NAAMS Locating Pins

description

Transcript of NAAMS Locating Pins

-

05/05/14

I-1

Assembly

TM

LOCATING PINSAND RETAINERS

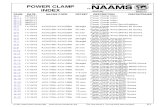

COMPONENTS INDEXPAGE DATE NAAMS CODE DESCRIPTION

I-1 02/12/14 Locating Pins and Retainers Components Index

I-1.1 02/12/14 Locating Pins and Retainers Components Index

I-2 06/23/04 Typical Locating Pin Retainer Assembly

I-3 01/17/06 Typical Locating Pin Retainer Assembly

I-4 02/12/14 APR010MAPR013M Locating Pin Retainers (Full Metric)

I-5 02/12/14 APR020MAPR021M Locating Pin Retainers (Full Metric)

I-6 02/12/14 APR030MAPR033M Locating Pin Retainers (Full Metric)

I-7 02/12/14 APR040MAPR041M Locating Pin Retainers (Full Metric)

I-8 02/12/14 APR050MAPR051M Locating Pin Retainers (Full Metric)

I-9 02/12/14 APR060MAPR063M Locating Pin Retainers (Full Metric)

I-10 02/12/14 APR070MAPR071M Locating Pin Retainers (Full Metric)

I-11 08/29/07 APS061MAPS199M Locating Pin, 6 mm Thru 19 mm Dia. (Full Metric)

I-12 02/12/14 APS061MAPS199M Locating Pin, 6 mm Thru 19 mm Dia. (Full Metric)

I-13 05/05/14 APS250MAPS259M Locating Pin, 25 mm Dia. (Full Metric)

I-14 08/29/07 APE061MAPE199M Locating Pin for 6 x 19 Thru 19 x 25 Slotted Holes(Full Metric)

I-15 02/12/14 APE061M APE199M Locating Pin for 6 x 19 mm Thru 19 x 25 mmSlotted Holes (Full Metric)

I-16 05/05/14 APE250M APE259M Locating Pin for 25 x 31 mm Slotted Holes(Full Metric)

I-17 08/29/07 ARP061M ARP199M Respot Pin, 6 mm Thru 19 mm Dia. (Full Metric)I-18 02/12/14 ARP061M ARP199M Respot Pin, 6 mm Thru 19 mm Dia. (Full Metric)I-19 08/29/07 ARE061M ARE199M Respot Pin for 6 x 12 mm Thru 19 x 25 mm Slotted

Holes (Full Metric)I-20 02/12/14 Discontinued Respot Pin for 6 x 12 mm Thru 19 x 25 mm Slotted

Holes (Full Metric)I-21 04/22/14 Discontinued Locating Pin Retainers

I-22 04/22/14 Discontinued Locating Pin Retainers

I-23 04/22/14 Discontinued Locating Pin Retainers

I-24 04/22/14 Discontinued Locating Pin Retainers

I-25 04/22/14 Discontinued Locating Pin Retainers

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

I-1.2 02/12/14 Locating Pins and Retainers Components Index

-

05/05/14

I-1.1

Assembly

TM

PAGE DATE NAAMS CODE DESCRIPTIONI-26 04/22/14 Discontinued Locating Pin Retainers

I-27 04/22/14 Discontinued Locating Pin Retainers

I-28 02/12/14 Discontinued Locating Pin 6 mm Thru 19 mm Dia.

I-29 04/22/14 Discontinued Locating Pin 6 mm Thru 19 mm Dia.

I-30 02/12/14 Discontinued Locating Pin 25 mm Dia.

I-31 02/12/14 Discontinued Locating Pin for 6 x 12 mm Thru 19 x 25 mm Slotted Holes

I-32 04/22/14 Discontinued Locating Pin for 6 x 12 mm Thru 19 x 25 mm Slotted Holes

I-33 02/12/14 Discontinued Locating Pin for 25 x 31 mm Slotted Holes

I-34 05/05/14 ARP250MARP259M Respot Pin 25 mm Dia. (Full Metric)

I-35 08/29/07 APQ081APQ208 Locating Pin 8 mm Thru 20 mm Dia. (Full Metric)

I-36 02/12/14 APQ081APQ208 Locating Pin 8 mm Thru 20 mm Dia. (Full Metric)

I-37 08/29/07 APQ251APQ408 Locating Pin 25 mm Thru 40 mm Dia. (Full Metric)

I-38 02/12/14 APQ251APQ408 Locating Pin 25 mm Thru 40 mm Dia. (Full Metric)

I-39 04/22/14 Discontinued Locating Pin Retainer (Full Metric) 20mm Series

I-40 04/22/14 Discontinued Locating Pin Retainer (Full Metric) 20mm Series

I-41 02/12/14 APR330MAPR333M Locating Pin Retainer (Full Metric) 20mm Series

I-42 02/12/14 APR045MAPR046M Locating Pin Retainer (Full Metric) 20mm Series

I-43 04/22/14 Discontinued Locating Pin Retainer (Full Metric) 20mm Series

I-44 04/22/14 Discontinued Locating Pin Retainer (Full Metric) 20mm Series

I-45 02/12/14 APR075MAPR076M Locating Pin Retainer (Full Metric) 20mm Series

I-46 04/22/14 Discontinued Locating Pin Retainer (Full Metric) 20mm Series

I-47 02/12/14 APR336MAPR339M Locating Pin Retainer (Full Metric) 20mm SeriesI-48 04/22/14 Discontinued Locating Pin Retainer (Full Metric) 20mm SeriesI-49 04/22/14 Discontinued Locating Pin Retainer (Full Metric) 20mm SeriesI-50 02/12/14 APR077MAPR078M Locating Pin Retainer (Full Metric) 20mm Series

