Par Krimp

-

Upload

raul-daniel-beron -

Category

Documents

-

view

218 -

download

0

Transcript of Par Krimp

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 126

Parkrimp Crimping

Equipment

Visit wwwparkerhosecom to view CrimpSourcecopy

the online resource for hose crimp specifications for

the complete line of Parker crimping machines

Visual In

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 226

C-2 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

C C r i m p i n g

E q u i p m e n t

A

B

D

E

G

A s s e m b l y

E q u i p m e n t

Catalog 4400 US

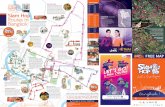

Visual Index

Karrykrimp 2 C-11

Assembly InstructionsC-17Minikrimp Karrykrimp amp

Karrykrimp 2 Pumps C-12

Minikrimp Karryrkimp amp

Karrykrimp 2 Pumps C-13-14

Parkrimp 1 C-15

Assembly Instructions C-17

PHastkrimp C-16

Assembly InstructionsC-17

Parkrimp 2 C-18

Assembly InstructionsC-19-20

Hydraulic Press Kit C-21-23 Weatherhead Conversion

Kit C-24

Gates Conversion Kit C-25

Parkrimp Tool Selection

Chart C-3-7

Crimp Diameters and Hose

Insertion Depths C-26

Minikrimp C-8

Assembly InstructionsC-9

Karrykrimp C-10

Assembly InstructionsC-17

Section C Parkrimp Crimping Equipment

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 326

C-3 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

Catalog 4400 US

Size Fitting Die Used

Hose Range Series (Base Color) Minikrimp Karrykrimp Karrykrimp 2 Parkrimp 1 PHastkrimp Parkrimp 2

AX -4-16 HY

80C-Hxx 82C-R01-PFD 82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

BXX -4-16 HY

80C-Hxx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 83C-OCB

CN -20-32 73

83C-Lxx

--------------- --------------- --------------- --------------- ---------------NONE

REQUIRED

SS23CG -6-10 26

80C-Exx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 83C-OCB

201261 -4-16 26

80C-Exx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 83C-OCB

201261 -20-32 26

83C-Exx

--------------- --------------- --------------- --------------- ---------------

83C-R02H

206 -4-16 26

80C-Exx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 83C-OCB

206 -20-32 26

83C-Exx

--------------- --------------- --------------- --------------- ---------------

83C-R02H

213 -4-16 26

80C-Exx 82C-R01-PFD 82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

S i l v e r

S i l v e r

S i l v e r

S i l v e

r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

O l i v e D r a

b

Parkrimp Tool Selection Chart ndash 1 of 5

PARKRIMP NO-SKIVE TOOL SELECTION CHARTS Select the Parker Hose that meets your application

requirements

bull Find the Parker Hose base part number size and theParker Fitting Series in the Parkrimp Tool SelectionChart below or on the following page(s)

bull Based on hose size select color coded unitized die train(HY Series Dies are not color coded The Brown cavity is for all sizes)

Hose Dash Hose (Nominal) Color Size Size (Size) Code-4 14rdquo (316rdquo ) RED-5 516rdquo (14rdquo ) PURPLE-6 38rdquo (516rdquo ) YELLOW-8 12rdquo (1332rdquo ) BLUE-10 58rdquo (12rdquo ) ORANGE-12 34rdquo (58rdquo ) GREEN-16 1rdquo (78rdquo ) BLACK-20 1-14rdquo (1-18rdquo ) WHITE-24 1-12rdquo (1-38rdquo ) RED-32 2rdquo (1-1332rdquo ) GREEN

Part DescriptionNumber

80C-E08 Silver 1332rdquo Blue Cavity 26 Series Die80C-A08 Silver 12rdquo Blue Cavity 43 Series Die83C-L32 Olive Drab 2rdquo Green Cavity 78 Series Die83C-D08 Black 12rdquo Blue Cavity 71 Series Die

bull Based on the Parkrimp machine select the tool(s) for proper assembly (die ring spacer ring spacer plate andor adapter bowl)

bull Hose assembly instructions for the Parkrimp machine are onthe pages following the catalog description of the unit (Aninstructional video is a standard part of each Parkrimp machineshipped from the manufacturer)

Examples

Black Die Ring Spacer Ring Spacer Plate Adapter Bowl

Parkrimp Crimping Equipment Parkrimp Tool Selection Chart

Silver Die Ring

Minikrimp Karrykr imp and Parkrimp 1 will not c rimp AX-16 and BXX-16 hose CONTINUED

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 426

C-4 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

C C r i m p i n g

E q u i p m e n t

A

B

D

E

G

A s s e m b l y

E q u i p m e n t

Catalog 4400 US

(1) - IF 83C-A16H OR 83C-A20H DIES ARE USED THE SPACER PLATE 83C-R02H MUST BE UTILIZED INSTEAD OF THE 83C-R02 RING

Parkrimp Tool Selection Chart ndash 2 of 5

Black Die Ring Silver Die Ring Spacer Ring Spacer Plate Adapter Bowl

Parkrimp Crimping Equipment Parkrimp Tool Selection Chart

Size Fitting Die Used

Hose Range Series (Base Color) Minikrimp Karrykrimp Karrykrimp 2 Parkrimp 1 PHastkrimp Parkrimp 2

213 -20-32 2683C-Exx

--------------- --------------- --------------- --------------- --------------- NONE

REQUIRED

221FR -5-16 26

80C-Exx 82C-R01-PFD 82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

225 -4-16 26

80C-Exx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 83C-OCB

225 -20-32 26

83C-Exx

--------------- --------------- --------------- --------------- --------------- NONE

REQUIRED

235 -16 2680C-Exx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 83C-OCB

244 -16 26

80C-Exx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 83C-OCB

244 -20-24 26

83C-Exx

--------------- --------------- --------------- --------------- ---------------

83C-R02H

266 -4-16 26

80C-Exx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 83C-OCB

266 -20-24 2683C-Exx

--------------- --------------- --------------- --------------- ---------------83C-R02H

285 -4-12 26

80C-Exx 82C-R01-PFD 82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

293 -4-16 26

80C-Exx 82C-R01-PFD 82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

301 -4-16 43

80C-Axx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 (1) 83C-OCB

301 -20 43

80C-Axx

---------------

82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 (1) 83C-OCB

301 -24-32 43

83C-Axx

--------------- --------------- --------------- --------------- ---------------

83C-R02H

301LT -4-16 43

80C-Axx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 (1) 83C-OCB

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S

i l v e r

S i l v e r

CONTINUED

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 526

C-5 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

Catalog 4400 US

Size Fitting Die Used

Hose Range Series (Base Color) Minikrimp Karrykrimp Karrykrimp 2 Parkrimp 1 PHastkrimp Parkrimp 2

304 -4-16 4380C-Axx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 (1) 83C-OCB

304 -20 43

80C-Axx

---------------

82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 (1) 83C-OCB

304 -24-32 43

83C-Axx

--------------- --------------- --------------- --------------- ---------------

83C-R02H

341 -6-12 43

80C-Axx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 (1) 83C-OCB

341 -16 4380C-Axx

---------------82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 (1) 83C-OCB

341 -20 43

80C-Axx

--------------- ---------------

85C-R02

---------------

85C-R02 83C-R02 (1) 83C-OCB

351TC

351ST-4-12 43

80C-Axx 82C-R01-PFD 82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

381 -4-16 43

80C-Axx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 (1) 83C-OCB

381 -20 4380C-Axx

---------------82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 (1) 83C-OCB

381 -24-32 43

83C-Axx

--------------- --------------- --------------- --------------- ---------------

83C-R02H

421424

426-4-16 43

80C-Axx 82C-R01-PFD 82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

421424

426-20 43

80C-Axx

---------------

82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

421424

426 -24-32 43

83C-Axx

--------------- --------------- --------------- --------------- ---------------NONE

REQUIRED

421WC -4-16 43

80C-Axx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 (1) 83C-OCB

451TC

451ST -4-16 43

80C-Axx 82C-R01-PFD 82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S

i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S

i l v e r

S i l v e r

S i l v e r

S

i l v e r

S i l v e r

S i l v e r

(1) - IF 83C-A16H OR 83C-A20H DIES ARE USED THE SPACER PLATE 83C-R02H MUST BE UTILIZED INSTEAD OF THE 83C-R02 RING

Parkrimp Tool Selection Chart ndash 3 of 5

Black Die Ring Silver Die Ring Spacer Ring Spacer Plate Adapter Bowl

Parkrimp Crimping Equipment Parkrimp Tool Selection Chart

CONTINUED

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 626

C-6 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

C C r i m p i n g

E q u i p m e n t

A

B

D

E

G

A s s e m b l y

E q u i p m e n t

Catalog 4400 US

Size Fitting Die Used

Hose Range Series (Base Color) Minikrimp Karrykrimp Karrykrimp 2 Parkrimp 1 PHastkrimp Parkrimp 2

451TC

451ST -20 4380C-Axx

--------------- ---------------85C-R01

---------------85C-R01 83C-OCB

431436 -4-16 43

80C-Axx 82C-R01-PFD 82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

471TC

471ST -4-16 43

80C-Axx 82C-R01-PFD 82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

472TC -20 43

80C-Axx

---------------

82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

472TC -24-32 4383C-Axx

--------------- --------------- --------------- --------------- ---------------NONE

REQUIRED

482TC

482ST -4-16 43

80C-Axx 82C-R01-PFD 82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

601 -4-16 43

80C-Axx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 (1) 83C-OCB

604-6-8

-1643

80C-Axx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 (1) 83C-OCB

701 -6-12 7083C-Dxx

--------------- ---------------85C-R02

---------------85C-R02 83C-R02 (1) 83C-OCB

721 -6-20 71

83C-Dxx

--------------- ---------------

85C-R01

---------------

85C-R01 83C-OCB

721 -24-32 71

83C-Dxx

--------------- --------------- --------------- --------------- ---------------NONE

REQUIRED

721TC -6-20 71

83C-Dxx

--------------- ---------------

85C-R01

---------------

85C-R01 83C-OCB

731 -12-16 7380C-Lxx

--------------- ---------------85C-R01

---------------85C-R01 83C-OCB

731 -12-32 73

83C-Lxx

--------------- --------------- --------------- --------------- ---------------NONE

REQUIRED

774

772TC

772ST

-6-20 71

83C-Dxx

--------------- ---------------

85C-R01

---------------

85C-R01 83C-OCB B l a c k

B l a c k

O l i v e

D r a b

S i l v e r

O l i v e D r a b

S i l v e r

B l a c k

B l a c k

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

S m

a l l

S m a l l

B l a c k

S i l v e r

(1) - IF 83C-A16H OR 83C-A20H DIES ARE USED THE SPACER PLATE 83C-R02H MUST BE UTILIZED INSTEAD OF THE 83C-R02 RING

Parkrimp Tool Selection Chart ndash 4 of 5

Black Die Ring Silver Die Ring Spacer Ring Spacer Plate Adapter Bowl

Parkrimp Crimping Equipment Parkrimp Tool Selection Chart

CONTINUED

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 726

C-7 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

Catalog 4400 US

Size Fitting Die Used

Hose Range Series (Base Color) Minikrimp Karrykrimp Karrykrimp 2 Parkrimp 1 PHastkrimp Parkrimp 2

