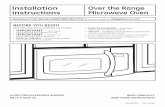

OVER THE RANGE MICROWAVE OVEN SERVICE MANUAL

Transcript of OVER THE RANGE MICROWAVE OVEN SERVICE MANUAL

! ATTENTION !This service manual is intended for use by persons having electrical and mechanical training and a level of knowledge of these subjects generally considered acceptable in the appliance repair trade. Electrolux Home Products cannot be responsible, nor assume any liability, for injury or damage of any kind arising from the use of this manual.

OVER THE RANGE MICROWAVE OVENSERVICE MANUAL

Models FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

CFMV157GSCFMV157GBCFMV157GMCFMV157GQCFMV157GC

Part # 316439269Publication # 5995528261 November 2008

Page 2

CONTENTS

TABLE OF CONTENTSPage

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TOAVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY................................................................. 3BEFORE SERVICING.................................................................................................................................................. 3WARNING TO SERVICE PERSONNEL....................................................................................................................... 4MICROWAVE MEASUREMENT PROCEDURE........................................................................................................... 5FOREWORD AND WARNING ..................................................................................................................................... 6 PRODUCT SPECIFICATIONS ..................................................................................................................................... 7GENERAL INFORMATION........................................................................................................................................... 7OPERATION............................................................................................................................................................... 10TROUBLESHOOTING GUIDE .................................................................................................................................. 14TEST PROCEDURE .................................................................................................................................................. 16TOUCH CONTROL PANEL ASSEMBLY..................................................................................................................... 26COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE....................................................................... 30SCHEMATIC DIAGRAM............................................................................................................................................. 38WIRING DIAGRAM .................................................................................................................................................... 39EXPLODED PARTS DIAGRAM.................................................................................................................................. 40PACKING AND ACCESSORIES ................................................................................................................................ 44

Page 32

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO AVOID POSSIBLE EXPO-SURE TO EXCESSIVE MICROWAVE ENERGY(a) Do not operate or allow the oven to be operated with the door open.(b) Make the following safety checks on all ovens to be serviced before activating the magnetron or other

microwave source, and make repairs as necessary: (1) interlock operation, (2) proper door closing, (3) seal and sealing surfaces (arcing, wear, and other damage), (4) damage to or loosening of hinges and latches, (5) evidence of dropping or abuse.

(c) Before turning on microwave power for any service test or inspection within the microwave generating compartments, check the magnetron, wave guide or transmission line, and cavity for proper alignment, integrity, and connections.

(d) Any defective or misadjusted components in the interlock, monitor, door seal, and microwave genera-tion and transmission systems shall be repaired, replaced, or adjusted by procedures described in this manual before the oven is released to the owner.

(e) A microwave leakage check to verify compliance with the Federal Performance Standard should be performed on each oven prior to release to the owner.

(RD8100U)

BEFORE SERVICINGBefore servicing an operative unit, perform a microwave emission check as per the Microwave Measurement Procedure outlined in this service manual.If microwave emissions level is in excess of the specified limit, contact ELECTROLUX HOME PRODUCTS, INC. immediately.

If the unit operates with the door open, service person should 1) tell the user not to operate the oven and 2) contact ELECTROLUX HOME PRODUCTS, INC. and Food and Drug Administration's Center for Devices and Radiological Health immediately.

Service personnel should inform ELECTROLUX HOME PRODUCTS, INC. of any certified unit found with emissions in excess of 4mW/cm2. The owner of the unit should be instructed not to use the unit until the oven has been brought into compliance.

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 4

3

WARNING TO SERVICE PERSONNELMicrowave ovens contain circuitry capable of pro-ducing very high voltage and current, contact with following parts may result in a severe, possibly fatal, electrical shock.(Example)High Voltage Capacitor, High Voltage Power Transformer, Magnetron, High Voltage Rectifier Assembly, High Voltage Harness etc..Read the Service Manual carefully and follow all instructions.

Before Servicing

1. Disconnect the power supply cord , and then remove outer case.

2. Open the door and block it open.3. Discharge high voltage capacitor.

WARNING:RISK OF ELECTRIC SHOCK. DISCHARGE THE HIGH-VOLTAGE CAPACITOR BEFORE SERVICING.

The high-voltage capacitor remains charged about 60 seconds after the oven has been switched off. Wait for 60 seconds and then short-circuit the connection of the high-voltage capacitor (that is the connecting lead of the high-voltage rectifier) against the chassis with the use of an insulated screwdriver.

Whenever troubleshooting is performed the power supply must be disconnected. It may, in some cases, be necessary to connect the power supply after the outer case has been removed, in this event,1. Disconnect the power supply cord, and then remove

outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. Disconnect the leads to the primary of the power

transformer.5. Ensure that these leads remain isolated from other

components and oven chassis by using insulation tape.

6. After that procedure, reconnect the power supply cord.

When the testing is completed,1. Disconnect the power supply cord, and then remove

outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. Reconnect the leads to the primary of the power

transformer.5. Reinstall the outer case (cabinet).6. Reconnect the power supply cord after the outer case

is installed.7. Run the oven and check all functions.

After repairing1. Reconnect all leads removed from components during

testing.2. Reinstall the outer case (cabinet).3. Reconnect the power supply cord after the outer case

is installed.4. Run the oven and check all functions.

Microwave ovens should not be run empty. To test for the presence of microwave energy within a cavity, place a cup of cold water on the oven turntable, close the door and set the power to HIGH and set the microwave timer for two (2) minutes. When the two minutes has elapsed (timer at zero) carefully check that the water is now hot. If the water remains cold carry out Before Servicing procedure and re-examine the connections to the component being tested.

When all service work is completed and the oven is fully assembled, the microwave power output should be checked and microwave leakage test should be carried out.

Don't Touch !Danger High Voltage

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 54

MICROWAVE MEASUREMENT PROCEDURE

A. Requirements:

1) Microwave leakage limit (Power density limit): The power density of microwave radiation emitted by a microwave oven should not exceed 1mW/cm2 at any point 5cm or more from the external surface of the oven, measured prior to acquisition by a purchaser, and thereafter (through the useful life of the oven), 5 mW/cm2 at any point 5cm or more from the external surface of the oven.

2) Safety interlock switches: Primary interlock switch shall prevent microwave radiation emission in excess of the requirement as above mentioned, secondary interlock relay and door sensing switch shall prevent microwave radiation emission in excess of 5 mW/cm2 at any point 5cm or more from the external surface of the oven.

B. Preparation for testing:Before beginning the actual measurement of leakage, proceed as follows:1) Make sure that the actual instrument is operating normally as specified in its instruction booklet.

Important:Survey instruments that comply with the requirement for instrumentation as prescribed by the performance standard for microwave ovens, 21 CFR 1030.10(c)(3)(i), must be used for testing.

2) Place the oven tray in the oven cavity.3) Place the load of 275±15 ml (9.8 oz) of tap water initially at 20±5½C (68½F) in the center of the oven cavity.

The water container shall be a low form of 600 ml (20 oz) beaker with an inside diameter of approx. 8.5 cm (3-1/2 in.) and made of an electrically nonconductive material such as glass or plastic.The placing of this standard load in the oven is important not only to protect the oven, but also to insure that any leakage is measured accurately.

4) Set the cooking control on Full Power Cooking Mode 5) Close the door and select a cook cycle of several minutes. If the water begins to boil before the survey is completed,

replace it with 275 ml of cool water.

C. Leakage test:

Closed-door leakage test (microwave measurement)1) Grasp the probe of the survey instrument and hold it perpendicular to the gap between the door and the body of the

oven.2) Move the probe slowly, not faster than 1 in./sec. (2.5 cm/sec.) along the gap, watching for the maximum indication on

the meter.3) Check for leakage at the door screen, sheet metal seams and other accessible positions where the continuity of the

metal has been breached (eg., around the switches, indicator, and vents).While testing for leakage around the door pull the door away from the front of the oven as far as is permitted by the closed latch assembly.

4) Measure carefully at the point of highest leakage and make sure that the highest leakage is no greater than 4mW/cm2,and that the primary interlock switch does turn the oven OFF before any door movement.

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 65

PRODUCT DESCRIPTION

GENERAL INFORMATION

OPERATION

TROUBLESHOOTING GUIDE AND TEST PROCEDURE

TOUCH CONTROL PANEL

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

WIRING DIAGRAM

PARTS LIST

ELECTROLUX HOME PRODUCTS, INC.