LOCATING PINSAND RETAINERS

COMPONENTS INDEX

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

I-51 02/12/14 APR250MAPR253M Locating Pin Retainer (Full Metric) 20mm SeriesI-52 02/12/14 APR255MAPR256M Locating Pin Retainer (Full Metric) 20mm Series

I-53 02/12/14 APR201MAPR204M Locating Pin Retainer (Full Metric) 20mm SeriesI-54 02/12/14 APR211MAPR212M Locating Pin Retainer (Full Metric) 20mm Series

02/12/14 APR260MAPR261M Locating Pin Retainer (Full Metric) 20mm SeriesI-55

-

02/12/14

I-1.2

Assembly

TM

PAGE DATE NAAMS CODE DESCRIPTION

LOCATING PINSAND RETAINERS

COMPONENTS INDEX

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

I-56 02/12/14 APR265MAPR268M Locating Pin Retainer (Full Metric) 20mm SeriesI-57 02/12/14 APR221MAPR222M Locating Pin Retainer (Full Metric) 20mm Series

I-58 02/12/14 APR271MAPR274M Locating Pin Retainer (Full Metric) 20mm SeriesI-59 02/12/14 APR231MAPR234M Locating Pin Retainer (Full Metric) 20mm Series

02/12/14 APR276MAPR277M Locating Pin Retainer (Full Metric) 20mm SeriesI-60I-61 02/12/14 APR280MAPR283M Locating Pin Retainer (Full Metric) 20mm Series

02/12/14 APR241MAPR242M Locating Pin Retainer (Full Metric) 20mm SeriesI-62

-

G L O B A L S TA N D A R D C O M P O N E N T S

I 4

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.020

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACK OXIDE FINISH.

L

8H6 (2) HOLES

15.00

9.0

30.000

49.0REF.

0.73

0.31

0. 31

35.040.0

5.0

000.52

A

0L

0L1.0 x 45

25.0REF.

12.50

10.0

0

12.50

+0.0

3-0

.00

+0.015 -0.00

16.00

0L

0L

XXX

CODEAPR010MAPR011MAPR012MAPR013M

LOCATING PIN RETAINERS(FULL METRIC)

APR010M, 011M, 012M, 013M 02/12/14

A

B

D

C

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

NAAMSkgWT.

A MATERIALSteel / ASTM A-36M10 x 1.5

M10 x 1.5Steel / ASTM A-3611.0SS type 303 or 30411.0

SS type 303 or 3040.320.320.320.32

SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHART

E

NO BLACK OXIDE FINISH TO SS TYPE COMPONENTSF

-

G L O B A L S TA N D A R D C O M P O N E N T S

I 5

AssemblyTM

LOCATING PIN RETAINERS(FULL METRIC)APR020M, 021M

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.020

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACK OXIDE FINISH.

L

8H6(2) HOLES

M10 x 1.5

15.00

12.5

49.0REF.

40.035.0

13.0

50.0REF.

9.0

5.0

30.000

12.5

0L

0L 0L

13.0

37.0

0

1.0 x 45

0L

25.0REF.

16.00

10.0

0+0.0

3-0

.00

+0.015 -0.00

XXX

02/12/14

A

CODEAPR020MAPR021M C

B

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

NAAMSkgWT.

MATERIALSteel / ASTM A-36SS type 303 or 304

0.320.32

SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHART

D

NO BLACK OXIDE FINISH TO SS TYPE COMPONENTSE

-

G L O B A L S TA N D A R D C O M P O N E N T S

I 6

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.020

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACK OXIDE FINISH.

L

8H6(2) HOLES (2) HOLES

64.0REF.

55.0

20.0

45.00

15.00

9.0

30.000

50.0REF.

37.0

50.0

13.0

13.0

0L

25.0

00

A

1.0 x 45

25.0REF.

12.50

12.50

0L

0L

16.00

10.0

0+0.

03-0

.00

+0.015 -0.00

XXX

LOCATING PIN RETAINERS(FULL METRIC)

APR030M, 031M, 032M, 033M 02/12/14

A

CODEAPR030MAPR031MAPR032MAPR033M

C

B

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

NAAMSkgWT.

A MATERIALSteel / ASTM A-36M10 x 1.5

M10 x 1.5Steel / ASTM A-3611.0SS type 303 or 30411.0

SS type 303 or 3040.450.450.450.45

SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHART

D

NO BLACK OXIDE FINISH TO SS TYPE COMPONENTSE

-

G L O B A L S TA N D A R D C O M P O N E N T S

I 7

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.020

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACK OXIDE FINISH.

LOCATING PIN RETAINERS(FULL METRIC)APR040M, 041M

L

M10 x 1.5(2) HOLES

8H6(2) HOLES

45.00

15.00

9.0

30.000

13.0

50.0REF.

64.0REF.

55.050.0

20.0

12.5

12.5

0L0L0L

0L

13.0

37.0

0

1.0 x 45

25.0REF.

10.0

0+0.

03-0

.00

16.00+0.015 -0.00

XXX

02/12/14

A

CODEAPR040MAPR041M

C

B

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

NAAMSkgWT.

MATERIALSteel / ASTM A-36SS type 303 or 304

0.450.45

SEE PAGE B-1.1 FORGLOBAL MATERIALS CHART

D

NO BLACK OXIDE FINISH TO SS TYPE COMPONENTS

E

-

G L O B A L S TA N D A R D C O M P O N E N T S

I 8

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.020BETWEEN DOWELS 0.015

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACK OXIDE FINISH.

