Optimal Long Term Acquisition of Coal for Fuel Blending

Transcript of Optimal Long Term Acquisition of Coal for Fuel Blending

IEEE Transactions on Power Apparatus and Systems, Vol. PAS-103, No. 5, May 1984

OPTIMAL LONG TERM ACQUISITIONOF COAL FOR FUEL BLENDING

J. KondraguntaApplications Engineer, EUSED

General Electric CompanySchenectady, New York 12345

Abstract - At present, most utilities must generatepower to serve their load plus desired interchange whilemeeting sulfur dioxide emission constraints. There are severalmethods of meeting the sulfur dioxide requirements. The mostcost effective method in most of the midwest is to blend highand low sulfur coal to meet sulfur dioxide constraints.

Typically several sources of varying grades of coal areavailable. It is difficult to acquire the right amounts of coalwell in advance to meet the load subject to minimum costwhile meeting emission requirements.

This paper presents a method to determine the coalacquisition requirements from each of several sources for aparticular generating unit to ensure minimum cost subject toconstraints of sulfur dioxide emissions and inventory require-ments. A linear programming approach is used to meet thedesired objectives subject to the constraints.

1. INTRODUCTION

During the early 1970's much consideration was given tothe environmental hazards of generating and transmittingelectric power. In many areas generating units had to operatesubject to environmental constraints. The constraints placed alimit on the amount of sulfur dioxide (SO2) that could beemitted into the atmosphere.

This led many utilities to seek low sulfur fuels to avoidexceeding SO constraints. Some utilities could obtain lowsulfur coal while others had to switch to oil.

At this time fuel costs were very stable. A particularfuel source could normally be contracted for long periods oftime at a reasonable price. The environmental constraintscould be built into the normal economic dispatch routines ifnecessary.

The Arab oil embargo of 1973 changed the fuelprocurement situation considerably. Fuel prices in effectbecame unstable. Fuel prices could not be consideredconstant, therefore the procurement of fuel became muchmore complicated. It is now evident that the economicdispatch routines alone are not sufficient to ensure operationat minimum cost. Both the long term fuel procurement, shortterm fuel procurement and the particular method chosen tomeet the pollution constraints has a significant impact on theultimate cost of electric power. Optimization over a longtime period may be more important to achieve minimum costthan the short term considerations of traditional economicdispatch. Economic dispatch may minimize operating cost onany given day resulted from many earlier decisions andactions. Further improvement of the overall process could beachieved by making various decisions about coal procurementconsidering additional information.

In some areas blending of coal can produce improvedeconomy while meeting various constraints. In many areas ofthe Midwest portion of the United States a large amount ofhigh sulfur coal is available at relatively low costs. However,

83 SM 359-7 A paper recommended and approvedby the IEEE Power System Engineering Committee ofthe IEEE Powqer Engineering Society for presentationat the IEEE/PES 1983 Summer Meeting, Los Angeles,California, July 17-22, 1983. Manuscript submittedAugust 20, 1982; made available for printing June13, 1983.

Lewis N. WalkerCollege of EngineeringUniversity of Hartford

West Hartford, Connecticut 06107

this coal cannot be burned alone to generate large amounts ofpower while meeting environmental constraints. Low sulfurcoal is available however it must be shipped long distancesresulting in high cost.

In the Midwest it is possible to blend high sulfur coalwith low sulfur coal to meet the SO2 constraints. The blendingof coal can yield a much lower production cost than if lowsulfur fuelsealone are used. For example consider a plant thatburns 3Xl0 tons of coal per year. The sulfur constraint maybe met by a 2/3 high sulfur, 1/3 low sulfur coal blend.Therefore 2X100 tons of high sulfur coal at $25/ton blendedwith lXl06 tons of low sulfur coal at $42/ton produces anaverage of $30.66/ton. Often times due to lack of equipmentto obtain a precise blend, a 50-50 blend-of high sulfur and lowsulfur coal is used to ensure the SO2 constraint is notexceeded.

Coal inventories are required to allow for emergencies.Normally a ninety day supply is desired, however, theinventory should not be allowed to go below a sixty (60) daysupply. When blending is used, inventories of both high sulfurand low sulfur coal are required. In some cases the high andlow sulfur inventories are subdivided according to sulfurcontent.

Typically, a large generating unit receives coal fromseveral sources or mines.