SERVICE MANUAL

ELECTROLUX

OVER THE RANGEMICROWAVE OVEN

FMV156DBE / FMV156DSEFMV156DQE / FMV156DCF

FOREWORD

This Manual has been prepared to provide Electrolux Home Prod-uctsService Personnel with Operation and Service Information for the ELECTROLUX OVER THE RANGE MICROWAVE OVENS, FM-V156DBE, FMV156DSE, FMV156DQE, FMV156DCF.

It is recommended that service personnel carefully study the entire text of this manual so that they will be qualified to render satisfactory customer service.

Check the interlock switches and the door seal carefully. Special attention should be given to avoid electrical shock and microwave radiation hazard.

WARNINGNever operate the oven until the following points are ensured.(A) The door is tightly closed.(B) The door brackets and hinges are not defective.(C) The door packing is not damaged.(D) The door is not deformed or warped.(E) There is not any other visible damage with the oven.

Servicing and repair work must be carried out only by trained service personnel.

DANGERCertain initial parts are intentionally not grounded and present a risk of electrical shock only during servicing. Service personnel - Do not contact the following parts while the ap-pliance is energized; High Voltage Capacitor, Power Transformer, Magnetron, High Voltage Rectifier Assembly, High Voltage Harness; If provided, Vent Hood, Fan assembly, Cooling Fan Motor.

All the parts marked “ * ” on parts list are used at voltages more than 250V.

Removal of the outer wrap gives access to voltage above 250V.

All the parts marked “ ∆ ” on parts list may cause undue mi-crowave exposure, by themselves, or when they are damaged,

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 7

6

ITEM DESCRIPTIONPower Requirements 20 Volts / 15 Amperes

60 HertzSingle phase, 3 wire grounded

Power Output 1000 watts (IEC TEST PROCEDURE)Operating frequency of 2450MHz

Case Dimensions Width 29-7/8"Height 16-13/32Depth 15-1/32"

Cooking Cavity Dimensions Width 20-/4"Height 9-/4"

Depth 14-13/32"

Hood lamp 2 bulbs, 30W x 2, Incandescent light bulbs

Hood fan Approx. 300 C.F. (High mode)

Control Complement Touch Control SystemClock ( :00 - 2:59 )Timer (0 - 99 min. 99 seconds)

Microwave Power for Variable Cooking

Repetition Rate;P-HI .................................................. Full power throughout the cooking timeP-90..................................................................... approx. 90% of Full PowerP-80..................................................................... approx. 80% of Full PowerP-70..................................................................... approx. 70% of Full PowerP-60..................................................................... approx. 60% of Full PowerP-50..................................................................... approx. 50% of Full PowerP-40..................................................................... approx. 40% of Full PowerP-30 .................................................................... approx. 30% of Full PowerP-20..................................................................... approx. 20% of Full PowerP-0..................................................................... approx. 0% of Full PowerP-0..................................................... No power throughout the cooking time

Popcorn pad, Reheat pad, Cook pad, Defrost pad, Number selection pads Power Level pad, Timer / Clock pad Light button, Fan button,Clear/Off button, START/ Plus Min button,

Oven Cavity Light 30W x Incandescent light bulb

Safety Standard UL Listed FCC Authorized

DHHS Rules, CFR, Title 2, Chapter , Subchapter J

Weight Approx. 63.9lbs.

PRODUCT SPECIFICATION

GENERAL INFORMATION

GROUNDING INSTRUCTIONS

This oven is equipped with a three prong grounding plug. It must be plugged into a wall receptacle that is properly installed and grounded in accordance with the National Electrical Code and local codes and ordinances.In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric current.WARNING: Improper use of the grounding plug can result in a risk of electric shock.

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

.5 Cubic Feet

Page 8

7

OVEN DIAGRAM

3-Pronged Plug

GroundedReceptacle Box

Grounding Pin

3-Pronged Receptacle

10

11

12

8

7

14

6

9

3

4

5

1

9

13

2

Electrical RequirementsThe oven is equipped with a 3-prong grounding plug. DO NOT UNDER ANY CIRCUMSTANCES CUT OR REMOVE THE GROUNDING PIN FROM THE PLUG.The power supply cord and plug must be connected to a separate 120 Volt AC, 60 Hz, 15 Amp. or more dedicated line, using a grounded receptacle. The receptacle should be located inside the cabinet directly above the Microwave Oven/Hood system mounting location.

1. Oven door with see-through window.2. Door hinges.3. Waveguide cover.4. Turntable motor shaft.5. Oven lamp.

It will light when oven is operating or door is open.

6. Door latches.The oven will not operate unless the door is securely closed.

7. Auto Touch control panel8. Time display: Digital display, 99 minutes 99

seconds.9. Ventilation openings.

10.Light Cover.11.Grease filters.12.Removable turntable.

The turntable will rotate clockwise or counterclockwise.Only remove for cleaning.

13.Removable turntable support.14. Power supply cord

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 109

OPERATION

DESCRIPTION OF OPERATING SEQUENCE

The following is a description of component functions dur-ing oven operation.

OFF CONDITIONClosing the door activates the door sensing switch and secondary interlock switch. (In this condition, the monitor switch contacts are opened.)When oven is plugged in, 120 volts A.C. is supplied to the control unit. (Figure O-1).

1. The display will show "WELCOME, PRESS CLEAR AND PRESS CLOCK".To set any program or set the clock, you must first touch the STOP/CLEAR pad. The display will clear, and " : " will appear .

COOKING CONDITIONProgram desired cooking time touching the NUMBER pads. When the START pad is touched, the following operations occur:

1. The contacts of relays are closed and components connected to the relays are turned on as follows.(For details, refer to Figure O-2)

RELAY CONNECTED COMPONENTS

RY1 Oven lamp / Fan motor

RY2 Power transformer

RY3 Cooktop lampRY4/5 Hood fan motor

2. 120 volts A.C. is supplied to the primary winding of the power transformer and is converted to about 3.3 volts A.C. output on the filament winding, and approximately 2200 volts A.C. on the high voltage winding.

3. The filament winding voltage heats the magnetron filament and the H.V. winding voltage is sent to a voltage doubler circuit.

4. The microwave energy produced by the magnetron is channelled through the waveguide into the cavity feed-box, and then into the cavity where the food is placed to be cooked.

5. Upon completion of the cooking time, the power transformer, oven lamp, etc. are turned off, and the generation of microwave energy is stopped. The oven will revert to the OFF condition.

6. When the door is opened during a cook cycle, monitor switch, door sensing switch, primary interlock switch, and secondary interlock relay are activated with the following results. The circuits to the stirrer motor, the cooling fan motor, the turntable motor, and the high voltage components are de-energized, and the digital read-out displays the time still remaining in the cook cycle when the door was opened.

7. The monitor switch is electrically monitoring the

of the primary interlock switch, and door sensing switch is mechanically associated with the door so that it will function in the following sequence.(1) When the door opens from a closed position, the

secondary interlock relay, door sensing switch, and primary interlock switch open their contacts, and then the monitor switch contacts close.

(2) When the door is closed from the open position, the monitor switch contacts open first. Then the contacts of the primary interlock switch and door sensing switch close. And contacts of the relay (RY1) open.

If the primary interlock switch and secondary interlock relay (RY2) fail with the contacts closed when the door is opened, the closing of the monitor switch contacts will form a short circuit through the monitor fuse, primary interlock switch, relay (RY1) and secondary interlock relay (RY2), causing the monitor fuse to blow.

POWER LEVEL P-0 TO P-90 COOKINGWhen Variable Cooking Power is programmed, the 120volts A.C. is supplied to the power transformer intermittently through the contacts of relay (RY2) which is operated by the control unit within an interval second time base. Microwave power operation is as follows:

VARI-MODE ON TIME OFF TIME

Power 10(P-HI) 29 sec. 0 sec.(100% power)

Power 9(P-90) 26 sec. 3 sec.(approx. 90% power)

Power 8(P-80) 23 sec. 6 sec.(approx. 80% power)Power 7(P-70) 20 sec. 9 sec.(approx. 70% power)

Power 6(P-60) 17 sec. 12 sec.(approx. 60% power)

Power 5(P-50) 14 sec. 15 sec.(approx. 50% power)

Power 4(P-40) 11 sec. 18 sec.(approx. 40% power)

Power 3(P-30) 8 sec. 21 sec.(approx. 30% power)

Power 2(P-20) 5 sec. 24 sec.(approx. 20% power)

Power 1(P-10) 3 sec. 26 sec.(approx. 10% power)

Note: The ON/OFF time ratio does not correspond with the percentage of microwave power, because approx. 2 seconds are needed for heating of the magnetron

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 11 10

VENTILATION METHODS HOT AIR EXHAUST1. VERTICAL VENTING

For this venting method, hot air rising from the conventional range below is drawn in by the hood fan motor through the grease filters at the right and left sides of the base cover, up through the right and left sides of the oven cavity, then discharged vertically at rear center top of the oven, into the customer's vent system.