L

8H6(2) HOLES

11.00

35.0REF.

30.0

0

10.00

00.51 9.0

20.075.0REF.

15.0

0L

0L

1.0 x 45

12.50

25.0REF.

12.50

0L

10.00+0.03-0.00

0.66

16.0000.55

+0.015 -0.00

XXX

LOCATING PIN RETAINERS(FULL METRIC)APR050M, 051M 02/12/14

A

CODEAPR050MAPR051M C

B

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

NAAMSkgWT.

MATERIALSteel / ASTM A-36SS type 303 or 304

0.410.41

SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHART

D

NO BLACK OXIDE FINISH TO SS TYPE COMPONENTS E

-

G L O B A L S TA N D A R D C O M P O N E N T S

I 9

AssemblyTM

LOCATING PIN RETAINERS(FULL METRIC)

APR060M, 061M, 062M, 063MTolerances: 1 PLACE 0.3

2 PLACE 0.033 PLACE 0.020BETWEEN DOWELS 0.015

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACK OXIDE FINISH.

L

Drill & C/Bore for M10 SHCS

75.0REF.

30.0

0L

35.0

1.0 x 45

20.0

8H6(2) HOLES

A9.

0

12.530

.00

15.0

012.5

66.0

0L

0L

16.00

25.0REF.

55.0

0

+0.015 -0.00

XXX

10.00+0.03-0.00

02/12/14

A

C

B

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

CODEAPR060MAPR061MAPR062MAPR063M

NAAMSkgWT.

A MATERIALSteel / ASTM A-36M10 x 1.5

M10 x 1.5Steel / ASTM A-36SS type 303 or 304

SS type 303 or 3040.410.410.410.41Drill & C/Bore for M10 SHCS

SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHART

D

NO BLACK OXIDE FINISH TO SS TYPE COMPONENTSE

-

G L O B A L S TA N D A R D C O M P O N E N T S

I 10

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.020BETWEEN DOWELS 0.015

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACK OXIDE FINISH.

L

LOCATING PIN RETAINERS(FULL METRIC)APR070M, 071M 02/12/14

A

8H6(2) HOLES

11.0(2) HOLES

35.0REF.

30.0

0

10.00

00.51

9.0

20.090.0REF.

15.0

0L

0L

1.0 x 45

00. 5412.50

25.0REF.

0L12.50

81.0

16.00

70.0

0+0.015 -0.00

XXX

10.00+0.03-0.00

CODEAPR070MAPR071M C

B

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

NAAMSkgWT.

MATERIALSteel / ASTM A-36SS type 303 or 304

0.450.45

SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHART

D

NO BLACK OXIDE FINISH TO SS TYPE COMPONENTS

E

-

DB RADIUS

C RADIUS

A

5.0

15.98

1.0 - 2.0 R

0.50 - 0.75 R

L REF.

28.0

1.0 X 45

M10 X 1.5 x 17.0 DEEP24.0 MAX DRILL DEPTH

+0.00 -0.01

+0.00 -0.02

0.5 x 45

A

B

LEAVE THISEND SOFT

22.0

10.00TYP.

+0.00 -0.03

G

XXX

G L O B A L S TA N D A R D C O M P O N E N T S

I 11

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.015

ALL MACHINED SURFACES TO FLAT.

LOCATING PIN 6mm THRU 19mm DIAMETER

08/29/07

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

TABULATED INFORMATION ON FOLLOWING PAGE

o

o

PARALLEL AND PERPINDICULAR TO WITHIN0.015 T.I.R. TO DATUMS A AND B ANDCONCENTRIC TO WITHIN 0.03 T.I.R.

MATERIAL: S.A.E. 8620 STEELHARDNESS: 58 - 62 Rc TO A DEPTH OF 0.5 - 0.7 mm

AFTER GRINDINGNOTE: IDENTIFY WITH NAAMS CODE NUMBER AS

SHOWN XXX.SEE PAGE B-1.1 FORGLOBAL MATERIALS CHART

(FULL METRIC)

F

A

H

D

D

B

E

C

G

-

02/12/14

I-12

Assembly

TM

LOCATING PIN6 mm THRU 19 mm DIAMETER

(FULL METRIC)

