Nanoporous carbonblackparticlesasanelectrodematerial.pdf

Transcript of Nanoporous carbonblackparticlesasanelectrodematerial.pdf

-

8/13/2019 Nanoporous carbonblackparticlesasanelectrodematerial.pdf

1/3

Nanoporous carbon black particles as an electrode materialfor electrochemical double layer capacitorsMahdi Nasibi a ,c ,n , Mohammad Ali Golozar b , Gholamreza Rashed aa Technical Inspection Engineering Department, Petroleum University of Technology, Abadan, Iranb Department of Materials Engineering, Isfahan University of Technology, Isfahan, Iranc Health and Safety Engineering (HSE) Ofce, National Iranian Oil Rening and Distribution Company (NIORDC), Yazd zone, Yazd, Iran

a r t i c l e i n f o

Article history:Received 27 July 2012Accepted 26 September 2012Available online 5 October 2012

Keywords:Electrode materialElectrochemical double layer capacitorsMicrostructureEnergy storage and conversion

a b s t r a c t

The aim of this work is to investigate the nanoporous carbon black particles as a possible electrodecandidate material for electrochemical double layer capacitors using cyclic voltammetry and electro-chemical impedance spectroscopy tests in 2 M KCl electrolyte at different scan rates. Scanning electronmicroscopy is also used to characterize the microstructure and nature of the produced electrodes whichconrms the nanoporous ( o 10 nm in diameter) structure of the prepared electrodes. This nanoporousstructure increases the specic surface area and electrical resistance of the electrodes, simultaneously.Proposed electrode shows a specic capacitance as high as 33.58 F g 1 , in the potential range from

0.15 to 0.55 V (vs. SCE) at a scan rate of 10 mV s 1 . It shows the low ratio of the outer to total charge(q

*

O /q*

T ) of 0.11 which conrms the low current response. Additionally, charge/discharge cycling testshows good reversibility after 100 cycles.

Crown Copyright & 2012 Published by Elsevier B.V. All rights reserved.

1. Introduction

Explosive growth in electronic equipments and the urgent needfor electronic and hybrid electronic vehicles demand high powerand energy storage devices. Among different energy storage sys-tems, ultracapacitors are recognized as highly attractive energystorage devices to satisfy the above needs [1] . High cycle life, highlife time, high energy efciency and high self-discharge rate aresome of the characteristics of supercapacitors [2,3].

Today, most researches in this area have been focused on thedevelopment of different new porous carbons and porous pseudo-capacitive electrode materials [47]. These porous structures canprovide a very short diffusion pathway for ion as well as largeactive surface area, leading to improved charge storage capabil-ity [6] . According to Ge et al. [7] , one of the signicant properties

of these materials during cycling is the structure and/or volumechanges due to the Faradic reactions, electrolyte decompositionand active material losses. Among different carbon base materials,carbon black is a highly conductive material such that the keyproperties of it are considered to be neness (primary particlesize), structure (aggregate size/shape), porosity, surface chemistryand its low cost [8] . The aim of this work is to investigate thenanoporous carbon black particles as a low cost material forsupercapacitors. Mechanical pressing as a novel, fast and easy

method was used to fabricate the electrodes. Then the productwas evaluated as a possible candidate electrode for electroche-mical double layer capacitors using cyclic voltammetry (CV),electrochemical impedance spectroscopy (EIS) and scanning elec-tron microscopy (SEM).

2. Experimental

Materials : High purity nickel foil (99.99% with 0.125 mmthickness) and polytetrauoroethylene ( o 2 mm) as a polymericbinder were purchased from Aldrich, USA. Nanoporous ( o 10 nmin diameter) carbon black (CB) as an active material ( o 2 mm) waspurchased from Degussa, Germany. All the other chemicals werepurchased from Merck, Germany. The electrode material contain-

ing 90% CB and 10 wt% polytetrauoroethylene was well mixed inethanol to form a paste and it was then pressed onto nickel foil(4 10 7 Pa) which served as a current collector (surface was0.785 cm 2 ). The typical mass load of the electrode material was30 mg. The electrolyte used was 2 M KCl.

Characterization : Electrochemical behavior of the electrodeswas characterized using the CV and EIS tests. The electrochemicalmeasurements were performed using an Autolab (Netherlands)model PGSTAT 302N. The CV test was performed within differentranges of potential, using scan rates of 10, 20, 30, 50, 100 and200 m V s 1 . EIS measurements were carried out in the frequencyrange from 100 kHz to 0.01 Hz at open circuit potential with acamplitude of 10 mV. The specic capacitance C (F g 1 ) of the

Contents lists available at SciVerse ScienceDirect

journal homepage: www.elsevier.com/locate/matlet

Materials Letters

0167-577X/$ - see front matter Crown Copyright & 2012 Published by Elsevier B.V. All rights reserved.

http://dx.doi.org/10.1016/j.matlet.2012.09.088

n Corresponding author. Tel.: 98 9113708480; fax: 98 6314423520.E-mail addresses: [email protected] , [email protected] (M. Nasibi) .

