Pandrol Double Resilient Baseplate Datasheet

-

Upload

kerri-murray -

Category

Documents

-

view

269 -

download

7

description

Transcript of Pandrol Double Resilient Baseplate Datasheet

PRODUCT INFORMATIONPANDROL DOUBLE RESILIENTBASEPLATE ASSEMBLY

T R A C K S Y S T E M S

PAN_11_014_Resilient baseplate Datasheet _Layout 1 11/02/2013 15:23 Page 2

PRODUCT INFORMATION

The PANDROL DOUBLE RESILIENT BASEPLATEASSEMBLY is typically suited for installation in ballastlessslab tracks and areas where a reduction in groundborne noise and vibration is required. The system suitseither top down or bottom up construction techniques.

The Pandrol e-Clip baseplate is mounted on a studdednatural rubber pad that provides the resilience whichcan be tuned within limits for axle loads and stiffnessrequirements. There is no need to grease or re-tightenthe fastening elements as the rail fastening elementsare non-threaded to provide low maintenance. As withall Pandrol fastenings, the Pandrol resilient baseplatesystem is backed by many years of worldwideexperience, and an unmatched depth of technicalunderstanding from Pandrol’s technical engineers.

CONSTRUCTION OF ASSEMBLY

Studded EVARail Pad

Cast Iron Baseplate

Nylon Sidepost Insulators Pandrol Brand ‘e’ Clip

Studded RubberBaseplate Pad

Fully complies with EN 13481-5

PAN_11_014_Resilient baseplate Datasheet _Layout 1 11/02/2013 15:23 Page 3

PANDROL DOUBLE RESILIENT BASEPLATE ASSEMBLY

FEATURES OF ASSEMBLYAdjustability

Typical lateral adjustment of ±3mm can be

achieved using an eccentric bush, in 1mm

locked steps (additional lateral adjustment can

be provided against specific requirements).

Typical vertical adjustment of up to 20mm can

be achieved using shims.

Maintenance

All resilient parts and wear components are

fully replaceable in-situ. The system has two

independent levels of electrical insulation and

uses Pandrol threadless fastening technology,

providing low maintenance throughout the life

of the system.

Experience

The system has been in use since the mid

1980s and is installed on MRT and LRT

systems in major cities such as Hong Kong,

Singapore, Sao Paulo, Dubai and Istanbul.

It is also installed on main line slab

applications and steel bridges on axle

loads up to 22.5 tonnes.

Installation

PANDROL RESILIENT BASEPLATE

ASSEMBLIES can be installed using either top

down or bottom up construction methods.

Testing

All Pandrol fastenings are tested against

standards published by the Comité Européen

de Normalisation (CEN).

PAN_11_014_Resilient baseplate Datasheet _Layout 1 11/02/2013 15:23 Page 4

Suitable for all track up to 25 tonne axle loads.

Normally for use on concrete, non-ballasted

tracks. May also be used on concrete sleepers.

Intended for applications where a degree of

vibration attenuation is required.

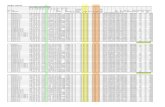

Application data (standard products – special variants may be supplied for other applications)

Rail inclination Suitable for all rail inclinations.

Clip type Pandrol Brand ‘e’ Clip.

Typical applications At grade, bridges, tunnels and viaducts for metro/LRT and mainline slab tracks.

Typical rail sections 60E1 (UIC60); 56E1 (BS113A); 54E1 (UIC54); BS.80A; AREMA 115RE, S49.

Vertical adjustment Up to 20mm.

Lateral adjustment Typically ±3mm – additional lateral adjustment can be provided against specific requirements

through consultation with Pandrol.

No. of anchors 2 or 4 dependent on track conditions.

Type of anchors Through-bolts (splade or stud type depending on construction method).

Typical performance data

Static stiffness Typically 22.5 kN/mm secant stiffness between 0 and 50 kN on assembly (stiffness can bereduced to 15 kN/mm or increased to >200 kN/mm through consultation with Pandrol).

Mitigation for noise Applicable. Resilient pad is located above and below the baseplate.and vibration after Stiffness can be reduced to ~15kN/mm or increased to >200kN/mm by substitutioninstallation of rail pad and/or baseplate pad.

Electrical resistance >20 kOhms (EN 13146-5:2002) – Two levels of insulation and long leakage pathsuitable for traction return currents in DC systems.

TECHNICAL SPECIFICATION

PANDROL DOUBLE RESILIENT BASEPLATE ASSEMBLY

Pandrol Rail Fastenings Ltd., 63 Station Road, Addlestone, Surrey KT15 2AR England.

Telephone: +44 1932 834500 Telefax: +44 1932 850858

E-mail: [email protected]: http://www.pandrol.com

Note: PANDROL is an innovator and designer of bespoke rail fastenings. The data shown above is indicative of typical performance,

but is naturally dependent on external factors. Should you have different requirements, please contact us to discuss tailoring products

to suit local operating conditions.

The technical information given in this brochure was correct at the time of printing, but the company undertakes a continuing programme

of research and development, and improvements may since have been introduced.

Issue 1January 2012

PAN_11_014_Resilient baseplate Datasheet _Layout 1 11/02/2013 15:23 Page 1