2. HORIZONTAL VENTINGThe air handing is the same as VERTICAL VENTING except that the final air discharge is directed horizontally out from the top rear of the oven into the customer's vent system.

3. RE-CIRCULATION (INSIDE VENTING)The air handing is the same as VERTICAL VENTING except that the final air discharge is directed horizontally through the upper front of the oven into the kitchen. IN this case, the accessory charcoal filter RK-240 must be provided to filter the air before it leaves the oven.

To DuctTo Duct

GreaseFilter

HoodIntakeDuct R

Hood Fan Motor

GreaseFilter

To Duct

HoodIntakeDuct R

Hood Fan Motor

HoodIntakeDuct R

Hood Exhaust Louver

Hood Fan Motor

CharcoalFilter

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 1211

SCHEMATICNOTE: CONDITION OF OVEN1. DOOR CLOSED.2. COOKING TIME PROGRAMMED.3. VARIABLE COOKING CONTROL

"HIGH".

Figure O-2. Oven Schematic-Cooking Condition

Figure O-1. Oven Schematic-Off Condition

SCHEMATICNOTE: CONDITION OF OVEN1. DOOR CLOSED.2. CLOCK APPEARS ON DISPLAY.

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 1312

DESCRIPTION AND FUNCTION OF COMPONENTS

vapors given off from the heating foods. It is then exhausted through the exhausting air vents at the oven cavity.

HOOD FAN MOTORThe hood fan motor is a two-speeds, single-phase, double pole induction type, requiring a hood fan capacitor. It is located outside the upper rear part of the oven cavity, is to remove, from around the oven, hot air rising from the conventional electric or gas range over which it is installed. This air is then expelled either vertically or horizontally through the customer supplied duct system, or discharged back into the kitchen.

HOOD LAMPThe hood lamps are mounted at the hood lamp angle on the base cover. The hood lamps can be turned off and on

Latch hook

Primary interlock switch

Latch heads

Monitor switch

Door sensing switch

Door

DOOR OPEN MECHANISMThe door is opened by pulling the door handle, refer to the Figure D-1.

CAUTION: BEFORE REPLACING A BLOWN MONITOR FUSE TEST THE DOOR SENSING SWITCH, SECONDARY INTERLOCK RELAY (RY2), RE-LAY (RY1), PRIMARY INTERLOCK SWITCH AND MONITOR SWITCH FOR PROPER OPERATION. (REFER TO CHAPTER "TEST PROCEDURE").

NOTE: MONITOR FUSE AND MONITOR SWITCH ARE REPLACED AS AN ASSEMBLY.

THERMAL CUT-OUT (HOOD )This thermal cut-out located on the right base plate. It is designed to automatically turn on the hood fan motor whenever the hot air rising from the conventional range below causes the temperature at the thermal cut-out to rise to158OF (70OC) or higher, thus removing this hot air from around microwave oven. When the temperature around the thermal cut-out drops to 104OF (40OC) or lower, the thermal cut-out shuts off the hood fan motor.

THERMAL CUT-OUT (CAVITY )This thermal cut-out is located on the top of the oven cavity. It is designed to prevent damage to the oven unit if the food in the oven catches fire due to overheating produced by improper setting of cooking time or failure of control unit.Under normal operation, the thermal cut-out remains closed. However, the thermal cut-out will open at 230OF (110OC)causing the oven to shut down.

TURNTABLE MOTORThe turntable motor rotates the turntable located on the bottom of the oven cavity, so that the foods on the turnta-ble cook evenly during cooking. Turntable will turn in either

COOLING FAN MOTORThe cooling fan motor drives a blade which draws external cool air. This cool air is directed through the air vanes sur-rounding the magnetron and cools the magnetron. This air is channelled through the oven cavity to remove steam and

Figure D-1. Door Open Mechanism

DOOR SENSING SWITCH, PRIMARY INTERLOCK SWITCHThe primary interlock switch is mounted in the upper positionof the latch hook, the door sensing switch in the primary interlock system is mounted in the lower position of the latch hook is mounted on upper position of the latch hook. They are activated by the latch heads on the door. When the door is opened, the switches interrupt the circuit to all components. A cook cycle cannot take place until the door is firmly closed thereby activating both interlock switches. The primary interlock system consists of the door sensing switch and secondary interlock relay located on the control circuit board.

MONITOR SWITCHThe monitor switch is activated (the contacts opened) by the latch head on the door while the door is closed. The switch is intended to render the oven inoperative, by means of blowing the monitor fuse, when the contacts of the second-ary interlock relay (RY2) and primary interlock switch fail to open when the door is opened.

Functions:1. When the door is opened, the monitor switch contact

close (to the ON condition) due to their being normally closed. At this time the secondary interlock relay (RY2), primary interlock switch are in the OFF condition (contacts open) due to their being normally open contact switches. And the contacts of relay (RY1) are in the ON condition (contacts close).

2. As the door goes to a closed position, the monitor switch contacts are first opened and then the door sensing switch and the primary interlock switch contacts close. (On opening the door, each of these switches operate inversely.)

3. If the door is opened, and the secondary interlock relay (RY2) and primary interlock switch contacts fail to open, the monitor fuse blows simultaneously with closing of the

direction.

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 1413

TROUBLESHOOTING GUIDE

Never touch any part in the circuit with your hand or an uninsulated tool while the power supply is con-nected.

When troubleshooting the microwave oven, it is helpful to follow the Sequence of Operation in performing the checks. Many of the possible causes of trouble will require that a specific test be performed. These tests are given a procedure letter which will be found in the "Test Procedure "section.

IMPORTANT: If the oven becomes inoperative because of a blown monitor fuse, check the monitor switch, relay (RY1)secondary interlock relay (RY2), door sensing switch and primary interlock switch before replacing the moni-tor fuse. If the monitor fuse is replaced, the monitor switch must also be replaced. Use part FFS-BA016/KITas an assembly.

IMPORTANT: Whenever troubleshooting is performed with the power supply cord disconnected. It may in, some cases, be necessary to connect the power supply cord after the outer case has been removed, in this event,1. Disconnect the power supply cord, and then remove outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. Disconnect the leads to the primary of the power transformer.5. Ensure that the leads remain isolated from other components and oven chassis by using insulation

tape.6. After that procedure, reconnect the power supply cord.

When the testing is completed1. Disconnect the power supply cord, and then remove outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. Reconnect the leads to the primary of the power transformer.5. Reinstall the outer case (cabinet).6. Reconnect the power supply cord after the outer case is installed.

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 1514

CK = Check / RE = Replace

POSSIBLE CASE ANDDEFECTIVE PARTS

PR

OB

LEM

TES

TP

RO

CE

DU

RE

CO

ND

ITIO

N

OF

FC

ON

DIT

ION

IDLE

CO

ND

ITIO

N

MIC

RO

WAV

EC

OO

KIN

GC

ON

DIT

ION

Hom

efu

sebl

ows

whe

npo

wer

cord

ispl

ugge

din

tow

all r

ecep

tacl

e.M

onito

rfu

sebl

ows

whe

npo

wer

cord

ispl

ugge

din

tow

all r

ecep

tacl

e.D

ispl

aydo

esno

till

umin

ate

whe

npo

wer

cord

isfir

stpl

ugge

din

tow

all

rece

ptac

le.

Dis

play

does

not

oper

ate

prop

erly

whe

nS

TO

P/C

LEA

Rke

yis

touc

hed.

(The

time

ofda

ysh

ould

appe

aron

the

disp

lay

with

beep

soun

ddu

ring

norm

alco

nditi

on.)

Ove

nla

mp

does

not l

ight

with

door

isop

ened

.H

ood

fan

mot

orop

erat

esw

hen

pow

erco

rdis

first

plug

ged

into

wal

lre

cept

acle

.T

empe

ratu

reof

oven

base

seem

sm

ore

than

140û

F(6

0ûC

)be

caus

eof

oper

atio

nof

the

rang

ebe

low

.B

utho

odfa

nm

otor

does

not

turn

onau

tom

atic

ally

.(N

orm

ally

,fo

odfa

nm

otor

shou

ldbe

oper

atin

gat

low

spee

d.)