A

C

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

B

NAAMSCODE A L

WT.kg

APS061M

APS062M

APS063M

APS064M

APS065M

APS066M

TiNCODE

TiNCODE

TiNCODE

TiNCODE

TiNCODE

TiNCODE

TiNCODE

APS061MT

APS062MT

APS063MT

APS064MT

APS065MT

APS066MT

15.0

20.0

30.0

40.0

50.0

60.0

51.8

56.8

66.8

76.8

86.8

96.8

0.05

0.05

0.05

0.05

0.06

0.06

6 mm Round HoleB Rad = 1.0C Rad = 18.0D = 5.85

8 mm Round HoleB Rad = 1.0C Rad = 24.0D = 7.85

NAAMSCODE A L

WT.kg

APS081M

APS082M

APS083M

APS084M

APS085M

APS086M

15.0

20.0

30.0

40.0

50.0

60.0

55.1

60.1

70.1

80.1

90.1

100.1

0.05

0.05

0.06

0.06

0.06

0.07

APS087M

APS088M

APS081MT

APS082MT

APS083MT

APS084MT

APS085MT

APS086MT

APS087MT

APS088MT

70.0

80.0

110.1

120.1

0.07

0.08

10 mm Round HoleB Rad = 2.0C Rad = 30.0D = 9.85

NAAMSCODE A L

WT.kg

APS101M

APS102M

APS103M

APS104M

APS105M

APS106M

15.0

20.0

30.0

40.0

50.0

60.0

57.4

62.4

72.4

82.4

92.4

102.4

0.06

0.06

0.07

0.07

0.08

0.08

APS107M

APS108M

70.0

80.0

112.4

122.4

0.09

0.10

APS109M

APS100M

APS101MT

APS102MT

APS103MT

APS104MT

APS105MT

APS106MT

APS107MT

APS108MT

APS109MT

APS100MT

90.0

100.0

132.4

142.4

0.10

0.11

13 mm Round HoleB Rad = 2.0C Rad = 39.0D = 12.85

NAAMSCODE A L

WT.kg

APS131M

APS132M

APS133M

APS134M

APS135M

APS136M

15.0

20.0

30.0

40.0

50.0

60.0

62.4

67.4

77.4

87.4

97.4

107.4

0.07

0.07

0.08

0.09

0.10

0.11

APS137M

APS138M

70.0

80.0

117.4

127.4

0.12

0.13

APS139M

APS130M

APS131MT

APS132MT

APS133MT

APS134MT

APS135MT

APS136MT

APS137MT

APS138MT

APS139MT

APS130MT

90.0

100.0

137.4

147.4

0.14

0.15

16 mm Round HoleB Rad = 2.0C Rad = 48.0D = 15.85

NAAMSCODE A L

WT.kg

APS161M

APS162M

APS163M

APS164M

APS165M

APS166M

15.0

20.0

30.0

40.0

50.0

60.0

67.5

72.5

82.5

92.5

102.5

112.5

0.09

0.09

0.11

0.13

0.14

0.16

APS167M

APS168M

70.0

80.0

122.5

132.5

0.17

0.19

APS169M

APS160M

APS161MT

APS162MT

APS163MT

APS164MT

APS165MT

APS166MT

APS167MT

APS168MT

APS169MT

APS160MT

90.0

100.0

142.5

152.5

0.20

0.22

19 mm Round HoleB Rad = 2.0C Rad = 38.0D = 18.85

NAAMSCODE A L

WT.kg

APS191M

APS192M

APS193M

APS194M

APS195M

APS196M

15.0

20.0

30.0

40.0

50.0

60.0

66.8

71.8

81.8

91.8

101.8

111.8

0.10

0.12

0.14

0.16

0.18

0.20

APS197M

APS198M

70.0

80.0

121.8

131.8

0.22

0.24

APS199M

APS190M

APS191MT

APS192MT

APS193MT

APS194MT

APS195MT

APS196MT

APS197MT

APS198MT

APS199MT

APS190MT

90.0

100.0

141.8

151.8

0.27

0.29

12 mm Round Hole B Rad = 2.0 C Rad = 36.0 D = 11.85

NAAMS CODE A L

WT. kg

APS121M 15.0 60.8 0.07 APS122M 20.0 65.8 0.07 APS123M 30.0 75.8 0.08 APS124M 40.0 85.8 0.09 APS125M 50.0 95.8 0.10 APS126M 60.0 105.8 0.11 APS127M 70.0 115.8 0.12 APS128M 80.0 125.8 0.13 APS129M 90.0 135.8 0.13 APS120M

APS121MTAPS122MTAPS123MTAPS124MTAPS125MTAPS126MTAPS127MTAPS128MTAPS129MTAPS120MT 100.0 145.8 0.14

-

2.0 RADIUS

50.0 RADIUS

1.0 X 45

M10 X 1.5 x 17.0 DEEP24.0 MAX DRILL DEPTH

28.0

6.0

0.50 - 0.75 R

15.98+0.00 -0.01

A

B

G L REF.

LEAVE THISEND SOFT

XXX

24.85+0.00 -0.02

10.00TYP.

+0.00 -0.03

0.5 x 45 A

G L O B A L S TA N D A R D C O M P O N E N T S

I 13

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.015

ALL MACHINED SURFACES TO FLAT.

LOCATING PIN 25mm DIAMETER

05/05/14

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

PARALLEL AND PERPINDICULAR TO WITHIN0.015 T.I.R. TO DATUMS A AND B ANDCONCENTRIC TO WITHIN 0.03 T.I.R.

MATERIAL: S.A.E. 8620 STEELHARDNESS: 58 - 62 Rc TO A DEPTH OF 0.5 - 0.7 mm

AFTER GRINDINGNOTE: IDENTIFY WITH NAAMS CODE NUMBER AS

SHOWN XXX.SEE PAGE B-1.1 FORGLOBAL MATERIALS CHA0RT

(FULL METRIC)

F

A

J

D

D

B

E

C

H

o

o

I

APS251M APS251MT 15.0 74.8 0.15

APS252M APS252MT 20.0 79.8 0.17

APS253M APS253MT 30.0 89.8 0.21

APS254M APS254MT 40.0 99.8 0.24

APS255M APS255MT 50.0 109.8 0.28

APS256M APS256MT 60.0 119.8 0.32

APS257M APS257MT 70.0 129.8 0.36

APS258M APS258MT 80.0 139.8 0.39

APS259M APS259MT 90.0 149.8 0.43

APS250M APS250MT 100.0 159.8 0.47

NAAMSCODE A L

WTkg

TiNCODE

K

-

M10 x 1.5 x 17.0 DEEP24.0 MAX DRILL DEPTH

D 25.0

B RADIUS

C RADIUS

A

5.0

15.98

1.0 - 2.0 R

0.5 - 0.75 R

L REF.

