Overview Waffle Slab 1. Quiz - 1 2 Two Way Joist Slab 3.

-

Upload

preston-eade -

Category

Documents

-

view

276 -

download

6

Transcript of Overview Waffle Slab 1. Quiz - 1 2 Two Way Joist Slab 3.

1

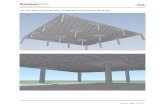

Overview Waffle Slab

2

Quiz - 1

3

Two Way Joist Slab

4

Two-Way Joist Introduction

5

Two-Way Joist Introduction

• A two-way joist system, or waffle slab, comprises

evenly spaced concrete joists spanning in both

directions and a reinforced concrete slab cast

integrally with the joists.

Joist

6

Two-Way Joist

• The joists are commonly formed by using standard

square “dome” forms and the domes are omitted

around the columns to form the solid heads.

Solid Head

7

Two-Way Joist

• Like one-way joist system, a two way system will be

called as two-way joist system if clear spacing between

ribs (dome width) does not exceed 30 inches.

8

Two-Way JoistIntroduction

• Standard Dome Data

• Generally the dome for waffle slab can be of any size.

However the commonly used standard domes are discussed as

follows:

• 30-inch × 30-inch square domes with 3-inch flanges; from which 6-

inch wide joist ribs at 36-inch centers are formed: these

are available in standard depths of 8, 10, 12, 14, 16 and 20 inches.

• 19-inch × 19-inch square domes with 2 ½-inch flanges, from which 5-

inch wide joist ribs at 24-inch centers are formed. These are

available in standard depths of 8, 10, 12, 14 and 16 inches.

9

Two-Way Joist • Standard Dome Data

10

Two-Way Joist

Characteristics

• Dome voids reduce dead load.

• Attractive ceiling (waffle like appearance).

• Electrical fixtures can be placed in the voids.

• Particularly advantageous where the use of longer spans and/or heavier loads are desired without the use of deepened drop panels or supported beams.

Behavior

• The behavior of two-way joist slab is similar to a two way flat Slab

system.

12

Two-Way Joist Sizes

• For Joist depth determination, waffle slabs are considered as flat

slab (ACI 13.1.3, 13.1.4 & 9.5.3).

• The thickness of equivalent flat slab is taken from table 9.5 (c).

• The thickness of slab and depth of rib of waffle slab can

be then computed by equalizing the moment of inertia of

equivalent flat slab to that of waffle slab.

• However since this practice is time consuming, tables

have been developed to determine the size of waffle slab from

equivalent flat slab thickness.

• Minimum Joist Depth

13

Two-Way Joist Sizes

• Minimum Joist Depth

• Equivalent Flat Slab Thickness

ACI 318-05 – Sect. 9.5.3• Minimum thickness = ln/33

14

Two-Way Joist Sizes

• Minimum Joist Depth

• Slab and rib depth from equivalent flat slab thickness

15

Two-Way Joist Sizes

• Minimum Joist Depth

• Slab and rib depth from equivalent flat slab thickness

16

Two-Way Joist Sizes

• ACI 8.11.2 states that ribs shall be not less than 4 inches in width.

• Maximum Depth of Rib

• ACI 8.11.2 also states that ribs shall have a depth of not more than 3½

times the minimum width of rib.

• Minimum Slab Thickness

• ACI 8.11.6.1 states that slab thickness shall be not less than one-

twelfth the clear distance between ribs, nor less than 2 inch.

• Minimum Width of Rib

17

Two-Way Joist Sizes

• Solid Head

• Dimension of solid head on either side of column centerline is

equal to l/6.

• The depth of the solid head is equal to the depth of the

combined depth of ribs and top slab.

18

Two-Way Joist Load

• Solid Head

• Floor dead load for two-way joist with certain dome size, dome

depth can be calculated from the table shown for two options of

slab thicknesses (3 inches and 4 ½ inches).

19

Two-Way Joist Load

• Solid Head

20

Two-Way Joist Load

• Floor dead load (wdj) for two-way joist can

also be calculated as follows:

Volume of solid:Vsolid = (36 36 11)/1728 = 8.24 ft3

Volume of void:Vvoid = (30 30 8)/1728 = 4.166 ft3

Total Load of joists per dome:wdj = (Vsolid – Vvoid) γconc

= ( 8.24 – 4.166) 0.15 = 0.61 kips/ dome

Total Load of joists per sq. ft:

wdj/ (dome area) = 0.61/ (3 3) = 0.0679 ksf

= 68 psf ≈ 71 psf (from table 03)

The difference is because sloped ribs are not considered.