Hoo

dlig

hts

dono

ttu

rnon

whe

nW

OR

KLI

GH

Tpa

dor

NIG

HT

LIG

HT

pad

ispr

esse

d.H

ood

fan

mot

ordo

esno

t rot

ate

atal

l with

touc

hed

FA

NH

I/LO

pad.

Spe

edof

the

hood

fan

mot

ordo

esno

tch

ange

whe

nth

eF

AN

HI/L

Opa

dis

touc

hed

for

this

func

tion.

Ove

nla

mp

does

not

light

inco

okcy

cle.

(But

itdo

eslig

htw

hen

door

isop

ened

.)F

anm

otor

does

not o

pera

te. (

Ove

nla

mp

and

turn

tabl

em

otor

oper

ate.

)T

urnt

able

mot

ordo

esno

top

erat

e(O

ven

lam

plig

hts

and

fan

mot

orop

erat

e.)

Ove

ndo

esno

t go

into

cook

cycl

ew

hen

ST

AR

Tpa

dis

touc

hed

Ove

nse

ems

tobe

oper

atin

gbu

tlit

tleor

nohe

atis

prod

uced

inov

enlo

ad.

(Foo

din

com

plet

ely

cook

edor

not c

ooke

dat

all a

t end

ofco

okcy

cle.

)O

ven

goes

into

aco

okcy

cle

but

extr

emel

yun

even

heat

ing

ispr

oduc

edin

oven

load

(foo

d).

Var

iabl

eco

okin

gdo

esno

top

erat

epr

oper

lyex

cept

Coo

king

Pow

er10

(P-

HI)

mod

e.F

unct

ion

ofC

OM

PU

DE

FR

OS

Tdo

esno

t ope

rate

prop

erly

.S

tirre

rm

otor

does

not o

pera

te. (

Oth

erpa

rts

oper

ate.

)O

ven

goes

into

CO

MP

UD

EF

RO

ST

but f

ood

isno

t def

rost

edw

ell.

CK LOW VOLTAGECK NO POWER AT OUTLETRE SHORTED IN POWER CORDCK OPENED OR SHORTED WIRINGCK HOOD MOTOR CAPACITORRE HOOD LAMP OR SOCKETCK TURNTABLE OFF CONDITIONRE TURNTABLE MOTORRE FAN MOTORRE OVEN LAMP OR SOCKET

FOIL PATERN ON P.W.B.O

N RELAY (RY-5)N RELAY (RY-4)N RELAY (RY-3)N RELAY (RY-2)N RELAY (RY-1)M KEY UNIT

L CONTROL UNITK HOOD FAN MOTORJ HOOD HERMAL CUT-OUTI MONITOR FUSEH MONITOR SWITCHG SECONDARY INTERLOCK SYSTEMF PRIMARY INTERLOCK SWITCHE TEMPERATURE FUSE OR THERMAL CUT-OUTD HIGH VOLTAGE CAPACITORC H.V. RECTIFIERB POWER TRANSFORMERA MAGNETRON

The

oven

stop

san

d"E

RR

OR

"is

disp

laye

dor

does

not

end

durin

gS

enso

rC

ooki

ngco

nditi

on. (

Ove

ndo

esno

t shu

t off

afte

ra

cup

ofw

ater

isbo

iling

byS

enso

rC

ooki

ng.)

Ove

nst

ops

at32

seco

nds

afte

rst

artin

g.

SE

NS

OR

CO

OK

ING

CO

ND

ITIO

N

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 1615

B POWER TRANSFORMER TEST

TEST PROCEDURESPROCEDURE

LETTER COMPONENT TEST

1. Disconnect the power supply cord, and then remove outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. To test for an open filament, isolate the magnetron from the high voltage circuit. A continuity check

across the magnetron filament leads should indicate less than 1 ohm.5. To test for a shorted magnetron, connect the ohmmeter leads between the magnetron filament leads

and chassis ground. This test should indicate an infinite resistance. If there is little or no resistance the magnetron is grounded and must be replaced.

6. Reconnect all leads removed from components during testing.7. Reinstall the outer case (cabinet).8. Reconnect the power supply cord after the outer case is installed.9. Run the oven and check all functions.

MICROWAVE OUTPUT POWERThe following test procedure should be carried out with the microwave oven in a fully assembled condi-tion (outer case fitted).

HIGH VOLTAGES ARE PRESENT DURING THE COOK CYCLE, SO EXTREME CAUTION SHOULD BE OBSERVED.

Power output of the magnetron can be measured by performing a water temperature rise test. This test should only be used if above tests do not indicate a faulty magnetron and there is no defect in the following components or wiring: silicon rectifier, high voltage capacitor and power transformer. This test will require a 16 ounce (453cc) measuring cup and an accurate mercury thermometer or thermocouple type temperature tester. For accurate results, the following procedure must be followed carefully:

1. Fill the measuring cup with 16 oz. (453cc) of tap water and measure the temperature of the water with a thermometer or thermocouple temperature tester. Stir the thermometer or thermocouple through the water until the temperature stabilizes. Record the temperature of the water.

2. Place the cup of water in the oven. Operate oven at POWER 10(HIGH) selecting more than 60 seconds cook time. Allow the water to heat for 60 seconds, measuring with a stop watch, second hand of a watch or the digital read-out countdown.

3. Remove the cup from the oven and again measure the temperature, making sure to stir the thermometer or thermocouple through the water until the maximum temperature is recorded.

4. Subtract the cold water temperature from the hot water temperature. The normal result should be 29.2 to 54.2οF(16.2 to 30.1οC) rise in temperature. If the water temperatures are accurately measured and tested for the required time period the test results will indicate if the magnetron tube has low power output (low rise in water temperature) which would extend cooking time or high power output (high rise in water temperature) which would reduce cooking time. Because cooking time can be adjusted to compensate for power output, the magnetron tube assembly should be replaced only if the water temperature rise test indicates a power output well beyond the normal limits. The test is only accurate if the power supply line voltage is 120 volts and the oven cavity is clean.

A MAGNETRON ASSEMBLY TEST

1. Disconnect the power supply cord, and then remove outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. Disconnect the primary input terminals and measure the resistance of the transformer with an

ohmmeter. Check for continuity of the coils with an ohmmeter. On the R x 1 scale, the resistance of the primary coil should be less than 1 ohm and the resistance of the high voltage coil should be approximately 83 ohms; the resistance of the filament coil should be less than 1 ohm.

5. Reconnect all leads removed from components during testing.6. Reinstall the outer case (cabinet).7. Reconnect the power supply cord after the outer case is installed.8. Run the oven and check all functions.

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 1716

TEST PROCEDURESPROCEDURE

LETTER COMPONENT TEST

1. Disconnect the power supply cord, and then remove outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. If the capacitor is open, no high voltage will be available to the magnetron. Disconnect input leads

and check for short or open between the terminals using an ohmmeter.Checking with a high ohm scale, if the high voltage capacitor is normal, the meter will indicate continuity for a short time and should indicate an open circuit once the capacitor is charged. If the above is not the case, check the capacitor with an ohmmeter to see if it is shorted between either of the terminals and case. If it is shorted, replace the capacitor.

5. Reconnect all leads removed from components during testing.6. Reinstall the outer case (cabinet).7. Reconnect the power supply cord after the outer case is installed.8. Run the oven and check all functions.

D HIGH VOLTAGE CAPACITOR TEST

E CAVITY THERMAL CUT-OUT TEST

C HIGH VOLTAGE RECTIFIER TEST1. Disconnect the power supply cord, and then remove outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. Isolate the rectifier from the circuit. Using the highest ohm scale of the meter, read the resistance

across the terminals and observe, reverse the leads to the rectifier terminals and observe meter reading. If a short is indicated in both directions, or if an infinite resistance is read in both directions, the rectifier is probably defective and should be replaced.

5. Reconnect all leads removed from components during testing.6. Reinstall the outer case (cabinet).7. Reconnect the power supply cord after the outer case is installed.8. Run the oven and check all functions.

NOTE: Be sure to use an ohmmeter that will supply a forward bias voltage of more than 6.3 volts.

(HIGH VOLTAGES ARE PRESENT AT THE HIGH VOLTAGE TERMINAL, SO DO NOT ATTEMPT TO MEASURE THE FILAMENT AND HIGH VOLTAGE.)