28.0

1.0 X 45 +0.00 -0.01

5.0(MAX)0.5 x 45

A

B

GG

XXX

+0.30 -0.00

EFLAT

+0.00 -0.02

G

G

10.00 TYP.+0.00 -0.03

LEAVE THISEND SOFT

G L O B A L S TA N D A R D C O M P O N E N T S

I 14

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.015

ALL MACHINED SURFACES TO FLAT.

LOCATING PIN FOR 6 x 12 THRU 19 x 25 mm

08/29/07

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

TABULATED INFORMATION ON FOLLOWING PAGE

o

PARALLEL AND PERPINDICULAR TO WITHIN0.015 T.I.R. TO DATUMS A AND B ANDCONCENTRIC TO WITHIN 0.03 T.I.R.

MATERIAL: S.A.E. 8620 STEELHARDNESS: 58 - 62 Rc TO A DEPTH OF 0.5 - 0.7 mm

AFTER GRINDINGNOTE: IDENTIFY WITH NAAMS CODE NUMBER AS

SHOWN XXX.SEE PAGE B-1.1 FORGLOBAL MATERIALS CHART

SLOTTED HOLES (FULL METRIC)

E

A

G

D

B

C

F

o

-

02/12/14

I-15

Assembly

TM

LOCATING PINFOR 6 x 12 THRU 19 x 25 mm

SLOTTED HOLES(FULL METRIC)

NAAMSCODE

TiNCODE A L

WT.kg

APE061M

APE062M

APE063M

APE064M

APE065M

APE066M

APE061MT

APE062MT

APE063MT

APE064MT

APE065MT

APE066MT

15.0

20.0

30.0

40.0

50.0

60.0

52.9

57.9

67.9

77.9

87.9

97.9

0.05

0.05

0.05

0.06

0.06

0.06

6 x 12 Slotted HoleB Rad = 1.0C Rad = 18.0D = 7.09E = 5.85

8 x 14 Slotted HoleB Rad = 1.0C Rad = 24.0D = 8.81E = 7.85

NAAMSCODE

TiNCODE

TiNCODEA L

WT.kg

APE081M

APE082M

APE083M

APE084M

APE085M

APE086M

15.0

20.0

30.0

40.0

50.0

60.0

56.0

61.0

71.0

81.0

91.0

101.0

0.05

0.06

0.06

0.07

0.07

0.08

APE087M

APE088M

APE081MT

APE082MT

APE083MT

APE084MT

APE085MT

APE086MT

APE087MT

APE088MT

70.0

80.0

111.0

121.0

0.08

0.08

10 x 16 Slotted HoleB Rad = 2.0C Rad = 30.0D = 10.63E = 9.85

NAAMSCODE A L

WT.kg

APE101M

APE102M

APE103M

APE104M

APE105M

APE106M

15.0

20.0

30.0

40.0

50.0

60.0

58.2

63.2

73.2

83.2

93.2

103.2

0.06

0.06

0.07

0.08

0.08

0.09

APE107M

APE108M

70.0

80.0

113.2

123.2

0.10

0.10

APE109M

APE100M

APE101MT

APE102MT

APE103MT

APE104MT

APE105MT

APE106MT

APE107MT

APE108MT

APE109MT

APE100MT

90.0

100.0

133.2

143.2

0.11

0.12

13 x 19 Slotted HoleB Rad = 2.0C Rad = 39.0D = 13.46E = 12.85

NAAMSCODE

TiNCODE

TiNCODE

TiNCODEA L

WT.kg

APE131M

APE132M

APE133M

APE134M

APE135M

APE136M

15.0

20.0

30.0

40.0

50.0

60.0

63.1

68.1

78.1

88.1

98.1

108.1

0.07

0.08

0.09

0.10

0.11

0.12

APE137M

APE138M

70.0

80.0

118.1

128.1

0.13

0.14

APE139M

APE130M

APE131MT

APE132MT

APE133MT

APE134MT

APE135MT

APE136MT

APE137MT

APE138MT

APE139MT

APE130MT

90.0

100.0

138.1

148.1

0.16

0.17

16 x 22 Slotted HoleB Rad = 2.0C Rad = 48.0D = 16.35E = 15.85

NAAMSCODE A L

WT.kg

APE161M

APE162M

APE163M

APE164M

APE165M

APE166M

15.0

20.0

30.0

40.0

50.0

60.0

68.0

73.0

83.0

93.0

103.0

113.0

0.09

0.10

0.11

0.13

0.15

0.16

APE167M

APE168M

70.0

80.0

123.0

133.0

0.18

0.20

APE169M

APE160M

APE161MT

APE162MT

APE163MT

APE164MT

APE165MT

APE166MT

APE167MT

APE168MT

APE169MT

APE160MT

90.0

100.0

143.0

153.0

0.21

0.23

19 x 25 Slotted HoleB Rad = 2.0C Rad = 38.0D = 19.27E = 18.85

NAAMSCODE A L

WT.kg

APE191M

APE192M

APE193M

APE194M

APE195M

APE196M

15.0

20.0

30.0

40.0

50.0

60.0

67.2

72.2

82.2

92.2

102.2

112.2

0.11

0.12

0.14

0.16

0.19

0.21

APE197M

APE198M

70.0

80.0

122.2

132.2

0.23

0.25

APE199M

APE190M

APE191MT

APE192MT

APE193MT

APE194MT

APE195MT

APE196MT

APE197MT

APE198MT

APE199MT

APE190MT

90.0

100.0

142.2

152.2

0.28

0.30

A

B

D

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

C

12 x 18 Slotted Hole

B Rad = 2.0 C Rad = 36.0

D = 12.50 E = 11.85

NAAMS CODE

TiNCODE A L

WT. kg

APE121M 15.0 62.2 0.07 APE122M 20.0 67.2 0.07 APE123M 30.0 77.2 0.08 APE124M 40.0 87.2 0.09 APE125M 50.0 97.2 0.10 APE126M 60.0 107.2 0.11 APE127M 70.0 117.2 0.12 APE128M 80.0 127.2 0.13 APE129M 90.0 137.2 0.14 APE120M

APE121MTAPE122MTAPE123MTAPE124MTAPE125MTAPE126MTAPE127MTAPE128MTAPE129MTAPE120MT 100.0 147.2 0.15

-

G L O B A L S TA N D A R D C O M P O N E N T S

I 16

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.015

ALL MACHINED SURFACES TO FLAT.