774

772TC 772ST

-24-32 7183C-Dxx

--------------- --------------- --------------- --------------- --------------- NONE

REQUIRED

781 -12-16 78

80C-Lxx

--------------- ---------------

85C-R01

---------------

85C-R01 83C-OCB

781 -12-24 78

83C-Lxx

--------------- --------------- --------------- --------------- --------------- NONE

REQUIRED

782TC

782ST -10-16 78

80C-Lxx

--------------- ---------------

85C-R01

---------------

85C-R01 83C-OCB

78C

782TC 782ST

-12-32 7883C-Lxx

--------------- --------------- --------------- --------------- --------------- NONE

REQUIRED

791TC

792TC

792ST

-12-20 79

83C-Lxx

--------------- --------------- --------------- --------------- --------------- NONE

REQUIRED

881 -12-16 43

80C-Axx 82C-R02-PFD 82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 (1) 83C-OCB

881 -20 43

80C-Axx

---------------

82C-R02 85C-R02 80C-R02 85C-R02 83C-R02 (1) 83C-OCB

881 -24-32 4383C-Axx

--------------- --------------- --------------- --------------- ---------------83C-R02H

881 811 -12-16 81

80C-Vxx 82C-R01-PFD 82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

881 811 -20 81

80C-Vxx

---------------

82C-R01 85C-R01 80C-R01 85C-R01 83C-OCB

881 811 -24-32 81

83C-Vxx

--------------- --------------- --------------- --------------- --------------- NONE

REQUIRED

S i l v e r

O l i v e D r a b

S

i l v e r

S i l v e r

S i l v e r

S i l v e r

S i l v e r

O l i v e

D r a b

O l i v e D r a b

O l i v e D r a b

O l i v e D r a b

B l a

c k

Parkrimp Tool Selection Chart ndash 5 of 5

Black Die Ring Silver Die Ring Spacer Ring Spacer Plate Adapter Bowl

Parkrimp Crimping Equipment Parkrimp Tool Selection Chart

(1) - IF 83C-A16H OR 83C-A20H DIES ARE USED THE SPACER PLATE 83C-R02H MUST BE UTILIZED INSTEAD OF THE 83C-R02 RING

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 826

C-8 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

C C r i m p i n g

E q u i p m e n t

A

B

D

E

G

A s s e m b l y

E q u i p m e n t

Catalog 4400 US

Note Reference page C-12-13 f or information on Hand Pump (82C-0HP and 85C-0HP) Electric Pump (82C-0EP and 85C-0EP) AirHydraulic Pump (82C-0AP) and Vehicle Battery-

Powered Pump (85C-12V) For crimp instructions see pages C-9

Note Hose assemblies must be inspected for cleanliness and free of all foreign particles

Note Parker Hannifin will not accept responsibility for the operation of or provide warranty coverage for a crimper that is operated by a power unit other than equipment supplied by Parker

Hannifin for the express purpose of operating the crimper

MiniKrimptrade

For use with 26 43 81 and HY Series Fittings

With its cast aluminum design the MiniKrimp is lightweight

portable and compact This all-in-one unit is c apable of crimp-

ing ho se sizes up to 1 Dies are sold separately

SpecificationsDimensions 6 wide 13 deep 15 high

Weight 42 lbs with hand pump

Rating 30 tons force 10000 psi maximum

Capability -1 SAE 100R1 maximum

-1 SAE 100R1AT maximum

-1 SAE 100R2 maximum

-1 SAE 100R2AT maximum

-1 SAE 100R3 maximum

-1 SAE 100R4 maximum

-1 SAE100R5 maximum

-34 SAE 100R9AT maximum

-1 SAE 100R16 maximum

-1rdquo SAE 100R17 maximum

-1 SAEJ1402 AI maximum

-1 SAEJ1402 AII maximum

Set up time 20 secondsFull cycle time 30 seconds with electric pump

Note Cycle times vary depending on hose and fitting styles and sizes

Standard EquipmentModel 94C-001-PFD includesbull Minikrimp Portable Crimper (base unit) 94C-080-PFDbull Hand Pump 015301bull Die r ing Cavity Color Coded Silver 82C-R01-PFDModel 94C-002-PFD includesbull Minikrimp Portable Crimper (base unit) 94C-080-PFDbull Air over Hydraulic Pump Kit (wtubing amp adapters) 025411bull Die r ing Cavity Color Coded Silver 82C-R01-PFD

Optional Toolingbull Side Vise Mount 015736bull Upright Table Mount 015306bull Upright Vise Mount 015307bull Die ring Cavity Color Coded Black 82C-R02-PFDbull Connection Hose with Quick Coupling 015309bull Bent Tube for Hand Pump Only 015308bull Bent Tube for Air Over Hydraulic Pump Only 02534926 Series Dies (Silver)

bull -4 (316) Cavity Color Coded Red 80C-E04bull -5 (14) Cavity Color Coded Purple 80C-E05bull -6 (516) Cavity Color Coded Yellow 80C-E06bull -8 (1332) Cavity Color Coded Blue 80C-E08bull -10 (12) Cavity Color Coded Orange 80C-E10

bull -12 (58) Cavity Color Coded Green 80C-E12bull -16 (78) Cavity Color Coded Black 80C-E1643 Series Dies (Silver)

bull -4 (14) Cavity Color Coded Red 80C-A04bull -5 (516) Cavity Color Coded Purple 80C-A05bull -6 (38) Cavity Color Coded Yellow 80C-A06bull -8 (12) Cavity Color Coded Blue 80C-A08bull -10 (58) Cavity Color Coded Orange 80C-A10bull -12 (34) Cavity Color Coded Green 80C-A12bull -16 (1) Cavity Color Coded Black 80C-A16

81 Series Dies (Silver)bull -12 (34rdquo) Cavity Color Coded Green 80C-V12bull -16 (1rdquo) Cavity Color Coded Black 80C-V16

HY Series Dies - AX Hose (Silver)bull -4 (14rdquo) Cavity Brown 80C-H585bull -6 (38rdquo) Cavity Brown 80C-H735bull -8 (12rdquo) Cavity Brown 80C-H840

bull -10 (58rdquo) Cavity Brown 80C-H970bull -12 (34rdquo) Cavity Brown 80C-H1120HY Series Dies - BXX Hose (Silver)

bull -4 (14rdquo) Cavity Brown 80C-H605bull -6 (38rdquo) Cavity Brown 80C-H775bull -8 (12rdquo) Cavity Brown 80C-H885bull -10 (58rdquo) Cavity Brown 80C-H1010bull -12 (34rdquo) Cavity Brown 80C-H1170

The Minikrimptrade is a product of Parker Hannifin Parflex DivisionPhone (330) 296-2871

Fax (330) 296-8433

Important The Minikrimp was developed by Parker Hannifin Parflex Division but is compatible with Parker Hannifin Hose Products Divisionproducts The Minikrimp is only compatible with rubber hose with a size range of 316rdquo ID through 1rdquo ID and only those hoses that utilize 26 43and HY Series fittings However there are two exceptions to these specifications In reference to Minikrimp stainless steel crimping capabilitiesplease refer to CrimpSource on wwwparkerhosecom (the online resource for hose crimp specifications for the complete line of Parker crimping machines) The Minikrimp DOES NOT crimp 341-16 (SAE 100R9 1rdquo ID) hose Any engineering and crimper performance issuespertaining to the Minikrimp should be directed to the Parflex Division Technical Services Department at (330) 296-2871

Parkrimp Crimping Equipment Minikrimp

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 926

C-9 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

Catalog 4400 US

MiniKrimp Assembly Instructions for 26 43 and HY Series Fittings

1 Mark the hose insertion

depth and push hose into

fitting until the mark on the

hose is even with the end

of the shell (lubricate hose

if necessary) Hose

Insertion Depth table is on

page C-26

2 Place unitized die set into base

plate3 Place proper die

ring on top of the

selected die

4 Slide pusher into

place onto

shoulder bolt

7 While holding hose

and fitting into

position on die step

begin pumping hand

pump until die ring

contacts base plate

Release pressure

remove finished

assembly Check

crimp diameter

5 Position the hose

and fitting in dies

from below

8a Measure crimp

diameter of each fitting

at the top middle and

bottom of the shell

Take measurements at

a minimum of three

places around the shell

circum-ference Verify

crimp diameter is within

tolerances

Parkrimp Crimping Equipment Minikrimp Assembly Instructions

Note Parker Hannifin will not accept responsi-bility for the operation of or provide warranty

coverage for a crimper that is operated by apower unit other than equipment supplied by

Parker Hannifin for the express purpose of

operating the crimper

Important Hose assemblies must be inspected

for cleanliness and free of all foreign particles

Color Coded

UnitizedDie-Train

darrdarr darrdarr darr

PARKALIGNreg Feature

Parkrimp Series 26 Series

6 Rest bottom of coupling on die step usingPARKALIGNreg feature

darr darr darr darr darr darr darr darr darrdarr

darr darr darr darr darr darr darr darr darrdarr

8b Measure crimp diameter on the flat

surfaces of the crimped shell referencedin the above illustration Reference crimp

diameter on page C-26

Crimp

Diameter

26 SeriesStandard

Parkrimp Series

darr darr darr darr darr darr darr darr darr darr

Important The Minikrimp was developed by Parker Hannifin Parflex Division but is

compatible with Parker Hannifin Hose Products Division products The Minikrimp is onlycompatible with rubber hose with a size range of 316rdquo ID through 1rdquo ID and only those

hoses that utilize 26 43 and HY Series fittings However there are two exceptions to

these specifications The Minikrimp DOES NOT crimp any stainless steel fittings and