1. Disconnect the power supply cord, and then remove outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. A continuity check across the thermal cut-out terminals should indicate a closed circuit unless the

temperature of the thermal cut-out reaches approximately 230OF(110OC). An open thermal cut-out indicates overheating of the oven, exchange the oven thermal cut-out and check inside of oven cavity and for improper setting of cooking time or operation of control unit. Check for restricted air flow through the vent holes of the oven cavity, especially the cooling fan and air guide.

5. Reconnect all leads removed from components during testing.6. Reinstall the outer case (cabinet).7. Reconnect the power supply cord after the outer case is installed.

MAGNETRON TEMPERATURE FUSE TEST1. Disconnect the power supply cord, and then remove outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. A continuity check across the magnetron temperature fuse terminals should indicate a closed circuit

unless the temperature of the magnetron temperature fuse reaches approximately 302OF(150OC). An open magnetron temperature fuse indicates overheating of the magnetron. Check for restricted air flow to the magnetron, especially the cooling fan air guide.

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 1817

TEST PROCEDURESPROCEDURE

LETTER COMPONENT TEST

1. Disconnect the power supply cord, and then remove outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. Isolate the switch and connect the ohmmeter to the common (COM.) and normally open (NO) terminal

of the switch. The meter should indicate an open circuit with the door open and a closed circuit with the door closed. If improper operation is indicated, replace the secondary interlock switch.

5. Reconnect all leads removed from components during testing.6. Reinstall the outer case (cabinet).7. Reconnect the power supply cord after the outer case is installed.8. Run the oven and check all functions.5. Reconnect all leads removed from

components during testing.6. Reinstall the outer case (cabinet).7. Reconnect the power supply cord after

the outer case is installed.8. Run the oven and check all functions.

F PRIMARY INTERLOCK SWITCH TEST

CAUTION: IF THE TEMPERATURE FUSE INDICATES AN OPEN CIRCUIT AT ROOM TEMPERATURE, REPLACE TEMPERATURE FUSE.

G PRIMARY INTERLOCK SYSTEM TEST

DOOR SENSING SWITCH1. Disconnect the power supply cord, and then remove outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. Isolate the switch and connect the ohmmeter to the common (COM.) and normally open (NO)

terminal of the switch. The meter should indicate an open circuit with the door open and a closed circuit with the door closed. If improper operation is indicated, replace the door sensing switch.

5. Reconnect all leads removed from components during testing.6. Reinstall the outer case (cabinet).7. Reconnect the power supply cord after the outer case is installed.8. Run the oven and check all functions.

NOTE: If the door sensing switch contacts fail in the open position and the door is closed, the cooling fan motor, stirrer motor and oven light will be activated by RY1.

5. Reconnect all leads removed from components during testing.6. Reinstall the outer case (cabinet).7. Reconnect the power supply cord after the outer case is installed.8. Run the oven and check all functions.

CAUTION: IF THE TEMPERATURE FUSE INDICATES AN OPEN CIRCUIT AT ROOM TEMPERATURE, REPLACE TEMPERATURE FUSE.

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 1918

TEST PROCEDURESPROCEDURE

LETTER COMPONENT TEST

H MONITOR SWITCH TEST

SECONDARY INTERLOCK RELAY (RY2)1. Disconnect the power supply cord, and then remove outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. Disconnect two (2) wire leads from the male tab terminals of the Secondary Interlock Relay. Check

the state of the relay contacts using a ohmmeter. The relay contacts should be open. If the relay contacts are closed, replace the circuit board entirely or the relay itself.

5. Reconnect all leads removed from components during testing.6. Reinstall the outer case (cabinet).7. Reconnect the power supply cord after the outer case is installed.8. Run the oven and check all functions.

plate of the oven cavity with the door opened (in this condition the plunger of the monitor switch is pushed in), the meter should indicate an open circuit. If improper operation is indicated, the switch may be defective. After testing the monitor switch, reconnect the wire lead to the monitor switch (COM) terminal and check the continuity of the monitor circuit.

Doorsensing switchh Monitor Switch

Screw Driver

Ohmmeter

White / White

1. Disconnect the power supply cord, and then remove outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. Before performing this test, make sure that the secondary interlock switch and the primary interlock

relay are operating properly, according to the above Switch Test Procedure. Disconnect the wire lead from the monitor switch (COM) terminal. Check the monitor switch operation by using the ohmmeter as follows. When the door is open, the meter should indicate a closed circuit. When the monitor switch actuator is pushed by a screw driver through the lower latch hole on the front plate of the oven cavity with the door opened (in this condition the plunger of the monitor switch is pushed in), the meter should indicate an open circuit. If improper operation is indicated, the switch may be defective. After testing the monitor switch, reconnect the wire lead to the monitor switch (COM) terminal and check the continuity of the monitor circuit.

5. Reconnect all leads removed from components during testing.6. Reinstall the outer case (cabinet).7. Reconnect the power supply cord after the outer case is installed.8. Run the oven and check all functions. of the oven cavity with the door opened (in this condition the plunger of the monitor switch is pushed

in), the meter should indicate an open circuit. If improper operation is indicated, the switch may be defective. After testing the monitor switch, reconnect the wire lead to the monitor switch (COM) terminal and check the continuity of the monitor circuit.

5. Reconnect all leads removed from components during testing.6. Reinstall the outer case (cabinet).7. Reconnect the power supply cord after the outer case is installed.8. Run the oven and check all functions.

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 209

TEST PROCEDURESPROCEDURE

LETTER COMPONENT TEST J HOOD THERMAL CUT-OUT TEST

. Disconnect the power supply cord, and then remove outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. A continuity check across the thermal cut-out terminals should indicate an open circuit unless the

temperature of the thermal cut-out reaches approximately 158½F(70½C) or more. At that temperature, the contacts will close. The thermal cut-out opens automatically at approximately 104½F(40½C).

5. Reconnect all leads removed from components during testing.6. Reinstall the outer case (cabinet).7. Reconnect the power supply cord after the outer case is installed.8. Run the oven and check all functions.

K HOOD FAN MOTOR TEST . Disconnect the power supply cord, and then remove outer case.

2. Open the door and block it open.3. Discharge high voltage capacitor.4. If the motor does not turn, touch the FAN button once and check voltage between pins "" and "2"

(Blue and Black wires) of the 6 pin connector. If 20 Volts appear and the hood capacitor is good, replace the hood fan assembly. If 20 Volts does not appear, check the motor circuit. The resistance values of motor terminals are as follows:

5. Reconnect all leads removed from components during testing.6. Reinstall the outer case (cabinet).7. Reconnect the power supply cord after the outer case is installed.8. Run the oven and check all functions.

Resistance between;

WHT() AND YLW (4) = 0Ω (Shorted)BLU (2) AND YLW (4) = 34ΩWHT() AND BLK (2) = 34ΩRED(5) AND WHT() = 77ΩRED(5) AND BLU (2) = 43ΩYLW(4) AND RED (5) = 77Ω

6-PIN CONNECTOROF HOOD FAN MOTOR

RED YLW

ORG BLU WHT

5

3 2 1

4

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 2120

TEST PROCEDURESPROCEDURE

LETTER COMPONENT TEST L TOUCH CONTROL PANEL ASSEMBLY TEST

The touch control panel consists of circuits including semiconductors such as LSI, ICs, etc. Therefore, unlike conventional microwave ovens, proper maintenance cannot be performed with only a voltmeter and ohmmeter. In this service manual, the touch control panel assembly is divided into two units, Con-trol Unit and Key Unit, and also the Control Unit is divided into two units, LSI Unit and Power Unit, and troubleshooting by unit replacement is described according to the symptoms indicated.Before testing,

1) Disconnect the power supply cord, and then remove outer case. Refer to procedure of " HOOD EXHAUST LOUVER REMOVAL ", " REMOVAL OF OVEN FROM WALL " and " OUTER CASE REMOVAL ".

2) Open the door and block it open.3) To discharge high voltage capacitor, wait for 60 seconds.4) Remove two (2) screws holding the hood intake duct R to the ovencavity top plate and the base

plate R. And remove the hood intake duct R. 5) Disconnect the leads to the primary of the power transformer.6) Ensure that these leads remain isolated from other components and oven chassis by using

insulation tape.1. Key Unit.

NOTE ;1) Check key unit ribbon connection before replacement.2) Reconnect all leads removed from components during testing.3) Re-install the hood intake duct R with two (2) screws.4) Re-install the outer case (cabinet).5) Reconnect the power supply cord after the outer case is installed.6) Run the oven and check all functions.