LOCATING PIN FOR 25 x 31 mm

05/05/14

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

PARALLEL AND PERPINDICULAR TO WITHIN0.015 T.I.R. TO DATUMS A AND B ANDCONCENTRIC TO WITHIN 0.03 T.I.R.

MATERIAL: S.A.E. 8620 STEELHARDNESS: 58 - 62 Rc TO A DEPTH OF 0.5 - 0.7 mm

AFTER GRINDINGNOTE: IDENTIFY WITH NAAMS CODE NUMBER AS

SHOWN XXX.SEE PAGE B-1.1 FORGLOBAL MATERIALS CHART

SLOTTED HOLES (FULL METRIC)

F

A

I

D

B

C

E

G

H

o

M10 x 1.5 TAP17.0 DEEP24.0 MAXDRILL DEPTH

2.0 RADIUS

50.0RADIUS

1.0 X 45

28.0

6.0

A

0.50 - 0.75 R

15.98+0.00 -0.01

5.0 MAX

A

B

G

25.1724.85FLAT

+0.00 -0.02

XXX

G

G

+0.00 -0.02

G

10.00+0.00 -0.03

10.00+0.00 -0.03

L REF.

LEAVE THISEND SOFT

0.5x45

o

J

APE251M APE251MT 15.0 75.1 0.15

APE252M APE252MT 20.0 80.1 0.17

APE253M APE253MT 30.0 90.1 0.21

APE254M APE254MT 40.0 100.1 0.25

APE255M APE255MT 50.0 110.1 0.29

APE256M APE256MT 60.0 120.1 0.33

APE257M APE257MT 70.0 130.1 0.37

APE258M APE258MT 80.0 140.1 0.40

APE259M APE259MT 90.0 150.1 0.44

APE250M APE250MT 100.0 160.1 0.48

NAAMSCODE A L

WTkg

TiNCODE

-

G L O B A L S TA N D A R D C O M P O N E N T S

I 17

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.015

ALL MACHINED SURFACES TO FLAT.

LOCATING PIN 6mm THRU 19mm DIAMETER

08/29/07

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

NOTE: DIMENSIONS FOR THIS SERIES OF PINS ARE THE SAME AS FOR THE LOCATING PINS. 6mmTHRU 19mm DIAMETER EXCEPT FOR TABULATED INFORMATION ON THE FOLLOWING PAGE

o

PARALLEL AND PERPINDICULAR TO WITHIN0.015 T.I.R. TO DATUMS A AND B ANDCONCENTRIC TO WITHIN 0.03 T.I.R.

MATERIAL: S.A.E. 8620 STEELHARDNESS: 58 - 62 Rc TO A DEPTH OF 0.5 - 0.7 mm

AFTER GRINDINGNOTE: IDENTIFY WITH NAAMS CODE NUMBER AS

SHOWN XXX.SEE PAGE B-1.1 FORGLOBAL MATERIALS CHART

(FULL METRIC)

E

A

G

B

D

C

F

D 25.0

B RADIUS

C RADIUS

A

5.0

15.98

1.0 - 2.0 R

0.50 - 0.75 R

L REF.