DOES NOT crimp 341-16 (SAE 100R9 1rdquo ID) hose Any engineering and crimper

performance issues pertaining to the Minikrimp should be directed to the Parflex

Division Technical Services Department at (330) 296-2871

Note For rubber based products reference step 8b and

for thermoplastic products reference step 8a for

crimp diameter measurement

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 1026

C-10 Hose Products DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

C C r i m p i n g

E q u i p m e n t

A

B

D

E

F

G

A s s e m b l y

E q u i p m e n t

Catalog 4400 US

US Patent No 4577485

Parkrimp Crimping Equipment Karrykrimp

KarrykrimpFor use with 26 43 81 and HY Series Fittings

The Karrykrimp is engineered for optimum durability has apivoting pusher which makes die changing easy and has anergonomically designed handle for a comfortable grip TheKarrykrimp gives you everything you need to crimp hosesfrom 14 to 1-14 In one convenient package Model 82C-001 includes crimping machine take-apart stand handpump die rings connection hose with quick coupling and diesets for 14 38 12 34 and 1 hoses (Die sets for 51658 and 1-14 hoses are available) Karrykrimp has the samecrimping capabilities as the Parkrimp 1 Model 80C-001

SpecificationsDimensions 15 wide 12 deep 27 highWeight 53middot12 lbs without power unitRating 30 tons force 10000 psi maximumCapability -1-14 SAE 100R1AT maximum

-1 DIN 20 022-1SN maximum-1-14 SAE 100R2AT maximum-1-14 DIN 20 022-2SN maximum-1 SAE 100R3 maximum-1-14 SAE 100R4 maximum-78 SAE100R5 maximum-1 SAE 100R9AT maximum-1 SAE 100R16 maximum-1 SAE 100R17 maximum-78 SAEJ1402 AI maximum-78 SAEJ1402 AII maximum

Set up time 20 secondsFull cycle time 30 seconds with electric pumpNote Cycle times vary depending on hose and fitting styles and sizesNote DO NOT use this machine to assemble 341-20 451TC-20hose or any size stainless steel fitting

Standard EquipmentModel 82C-001 includes

bull Karrykrimp Portable Crimper (base unit) 82C-080bull 2 Piece Stand 832021bull Hand Pump 82C-0HPbull Connection Hose with Quick Coupling 82C-00Lbull Die ring Cavity Color Coded Silver 82C-R01bull Die ring Cavity Color Coded Black 82C-R02

43 Series Dies (Silver)bull -4 (14) Cavity Color Coded Red 80C-A04bull -6 (38) Cavity Color Coded Yellow 80C-A06bull -8 (12) Cavity Color Coded Blue 80C-A08bull -12 (34) Cavity Color Coded Green 80C-A12bull -16 (1) Cavity Color Coded Black 80C-A16

Model 82C-002 includesbull Same as 82C-001 less hand pump

Model 82C-061 includesbull Karrykrimp Portable Crimper (base unit) 82C-080bull 2 Piece Stand 832021bull Die ring Cavity Color Coded Silver 82C-R01bull Die ring Cavity Color Coded Black 82C-R02bull Connection hose with Quick Coupling 82C-00Lbull No Pumpbull No Dies

Model 82C-080 includes

bull Karrykrimp Portable Crimper (base unit) 82C-080bull No Dies Die Rings Pumps or Connection Hose

Optional Tooling26 Series Dies (Silver)

bull -4 (316) Cavity Color Coded Red 80C-E04bull -5 (14) Cavity Color Coded Purple 80C-E05bull -6 (516) Cavity Color Coded Yellow 80C-E06bull -8 (1332) Cavity Color Coded Blue 80C-E08bull -10 (12) Cavity Color Coded Orange 80C-E10bull -12 (58) Cavity Color Coded Green 80C-E12bull -16 (78) Cavity Color Coded Black 80C-E16

43 Series Dies (Silver)bull -4 (14) Cavity Color Coded Red 80C-A04bull -5 (516) Cavity Color Coded Purple 80C-A05bull -6 (38) Cavity Color Coded Yellow 80C-A06bull -8 (12) Cavity Color Coded Blue 80C-A08bull -10 (58) Cavity Color Coded Orange 80C-A10bull -12 (34) Cavity Color Coded Green 80C-A12bull -16 (1) Cavity Color Coded Black 80C-A16bull -20 (1-14) Cavity Color Coded White 80C-A20

81 Series Dies (Silver)bull -12 (34rdquo) Cavity Color Coded Green 80C-V12bull -16 (1rdquo) Cavity Color Coded Black 80C-V16bull -20 (1-14rdquo) Cavity Color Coded White 80C-V20

HY Series Dies - AX Hose (Silver)bull -4 (14rdquo) Cavity Brown 80C-H585bull -6 (38rdquo) Cavity Brown 80C-H735bull -8 (12rdquo) Cavity Brown 80C-H840bull -10 (58rdquo) Cavity Brown 80C-H970bull -12 (34rdquo) Cavity Brown 80C-H1120

HY Series Dies - BXX Hose (Silver)bull -4 (14rdquo) Cavity Brown 80C-H605bull -6 (38rdquo) Cavity Brown 80C-H775bull -8 (12rdquo) Cavity Brown 80C-H885bull -10 (58rdquo) Cavity Brown 80C-H1010bull -12 (34rdquo) Cavity Brown 80C-H1170

Note Reference page C-12-13 for information on Hand Pump (82C-0HP and 85C-0HP) Electric Pump (82C-0EP and 85C-0EP) AirHydraulic Pump (82C-0AP) and Vehicle Battery-

Powered Pump (85C-12V) For crimp instructions see pages C-17Note Hose assemblies must be inspected for cleanliness and free of all foreign particlesNote Parker Hannifin will not accept responsibility for the operation of or provide warranty coverage for a crimper that is operated by a power unit other than equipment supplied by ParkerHannifin for the express purpose of operating the crimper

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 1126

C-11 Hose Products DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

Catalog 4400 US Parkrimp Crimping Equipment Karrykrimp 2

Karrykrimp 2For use with 26 43 70 71 73 78 81 and HYSeries FittingsKarrykrimp 2 is portable compact and ruggedly built TheKarrykrimp 2 gives you everything you need to crimp hosesfrom 14 to 1-14 (through 4 spiral SAE 100R12) and from34rdquo to 1rdquo (through 6 spiral SAE 100R13) In one convenientpackage Model 85C-061 includes crimping machine take-apart stand die rings and connection hose with quick coupling Select the power unit and dies that meet your needs

SpecificationsDimensions 14 wide 15 deep 30 highWeight 100 lbs without power unitRating 60 tons force 10000 psi maximumCapability - 1-14 SAE 100R1AT maximum

- 1 DIN 20 022-1SN maximum- 1-14 SAE 100R2AT maximum- 1-14 DIN 20 022-2SN maximum- 1 SAE 100R3 maximum- 1-14 SAE 100R4 maximum- 78 SAE100R5 maximum- 78 SAEJ1402 AI maximum- 78 SAEJ1402 AII maximum- 1-14 SAE 100R9AT maximum- 1-14 SAE 100R12 maximum- 1rdquo SAE 100R13 maximum- 1 SAE 100R16 maximum- 1-14 SAE 100R17 maximum

Set up Time - 20 secondsNote Cycle times vary depending on hose and fitting styles andsizes

Standard EquipmentModel 85C-061 includes

bull Karrykrimp 2 Portable Crimper (base unit) 85C-080bull Die ring Color Coded Silver 85C-R01bull Die ring Color Coded Black 85C-R02bull Connection hose with Quick Coupling 82C-00Lbull Stand (2 piece) 832021bull No Dies or Pumps

Model 85C-KDA (Die Kit) Includes 43 Series -4 -6 -8 -12 -16 and -20 dies and 7071 Series -6 -8 -12 -16 and -20 dies ONLY

Optional Tooling26 Series Dies (Silver)

bull -4 (316) Cavity Color Coded Red 80C-E04bull -5 (14) Cavity Color Coded Purple 80C-E05bull -6 (516) Cavity Color Coded Yellow 80C-E06bull -8 (1332) Cavity Color Coded Blue 80C-E08bull -10 (12) Cavity Color Coded Orange 80C-E10bull -12 (58) Cavity Color Coded Green 80C-E12bull -16 (78) Cavity Color Coded Black 80C-E16

43 Series Dies (Silver)bull -4 (14) Cavity Color Coded Red 80C-A04bull -5 (516) Cavity Color Coded Purple 80C-A05bull -6 (38) Cavity Color Coded Yellow 80C-A06bull -8 (12) Cavity Color Coded Blue 80C-A08bull -12 (34) Cavity Color Coded Green 80C-A12bull -16 (1) Cavity Color Coded Black 80C-A16bull -20 (1-14) Cavity Color Coded White 80C-A20

70 and 71 Series Dies (Black)bull -6 (38) Cavity Color Coded Yellow 83C-D06bull -8 (12) Cavity Color Coded Blue 83C-D08bull -10 (58) Cavity Color Coded Orange 83C-D10bull -12 (34) Cavity Color Coded Green 83C-D12bull -16 (1) Cavity Color Coded Black 83C-D16bull -20 (1-14) Cavity Color Coded White 83C-D20

73 and 78 Series Dies (Olive Drab)bull -12 (34) Cavity Color Coded Green 80C-L12bull -16 (1) Cavity Color Coded Black 80C-L16

81 Series Dies (Silver)bull -12 (34rdquo) Cavity Color Coded Green 80C-V12bull -16 (1rdquo) Cavity Color Coded Black 80C-V16bull -20 (1-14rdquo) Cavity Color Coded White 80C-V20