The following symptoms indicate a defective key unit.a) When touching the pads, a certain pad produces no signal at all.b) When touching a number pad, two figures or more are displayed.c) When touching the pads, sometimes a pad produces no signal.If the key unit is defective.1) Disconnect the power supply cord, and then remove outer case.2) Open the door and block it open.3) To discharge high voltage capacitor, wait for 60 seconds.4) Replace the key unit.5) Reconnect all leads removed from components during testing.6) Re-install the outer case (cabinet).7) Reconnect the power supply cord after the outer case is installed.8) Run the oven and check all functions.

2. Control Unit.The following symptoms indicate a defective control unit. Before replacing the control unit, perform the Key unit test (Procedure M) to determine if control unit is faulty.

2-1 In connection with pads.a) When touching the pads, a certain group of pads do not produce a signal.b) When touching the pads, no pads produce a signal.

2-2 In connection with indicatorsa) At a certain digit, all or some segments do not light up.b) At a certain digit, brightness is low.c) Only one indicator does not light. d) The corresponding segments of all digits do not light up; or they continue to light up.e) Wrong figure appears.f) A certain group of indicators do not light up.g) The figure of all digits flicker.

2-3 Other possible problems caused by defective control unit.a) Buzzer does not sound or continues to sound.b) Clock does not operate properly.c) Cooking is not possible.

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 2221

When testing is completed,1) Disconnect the power supply cord.2) Open the door and block it open.3) To discharge high voltage capacitor, wait for 60 seconds. 4) Reconnect all leads removed from components during testing.5) Re-install the hood intake duct R.6) Re-install the outer case (cabinet).7) Reconnect the power supply cord after the outer case is installed.8) Run the oven and check all functions.

TEST PROCEDURESPROCEDURE

LETTER COMPONENT TEST

N RELAY TEST

1. Disconnect the power supply cord.2. Open the door and block it open.3. To discharge high voltage capacitor, wait for 60 seconds.4. Remove the control panel assembly.5. If the display fails to clear when the CLEAR-OFF pad is depressed, first verify the flat ribbon cable is

making good contact, verify that the door sensing switch (stop switch) operates properly; that is the contacts are closed when the door is closed and open when the door is open. If the door sensing switch (stop switch) is good, disconnect the flat ribbon cable that connects the key unit to the control unit and make sure the door sensing switch is closed (either close the door or short the door sensing switch connecter). Use the Key unit matrix indicated on the control panel schematic and place a jumper wire between the pins that correspond to the CLEAR-OFF pad making momentary contact. If the control unit responds by clearing with a beep the key unit is faulty and must be replaced. If the control unit does not respond, it is faulty and must be replaced. If a specific pad does not respond, the above method may be used (after clearing the control unit) to determine if the control unit or key pad is at fault.

6. Reconnect all leads removed from components during testing.7. Re-install the control panel assembly.8. Reconnect the power supply cord.9. Run the oven and check all functions.

M KEY UNIT TEST

1. Disconnect the power supply cord, and then remove outer case. Refer to procedure of " HOOD EXHAUST LOUVER REMOVAL ", " REMOVAL OF OVEN FROM WALL " and " OUTER CASE REMOVAL ".

2. Open the door and block it open.3. To discharge high voltage capacitor, wait for 60 seconds.4. Remove the hood intake duct R.5. Disconnect the leads to the primary of the power transformer.6. Ensure that these leads remain isolated from other components and oven chassis by using insulation

tape.

G2

G1

G4

G 5

KEY UNIT

Cook

Reheat

Defrost

PowerLevel

TIMERCLOCK

Popcorn Light

Fan

1

2

4 5

3

8

6

9

0

7

G 6 G 7 G 8 G 9 G10 G11 G12

G3

ClearOff

STARTPlus 1 Min

G1

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 2322

TEST PROCEDURESPROCEDURE

LETTER COMPONENT TEST

7. After that procedure, re-connect the power supply cord.8. Check voltage between normal open terminal of the relay RY2 and the normal open terminal of the

relay RY1 on the control unit with an A.C. voltmeter.The meter should indicate 120 volts, if not check oven circuit.

RY1, RY2, RY4, and RY5 Relay Test These relays are operated by D.C. voltageCheck voltage at the relay coil with a D.C. voltmeter during the microwave cooking operation.

DC. voltage indicated Defective relay.DC. voltage not indicated Check diode which is connected to the relay coil. If diode

is good, control unit is defective.

RELAY SYMBOL OPERATIONAL VOLTAGE CONNECTED COMPONENTS

RY1 Approx. 26.6V D.C. Oven lamp / Fan motor / Turntable motor

RY2(COOK) Approx. 26.0V D.C. Power transformer

RY4 Approx. 26.6V D.C. Hood motor

RY3 Approx. 26.6V D.C. Hood lamp

9. Disconnect the power supply cord.10. Open the door and block it open.11. To discharge high voltage capacitor, wait for 60 seconds.12. Reconnect all leads removed from components during testing.13. Re-install the hood intake duct R.14. Re-install the outer case (cabinet).15. Reconnect the power supply cord after the outer case is installed.16. Run the oven and check all functions.

O DEFROST CENTER TEST(1) Open the door.(2) Place one cup of water in the center of the turntable tray in the oven cavity.(3) Close the door.(4) Touch the " DEFROST" pad once.(5) Touch the number pad "2".(6) Touch the number pad "5".(7) Touch the " START " button.(8) The oven is in Defrost center cooking condition.(9) The oven will operate as follows.

Menu 1ST STAGE 2ND STAGESteaks/Chops LEVEL TIME LEVEL TIME

0.5lbs 60% 57sec. 40% 17sec.

(8) If improper operation is indicated, the control unit is probably defective and should be checked.

To protect the electronic circuits, this model is provided with a fine foil pattern added to the primary on the PWB, this foil pattern acts as a fuse.1. Foil pattern check and repairs.

1) Disconnect the power supply cord.2) Open the door and block it open.3) To discharge high voltage capacitor, wait for 60 seconds.4) Remove the control unit, referring to the procedure of " CONTROL PANEL ASSEMBLY, CONTROL

UNIT AND KEY UNIT REMOVAL ".5) Follow the troubleshooting guide given below for repair.

P FOIL PATTERN ON THE PRINTED WIRING BOARD TEST

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 2423

CN

-A

VR

S1

P

T1

RY3(J1)

ac

d

b

7

TEST PROCEDURESPROCEDURE

LETTER COMPONENT TEST

STEPS OCCURRENCE CAUSE OR CORRECTION 1 Only pattern at "a" is broken. *Insert jumper wire J1 and solder.

2 Pattern at "a" and "b" are broken. *Insert the coil RCILF2003YAZZ between "c" and "d".

6) Make a visual inspection of the varistor. Check for burned damage and examine the transformer with a tester for the presence of layer short-circuit (check the primary coil resistance which is approximately 215Ω ± 10%). If any abnormal condition is detected, replace the defective parts.

7) Reconnect all leads removed from components during testing.8) Re-install the control unit to the control panel and re-install the control panel to the oven.9) Reconnect the power supply cord.

10) Run the oven and check all functions.2. Follow the troubleshooting guide given below, if indicator does not light up after above check and

repairs are finished.1) Disconnect the power supply cord, and then remove outer case. Refer to procedure of " HOOD

EXHAUST LOUVER REMOVAL ", " REMOVAL OF OVEN FROM WALL " and " OUTER CASE REMOVAL ".

2) Open the door and block it open.3) To discharge high voltage capacitor, wait for 60 seconds.4) Remove the hood intake duct R.5) Disconnect the leads to the primary of the power transformer.6) Ensure that these leads remain isolated from other components and oven chassis by using

insulation tape.7) After that procedure, re-connect the power supply cord.8) Follow the troubleshooting guide given below for repair.

STEPS OCCURRENCE CAUSE OR CORRECTION

The rated AC voltage is not present between 1 the normal open terminal of the relay RY2 and Check supply voltage and oven power cord. the normal open terminal of the relay RY1.

2 The rated AC voltage is present at primary Low voltage transformer or secondary circuit defective. side of low voltage transformer. Check and repair.

9) Disconnect the power supply cord.10) Open the door and block it open.11) To discharge high voltage capacitor, wait for 60 seconds.12) Reconnect all leads removed from components during testing.13) Re-install the hood intake duct R.14) Re-install the outer case (cabinet).15) Reconnect the power supply cord after the outer case is installed.16) Run the oven and check all functions.