28.0

1.0 X 45

M10 x 1.5 x 17.0 DEEP24.0 MAX DRILL

+0.00 -0.01

+0.00 -0.02

0.5 x 45

A

B

G

XXX

10.00+0.00 -0.03

LEAVE THISEND SOFT

o

-

02/12/14

I-18

Assembly

TMRESPOT PIN

6 mm THRU 19 mm DIAMETER

NAAMSCODE

TiNCODE

TiNCODE

TiNCODEA L

WT.kg

ARP061M

ARP062M

ARP063M

ARP064M

ARP065M

ARP066M

ARP061MT

ARP062MT

ARP063MT

ARP064MT

ARP065MT

ARP066MT

15.0

20.0

30.0

40.0

50.0

60.0

51.8

56.8

66.8

76.8

86.8

96.8

0.05

0.05

0.05

0.05

0.05

0.06

6 mm Round HoleB Rad = 1.0C Rad = 18.0D = 5.72

8 mm Round HoleB Rad = 1.0C Rad = 24.0D = 7.72

NAAMSCODE A L

WT.kg

ARP081M

ARP082M

ARP083M

ARP084M

ARP085M

ARP086M

15.0

20.0

30.0

40.0

50.0

60.0

55.1

60.1

70.1

80.1

90.1

100.1

0.05

0.05

0.06

0.06

0.06

0.07

ARP087M

ARP088M

ARP081MT

ARP082MT

ARP083MT

ARP084MT

ARP085MT

ARP086MT

ARP087MT

ARP088MT

70.0

80.0

110.1

120.1

0.07

0.08

10 mm Round HoleB Rad = 2.0C Rad = 30.0D = 9.72

NAAMSCODE A L

WT.kg

ARP101M

ARP102M

ARP103M

ARP104M

ARP105M

ARP106M

15.0

20.0

30.0

40.0

50.0

60.0

57.4

62.4

72.4

82.4

92.4

102.4

0.06

0.06

0.07

0.07

0.08

0.08

ARP107M

ARP108M

70.0

80.0

112.4

122.4

0.09

0.09

ARP109M

ARP100M

ARP101MT

ARP102MT

ARP103MT

ARP104MT

ARP105MT

ARP106MT

ARP107MT

ARP108MT

ARP109MT

ARP100MT

90.0

100.0

132.4

142.4

0.10

0.11

13 mm Round HoleB Rad = 2.0C Rad = 39.0D = 12.72

NAAMSCODE A L

WT.kg

ARP131M

ARP132M

ARP133M

ARP134M

ARP135M

ARP136M

15.0

20.0

30.0

40.0

50.0

60.0

62.4

67.4

77.4

87.4

97.4

107.4

0.07

0.07

0.08

0.09

0.10

0.11

ARP137M

ARP138M

70.0

80.0

117.4

127.4

0.12

0.13

ARP139M

ARP130M

TiNCODE

TiNCODE

TiNCODE

ARP131MT

ARP132MT

ARP133MT

ARP134MT

ARP135MT

ARP136MT

ARP137MT

ARP138MT

ARP139MT

ARP130MT

90.0

100.0

137.4

147.4

0.14

0.15

16 mm Round HoleB Rad = 2.0C Rad = 48.0D = 15.72

NAAMSCODE A L

WT.kg

ARP161M

ARP162M

ARP163M

ARP164M

ARP165M

ARP166M

15.0

20.0

30.0

40.0

50.0

60.0

67.5

72.5

82.5

92.5

102.5

112.5

0.08

0.09

0.10

0.12

0.13

0.15

ARP167M

ARP168M

70.0

80.0

122.5

132.5

0.16

0.18

ARP169M

ARP160M

ARP161MT

ARP162MT

ARP163MT

ARP164MT

ARP165MT

ARP166MT

ARP167MT

ARP168MT

ARP169MT

ARP160MT

90.0

100.0

142.5

152.5

0.20

0.21

19 mm Round HoleB Rad = 2.0C Rad = 38.0D = 18.72

NAAMSCODE A L

WT.kg

ARP191M

ARP192M

ARP193M

ARP194M

ARP195M

ARP196M

15.0

20.0

30.0

40.0

50.0

60.0

66.8

71.8

81.8

91.8

101.8

111.8

0.10

0.11

0.14

0.16

0.18

0.20

ARP197M

ARP198M

70.0

80.0

121.8

131.8

0.22

0.24

ARP199M

ARP190M

ARP191MT

ARP192MT

ARP193MT

ARP194MT

ARP195MT

ARP196MT

ARP197MT

ARP198MT

ARP199MT

ARP190MT90.0

100.0

141.8

151.8

0.26

0.28

A

C

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

12 mm Round Hole B Rad = 2.0 C Rad = 36.0 D = 11.72

NAAMS CODE

TiN CODE A L

WT. kg

ARP121M 15.0 60.8 0.07 ARP122M 20.0 65.8 0.07 ARP123M 30.0 75.8 0.08 ARP124M 40.0 85.8 0.08 ARP125M 50.0 95.8 0.09 ARP126M 60.0 105.8 0.10 ARP127M 70.0 115.8 0.11 ARP128M 80.0 125.8 0.12 ARP129M 90.0 135.8 0.13 ARP120M

ARP121MTARP122MTARP123MTARP124MTARP125MTARP126MTARP127MTARP128MTARP129MTARP120MT 100.0 145.8 0.14

B

-

M10 x 1.5 x 17.0 DEEP24.0 MAX DRILL DEPTH

D 25.0

B RADIUS

C RADIUS

A

5.0

15.98

1.0 - 2.0 R

0.5 - 0.75 R

L REF.

28.0

1.0 X 45 +0.00 -0.01

5.0(MAX)0.5 x 45

A

B

GG

XXX

+0.30 -0.00

EFLAT

+0.00 -0.02

G

G

10.00 TYP.+0.00 -0.03

LEAVE THISEND SOFT

G L O B A L S TA N D A R D C O M P O N E N T S

I 19

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.015

ALL MACHINED SURFACES TO FLAT.

LOCATING PIN FOR 6 x 12 THRU 19 x 25 mm

08/29/07

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

TABULATED INFORMATION ON FOLLOWING PAGE

o

PARALLEL AND PERPINDICULAR TO WITHIN0.015 T.I.R. TO DATUMS A AND B ANDCONCENTRIC TO WITHIN 0.03 T.I.R.

MATERIAL: S.A.E. 8620 STEELHARDNESS: 58 - 62 Rc TO A DEPTH OF 0.5 - 0.7 mm

AFTER GRINDINGNOTE: IDENTIFY WITH NAAMS CODE NUMBER AS

SHOWN XXX.SEE PAGE B-1.1 FORGLOBAL MATERIALS CHART

SLOTTED HOLES (FULL METRIC)

E

A

G

B

D

C

F

o

-

02/12/14

I-20

Assembly

TM

RESPOT PINFOR 6 x 12 THRU 19 x 25 mm

SLOTTED HOLES(FULL METRIC)