The procurement of coal falls into two general cate-gories: 1) Long term contract agreement, 2) Short termcontract agreement. Long term contracts range from 1 yearto 10 years. The long term contracts of longer durations arenormally available for the acquisition of high sulfur coal only.Annual contracts are normally used for low sulfur coal. Thespot market can be used to obtain fuel on a shorter time framewhen more fuel is needed than was contracted in long termcontracts. The spot market is normally used to obtain fuel 1month to 1 year in advance of utilization.

2. Problem Statement

The problem is to acquire coal necessary to generatepower to supply the native load plus desired interchange whilemaintaining inventory. The load should be met at theminimum cost possible utilizing blending to meet the SO2operating constraint. Portions of the coal acquisition problemcan be solved using linear programming to determine howmuch coal should be obtained from each source to minimizethe operating cost. Assume that long term contracts are ineffect which gives limits on various coal sources. Linearprogramming can be used to determine how much coal shouldbe taken from the sources duringf each month with theobjective to minirnize cost subject to the constraints ofmaintaining the required inventory without exceeding the SOconstraint. The minimum possible purchase from the spoomarket should be made each year since the spot market will bethe most expensive source of coal.

The problerh can be formulated mathematically. Themain objective is to:

MinimizeM NEC. Ex..

i=l j=l g

0018-9510/84/0500-1000$01.00 © 1984 IEEE

1000

1001

Subject toNZM A >G,=J1 3

M NEs. Ex.

i-l Ij-li

NEX. .<T.

j=113 1

(2)

(3)M N

- 2.4EB. EX. <0i=l j=l z

for i=1,2, . . . M

LE(I k-)IPkk for

k=l

M .CL.13 13

for j=1,2,M. <CU.

13 1

kk=1,2, . . . NP

(4)

(5)

a)rS

(6)

(7)

2-Slope

Exact

1-Slope

CUjPower outputof unit j, MW

CLj

Where:L =Total number of inventory sources for

plant KKM =Total number of sources of coalN =Total number of generating unitsCi =Cost of coal from source i, $/tonXi; =Amount of coal, tons, from source i to be

burnt in generating unit jM. =Mw generation of unit jAj =Number of hours of operation of unit j in

the study periodG =MWHR requirement of the fossil fuel

energy in the study periodS =Sulfur content in coal from Source i,

lb/tonBi =Btu content of coal in coal from Source i,

Mbtu/tonTi =Maximum amount of available coal from

Source i tonsNP =Total number of generating plantsIk =Amount of coal available from inventory KJk =Amount of coal that can be burnedIPkk =Minimum amount of coal to be kept in

inventory for plant kkCL. =Lower limit of MN generation of unit jCU. =Upper limit of Mw generation of unit j

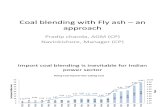

The constant 2.4 in constraint equation 3 corresponds tothe maximum amount of sulfur emission in lb/ MBtu allowed.The input-output characteristic of a generating unit is neces-sary to determine the amount of Btu required in order togenerate a predetermined electric power output. This input-output characteristic can be represented as shown in figure 1.The most accurate way of using this characteristic is todevelop a polynomial equation giving the relation between Bturequirement and generated power. However, developing thatrelationship is a difficult job.

The polynomial equation representing the input-outputcharacteristic can be represented by a piecewise linearapproach using 2 slope curve as shown in figure 1. Thecharacteristic could be further simplified using a single slopecurve for ease of computation

FIGURE 1: INPUT-OUTPUTCHARACTERISTIC OF GENERATING UNIT j

Equations (2) - (7) can be solved using linear program-ming techniques for X... TIen the cost of the coal can becalculated from equation (1). In equations (2) - (7) the decisionvariables are M. and X... Most of the linear programminogcodes will not allow more than one decision variable. So, it isnecessary to develop a mathematical relationship between M.,Xii, and other variables.

2.1 Relationship Between M. and X.. with generating unitInput-Output Characterist1ic Rep%-sented By A 2-SlopeCurve

Assume that generating unit j input-output charac-teristic is represented by a two-slope curve as shown in figure1. Also assume that the generating unit j is generating M. MW.Then the Btu consumption of unit j, H., can be written as:

H .=CL *S1 .+ (M -CL.) *A .*S213 1313 13 13 3 13 13

(8)

Where:H. = Btu consumption of unit jSi = Slope of heat rate of unit j betweenO and

CL. MW generation, Mbtu/MWHRS2j = Slope of heat rate of unit j between C I:

and CU. MW generation, Mbtu/MWHR

The Btu consumption of unit j can also be expressed bythe amount of coal burned in that unit. Let Xij for i = 1, 2, .