HY Series Dies - AX Hose (Silver)bull -4 (14rdquo) Cavity Brown 80C-H585bull -6 (38rdquo) Cavity Brown 80C-H735bull -8 (12rdquo) Cavity Brown 80C-H840bull -10 (58rdquo) Cavity Brown 80C-H970bull -12 (34rdquo) Cavity Brown 80C-H1120bull -16 (1rdquo) Cavity Brown 80C-H1365

HY Series Dies - BXX Hose (Silver)bull -4 (14rdquo) Cavity Brown 80C-H605bull -6 (38rdquo) Cavity Brown 80C-H775bull -8 (12rdquo) Cavity Brown 80C-H885bull -10 (58rdquo) Cavity Brown 80C-H1010bull -12 (34rdquo) Cavity Brown 80C-H1170bull -16 (1rdquo) Cavity Brown 80C-H1465

Note Reference page C-12-13 for information on Hand Pump (82C-0HP and 85C-0HP) Electric Pump (82C-0EP and 85C-0EP) AirHydraulic Pump (82C-0AP) and Vehicle Battery-Powered Pump (85C-12V) For crimp instructions see pages C-17Note Hose assemblies must be inspected for cleanliness and free of all foreign particlesNote Parker Hannifin will not accept responsibility for the operation of or provide warranty coverage for a crimper that is operated by a power unit other than equipment supplied by ParkerHannifin for the express purpose of operating the crimper

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 1226

C-12 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

C C r i m p i n g

E q u i p m e n t

A

B

D

E

G

A s s e m b l y

E q u i p m e n t

Catalog 4400 US Parkrimp Crimping Equipment Power Units

Hand PumpPart No 82C-0HP

(for use with Minikrimp and Karrykrimp) Ease of operation hand pump delivers 10000 psi

Length - 22-1116

Width - 3-14Height - 4-1116

Port size - 38 NPTF

Weight - 9 lb

Hydraulic Fluid - Enerpac Oil

Hand PumpPart No 85C-0HP(for use with Minikrimp Karrykrimp and Karrykrimp 2) Ease of operation hand pump delivers 10000 psi

Length - 28-1516

Width - 12-18

Height - 11

Port Size - 38 NPTF

Weight - 61 lb

Hydraulic Fluid - Enerpac Oil

Electric PumpPart No 82C-0EP

(for use with Minikrimp Karrykrimp and Karrykrimp 2) Heavy duty electric pump delivers 10000 psi

Length - 12-18

Width - 12-58

Height - 15

Port Size - 38 NPTF

Weight - 31 lb

Hydraulic Fluid - Enerpac Oil

115 volt 1 phase 60 hertz 9 amp

Electric PumpPart No 85C-0EP

(for use with Minikrimp Karrykrimp and Karrykrimp 2) Heavy duty electric pump delivers 10000 psi at a faster cycle

time

Length - 14-18

Width - 9-12

Height - 22-34Port Size - 38 NPTF

Weight - 54 lb

Hydraulic Fluid - Enerpac Oil

115 volt 1 phase 60 hertz 25 amp

(continued)CONTINUED

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 1326

C-13 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

Catalog 4400 US Parkrimp Crimping Equipment Power Units Enerpac Warrant Policy

Ai rHydraul ic PumpPart No 82C-0AP

(for use with Minikrimp Karrykrimp and Karrykrimp 2) Lightweight pump operates with 80-120 psi sho p air pressure and d elivers

10000 psi

Length - 14-34Width - 5-58

Height - 5-34

Weight - 14lb

Intake Port Size - 14 NPTF

Output Port Size - 38 NPTF

Hydraulic Fluid - Enerpac Oil

ENERPAC WARRANTY POLICY

For those ENERPAC items sold as part of the Parker HoseProducts offering the following warranty applies

ENERPAC products are warranted to be free of defects inmaterials and workmanship under normal use for as long as

they are owned by the original user for as long as they areowned by the original purchaser subject to the exclusions and

limitations described below This warranty does not cover

ordinary wear and tear overloading alterations (includingrepairs or attempted repairs by parties other than ENERPAC or

its authorized service representatives) improper fluid use in amanner for which they are not intended or use which is contrary

to instructions for the products

THIS WARRANTY IS LIMITED TO NEW PRODUCTS SOLD

THROUGH ENERPAC AUTHORIZED DISTRIBUTORSORIGINAL EQUIPMENT MANUFCTURERS OR OTHER

DESIGNATED CHANNELS OF DISTRIBUTION NO AGENTEMPLOYEE OR OTHER REPRESENTATIVE OF ENERPAC

HAS THE AUTHORITY TO IN ANY WAY CHANGE OR AMEND

THIS WARRANTY

Electronic products and components are warranted against defectsin material and workmanship for a period of two years from the

date of purchase

The following items supplied with ENERPAC products are excluded

from this warranty

bull Components not manufactured by ENERPAC including air

motors electric motors gasoline engines and diesel enginesSuch items are warranted to the extent of the warranty provided

by the manufacturers of such items

If the customer believes a product is defective the product must bedelivered or shipped freight prepaid to the nearest ENERPAC

Authorized Service Center The customer should contactENERPAC to locate an Authorized Service Center in thecustomerrsquos area Products that do not conform to this warranty

will be repaired or replaced at ENERPACrsquos expense andreturned by ground transportation freight prepaid

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU

OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRAN-TIES OF MERCHANTABILITY AND FITNESS FOR A PAR-

TICULAR PURPOSE

The remedy of repair replacement or refund is customerrsquos

exclusive remedy in the event of breach of this warranty

SELLER SHALL NOT BE SUBJECT TO AND DISCLAIMS

(a) ANY OTHER OBLIGATIONS OR LIABILITIES ARISING OUTOF BREACH OF CONTRACT OR OF WARRANTY

(b) ANY OBLIGATIONS WHATSOEVER ARISING FROM TORT

CLAIMS (INCLUDING NEGLIGENCE AND STRICT LIABILITY)OR ARISING UNDER THEORIES OF LAW WITH RESPECT

TO PRODUCTS SOLD OR SERVICES RENDERED BYSELLER OR ANY UNDERTAKINGS ACTS OR OMISSIONS

RELATING THERETO AND

(c) ALL CONSEQUENTIAL INCIDENTAL AND CONTINGENTDAMAGES WHATSOEVER

ENERPACrsquos liability in all cases is limited to and shall not exceed

the purchase price paid

For the nearest authorized ENERPAC SERVICE CENTER please

call ENERPAC at 8005580530 or visit the ENERPACWEBSITE wwwEnerpaccom

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 1426

C-14 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

C C r i m p i n g

E q u i p m e n t

A

B

D

E

G

A s s e m b l y

E q u i p m e n t

Catalog 4400 US Parkrimp Crimping Equipment Enerpac Warranty Policy Power Units

Vehicle Battery-Powered PumpPart No 85C-12V

(for use with Minikrimp Karrykrimp and Karrykrimp 2) Ideal unit for Parker Mobile Hose Replacement Service

Delivers 10000psi

Length - 9-12

Width - 11-12

Height - 19-12

Weight - 79lb

12 volt pump

Hydraulic Fluid

- ISO-32 (150 SUS) Less than 50deg F

- ISO-46 (215 SUS) Normal Conditions

- ISO-68 (315 SUS) Greater than 85deg F

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 1526

C-15 Hose Products DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

Catalog 4400 US

Parkrimp 1For use with 26 43 81 and HY Series Fittings

The Parkrimp 1 Model 80C-101 gives you everything youneed to crimp hoses from 14 to 1-14 in one convenientpackage It includes crimping machine electric pump dierings die sets for 14 38 12 34 and 1 hoses (Die setsfor 516 58 and 1-14 hoses are available)

All you need to be in business is a small inventory of ParkerNo-Skive hose and Parker Parkrimp No-Skive fittings

SpecificationsDimensions 26 (661mm) wide 19-12 (495mm) deep

24-14 (616mm) highWeight 275 lbs with power unitRating 30 tons force 3000 psi maximumCapability -1-14 SAE 100R1AT maximum

-1-14 DIN 20 022-1SN maximum

-1-14 SAE 100R2AT maximum-1-14 DIN 20 022-2SN maximum-1 SAE 100R3 maximum-1-14 SAE 100R4 maximum-78 SAE100R5 maximum-1 SAE 100R9AT maximum-1 SAE 100R16 maximum-1 SAE 100R16 maximum-1 SAE 100R17 maximum-78 SAEJ1402 AI maximum-78 SAEJ1402 AII maximum

Set up time 20 secondsFull cycle time 20 secondsHydraulic Fluid AW32

Note Cycle times vary depending on hose and fitting styles andsizes

Note DO NOT use this machine to assemble 341-20 451TC-20hose or any size stainless steel fitting

Standard EquipmentModel 80C-101 includes

Parkrimp 1 Crimper with 115230 volt 1 phase 60 hertz powerunit wired for 115V Note Must run on a dedicated 20 AMP circuitbull Die ring Cavity Color Coded Silver 80C-R01bull Die ring Cavity Color Coded Black 80C-R0243 Series Dies (Silver)

bull -4 (14) Cavity Color Coded Red 80C-A04bull -6 (38) Cavity Color Coded Yellow 80C-A06bull -8 (12) Cavity Color Coded Blue 80C-A08bull -12 (34) Cavity Color Coded Green 80C-A12bull -16 (1) Cavity Color Coded Black 80C-A16

Model 80C-061 includesbull Parkrimp 1 Crimper 80C-081bull Die ring Color Coded Silver 80C-R01bull Die ring Color Coded Black 80C-R02bull No Dies - Order seperately from list below

Model 80C-181 includesbull Parkrimp 1 Crimper 80C-080bull 115230 volt 1 phase 60 Hz power unitwired for 115V 80C-115bull No Die Ringsbull No Dies - Order seperately from list below

Optional Tooling26 Series Dies (Silver)

bull -4 (316) Cavity Color Coded Red 80C-E04bull -5 (14) Cavity Color Coded Purple 80C-E05bull -6 (516) Cavity Color Coded Yellow 80C-E06bull -8 (1332) Cavity Color Coded Blue 80C-E08bull -10 (12) Cavity Color Coded Orange 80C-E10bull -12 (58) Cavity Color Coded Green 80C-E12bull -16 (78) Cavity Color Coded Black 80C-E16