21

Two-Way Joist Load

• Taking a panel out of the system:

22

Two-Way Joist Load

• If the complete area l1 × l2 is assumed to occupy

joists alone, then the dead load in the area l1 × l2 will be wdj.

• However since there are solid head regions

present, therefore additional dead load due to solid head

region shall be:

• Wdsh = hsolid x γconc - wdj

23

Two-Way Joist Load

• ACI code allows use of DDM for analysis of waffle slabs

(ACI R13.1). In such a case, waffle slabs are

considered as flat slabs, with the solid head acting as drop

panels (ACI 13.1.3).

24

Two-Way Joist Design

• Design of slab for punching shear.

• The solid head shall be checked against punching shear.

• The critical section for punching shear is taken at a section d/2

from face of the column, where d is the effective depth at solid

head.

25

Two-Way Joist Design

d/2

l2

l1

• Design of slab for

punching shear.

• Load on tributary area will

cause punch out shear.

• Within tributary area, two

types of loads are acting:

• Solid head load

• Joist load

• Both types shall be considered

while calculating punching

shear demand.

26

Two-Way Joist Design

l2

l1

• Design of slab for

punching shear.

• Total area (At) = l1 l2

• Solid head area = Asolid

• Critical perimeter area = Acp

• Vu =At wuj + Asolid (wish − wuj)

• Where,

wuj = Factored load considering

joist alone

wsh = Factored solid head dead

load

27

Two-Way Joist Design

• Design of slab for punching shear.

• ΦVn = ΦVc + ΦVs

• ΦVc is least of:

• Φ4√ (fc′)bod

• (2 + 4/βc) √ (fc′)bod

• {(αsd/bo +2} √ (fc′)bod

βc = longer side of column/shorter side of column

αs = 40 for interior column, 30 for edge column, 20 for corner columns

28

Two-Way Joist Design

• Design of Joist for Beam Shear:

• Beam Shear Demand

• Beam shear is not usually a problem in slabs including waffle

slabs. However for completion of design beam shear

may also be checked. Beam shear can cause problem in

case where larger spans and heavier loads with relatively

shallow waffle slabs are used.

• The critical section for beam shear is taken at a section d from

face of the column, where d is the effective depth at solid head.

29

Two-Way Joist Design

• Design of Joist for Beam Shear:• Beam shear capacity of concrete joist:

• ΦVn = ΦVc + ΦVs

• ΦVc is least of:

• Φ2√ (fc′)bribd

• ΦVs = ΦAvfy/bribs

• For joist construction, contribution of concrete to shear strength Vc shall

be permitted to be 10 percent more than that specified in Chapter 11.

• If required, one or two single legged stirrups are provided in the rib to

increase the shear capacity of waffle slab.

30

Two-Way Joist ACI Recommendations on Reinforcement Requirement of Waffle Slab:

• Recommendations for Ribs:

• ACI 10.6.7 states that if the effective depth d of a beam or

joist exceeds 36 inches, longitudinal skin reinforcement shall be

provided as per ACI section 10.6.7.

• Recommendations for Slab:

• According to ACI 13.3.2, for cellular or ribbed construction

reinforcement shall not be less than the requirements of ACI 7.12.

• As per ACI 7.12, Spacing of top bars cannot exceed 5h or 18

inches.

31

Two-Way Joist Other Important Points:

• The amount of reinforcement and, if necessary, the top slab

thickness can be changed to vary the load capacities for

different spans, areas, or floors of a structure.

• Each joist rib contains two bottom bars. Straight bars are

supplied over the column centerlines for negative factored

moment.

32

Two-Way Joist Other Important Points:

• For layouts that do not meet the standard 2-feet and 3-feet

modules, it is preferable that the required additional width be

obtained by increasing the width of the ribs framing into the

solid column head.

33

Two-Way Joist Other Important Points:

• The designer should sketch out the spacing for a typical panel

and correlate with the column spacing as a part of the

early planning.

34

Moment Coefficient Method

35

Two-Way Slab

Moment Coefficient Method (Introduction)

• The Moment Coefficient Method included for the first time

in 1963 ACI Code is applicable to two-way slabs supported

on four sides of each slab panel by walls, steel beams

relatively deep, stiff, edge beams (h = 3hf).

• Although, not included in 1977 and later versions of ACI code,

its continued use is permissible under the ACI 318-08 code

provision (13.5.1).

![Comparative Study between Waffle and Solid Slab Systems … · solid slab system extend further than just achieving a more lighter and economical slab [7-10]. By investigating the](https://static.fdocuments.us/doc/165x107/5b4528917f8b9a202f8b80b7/comparative-study-between-waffle-and-solid-slab-systems-solid-slab-system-extend.jpg)