Materials Letters 91 (2013) 323325

http://www.elsevier.com/locate/matlethttp://www.elsevier.com/locate/matlethttp://localhost/var/www/apps/conversion/tmp/scratch_2/dx.doi.org/10.1016/j.matlet.2012.09.088mailto:[email protected]:[email protected]://localhost/var/www/apps/conversion/tmp/scratch_2/dx.doi.org/10.1016/j.matlet.2012.09.088http://localhost/var/www/apps/conversion/tmp/scratch_2/dx.doi.org/10.1016/j.matlet.2012.09.088mailto:[email protected]:[email protected]://localhost/var/www/apps/conversion/tmp/scratch_2/dx.doi.org/10.1016/j.matlet.2012.09.088http://localhost/var/www/apps/conversion/tmp/scratch_2/dx.doi.org/10.1016/j.matlet.2012.09.088http://localhost/var/www/apps/conversion/tmp/scratch_2/dx.doi.org/10.1016/j.matlet.2012.09.088http://www.elsevier.com/locate/matlethttp://www.elsevier.com/locate/matlet -

8/13/2019 Nanoporous carbonblackparticlesasanelectrodematerial.pdf

2/3

-

8/13/2019 Nanoporous carbonblackparticlesasanelectrodematerial.pdf

3/3

Nyquist plots show a double layer capacitance and shift to higherimpedances after 100 cycles. As shown in Fig. 3(b), the point of intersection with the real axis of the Nyquist curves in the rangeof high frequency is the equivalent series resistance (ESR). Itindicates the total resistance of the electrode, the bulk electrolyteresistance and the resistance at the electrolyte/electrode inter-face [4]. After 100 cycles, the anodic and cathodic currentsdecrease, but the C /V curves remain in their rectangular shapedproles ( Fig. 3(a)) and the capacitance decreases only by 11% of the initial capacitance demonstrating good cycle stability. Thedecrease of the specic capacitance could be attributed to theelectrolyte deposition and redox reactions on the electrode sur-face which increase the electrical resistance of the electrodes.

4. Conclusion

In summary, nanoporous carbon black was studied as anelectrode material for electrochemical double layer capacitors.

Two counter acting parameters act simultaneously on these

nanoporous electrodes: increasing the specic surface area inthe presence of the nano-pores and decreasing the electrodeconductivity due to the resistance down the pores. This nano-porous structure shows a double layer characteristic and a lowratio of the outer charge to total charge ( q

*

O /q*

T ) of 0.11 whichconrms the low current response on voltage reversal. Theproposed CB electrode shows specic capacitance as high as33.58 F g 1 in 2 M KCl electrolyte at the scan rate of 10 mV s 1 .Finally, charge/discharge cycling tests conrm a good cyclingperformance of the electrodes.

References

[1] Chau KT, Wong YS, Chan CC. Energy Convers Manage 1999;40:102139.[2] Hadjipaschalis I, Poullikkas A, Efthimiou V. Renew Sustain Energy Rev

2009;13:151322.[3] Sharma P, Bhatti TS. Energy Convers Manage 2010;51:290112.[4] Zhang Y, Feng H, Wu X, Wang L, Zhang A, Xia T, et al. Int J Hydrogen Energy

2009;34:488999.[5] Banerjee N, Krupanidhi SB. J Alloys Compd 2011;509:43815.[6] Rakhi RB, Chen W, Cha D, Alshareef HN. Nano Lett 2012;12(5):255967.[7] Ge M, Rong J, Fang X, Ch Zhou. Nano Lett 2012;12(5):231823.[8] Pandolfo AG, Hollenkamp AF. J Power Sources 2006;157:1127.[9] Babakhani B, Ivey DG. J Power Sources 2010;195:21107.

[10] Donnet JB, Bansal RC, Wang MJ. Carbon black science technology. 2nd ed.New York: Marcel Dekker; 1993.

[11] Conway BE, Pell WG. J Power Sources 2002;105:16981.[12] Nasibi M, Golozar MA, Gh. Rashed. J Power Sources 2012;206:10810.[13] Sun G, Song W, Liu X, Qiao W, Long D, Ling L. Mater Lett 2011;65:13925.[14] Ardizzone S, Fregonara G, Trasatti S. Electrochim Acta 1990;35:2637.

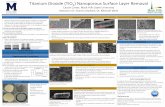

Fig. 2. (a) Capacitance vs. potential curves obtained from different scan rates of CBelectrodes in 2 M KCl electrolyte. Variation of the voltammetric charge density ( q)with respect to scan rates, (b) extrapolation of q to v 0 from the q 1 vs. v0.5 plotgiven the total charge and (c) extrapolation of q to v N from the q vs. v 0.5 plotgiven the outer charge for CB electrodes.

Fig. 3. (a) Representative cyclic voltammograms obtained from CB electrode at10 mV s 1 in 2 M KCl electrolyte. (b) EIS curves obtained from CB electrodes afterand before 100 CV cycles.

M. Nasibi et al. / Materials Letters 91 (2013) 323325 325