43 Series Dies (Silver)bull -4 (14) Cavity Color Coded Red 80C-A04bull -5 (516) Cavity Color Coded Purple 80C-A05bull -6 (38) Cavity Color Coded Yellow 80C-A06bull -8 (12) Cavity Color Coded Blue 80C-A08bull -10 (58) Cavity Color Coded Orange 80C-A10bull -12 (34) Cavity Color Coded Green 80C-A12bull -16 (1) Cavity Color Coded Black 80C-A16

bull -20 (1-14) Cavity Color Coded White 80C-A2081 Series Dies (Silver)

bull -12 (34rdquo) Cavity Color Coded Green 80C-V12bull -16 (1rdquo) Cavity Color Coded Black 80C-V16bull -20 (1-14rdquo) Cavity Color Coded White 80C-V20

HY Series Dies - AX Hose (Silver)bull -4 (14rdquo) Cavity Brown 80C-H585bull -6 (38rdquo) Cavity Brown 80C-H735bull -8 (12rdquo) Cavity Brown 80C-H840bull -10 (58rdquo) Cavity Brown 80C-H970bull -12 (34rdquo) Cavity Brown 80C-H1120

HY Series Dies - BXX Hose (Silver)bull -4 (14rdquo) Cavity Brown 80C-H605bull -6 (38rdquo) Cavity Brown 80C-H775bull -8 (12rdquo) Cavity Brown 80C-H885bull -10 (58rdquo) Cavity Brown 80C-H1010bull -12 (34rdquo) Cavity Brown 80C-H1170

Parkrimp Crimping Equipment Parkrimp 1

U S

P a t e n t N o

4

3 0 9 8

9 2

a n d

4 5

7 7 4

8 5

Note Hose assemblies must be inspected for cleanliness and free of all foreign particlesNote Parker Hannifin will not accept responsibility for the operation of or provide warranty coverage for a crimper that is operated by a power unit other than equipment supplied by Parker Hannif in forthe express purpose of operating the crimper

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 1626

C-16 Hose Products DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

C C r i m p i n g

E q u i p m e n t

A

B

D

E

F

G

A s s e m b l y

E q u i p m e n t

Catalog 4400 US Parkrimp Crimping Equipment PHastkrimp

PHastkrimpFor use with 26 43 70 71 73 78 81 and HYSeries FittingsOnly Parker offers a No-Skive system for crimping SAE100R12through 1middot14rdquo and SAE100R13 six spiral through 1rdquo inchPHastkrimp is the fastest cycling benchmounted crimper available

SpecificationsDimensions 22 wide 33 deep 37middot12 highWeight 550 lbsRating 60 tons 4200psiCapability - 1-14 SAE 100R1AT maximum

- 1 DIN 20 022-1SN maximum- 1-14 SAE 100R2AT maximum- 1-14 DIN 20 022-2SN maximum- 1 SAE 100R3 maximum- 1-14 SAE 100R4 maximum- 78 SAE100R5 maximum- 78 SAEJ1402 AI maximum- 78 SAEJ1402 AII maximum- 1-14 SAE 100R9AT maximum

- 1-14 SAE 100R12 maximum- 1rdquo SAE 100R13 maximum- 1 SAE 100R16 maximum- 1-14 SAE 100R17 maximum

Set up time 20 secondsFull cycle time 6 secondsNote Cycle times vary depending on hose and fitting styles and sizes

Hydraulic Oil AW32 oil

Standard EquipmentModel 89C-061 includes PHastkrimp crimper with 230VAC 3phase 60 Hz power unit wired for 230 volts (Can be rewired to460VAC by qualified electrician)

bull Die Ring Silver 85C-R01bull Die Ring Black 85C-R02

bull No Dies - Order seperately from list below

Model 89C-062 includes PHastkrimp crimper with 230VAC 1phase 60 Hz power unit wired for 230 volts

bull Die Ring Silver 85C-R01bull Die Ring Black 85C-R02bull No Dies - Order seperately from list below

Optional Tooling26 Series Dies (Silver)

bull -4 (316) Cavity Color Coded Red 80C-E04bull -5 (14) Cavity Color Coded Purple 80C-E05bull -6 (516) Cavity Color Coded Yellow 80C-E06bull -8 (1332) Cavity Color Coded Blue 80C-E08bull -10 (12) Cavity Color Coded Orange 80C-E10bull -12 (58) Cavity Color Coded Green 80C-E12bull -16 (78) Cavity Color Coded Black 80C-E16

43 Series Dies (Silver)bull -4 (14) Cavity Color Coded Red 80C-A04bull -5 (516) Cavity Color Coded Purple 80C-A05bull -6 (38) Cavity Color Coded Yellow 80C-A06bull -8 (12) Cavity Color Coded Blue 80C-A08bull -10 (58) Cavity Color Coded Orange 80C-A10bull -12 (34) Cavity Color Coded Green 80C-A12bull -16 (1) Cavity Color Coded Black 80C-A16bull -20 (1-14) Cavity Color Coded White 80C-A20

70 and 71 Series Dies (Black)bull -6 (38) Cavity Color Coded Yellow 83C-D06bull -8 (12) Cavity Color Coded Blue 83C-D08bull -10 (58) Cavity Color Coded Orange 83C-D10bull -12 (34) Cavity Color Coded Green 83C-D12bull -16 (1) Cavity Color Coded Black 83C-D16bull -20 (1-14) Cavity Color Coded White 83C-D20

73 and 78 Series Dies (Olive Drab)bull -12 (34) Cavity Color Coded Green 80C-L12bull -16 (1) Cavity Color Coded Black 80C-L16

81 Series Dies (Silver)bull -12 (34rdquo) Cavity Color Coded Green 80C-V12bull -16 (1rdquo) Cavity Color Coded Black 80C-V16bull -20 (1-14rdquo) Cavity Color Coded White 80C-V20

HY Series Dies - AX Hose (Silver)bull -4 (14rdquo) Cavity Brown 80C-H585bull -6 (38rdquo) Cavity Brown 80C-H735bull -8 (12rdquo) Cavity Brown 80C-H840bull -10 (58rdquo) Cavity Brown 80C-H970bull -12 (34rdquo) Cavity Brown 80C-H1120bull -16 (1rdquo) Cavity Brown 80C-H1365

HY Series Dies - BXX Hose (Silver)bull -4 (14rdquo) Cavity Brown 80C-H605bull -6 (38rdquo) Cavity Brown 80C-H775bull -8 (12rdquo) Cavity Brown 80C-H885bull -10 (58rdquo) Cavity Brown 80C-H1010bull -12 (34rdquo) Cavity Brown 80C-H1170bull -16 (1rdquo) Cavity Brown 80C-H1465

Note Hose assemblies must be inspected for cleanliness and free of all foreign particlesNote Parker Hannifin will not accept responsibility for the operation of or provide warranty coverage for a crimper that is operated by a power unit other than equipment supplied by Parker Hannifin forthe express purpose of operating the crimper

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 1726

C-17 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

Catalog 4400 US Parkrimp Crimping Equipment General Assembly Instructions

Karrykrimp Karrykrimp 2 Parkrimp 1 and PHastkrimp

General Assembly Instructions

Mark the hose insertion depth and push hose

into fitting until the mark on the hose is evenwith the end of the shell (lubricate hose if

necessary however do not lubricate any

spiral hose) Hose Insertion Depthtable is on page C-26

Pull pin at the top of pusher to swing it back NoteParkrimp 1 does not have a pin at the top of thepusher Place unitized die-train into base plate Seedecal on crimper for proper die set Position the hoseand fitting in dies from below Important The die bowl

for the Crimping Machines should be lubricated usinga premium quality lithium base grease

Color

CodedUnitized

Die-Train

Place correct die ring on top of the dies

See decal on crimper for proper die ringPosition pusher replace pin and operate

pump until the pump bottoms out Releasepressure within the pump mdash remove finished

assembly

Note Karrykrimp amp Karrykrimp 2 haveseveral types of pumps all of which are

separate units from the actual crimpingmachine

Note Parkrimp 1 does not have a pin atthe top of pusher

Measure crimp diameter on the flat surfaces

of the crimped shell referenced in the above

illustration Reference crimp diameter onpage C-26

Note Parker Hannifin will not accept

responsibility for the operation of or provide warranty coverage for a crimper

that is operated by a power unit other

than equipment supplied by Parker Hannifin for the express purpose of

operating the crimper

Important Hose assemblies must be

inspected for cleanliness and free of allforeign particles

PARKALIGNreg Feature

Parkrimp Series 26 Series 81 Series

Rest bottom of coupling on die step using PARKALIGNreg feature

Crimp

Diameter

26 SeriesStandard

Parkrimp Series

darr darr darr darr darr darr darr darr darr darr

darr darr darr darr darr

darrdarr darrdarr darr

NOTE See Technical Manual and Video suppli ed with each machine for specific operating i nstructions

darr darr darr darr darr darr darr darr darrdarr darr darrdarr darr darr darr darr darr darr darr

darr darr darr darr darr

Place 81 SeriesShell onto end of hose and makesure the end of theshell lines up withthe Insertion Depthmark See chart onpage C-26 for Insertion Depths

Push hose onto the88 Series fittinguntil the shell inStep 1a bottomsagainst the fittingrsquosstop ring or hexLubricate hose if necessary

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 1826

C-18 Hose Products DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

C C r i m p i n g

E q u i p m e n t

A

B

D

E

F

G

A s s e m b l y

E q u i p m e n t

Catalog 4400 US Parkrimp Crimping Equipment Parkrimp 2

U S

P a t e n t N o

4 5

2 7 4

1 4

a n d

4 5

7 7 4

8 5

Note 83C-A16H 83C-A20H 83C-D16H and 83C-D20H are used with jumpsize fittings and certain metric fittings to permit insertion and removal of fittings

Note The 83C-R02H Spacer Plate must be used when using the 83C-A16H83C-A24 83C-A20H or 83C-A32 to crimp SAE 100R2 and 100R4 hose

Standard EquipmentModel 83C-001 includes

Parkrimp 2 Crimper Head Assembly 83C-080bull Parkrimp 2 Stand Assembly with 230460 volt3 phase 5060 Hz power unit (wired for 230 volt) 83C-S40bull Adapter Bowl 83C-OCBbull Spacer Ring 83C-R02bull Die Kit 83C-KDA

