NEWS® 13

For more information please visit www.harrydavis.com

EQUIPMENT 1• EQUIPMENT 1•

C L A S S I F I E D A D V E R T I S I N GEQUIPMENT 1•

AUCTION: Cheese Packaging Facility

HARRYDAVIS& COMPANY

www.harrydavis.com412-765-1170 - [email protected]

Asset Solutions Experts Since 1955

former KRAFT FOODS Facility & REAL ESTATE AUCTION: December 3 - Kraft/Churny Cheese - Waupaca, WI

PACKAGING EQUIPMENT HIGHLIGHTS:• GEA Tiromat Horizontal Thermo Former Line w/Labeler

• Kliklok Wraparound Cartoner - Schenek Ingredient Feeders

• Edlund Automatic Can Opener; S/S Can Washing System

• (2) Ohlson 8-Head Scale Fillers w/A.B. Logix 5561 PLC

• (2) Sabel Automatic Case Packers with Nordson Gluers

• (3) 2008 Zarpack Barcode Readers & Marsh Printers

• Urschel Dicer - Koss Ultrasonic Cutter - All S/S Fitzmill

• LabelAire Labeler, Sleever, Additional Packaging Equipment

• LARGE Assortment WeighTronix & Mettler Toledo Scales

• FES/GEA 125 hp Screw Ammonia Compressor, Evapco Evaporative Condensers, Air Handlers, Boiler & MORE!

• EXTENSIVE S/S Conveying Systems, Material Handling

• PRIME REAL ESTATE: 57,000 sq. ft. Very Well Maintained food facility on 3.56 Acres with Warehouse, Cold Storageand Offices - Equipped with Full Utilities, Much More!

For more information please visit www.whalenfoodsinc.com

STORAGE 13•

BIG REWARD OFFERED FOR YOUR...

• Cheese Trim • Cheese Fines• #1 and Undergrades

• Close Coded Products• Natural, Processed, Imitation or Flavored

Call Dean, Eric or Pat: (877) 914-5400horizonsalesinc.com

CHEESE/DAIRY 12•

For more information please visit www.horizonsalesinc.com

MISCELLANEOUS 11•

MARKETING 10•

FOR SALE:5 YEAR OLD

WHITE CHEDDAR• Produced by Master

Cheese Maker• Sufficient Quantities

Available• Call For Pricing

(800) 200-6020www.cedargrovecheese.com

For more information please visit www.cedargrovecheese.com

Reprinted with permission from the Nov. 8, 2013, edition of CHEESE MARKET NEWS® © Copyright 2013 Quarne Publishing LLC; PH: (509) 962-4026; www.cheesemarketnews.com

14 CHEESE MARKET NEWS® — November 8, 2013

For more information please visit www.harrydavis.com

NEWS/BUSINESS

AUCTION: Unilever Margarine Facility

HARRYDAVIS& COMPANY

www.harrydavis.com412-765-1170 - [email protected]

Asset Solutions Experts Since 1955

FOOD PROCESSING & PACKAGING - REAL ESTATE 2-DAY AUCTION: November 19-20 - Unilever facility - Atlanta, GA

• (34) S/S Processors: (9) 2006 Feldmeier 3,000 Gal. Processors,(25) C.B., Mueller & other Dome-Top Processors 500-1,000 Gal.

• Margarine Processing & Packaging: (7) Gerstenberg Margarine Processing Units & (3) Pin Rotors, (5) C.B. Votators,Trefa Mixer & Whipper, Egli Melter, Plate Heat Exchangers,High Pressure Pumps, Morpac Butter Printers, Bottle Filler

• Packaging: Autoprod 4-Wide Tub Filling Lines, Squeeze Bottle Filling Line, Case Sealers, Videojet Coders, Metal Detectors,Check Weighers, Scales, (10) Palletizers, (2) Pallet Wrappers

• Additional Food Processing: (4) CIP Systems, S/S Pumps & Air Valves, (20) 70,000 lb. & other Bulk Storage Tanks; Tri-Blender, Lab Equipment, Plant Controls, MUCH MORE!

• Refrigeration, Boilers, Air Compressors: (19) Mycom &Vilter Ammonia Compressors (New as 2012), Evap. Cond. &2012 Cooling Tower, I.R. Air Comprsrs., Cleaver Brooks Boilers

• EXTENSIVE General Plant, Maintenance, Much More!

• REAL ESTATE: 140,000 sf Manufacturing plant, Atlanta, GA

NEW 2012!

EQUIPMENT 1• EQUIPMENT 1• EQUIPMENT 1•

CLASSIF IED ADVERTIS ING

innovation, Domino’s.“Over the last couple years, we’ve

expanded from product development and promotion to diversifying the way we partner together and diversify sales growth,” he adds.

Jordan notes that DMI brought on checkoff-funded chefs who have been concepting Domino’s ideas for innova-tion and fi nding ways to make them cheese-centric.

This has included Domino’s launch in late 2012 of Handmade Pan Pizza, which uses up to 40 percent more cheese than the chain’s two-topping, hand-tossed pizzas. The ideas expressed

by the checkoff-funded chefs played a role in this decision.

“They’ve really helped us, from im-proving what’s on our menu to bringing new items on,” Jordan says.

Jordan notes that DMI also has brought health and wellness consumer trends to Domino’s attention.

“We’ve been working on what type of product development messaging we

can bring related to health and well-ness,” he says.