. . M be the tons of coal burned in unit j in the study period.Then the Btu consumption of unit j can be written as:

NH.=EX. B.Di=l D I

Now, equations (8) and (9) can be equated:NEX. B.=CL.A.Sl .+(M-CL,)A.S2.

i=l 131 3 3 1 3 3

E X. ,B.-CL.A.Sl.i=l 1131 + CL.3 A. S2

1 31

(9)

(10)

. . . N

1002Therefore, eq. (10) represents the relationship between Mj and

X... Now M. in eq. (2), (6), and (7) can be replaced by eq. (10)as shown below.

Equation (2) can be written as:NZM.A,>G (2)

j=13 3

Substituting eq. (10) into eq. (2):

MX..B.-CL.A.S1.

N *113 1 3 3 3z 1- + CL. A] Gj=l A.S2. . 3+

M

N i- ij 3L ~~~~+CL.A. >G

i=l ~S2. 33

N M NI E x..B. N C..1

j=1 i=1 S2 j-1K - CLiAjj

In equation (11) the right hand side (RHS) can be calculatedbecause all the variables are known.

Equation (6) can be written as:

M..CL. for j=1, 2, . . . NJ 3Substituting eq. (9) into eq. (6):

ME X. B.-CL.A.S1.

i=l 13 1 3 J3

A. S2.3

(6)

+ CL..CL.3 3

M X. .B. CL.AS1.z: 11 > I I I

A.S2. A.S2.i=1 3 3 j jOnce again the RHS in eq (12) can be calculated.

Equation (7) can be written as:

M.-CU. for j=1,2, . . . N3 J

Substituting eq (10) into eq (7):

(12)

(7)

2.2 Relationship Between M. and X.. With Generating UnitInput-Output Characteristic R:epresen?dd By a 1 Slope Curve.

As mentioned earlier, in Section 2.1, it is possible torepresent the input-output characteristic of generating unit jby a one slope curve, instead of 2 slope curve, as shown infigure 1. Then the relationship between M. and X.. developedin Section 2.2, that is eq (10), is not valid. Therefore, there isa necessity to develop the relationship between Mj and Xijwhen the generating unit input-output characteristic is repre-sented by 1 slooe curve.

Assume generating unit j lower and upper MW gener-ating capacities are CL. and CU. respectively. Assume thatgenerating unit j is generating M. MW (where CL <Mj<CU)Between CL. and CU. the input-output characteristic of unit jis represented by a single slope Sj, MBtu/MWHR.

Then the Btu consumption of unit j, H., can be writtenas:

(14)H.=M. A. S.3 JJJ

Let Xi; for i = 1, 2,... M be the tons of coal burned inunit j in the study period to generate M. MW. Ten

M JH.= ZX. .B. (15)J i=1)1

Now, eq (14) and (15) can be equated:MI X. .B.=M.A.S.

i=l 1 1)J 3 3 IM X. B.

M.= I 1. 13 1*_ A S.

Once again eq (16) should be substituted in eq (2), (6), and (7)so that Xi. will be the only decision variable in eq (2) - (7).

Now eq (2) can be rewritten as:NI M.A. >G (2)

i=1 3 1

N M X. .B.E A131 A. >G

j=1 i=ljA S

N M X. .B.I I 3

j=1 i=l j(17)

(16)

M X. B. -CL.A. S1.I 13 1 3J 3 + CL.<CU.

i=1 A.S2, 3

M X. B. CL.A.S1.i 1- 1<CU -CLA S2. j j A.S2.i= L

(13)

The RHS of eq (13) can be calculated.

Now equations (1), (11), (3), (4), (5), (12), and (13) can be solvedusing linear programming techniques to determine the amountof coal from Source i to be burnt in unit j, quantity of coalused from Source i (for i = 1, . . . M), amount of inventory tobe used for the necessary MW generation from unit j (for j = 1,... N) and the cost of coal.