Model 83C-081 includes bull Model 83C-001 less diesModel 83C-002 includes

bull Parkrimp 2 Crimper Head Assembly 83C-080bull Parkrimp 2 Stand Assembly with 230 Volt 1 Phase

60Hz power unit 83C-S20bull Adapter Bowl 83C-OCBbull Spacer Ring 83C-R02bull Die Kit 83C-KDA

Model 83C-082 includes bull Model 83C-002 less diesModel 83C-KDA (Die Kit) Includes 43 Series -4 -6 -8 -12 -16 and -20dies and 7071 Series -6 -8 -12 -16 -20 -24 and -32 dies ONLY

Optional Toolingbull Spacer Plate 83C-R02H

26 Series Dies (Silver)bull -4 (316) Cavity Color Coded Red 80C-E04bull -5 (14) Cavity Color Coded Purple 80C-E05bull -6 (516) Cavity Color Coded Yellow 80C-E06bull -8 (1332) Cavity Color Coded Blue 80C-E08bull -10 (12) Cavity Color Coded Orange 80C-E10bull -12 (58) Cavity Color Coded Green 80C-E12bull -16 (78) Cavity Color Coded Black 80C-E16bull -20 (1-18) Cavity Color Coded White 83C-E20bull -24 (1-38) Cavity Color Coded Red 83C-E24bull -32 (1-1316) Cavity Color Coded Green 83C-E32

43 Series Dies (Silver)bull -4 (14) Cavity Color Coded Red 80C-A04bull -5 (516) Cavity Color Coded Purple 80C-A05bull -6 (38) Cavity Color Coded Yellow 80C-A06bull -8 (12) Cavity Color Coded Blue 80C-A08bull -10 (58) Cavity Color Coded Orange 80C-A10bull -12 (34) Cavity Color Coded Green 80C-A12bull -16 (1) Cavity Color Coded Black 80C-A16bull -16 (1) Cavity Color Coded Black 83C-A16Hbull -20 (1-14) Cavity Color Coded White 80C-A20bull -20 (1-14) Cavity Color Coded White 83C-A20Hbull -24 (1-12) Cavity Color Coded Red 83C-A24

bull -32 (2) Cavity Color Coded Green 83C-A3270 and 71 Series Dies (Black)

bull -6 (38) Cavity Color Coded Yellow 83C-D06bull -8 (12) Cavity Color Coded Blue 83C-D08bull -10 (58) Cavity Color Coded Orange 83C-D10bull -12 (34) Cavity Color Coded Green 83C-D12bull -16 (1) Cavity Color Coded Black 83C-D16bull -16 (1) Cavity Color Coded Black 83C-D16Hbull -20 (1-14) Cavity Color Coded White 83C-D20bull -20 (1-14) Cavity Color Coded White 83C-D20Hbull -24 (1-12) Cavity Color Coded Red 83C-D24bull -32 (2) Cavity Color Coded Green 83C-D32

73 and 78 Series Dies (Olive Drab)bull -12 (34) Cavity Color Coded Green 83C-L12bull -16 (1) Cavity Color Coded Black 83C-L16bull -20 (1-14) Cavity Color Coded White 83C-L20bull -24 (1-12) Cavity Color Coded Red 83C-L24bull -32 (2) Cavity Color Coded Green 83C-L32

79 Series Dies (Olive Drab)bull -12 (34) Cavity Color Coded Green 83C-L12bull -16 (1) Cavity Color Coded Black 83C-L16bull -20 (1-14) Cavity Color Coded White 83C-L20

81 Series Dies (Silver)bull -12 Cavity Color Coded 80C-V12bull -16 Cavity Color Coded 80C-V16bull -20 Cavity Color Coded 80C-V20bull -24 Cavity Color Coded 83C-V24bull -32 Cavity Color Coded 83C-V32

Note For HY Series Die information reference Phastkrimp CrimpingEquipment page

Parkrimp 2For use with 26 43 70 71 73 78 79 81 and

HY Series Fittings

Only Parker offers a No-Skive system for SAE100R13 spiral hose up to 2 indiameter and SAE100R15 spiral hose up to 1middot14 in diameter

SpecificationsDimensions 28 wide 22 deep 70 highWeight Head-558 lbs Base-284 lbs Total-843 lbsRating 125 tons force 5000 psi maximumCapability - 2 SAE 100R1AT maximum

- 2 SAE 100R2AT maximum- 1 SAE 100R3 maximum- 2 SAE 100R4 maximum- 1middot1316 SAE100R5 maximum- 1middot1316 SAEJ1402 AI maximum- 1middot1316 SAEJ1402 AII maximum- 1middot14 SAE 100R9AT maximum- 2 SAE 100R12 maximum- 2 SAE 100R13 maximum

- 1middot14 SAE100R15 maximum- 1 SAE 100R16 maximum- 1middot14 SAE100R17 maximum- All stainless steel fittings

Set up time 30 secondsFul l cycle t ime 30 seconds without adapter bowl

20 seconds with adapter bowl

Note Cycle times vary depending on hose and fitting styles andsizes

Hydraulic Oil Enerpac Oil

Note Hose assemblies must be inspected for cleanliness and free of all foreign particlesNote Parker Hannifin will not accept responsibility for the operation of or provide warrantycoverage for a crimper that is operated by a power unit other than equipment supplied byParker Hannifin for the express purpose of operating the crimper

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 1926

C-19 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

Catalog 4400 US

Note See page C-26 for Parkrimp crimp diametersNote Hose assemblies must be inspected for cleanliness and free of all foreign particles

Note Parker Hannifin will not accept responsibility for the operation of or provide warranty coverage for a crimper that is operated by a

power unit other than equipment supplied by Parker Hannifin for the express purpose of operating the crimper

Parkrimp Crimping Equipment Parkrimp 2 Assembly Instructions

Parkrimp 2 Assembly InstructionsCrimping Instructions when the Adapter Bowl IS required

7 Insert the front half of the

split die ring aligning the

pin in the back half withthe hole in the front half

3 Lubricate Die Bowl using a

premium quality lithium basegrease Carefully insert the

adapter bowl 83C-OCB into the

base bowl The adapter bowl mustbe tilted toward the back of the

crimper during insertion See decalon side of crimper for proper tool

selection

6 Lower the back half of the

split die ring onto the dies

by pulling the slide pinforward

8bRest bottom of coupling on die step using

PARKALIGNreg feature Once positioned

go to Step 7 on page C-20

2 With the pusher in the full up position lift

the back half of the split die ring Lock it inthe up position by pushing the slide pin in

(The slide pin is located inside the pusher

at the back)

5 If required place spacer ring on locating

step of adapter bowl Reference hosedieselection chart on pages C-3 mdashC-7 for usage

8aPosition hose in dies

from below

SlidePin

PARKALIGNreg FEATURE

1 Mark the hose insertion depth and push

hose into fitting until the mark on the hoseis even with the end of the shell (DO NOT

use any lubricant to assemble spiral

hose and fittings) Hose Insertion Depthtable is on page C-26

Color

Coded

UnitizedDie-Train

SlidePin

4 Lubricate Die Bowl using a premium

quality lithium base grease Place unitizeddie-train into the adapter bowl See decal

on crimper for proper die setNote Die sets have color coded cavities

indicating size and have the fitting seriesand dash size stamped on the top

Note Select correct dies and die ringbased on size See Parkrimp Tool

Selection Chart on pages C-3 mdashC-7

1aPlace 81 Series

Shell onto end of hose and make

sure the end of the

shell lines up withthe Insertion Depth

mark See charton page C-26 for

Insertion Depths

1bPush hose onto

the 88 Seriesfitting until the

shell in Step 1a

bottoms againstthe fittingrsquos stop

ring or hexLubricate hose if

necessary

NOTE See Technical Manual and Video suppli ed with each machine for specific operating i nstructions

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 2026

C-20 Hose Products DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

C C r i m p i n g

E q u i p m e n t

A

B

D

E

F

G

A s s e m b l y

E q u i p m e n t

Catalog 4400 US

Parkrimp 2 Assembly InstructionsCrimping instructions when the Adapter Bowl IS NOT required

2 With the pusher in the full upposition lift the back half of thesplit die ring Lock it in the upposition by pushing the slidepin in (The slide pin is insidethe pusher at the back) Pullpin at the top of pusher to

swing it back Lubricate DieBowl using a premium qualitylithium base grease

3aInsert the proper size andseries die set into the die bowl(The die sets are in two halvesof four dies each Place onehalf in the back and one half inthe front to facilitate removal ofbent tube fittings) Referencehosedie selection chart onpages C-3mdashC-7 or decal oncrimp cover for proper toolselection

Parkrimp Crimping Equipment Parkrimp 2 Assembly Instructions

SlidePin

Pusher

SpacerPlate

3b If required place spacer plate

around dies Reference hose die selection charts on pagesC-3mdashC-7

4 Lower the back half of the split

die ring onto the dies by pullingthe slide pin forward

5 Insert the front half of the split

die ring aligning the pins in theback half with the hole in thefront half

6 Position hose in dies frombelow

6bRest bottom of coupling on diestep using PARKALIGN reg

feature

Note See page C-26 for Parkrimp crimp diametersNote Hose assemblies must be inspected for cleanliness and free of all foreign particlesNote Parker Hannifin will not accept responsibility for the operation of or provide warranty coverage for a crimper that is operated by apower unit other than equipment supplied by Parker Hannifin for the express purpose of operating the crimper

PARKALIGN reg FEATURE

1 Mark the hose insertion depthand push hose into fitting untilthe mark on the hose is evenwith the end of the shell (DONOT use any lubricant toassemble spiral hose andfittings) Hose Insertion Depthtable is on page C-26

SlidePin

7 Turn on the pump by depress-ing the ldquoONrdquo switch Pull thevalve handle forward to bringthe pusher down for crimping

When the split die ringcontacts the base plate thecrimp is complete Push thevalve handle back to lift thepusher open the dies andrelease the finished assembly

8 You do not have to remove any tooling to remove or insert straightfittings The front half of the split die ring and the front die train mustbe removed to insert and remove bent tube fittings