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 2524

TEST PROCEDURESPROCEDURE

LETTER COMPONENT TEST Q NOISE FILTER TEST

1. Disconnect the power supply cord, and then remove outer case.2. Open the door and block it open.3. Discharge high voltage capacitor.4. Disconnect the leads to the primary of the power transformer.5. Using an ohm-meter, check between the terminals as described in the following table:

MEASURING POINT INDICATION OF OHM-METER

Between N and H Open Circuit

Between terminal N and LOAD Short Circuit

Between terminal H and LOAD Short Circuit

If incorrect readings are obtained, replace the noise filter.

6. Reconnect all leads removed from components during testing.7. Re-install the outer case (cabinet).8. Reconnect the power supply cord after the outer case is installed.9. Run the oven and check all functions.

NOISE FILTER UNIT

NOISE SUPPRESSION COIL

LINE CROSS CAPACITOR

RESISTOR

LINE BYPASS CAPACITORLINE BYPASS CAPACITOR

0.0033uF/ 250v0.0033uF/ 250v

LOADLOAD

HN

MONITORFUSE

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 2625

DESCRIPTION OF LSILSIThe I/O signal of the LSI is detailed in the following table.

Pin No. Signal I/O Description1-2 VL2-VL1 IN Power source voltage input terminal.

Standard voltage for LCD.

3-6 AN7-AN4 IN Terminal to change cooking input according to the Model. By using the A/D converter contained in the LSI, DC voltage in accordance with the Model

in operation is applied to set up its cooking constant.

TOUCH CONTROL PANEL ASSEMBLY

OUTLINE OF TOUCH CONTROL PANEL

Symbol Voltage Application

VC -5.3V LSI(IC1)

3) Synchronizing Signal CircuitThe power source synchronizing signal is available in order to compose a basic standard time in the clock cir-cuit. It incorporates a very small error because it works on commercial frequency.

4) Reset CircuitA circuit to generate a signals which resetting the LSI to the initial state when power is applied.

5) Buzzer CircuitThe buzzer is responds to signals from the LSI to emitaudible sounds (key touch sound and completion sound).

6) Door Sensing SwitchA switch to inform the LSI if the door is open or closed.

7) Relay CircuitTo drive the magnetron, fan motor, turntable motor, hood motor, and light the oven lamp and hood lamp.

8) Indicator CircuitThis circuit consists of 22 segments and 3 common electrodes using a Light Crystal Display.

9) Back Light CircuitA circuit to drive the back light (Light emitting diodes LD1-LD4).

The touch control section consists of the following unitsas shown in the touch control panel circuit.

(1) Key Unit (2) Control Unit (The Control unit consists of LSI Unit and

Power U nit)

The principal functions of these units and the signals com-municated among them are explained below.

Key UnitThe key unit is composed of a matrix, signals generated in the LSI are sent to the key unit through P20, P21, P22, P25, and P26.When a key pad is touched, a signal is completed through the key unit and passed back to the LSI through P43, P44, P45 and P46 to perform the function that was requested.

Control Unit Control unit consists of LSI, power source circuit, synchro-nizing signal circuit, reset circuit, buzzer circuit, relay circuit indicator circuit and back light circuit.

1) LSIThis LSI controls the key strobe signal, relay driving signal for oven function and indicator signal.

2) Power Source CircuitThis circuit generates voltages necessary for the control unit from the AC line voltage.In addition, the synchronizing signal is available in order to compose a basic standard time in the clock circuit.

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 27

26

Maximumoutput

70% ofmaximumoutput

H : GND

L : -5V

H : GND

L : -5V

ON

ON

OFF

OFF OFF

24 sec.

8 sec.

16.7 msec.

H : GND

L : -5V

7 AN3 OUT Back light circuit (Light emitting diodes) driving signal.

8 AN2 IN To input signal which communicates the door open/close information to LSI. Door close "H" level signal (0V). Door open "L" level signal (-5V).

9-10 AN1-AN0 OUT Terminal not used.

11-13 P57-P55 OUT Terminal not used.

14 CNTR0 OUT Signal to sound buzzer (2.0 kHz). A: key touch sound.

B: Completion sound.

15 P53 OUT Terminal not used.

16 P52 OUT Oven lamp, fan motor and turntable motor driving signal To turn on and off shut off relay (RY1). The square

waveform voltage is delivered to the RY1 driving circuit and RY2 control circuit.

17-18 P51-P50 OUT Terminal not used.

19 P47 OUT Magnetron high-voltage circuit driving signal. To turn on and off the cook relay (RY2). The

signals holds "L" level during microwave cooking and "H" level while not cooking. In other cooking modes (variable cooking) the signal turns to "H" level and "L" level in repetition according to the power level.

(ON and OFF times for other power level.)

20 P46 IN Signal coming from touch key. When either G12 line on key matrix is touched, a corresponding signal out of P20, P21,

P22, P25 and P26 will be input into P46. When no key is touched, the signal is held at "H" level.

21 P45 IN Signal similar to P46. When either G11 line on key matrix is touched, a corresponding signal will be input into

P45.

22 P44 IN Signal similar to P46. When either G10 line on key matrix is touched, a corresponding signal will be input into

P44.

23 P43 IN Signal similar to P46. When either G9 line on key matrix is touched, a corresponding signal will be input into

P43.

24 INT0 IN Signal synchronized with commercial power source frequency. This is the basic timing for time processing of LSI.

25 P41 OUT Terminal not used.

26 P40 IN Connected to GND through the pull-down resistor R100.

27 RESET IN Auto clear terminal. Signal is input to reset the LSI to the initial state when power is applied.

28-29 P71-P70 OUT Terminal not used.

30 XIN IN Internal clock oscillation frequency input setting. The internal clock frequency is set by inserting the ceramic filter oscillation circuit with

respect to XOUT terminal.

31 XOUT OUT Internal clock oscillation frequency control output. Output to control oscillation input of XIN.

32 VSS IN Power source voltage: -5.0V. VC voltage of power source circuit input.

Pin No. Signal I/O Description

A

B

0.1 sec.

2.0 sec.

H : GND

L : -5V

H : GND

L : -5V

16.7 msec.

During cooking

H : GND

L : -5V

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 2827

34 P26 OUT Key strobe signal. Signal applied to touch-key section. A pulse signal is input to P43-P46 terminal while one

of G7 line keys on key matrix is touched.

35 P25 OUT Key strobe signal. Signal applied to touch-key section. A pulse signal is input to P43-P46 terminal while one

of G6 line keys on key matrix is touched.

36 P24 OUT Terminal not used.

37 P23 OUT Terminal not used.

38 P22 OUT Key strobe signal. Signal applied to touch-key section. A pulse signal is input to P43-P46 terminal while one

of G3 line keys on key matrix is touched.

39 P21 OUT Key strobe signal. Signal applied to touch-key section. A pulse signal is input to P43-P46 terminal while one

of G2 line keys on key matrix is touched.

40 P20 OUT Key strobe signal. Signal applied to touch-key section. A pulse signal is input to P43-P46 terminal while one

of G1 line keys on key matrix is touched.

41 P17 OUT Terminal not used.

42 P16 OUT Hood lamp driving signal. To turn on and off relay(RY5). " L " level: During

Hood lamp ON. "H" level: During Hood lamp OFF.

43 P15 OUT Terminal not used.

44 P14 OUT Hood motor driving signal. To turn on and off relay(RY4). "L" level: During

Hood motor ON. "H" level: During Hood motor OFF.

45-47 P13-P11 OUT Terminal not used.

48-50 SEG24-SEG22 OUT Terminal not used.

51-72 SEG21-SEG0 OUT Segment data signal. Connected to LCD.

The relation between signals are as follows: LSI signal (Pin No.) LCD (Pin No.) LSI signal (Pin No.) LCD (Pin No.) SEG 21 (51) -------------------- SEG21 ( 1) SEG 10 (62) --------------------- SEG10 (12) SEG 20 (52) -------------------- SEG20 ( 2) SEG 9 (63) ---------------------- SEG 9 (13) SEG 19 (53) -------------------- SEG19 ( 3) SEG 8 (64) ---------------------- SEG 8 (14) SEG 18 (54) -------------------- SEG18 ( 4) SEG 7 (65) ---------------------- SEG 7 (15) SEG 17 (55) -------------------- SEG17 ( 5) SEG 6 (66) ---------------------- SEG 6 (16) SEG 16 (56) -------------------- SEG16 ( 6) SEG 5 (67) ---------------------- SEG 5 (17) SEG 15 (57) -------------------- SEG15 ( 7) SEG 4 (68) ---------------------- SEG 4 (18) SEG 14 (58) -------------------- SEG14 ( 8) SEG 3 (69) ---------------------- SEG 3 (19) SEG 13 (59) -------------------- SEG13 ( 9) SEG 2 (70) ---------------------- SEG 2 (20) SEG 12 (60) --------------------SEG12 (10) SEG 1 (71) ---------------------- SEG 1 (21) SEG 11 (61) --------------------SEG11 (11) SEG 0 (72) ---------------------- SEG 0 (22)

73/74 VCC/VREF IN Connected to GND.