Eq (6) can be rewritten as:

M...CL. for j=1,2, . . . N3 3

M X.B.I 1 I > CL. for j=1,2, . . .N=

A.S.ii3Similarly, eq (7) can be rewritten as:

M. :CU. for j=1,2, . . . N

M X. B.I -1i < CL. for j=1,2, . . . NA S j

(6)

(18)

(7)

(19)

Now equations (1), (17), (3), (4), (5), (18), and (19) are solvedusing linear programming techniques to determine the amountof coal from Source i (Xi.) to be used in unit j, total quantityof coal from Source i (for i = 1, ... M), amount of inventory tobe used, MW generation for unit j (for j = 1, ... N) and cost ofcoal.

3. System to be studied

Data for the system to be studied was obtained from aMidwest utility. The system has two power plants A and B.Plant A has 7 sources of coal and Plant B has 4 sources of coal.Plant B cannot use the coal sources that are identified forPlant A. In order to see that this condition is satisfied, careshould be taken while expanding eq (2). The SO compliance is4.8 lbs. of S02/MBtu which corresponds to 2.4 lbs. ofsulfur/MBtu. The coal source data for power plants A and B isshown in tables 1 and 2 respectively. The spot market data isshown in Table 3.

The generating plant data is shown in table 4. Thepolicy of the utility is to schedule maintenance of the unitsbeginning September 1st and no more than one unit can betaken out of service at a time for scheduled maintenance.Based on the above philosophy, the number of days ofoperation of each unit can be determined and is shown in table5.

rhe operating hours for each unit for a given monthcan be obtained by multiplying the numbers in table 5 by 24and these are the A.'s that should be used in eqs (11), (12), (13),(15), (19). 1

TABLE 1. SOURCES OF COAL FOR POWER PLANT A

Tons Sulfur Btu Price/TonMine X 1,000 %/lb. per lb. Mine Plant

1 16 3.04 11,123 $15.08 $17.15

2 196 3.04 11,123 $13.98 $16.05

3 21 1.08 10,621 $16.00 $38.21

4 127 2.89 11,034 $15.32 $17.30

5 7 2.89 11,034 $16.42 $18.40

6 71 2.03 11.612 $29.50 $31.91

7 59 0.77 10,649 $19.00 $37.87

Inventory 1 140 1.40 11,096 - $35.11

Inventory 2 947 2.98 11,088 - $16.61

Management would like to keep a minimum of 900,000 tons ofcoal in inventory.

TABLE 4. DATA FOR -POWER PLANTS A AND B

Plant A Plant B

Numsber of units 4 2

Minimum generation/unit, MW 240 225

Maximum generation/unit, MW 555 452

Maintenance days/unit 42 53

For 2 slope representation:Heat rate, Mbtu/MWhr 11.36 11.38

(0-240 MW) (0-225 MW)9.33 9.97

(240-555 MW) (225-452 MW)

For 1 slope representationHeat rate, Mbtu/MWhr 10.21 10.68

(0-555 MW) (0-452 MW)

Equivalent forced outage rate/unit 0.22 0.32

TABLE 5. UNIT OPERATING SCHEDULE

Plant A Unit Days Plant BUnit Days

1 2 3 4 1 2

Sept

Oct

Nov

Dec

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

/19

30

31

31

28

31

30

31

30

31

31

30

12/

/7

31

31

28

31

30

31

30

31

31

30

31

23/

/27

28

31

30

31

30

31

31

30

31

30

31

4/

/13

31

30

31

30

31

31

30

31

30

31

31

15/

/22

31

30

31

31

30

31

30

31

31

28

30

22/

30

31

31

/XX Indicates last days of the monthXX/ Indicates first days of the month

TABLE 2. SOURCES OF COAL FOR POWER PLANT B

Tons Sulfur Btu Price/TonMine X 1,000 %/lb. per lb. Mine Plant

lB 85 0.62 8,981 $ 7.59 $24.53

29 50 2.89 11,144 $16.79 $22.90

3B 9 3.13 10,590 $16.79 $22.90

4B 82 3.57 10,492 $16.40 $20.33

Inventory 3 136 0.62 8,981 - $25.08

Inventory 4 395 3.29 10,733 - $21.46

Management would like to keep a minimum of 400,000 tons ofcoal in inventory.

TABLE 3. SPOT MARKET SOURCES OF COAL FOR POWER PLANT A AND B

Tons Sulfur Btu Price/TonMine X 1,000 %/lb. per lb. Mine Plant

SML inf 1.08 10,621 $16.00 $38.21

SMH inf 3.13 10,590 $16.79 $22.90

A levelized forced outage rate is used to account forforced outages.