1aPlace 81 Series Shell onto endof hose and make sure the endof the shell lines up with theInsertion Depth mark Seechart on page C-26 forInsertion Depths

1bPush hose onto the 88 Seriesfitting until the shell in Step 1abottoms against the fittingrsquosstop ring or hex Lubricatehose if necessary

NOTE See Technical Manual and Video supplied with each machine for specific operating instructions

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 2126

C-21 Hose Products DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

Catalog 4400 US Parkrimp Crimping Equipment Hydraulic Press Kit

US Patent No 4577485 Standard EquipmentModel 8PC-001 includes

Bowl Assembly 8PC-030bull Pusher 8PC-00Pbull Silver Die Ring 81C-R01bull Black Die Ring 81C-R0243 Series Dies (Silver)

bull -4 (14) Cavity Color Coded Red 80C-A04bull -6 (38) Cavity Color Coded Yellow 80C-A06bull -8 (12) Cavity Color Coded Blue 80C-A08bull -12 (34) Cavity Color Coded Green 80C-A12bull -16 (1) Cavity Color Coded Black 80C-A16

Optional Tooling26 Series Dies (Silver)

bull -4 (316) Cavity Color Coded Red 80C-E04bull -5 (14) Cavity Color Coded Purple 80C-E05bull -6 (516) Cavity Color Coded Yellow 80C-E06bull -8 (1332) Cavity Color Coded Blue 80C-E08bull -10 (12) Cavity Color Coded Orange 80C-E10bull -12 (58) Cavity Color Coded Green 80C-E12bull -16 (78) Cavity Color Coded Black 80C-E16

43 Series Dies (Silver)

bull -5 (516) Cavity Color Coded Purple 80C-A05bull -10 (58) Cavity Color Coded Orange 80C-A10bull -20 (1-14) Cavity Color Coded White 80C-A20

81 Series Dies (Silver)bull -12 (34rdquo) Cavity Color Coded Green 80C-V12bull -16 (1rdquo) Cavity Color Coded Black 80C-V16bull -20 (1-14rdquo) Cavity Color Coded White 80C-V20

HY Series Dies - AX Hose (Silver)bull -4 (14rdquo) Cavity Brown 80C-H585bull -6 (38rdquo) Cavity Brown 80C-H735bull -8 (12rdquo) Cavity Brown 80C-H840bull -10 (58rdquo) Cavity Brown 80C-H970bull -12 (34rdquo) Cavity Brown 80C-H1120

HY Series Dies - BXX Hose (Silver)bull -4 (14rdquo) Cavity Brown 80C-H605bull -6 (38rdquo) Cavity Brown 80C-H775bull -8 (12rdquo) Cavity Brown 80C-H885

bull -10 (58rdquo) Cavity Brown 80C-H1010bull -12 (34rdquo) Cavity Brown 80C-H1170

Note For Hydraulic Press Kit operating instructions for see page C-22mdashC-23 or Hose Products Division Bulletin 4480-B11

Hydraulic Press KitFor use with 26 43 81 and HY SeriesFittings ONLY

Now you can convert your hydraulic press to utilize ParkerParkrimp No-Skive thru the cover fittings Crimping iseasy using the Parkrimp 8PC-001 Conversion Kit

SpecificationsRequired Height Press Base to Press Ram 10 InchesRequired Width Bowl Diameter 5 InchesBowl Rating 30 Tons Force MaximumCapability - 1-14 SAE 100R1AT maximum

- 1-14 SAE 100R2AT maximum- 1 SAE 100R3 maximum- 1-14 SAE 100R4 maximum- 78 SAE100R5 maximum- 1 SAE 100R16 maximum- 1 SAE 100R17 maximum

- 78 SAEJ1402 AI maximum- 78 SAEJ1402 AII maximum

Set Up Time 30 Seconds

Minimum Required Press CapacityHose Size Press Size-4 -5 -6 -8 20 Ton Press-10 -12 -16 -20 30 Ton Press

Note Hose assemblies must be inspected for cleanliness and free of all foreign particlesNote Parker Hannifin will not accept responsibility for the operation of or provide warranty coverage for a crimper that is operated by a power unit other than equipment supplied by ParkerHannifin for the express purpose of operating the crimper

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 2226

C-22 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

C C r i m p i n g

E q u i p m e n t

A

B

D

E

G

A s s e m b l y

E q u i p m e n t

Catalog 4400 US Parkrimp Crimping Equipment Hydraulic Press Kit Assembly Instructions

3 Lubricate Die Bowl using a premium quality lithium basegrease Place unitized die-train into base plate See decal

on crimper for proper die setNote Die sets have color coded cavities indicating size and

have the dash size stamped on the top Reference page

C-3 mdashC-7 for proper die set

Parkrimp Hydraulic Press Kit Assembly Instructions for 43 81 and HY

Series Fittings

2 Position the die bowl

assembly on the press

using two supports if necessary Leave a

space between thesupports for insertion

of the hose and fitting

from the bottom

4 Place die ring on top of

the dies with the flat

side up In selectingthe proper die ring see

decal on die bowl

5 Center the pusher on

the die ring andposition under the

cylinder of the press

7 Activate the press tocrimp fitting to hose

When die ring contacts

bowl crimp is com-plete

6 Rest bottom of coupling on die

step using PARKALIGNreg

feature

8 Deactivate the pressand remove the

finished assembly You

do not have to removedies for straight fittings

Die ring must beremoved for most bent

tube fittings Checkcrimp diameter (see

page C-26)

Note A 20 ton press will crimp 26 Series and 43 Series fittings

through -8 (12rdquo) For larger sizes of 43 81 and HY Series fittings a

30 ton press is required

PARKALIGNreg FEATURE

1 Mark the hose insertion depthand push hose into fitting until

the mark on the hose is evenwith the end of the shell

(lubricate hose if necessary)Hose Insertion Depth table is

on page C-26

Color Coded

Unitized

Die-Train

Note Hose assemblies must be inspected for cleanliness and free of all foreign particles

Note Parker Hannifin will not accept responsibility for the operation of or provide warranty coverage for a crimper that is operated by a power unit other than equipment supplied by Parker

Hannifin for the express purpose of operating the crimper

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 2326

C-23 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

Catalog 4400 US

Parkrimp Hydraulic Press Kit Assembly Instructions for 26 Series Fittings

1 Place the hose next to

the fitting shell andmark the length of the

shell on to the hose

Push hose into thefitting until the mark on

the hose is even withthe end of the shell

7aDeactivate the press

and remove thefinished assembly

Check crimp diameter of the flat surface of the

grooves closest to shellend (see illustration)

7bCheck crimp diameter

of the flat surface of the grooves at location

shown in aboveillustration See chart

on page C-26 for crimpdiameters

3 Lubricate Die Bowl using a premium quality lithium base

grease Place unitized die-train into base plate See decalon crimper for proper die set

Note Die sets have color coded cavities indicating size and

have the dash size stamped on the top

2 Position the die bowl

assembly on the pressusing two supports if

necessary Leave aspace between the

supports for insertionof the hose and fitting

from the bottom

4 Place die ring on top of

the dies with the flatside up In selecting the

proper die ring seedecal on die bowl

5aCenter the pusher on

the die ring andposition under the

cylinder of the press

6 Activate the press tocrimp fitting to hose

When die ring contacts

bowl crimp iscomplete

Note A 20 ton press will crimp 26 Series fittings through -8 (1332rdquo)For larger sizes a 30 ton press is required

Color

Coded

UnitizedDie-Train

5bRest bottom of coupling on diestep using PARKALIGNreg

feature

PARKALIGNreg FEATURE

Hydraulic Press Kit and Conversion

Kits Tool Selection for 26 Series Fittings

Hydraulic Press Kit

213 285 amp 293 Hose Silver Die Ring - 81C-R01

SS23CG 201261 206 225 244

amp 266 Hose Black Die Ring - 81C-R02

Weatherhead amp Gates Conversion Kits

213 285 amp 293 Hose Silver Die Ring - 81C-R01

201261 206 225 235 amp 266 Hose Black Die Ring - 81C-R02

Parkrimp Crimping Equipment Air-Con Hydraulic Press Kit Assembly Instructions

Note Hose assemblies must be inspected for cleanliness and free of all foreign particles

Note Parker Hannifin will not accept responsibility for the operation of or provide warranty coverage for a crimper that is operated by a power unit other than equipment supplied by Parker

Hannifin for the express purpose of operating the crimper

Crimp

Diameter

26 Series

darr darr darr darr darr

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 2426

C-24 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

C C r i m p i n g

E q u i p m e n t

A

B

D

E

G

A s s e m b l y

E q u i p m e n t

Catalog 4400 US

Weatherhead Conversion KitFor use with 26 43 and HY Series Fitt ings

ONLY

Now you can convert Weatherhead T-400 Crimpers to utilize

Parker Parkrimp No-Skive thru-the-cover fittings Crimpin g i s

easy and quick using Parkrimp 8WC-001 Conversion Kit

Standard EquipmentModel 8WC-001 for T-400 machines i ncludes

bull Bowl Assembly 8PC-030bull Pusher 8WC-00Pbull Silver Die Ring 81C-R01bull Black Die Ring 81C-R02

43 Series Dies (Silver)bull -4 (14) Cavity Color Coded Red 80C-A04bull -6 (38) Cavity Color Coded Yellow 80C-A06bull -8 (12) Cavity Color Coded Blue 80C-A08bull -12 (34) Cavity Color Coded Green 80C-A12

Optional Tooling

43 Series Dies (Silver)bull -5 (516) Cavity Color Coded Purple 80C-A05bull -10 (58) Cavity Color Coded Orange 80C-A10

26 Series Dies (Silver)bull -4 (316) Cavity Color Coded Red 80C-E04bull -5 (14) Cavity Color Coded Purple 80C-E05bull -6 (516) Cavity Color Coded Yellow 80C-E06bull -8 (1332) Cavity Color Coded Blue 80C-E08bull -10 (12) Cavity Color Coded Orange 80C-E10bull -12 (58) Cavity Color Coded Green 80C-E12