75 AVSS IN Connected to VC.

76 COM3 OUT Terminal not used.

77 COM2 OUT Common data signal: COM2. Connected to LCD signal COM2.

78 COM1 OUT Common data signal: COM1. Connected to LCD signal COM1.

79 COM0 OUT Common data signal: COM0. Connected to LCD signal COM0.

80 VL3 IN Power source voltage input terminal. Standard voltage for LCD.

Pin No. Signal I/O Description

ON

OFFH : GND

L

ON

OFFH : GND

L

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 2928

1. Precautions for Handling Electronic ComponentsThis unit uses CMOS LSI in the integral part of the circuits. When handling these parts, the following precautions should be strictly followed. CMOS LSI have extremely high impedance at its input and output terminals. For this reason, it is easily influenced by the surrounding high voltage power source, static electricity charge in clothes, etc. and sometimes it is not fully protected by the built-in protection circuit.In order to protect CMOS LSI.

1) When storing and transporting, thoroughly wrap them in aluminium foil. Also wrap all PW boards containing them in aluminium foil.

2) When soldering, ground the technician as shown in the figure and use grounded soldering iron and work table.

2. Shapes of Electronic Components

3. Servicing of Touch Control PanelWe describe the procedures to permit servicing of the touch control panel of the microwave oven and the precautions you must take when doing so. To perform the servicing, power to the touch control panel is available either from the power line of the oven itself or from an external power source.

(1) Servicing the touch control panel with power supply of the oven:CAUTION: THE HIGH VOLTAGE TRANSFORMER OF THE MICROWAVE OVEN IS STILL LIVE DURING SERVICING AND PRESENTS A HAZARD.Therefore, before checking the performance of the touch control panel,1) Disconnect the power supply cord, and then remove

outer case.2) Open the door and block it open.3) Discharge high voltage capacitor.4) Disconnect the leads to the primary of the power

transformer.5) Ensure that these leads remain isolated from other

components and oven chassis by using insulation tape.

6) After that procedure, re-connect the power supply cord.

After checking the performance of the touch control panel,1) Disconnect the power supply cord.2) Open the door and block it open.3) Re-connect the leads to the primary of the power

transformer.4) Re-install the outer case (cabinet).5) Re-connect the power supply cord after the outer

case is installed.6) Run the oven and check all functions.

A. On some models, the power supply cord between the touch control panel and the oven itself is so short that the two can’t be separated. For those models, check and repair all the controls (sensor-related ones included) of the touch control panel while keeping it connected to the oven.

B. On some models, the power supply cord between the touch control panel and the oven proper is long enough that they may be separated from each other. For those models, it is possible to check and repair the controls of the touch control panel while keeping it apart from the oven proper; in this case you must short both ends of the door sensing switch (on PWB) of the touch control panel with a jumper, which activates an operational state that is equivalent to the oven door being closed. As for the sensor-related controls of the touch control panel, checking them is possible if dummy resistor(s) with resistance equal to that of the controls are used.

(2) Servicing the touch control panel with power supply from an external power source:Disconnect the touch control panel completely from the oven proper, and short both ends of the door sensing switch (on PWB) of the touch control panel, which activates an operational state that is equivalent to the oven door being closed. Connect an external power source to the power input terminal of the touch control panel, then it is possible to check and repair the controls of the touch control panel it is also possible to check the sensor-related controls of the touch control panel by using the dummy resistor(s).

4. Servicing ToolsTools required to service the touch control panel assembly.1) Soldering iron: 30W

(It is recommended to use a soldering iron with a grounding terminal.)

2) Oscilloscope: Single beam, frequency range: DC-10MHz type or more advanced model.

3) Others: Hand tools

5. Other Precautions1) Before turning on the power source of the control

unit, remove the aluminium foil applied for preventing static electricity.

2) Connect the connectors of the key unit to the control unit being sure that the lead wires are not twisted.

3) After aluminium foil is removed, be careful that abnormal voltage due to static electricity etc. is not applied to the input or output terminals.

4) Attach connectors, electrolytic capacitors, etc. to PWB, making sure that all connections are tight.

SERVICING

approx. 1M ohm

TransistorKRC243M

EC B

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 3029

result in severe, possibly fatal, electric shock.(Example)High Voltage Capacitor, Power Transformer, Magnetron, High Voltage Rectifier Assembly, High Voltage Harness etc..

WARNING: Avoid possible exposure to microwave energy. Please follow the instructions below before operat-ing the oven.

WARNING AGAINST HIGH VOLTAGE:Microwave ovens contain circuitry capable of producing very high voltage and current, contact with following parts may

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

To prevent an electric shock, take the following pre-cautions.1. Before wiring,

1) Disconnect the power supply cord.2) Open the door block it open.3) Discharge the high voltage capacitor and wait for 60

seconds.2. Don’t let the wire leads touch to the followiong parts;

1) High voltage parts:Magnetron, High voltage transformer, High voltage capacitor and High voltage rectifier assembly.

2) Hot parts:Oven lamp, Magnetron, High voltage transformer and Oven cavity.

WARNING FOR WIRING

1. Disconnect the power supply cord.2. Make sure that a definite” click” can be heard when

the microwave oven door is unlatched. (Hold the door in a closed position with one hand, then push the door open button with the other, this causes the latch leads to rise, it is then possible to hear a “click’ as the door switches operate.)

3. Visually check the door and cavity face plate for damage (dents, cracks, signs of arcing etc.).

Carry out any remedial work that is necessary before operating the oven.Do not operate the oven if any of the following conditions exist;

1. Door does not close firmly.2. Door hinge, support or latch hook is damaged.3. The door gasket or seal is damaged.4. The door is bent or warped.5. There are defective parts in the door interlock

system.6. There are defective parts in the microwave generating

and transmission assembly.7. There is visible damage to the oven.

Do not operate the oven:1. Without the RF gasket (Magnetron).2. If the wave guide or oven cavity are not intact.3. If the door is not closed.4. If the outer case (cabinet) is not fitted.

3) Sharp edge:Bottom plate, Oven cavity, Waveguide flange, Chassis support and other metallic plate.

4) Movable parts (to prevent a fault)Fan blade, Fan motor, Switch, Open lever, Open button.

3. Do not catch the wire leads in the outer case cabinet.4. Insert the positive lock connector until its pin is locked

and make sure that the wire leads do not come off even if the wire leads are pulled.

5. To prevent an error function, connect the wire leads correctly, referring to the Pictorial Diagram.

Please refer to ‘OVEN PARTS, CABINET PARTS, CONTROL PANAL PARTS, DOOR PARTS’, when carrying out any of the following removal procedures:

THE FOLLOWING ADJUSTMENTS OR COMPONENT REPLACEMENT CAN BE PERFORMED WITHOUT REMOVING THE OVEN FROM THE WALL

1. Hood lamps, sockets, grease filter and charcoal filter.2. Base cover and hood lamp glass assembly.3. Turntable motor.

4. Hood exhaust louver.5. Control panel assembly or components.

HOOD EXHAUST LOUVER REMOVAL

1. Disconnect the power supply cord.2. Open the door and block it open.3. To discharge the high voltage capacitor, wait for 60

seconds.4. Remove the two (2) screws on the top holding the hood

exhaust louver to the oven cavity front face plate.

FMV157GSFMV157GBFMV157GMFMV157GQFMV157GC

Page 31

30

REMOVAL OF OVEN FROM WALL (Two persons recommended to remove the oven)1. Disconnect the power supply cord, and uncoil the power supply cord.2. To discharge the high voltage capacitor, wait for 60

seconds.3. Remove the turntable tray and support from the oven

cavity.4. If the exhaust damper assembly is installed, remove the

one (1) screw holding the exhaust damper assembly to the rear stay, and remove the exhaust damper assembly by sliding it backward.

5. Remove theThree (3) screws holding the oven (outer case cabinet) to the top cabinet.

6. While supporting the front of the oven, pull down the Three(3) mounting levers and release the oven from the unit mounting plate.