The minimum and maximum ratings of units are adiustedby multiplying by the factor (1-equivalent forced outage rate)to consider the unavailability of the units. The adjustedratings are used as the minimum and maximum ratings of theunits. The monthly energy demand is given in Table 6.

TABLE 6. ENERGY DEMAND

Energy DemandMonth (X 1,000 MWhr)

1003

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

1312

1271

1026

1208

1190

1285

1693

1701

1281

1016

1194

1361

1004

4. Results

The amount of coal from various sources to generatethe required power output subject to the SO2 constraint is

determined using linear programming. The MathmeticalProgramming System Extended Software package, MPSX/370,available on the University of Missouri Computing Networkwas utilized.

If the coal inventory is below the minimum requiredlevels for both the plants, then eq (5) has to be eliminatedfrom the linear programming formulation. Two cases are

studied, the first case assumes that there is no inventory tobegin with and the second case considers inventory for eachunit. Each case is run with both a one slope and a two slopeapproximation for the input-output curve. The results for thefirst case are shown in tables 7 and 8 for the generating unitinput-output characteristic represented by one slope and twoslope respectively. Tables 9 and 10 present results for thesecond case.

The coal cost figures for both cases is shown in table 11with and without inventory for one slope and two sloperepresentation.

TABLE 7. AMOUNT OF COAL (X 1,000 TONS) FROM DIFFERENT

SOURCES WITHOUT INVENTORY: 1-SLOPE

Scheduled Plant A Plant B

Energy Spot Spot

Producti' n Mines Market Mines Market

Month (MWHxl0 1 2 3 4 5 6 7 SMH SML 1 2 3 4 SMH SML

Jan 1312 16 196 127 7 - 25.6 85 50 2.1

Feb 1271 16 196 127 7 51.6 67.0 85 50

Mar 1026 16 196 127 7 1.6 20.3 85 41.0

Apr 1208 16 196 127 7 36.0 61.3 85 50

May 1190 16 196 127 7 34.8 63.0 85 41.0

Jun 1285 16 196 127 7 51.6 81.3 85 50

Jul 1693 16 196 127 7 71 142. 85 50 9 70.4

Aug 1701 16 196 127 7 71 141. 85 50 9 74.4

Sep 1281 16 196 127 7 68.5 13.1 85 50 50.2

Oct 1016 16 196 127 7 9. 83.0 50

Nov 1194 16 196 127 7 35.3 49.8 85 50 5.9

Dec 136 16 196 127 7 71 25.6 85 50 9 7.9 57.6

1005

TABLE 8. AMOUNT OF COAL (X 1,000 TONS) FROM DIFFERENTSOURCES WITHOUT INVENTORY: 2-SLOPE

Scheduled Plant A Plant BEnergy Spot Spot

Productiqn Mines Market Mines MarketMonth (MWHxlO ) 1_2 3 4 5 6 7 SMH SML 1 2 13 4 SMH SML

Jan 1312 16 196 127 7 71 25.5 85 50 9 34.5 100.2

Feb 1271 16 196 127 7 52.9 65.5 85 50 9.8

Mar 1026 16 196 127 7 10. 31.3 85 41.0

Apr 1208 16 196 127 7 42. 68.9 85 50

May 1190 16 196 127 7 40.4 70.3 85 41.

Jun 1285 16 196 127 7 57.7 89.2 85 50

Jul 1693 16 196 127 7 71 38. 142.1 85 50 9 71.9

Aug 1701 16 196 127 7 71 39. 141.1 85 50 9 75.7

Sep 1281 16 196 127 7 70. 10. 85 50 53.3

Oct 1016 16 196 127 7 3.3 19.2 85 50

Nov 1194 16 196 127 7 39.8 44. 85 50 11.9

Dec 1361 16 196 127 7 71 25.5 85 50 9 |5.5 61.8

TABLE 9. AMOUNT OF COAL (X 1,000 TONS) FROM DIFFERENTSOURCES WITH INVENTORY: 1-SLOPE

Scheduled Plant A_ Plant BEnergy Spot Spot

ProductiSn Mines Inventory Market Mines Inventory MarketMonth (MWHxlO) 1 2 3 4 5 6 7 I1 I2 SMH SML 1 2 3 4 I3 I4 SMH SML

Jan 1312 16 196 76L 1 85 50 29. 4 24.