HY Series Dies - AX Hose (Silver)bull -4 (14rdquo) Cavity Brown 80C-H585

bull -6 (38rdquo) Cavity Brown 80C-H735bull -8 (12rdquo) Cavity Brown 80C-H840

bull -10 (58rdquo) Cavity Brown 80C-H970bull -12 (34rdquo) Cavity Brown 80C-H1120

HY Series Dies - BXX Hose (Silver)

bull -4 (14rdquo) Cavity Brown 80C-H605bull -6 (38rdquo) Cavity Brown 80C-H775bull -8 (12rdquo) Cavity Brown 80C-H885bull -10 (58rdquo) Cavity Brown 80C-H1010bull -12 (34rdquo) Cavity Brown 80C-H1170

US Patent No 4577485

Parkrimp Crimping Equipment Weatherhead Conversion Kit

Note For additional information and operating instructions reference Hose Products Division Bulletin 4480-B10

Note For crimping information see pages C-22 mdash C-23

Note Hose assemblies must be inspected for cleanliness and free of all foreign particles

Note Parker Hannifin will not accept responsibility for the operation of or provide warranty coverage for a crimper that is operated by a

power unit other than equipment supplied by Parker Hannifin for the express purpose of operating the crimper

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 2526

C-25 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

Catalog 4400 US Parkrimp Crimping Equipment Gates Conversion Kit

Gates Conversion KitFor use with 26 43 81 and HY Series Fitt ings

ONLY

Now you c an convert the Gates 701 703 and 707 bottom

loading cri mp machines to crimp Parkrimp 43 Series No-Skive

thru-the-cover fittings Crimping is easy and quick usin g theParkrimp 8GC-002 conversion kit

Standard EquipmentModel 8GC-002 includes

bull Bowl Assembly 8PC-030bull Silver Die Ring 81C-R01bull Black Die Ring 81C-R02

43 Series Dies (Silver)bull -4 (14) Cavity Color Coded Red 80C-A04bull -6 (38) Cavity Color Coded Yellow 80C-A06bull -8 (12) Cavity Color Coded Blue 80C-A08bull -12 (34) Cavity Color Coded Green 80C-A12bull -16 (1) Cavity Color Coded Black 80C-A16

Optional Tooling26 Series Dies (Silver)

bull -4 (316) Cavity Color Coded Red 80C-E04bull -5 (14) Cavity Color Coded Purple 80C-E05bull -6 (516) Cavity Color Coded Yellow 80C-E06bull -8 (1332) Cavity Color Coded Blue 80C-E08bull -10 (12) Cavity Color Coded Orange 80C-E10bull -12 (58) Cavity Color Coded Green 80C-E12bull -16 (78) Cavity Color Coded Black 80C-E16

43 Series Dies (Silver)bull -5 (516) Cavity Color Coded Purple 80C-A05bull -10 (58) Cavity Color Coded Orange 80C-A10bull -20 (1-14) Cavity Color Coded White 80C-A20

HY Series Dies - AX Hose (Silver)bull -4 (14rdquo) Cavity Brown 80C-H585bull -6 (38rdquo) Cavity Brown 80C-H735bull -8 (12rdquo) Cavity Brown 80C-H840bull -10 (58rdquo) Cavity Brown 80C-H970bull -12 (34rdquo) Cavity Brown 80C-H1120

HY Series Dies - BXX Hose (Silver)bull -4 (14rdquo) Cavity Brown 80C-H605bull -6 (38rdquo) Cavity Brown 80C-H775bull -8 (12rdquo) Cavity Brown 80C-H885bull -10 (58rdquo) Cavity Brown 80C-H1010bull -12 (34rdquo) Cavity Brown 80C-H1170

81 Series Dies (Silver)bull -12 (34rdquo) Cavity Color Coded Green 80C-V12bull -16 (1rdquo) Cavity Color Coded Black 80C-V16bull -20 (1-14rdquo) Cavity Color Coded White 80C-V20

Note For additional information and operating instructions reference Hose Products Division Bulletin 4480-B8

Note For crimping information see pages pages C-22 mdash C-23

Note Hose assemblies must be inspected for cleanliness and free of all foreign particles

Note Parker Hannifin will not accept responsibility for the operation of or provide warranty coverage for a crimper that is operated by a

power unit other than equipment supplied by Parker Hannifin for the express purpose of operating the crimper

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 2626

C C r i m p i n g

E q u i p m e n t

A

B

D

E

G

A s s e m b l y

E q u i p m e n t

Catalog 4400 US Parkrimp Crimping Equipment Crimp Diameters and Hose Insertion Depths

Crimp Diameters

Hose Insertion Depths

If you have questions concerning the Parkrimp Hose Assembly Instructions Products or Ap plication of Products co ntained in

this catalog please call

Parker Hose Products Division - Technical Services Department for Equipment

Phone 440943-5700

FAX 440946-0843

wwwparkerhosecom

Note When making up hose assemblies with your Parkrimp system it is a good quality practice to follow these steps

1 Be sure the hose has been fully inserted into the fitting Use of the Hose Insertion Depth Gauges for correct

marking The hose insertion depth measurements are listed in the above table

2 Next after crimping check for the proper crimp diameter This means check the crimp diameter of the 1st50th and last hose assembly of each type and size produced Proper crimp diameters are listed in the above table

and are located on wwwparkerhosecomgt TechnologiesgtCrimpSource 991522 Should you find crimp diameters out of

tolerance inspect each assembly made Never use hose assembl ies w i th an incor rec t c r imp

d iameter Use the appropriate Parkrimp Machine Trouble-Shooting Guide to determine the cause of a problem

inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm inch mm

-4 1316 21 1316 21 - - - - - - - - - - 1-716 37

-5 1316 21 1516 24 - - - - - - - - - - - -

-6 1316 21 1-18 29 1-116 27 1-116 27 - - - - - - - - 1-12 40

-8 1316 21 1-516 33 1-516 33 1-14 32 - - - - - - - - 1-916 40-10 78 22 1-916 40 1-38 35 1-516 33 - - 1-78 47 - - - - 1-916 40

-12 78 22 1-12 38 1-12 38 1-716 37 1-78 48 1-78 48 2-316 56 1-18 29 1-58 40

-16 1 25 1-34 44 1-1316 46 1-34 44 2 51 2 51 2-516 59 1-14 32 1-34 43

-20 1 25 1-78 48 1-34 44 1-1316 46 2-12 64 2-12 64 2-1316 71 1-516 33 - -

-24 1-116 27 1-716 37 - - 2-516 59 2-716 62 2-716 62 - - 1-516 33 - -

-32 1-14 32 1-1316 46 - - 2-716 62 2-1316 71 2-78 73 - - 1-1116 43 - -

HY

Fitting SeriesFitting

Size 26 43 70 71 73 78 79 81

Crimp diameters for stainless steel fittings are 0010 larger than standard steel fittings

Crimp diameters for HY Series stainless steel fittings are 0005 larger than standad steel fittings

Note Reference pages C-3mdash C-7 for Die Die Ring Spacer Plate and Spacer Ring Selection Chart

Note Crimp diameters for Parker Hose Products Parflex and Industrial Hose products are located in CrimpSource a dynamic website

resource located at wwwparkerhosecom

Fittings

Series26 Series 26 Series 43 Series 43 Series 70 Series 71 Series 73 Series 78 Series 79 Series 81 Series

Size Hose213 221FR225 285 amp

293

201261 206

235 244

266 amp

SS23CG

351TC 351ST

421 424 426

431 436451TC 451ST

471TC 471ST

472TC 482TC

amp 482ST

301 301LT

304 381341 421WC

601 604 amp

881

701721 721TC

772TC

772ST amp 774

CN 731781 78C782TC amp

782ST

791TC792TC amp

792ST

881 amp 811 AX BXX

-4 0460 0480 0500 0520 0645 0665 0685 0705 - - - - - - 0575 0595 0635 0655

-5 0520 0540 0560 0580 0710 0730 0750 0770 - - - - - - - -

-6 0575 0595 0615 0635 0825 0845 0865 0885 0990 1010 0950 0970 - - - - 0725 0745 0805 0825

-8 0670 0690 0710 0730 0945 0965 0985 1005 1140 1160 1100 1120 - - - - 0830 0850 0915 0935

-10 0805 0825 0845 0865 1060 1080 1100 1120 1260 1280 1220 1240 - 1390 1410 - - 0960 0980 1040 1060

-12 0915 0935 0955 0975 1245 1265 1285 1305 1395 1415 1355 1375 1420 1440 1420 1440 1420 1440 1155 1175 1110 1130 1200 1220

-16 1175 1195 1215 1235 1590 1610 1630 1650 1735 1755 1695 1715 1730 1750 1730 1750 1730 1750 1450 1470 1355 1375 1495 1515

- 20 1420 1440 1460 1480 1970 1990 2010 2030 - 2025 2045 2140 2160 2140 2160 2140 2160 1740 1760 - -

-24 1670 1690 1710 1730 2290 2310 2330 2350 - 2290 2310 2440 2460 2440 2460 - 2010 2030 - -

-32 2160 2180 2200 2220 2735 2755 2775 2795 - 2775 2795 3025 3045 3025 3045 - 2430 2450 - -

CRIMP DIAMETERS

HY Series

7232019 Par Krimp

httpslidepdfcomreaderfullpar-krimp 226

C-2 Hose Product s DivisionParker Hannifin Corporation

Wickliffe Ohiowwwparkerhosecom

C C r i m p i n g

E q u i p m e n t

A

B

D

E

G

A s s e m b l y

E q u i p m e n t

Catalog 4400 US

Visual Index

Karrykrimp 2 C-11

Assembly InstructionsC-17Minikrimp Karrykrimp amp

Karrykrimp 2 Pumps C-12

Minikrimp Karryrkimp amp

Karrykrimp 2 Pumps C-13-14

Parkrimp 1 C-15

Assembly Instructions C-17

PHastkrimp C-16

Assembly InstructionsC-17

Parkrimp 2 C-18

Assembly InstructionsC-19-20

Hydraulic Press Kit C-21-23 Weatherhead Conversion

Kit C-24

Gates Conversion Kit C-25

Parkrimp Tool Selection

Chart C-3-7

Crimp Diameters and Hose

Insertion Depths C-26

Minikrimp C-8

Assembly InstructionsC-9

Karrykrimp C-10

Assembly InstructionsC-17