Feb 1271 16 196 127 7 97I5I85 50 L347 5.

Mar 1026 16 196 127 7 22. 1 85 40.0 1.3

Apr 1208 16 196 127 7 71.0 85 50 25.9 9.2

May 1190 16 196 127 7 34. 63.0 85 41.7

Jun 1285 16 196 127 7 51. 6 81.3 85 50Jul 1693 16 196 127 7 71 8. 142.6 85 50 9 70.4

-Aug l 1701 16 196 127 7 71 9. 141.6 85 50 9 74.4

Sep 1281 16 196 127 7 68.E 13.4 85 50

Oct 1016 16 196 127 7 9.9 83.3 50

Nov 1194 16 196 127 7 35. 49.3 85 50

Dec 1361 16 196 127 7 71 25.6 85 50 9 17.9 57.

1006

TABLE 10. AMOUNT OF COAL (X 1,000 TONS) FROM DIFFERENTSOURCES WITH INVENTORY: 2-SLOPE

Scheduled Plant A Plant BEnergy Spot Spot

Productign Mines Inventory Market Mines Inventory MarketMonth (MWHxlO) 1 2 3 4 5 6 7 II I2 SMH SML 1 2 3 4 I3 I4 SMH SML

Jan 1312 16 196 61. 187 85 50 30.4 27.0

Feb 1271 16 196 127 7 105.0 85 .50 34.8

Mar 1026 16 196 127 7 42.4 85 34.3 8.4

Apr 1208 16 196 127 7 91.5 85 50 29.6

May 1190 16 196 127 7 39.7 71.0 85 40.5 0.6

Jun 1285 16 196 127 7 57.7 89.2 85 50

Jul 1693 16 196 127 7 71 142.1 85 50 9 71.9

Aug 1701 16 196 127 7 71 141.1 85 50 9 75.7

Sep 1281 16 196 127 7 70.E 10.7 85 50

Oct 1016 16 196 127 7 3. 19.2 50

Nov 1194 16 196 127 7 39. ; 44.8 85 50 12.0

Dec 13611 16 196 127 7 71 25.5 85 50 9 5.6 61.8

TABLE 11: COST OF COAL WITH AND WITHOUT INVENTORYFOR 2-SLOPE AND 1-SLOPE UNIT REPRESENTATION

Cost of Coal ($C)Energy With In entory Without Inventory

Month (MWhrxl,000) 2-Slope 1-Slope 2-Slope 1-Slope(1) (2) j (3) (4) (5) (6)i if~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

January

February

March

April

May

June

July

August

September

October

November

December

1312

1271

1026

1208

1190

1285

1693

1701

1281

1016

1194

1361

11890689

12251688

9794968

11812083

11667797

12860170

17806248

17906319

12564983

9520787

11513693

13560411

11808064

12202829

9286079

11448049

11324229

12486085

17767516

17874713

12488580

9153903

11362475

13513251

12963938

12361347

9808171

11892369

11668716

12860170

17806248

17906319

12564983

9520787

11513693

13560411

12874282

12320646

9288198

11530143

11324229

12486085

17767516

17874713

12488580

9153903

11362475

13513251

Annual Cost 153149836 150715773 154427152 1519834021

1007

5. Conclusions

This paper has demonstrated the use of linear prog-gramming to determine the coal acquisition requirements frommultiple sources to generate the required power to serve loadrequirements. The objective is to serve the load at minimumcost, subject to SO2 emission and inventory constraints. Thebasic approach is to meet the SO2 constraint by blending ofhigh and low sulfur coal. The linear programming approachcan be used to determine the coal requirements in a costeffective manner.

Commitments for the coal purchase from particularplants must be made quite far in advance. Once thesecommitments are made the spot market may be the onlychoice for short term coal acquisition. The spot market isusually very expensive and, therefore, is not cost effective.This gives rise to a problem in determining the time periodover which to optimize cost. Economic dispatch routines mayvery well provide daily optimums of generation cost but maynot consider the longer term limits on the acquisition of lowsulfur coal. Further efforts should be made to determine howto best coordinate the short term economic dispatch routinewith the longer term coal acquisition problem.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the support anddirection of Mr. Tom Kennedy and Mr. Frank Buchmeier Jr. ofUnion Electric Co., St. Louis, Missouri.