NAAMSCODE

TiNCODE A L

WT.kg

ARE061M

ARE062M

ARE063M

ARE064M

ARE065M

ARE066M

ARE061MT

ARE062MT

ARE063MT

ARE064MT

ARE065MT

ARE066MT

15.0

20.0

30.0

40.0

50.0

60.0

52.9

57.9

67.9

77.9

87.9

97.9

0.05

0.05

0.05

0.06

0.06

0.06

6 x 12 Slotted HoleB Rad = 1.0C Rad = 18.0D = 7.09E = 5.72

8 x 14 Slotted HoleB Rad = 1.0C Rad = 24.0D = 8.81E = 7.72

NAAMSCODE

TiNCODE A L

WT.kg

ARE081M

ARE082M

ARE083M

ARE084M

ARE085M

ARE086M

15.0

20.0

30.0

40.0

50.0

60.0

56.0

61.0

71.0

81.0

91.0

101.0

0.05

0.06

0.06

0.07

0.07

0.08

ARE087M

ARE088M

ARE081MT

ARE082MT

ARE083MT

ARE084MT

ARE085MT

ARE086MT

ARE087MT

ARE088MT

70.0

80.0

111.0

121.0

0.08

0.08

10 x 16 Slotted HoleB Rad = 2.0C Rad = 30.0D = 10.63E = 9.72

NAAMSCODE

TiNCODE A L

WT.kg

ARE101M

ARE102M

ARE103M

ARE104M

ARE105M

ARE106M

15.0

20.0

30.0

40.0

50.0

60.0

58.2

63.2

73.2

83.2

93.2

103.2

0.06

0.06

0.07

0.08

0.08

0.09

ARE107M

ARE108M

70.0

80.0

113.2

123.2

0.10

0.10

ARE109M

ARE100M

ARE101MT

ARE102MT

ARE103MT

ARE104MT

ARE105MT

ARE106MT

ARE107MT

ARE108MT

ARE109MT

ARE100MT

90.0

100.0

133.2

143.2

0.11

0.12

13 x 19 Slotted HoleB Rad = 2.0C Rad = 39.0D = 13.46E = 12.72

NAAMSCODE

TiNCODE A L

WT.kg

ARE131M

ARE132M

ARE133M

ARE134M

ARE135M

ARE136M

15.0

20.0

30.0

40.0

50.0

60.0

63.1

68.1

78.1

88.1

98.1

108.1

0.07

0.08

0.09

0.10

0.11

0.12

ARE137M

ARE138M

70.0

80.0

118.1

128.1

0.13

0.14

ARE139M

ARE130M

ARE131MT

ARE132MT

ARE133MT

ARE134MT

ARE135MT

ARE136MT

ARE137MT

ARE138MT

ARE139MT

ARE130MT

90.0

100.0

138.1

148.1

0.16

0.17

16 x 22 Slotted HoleB Rad = 2.0C Rad = 48.0D = 16.35E = 15.72

NAAMSCODE

TiNCODE A L

WT.kg

ARE161M

ARE162M

ARE163M

ARE164M

ARE165M

ARE166M

15.0

20.0

30.0

40.0

50.0

60.0

68.0

73.0

83.0

93.0

103.0

113.0

0.09

0.10

0.11

0.13

0.15

0.16

ARE167M

ARE168M

70.0

80.0

123.0

133.0

0.18

0.20

ARE169M

ARE160M

ARE161MT

ARE162MT

ARE163MT

ARE164MT

ARE165MT

ARE166MT

ARE167MT

ARE168MT

ARE169MT

ARE160MT

90.0

100.0

143.0

153.0

0.21

0.23

19 x 25 Slotted HoleB Rad = 2.0C Rad = 38.0D = 19.27E = 18.72

NAAMSCODE A L

WT.kg

ARE191M

ARE192M

ARE193M

ARE194M

ARE195M

ARE196M

15.0

20.0

30.0

40.0

50.0

60.0

67.2

72.2

82.2

92.2

102.2

112.2

0.11

0.12

0.14

0.16

0.19

0.21

ARE197M

ARE198M

70.0

80.0

122.2

132.2

0.23

0.25

ARE199M

ARE190M

TiNCODE

ARE191MT

ARE192MT

ARE193MT

ARE194MT

ARE195MT

ARE196MT

ARE197MT

ARE198MT

ARE199MT

ARE190MT

90.0

100.0

142.2

152.2

0.28

0.30

A

B

D

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

C

12 x 18 Slotted Hole

B Rad = 2.0 C Rad = 36.0 D = 12.50 E = 11.72

NAAMS CODE

TiN CODE A L

WT. kg

ARE121M 15.0 62.2 0.07 ARE122M 20.0 67.2 0.07 ARE123M 30.0 77.2 0.08 ARE124M 40.0 87.2 0.09 ARE125M 50.0 97.2 0.10 ARE126M 60.0 107.2 0.11 ARE127M 70.0 117.2 0.12 ARE128M 80.0 127.2 0.13 ARE129M 90.0 137.2 0.14 ARE120M

ARE121MTARE122MTARE123MTARE124MTARE125MTARE126MTARE127MTARE128MTARE129MTARE120MT 100.0 147.2 0.15

-

DISCO

NTINU

ED

G L O B A L S TA N D A R D C O M P O N E N T S

I 21

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.020

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACKNO BLACK OXIDE FINISH TO SS TYPE COMPONENTS

OXIDE FINISH.

L

15.00

9.0

30.000

49.0REF.

50.0REF.

0.73

P.F. FOR 5/16 DOWEL(2) HOLES

0.31

0.31

35.040.0

5.0

000.52A

0L

0L1.0 x 45

25.0REF.

12.50

10.0

0

12.50

+0.0

3-0

.00

+0.015 -0.00

16.00 DIA.

0L

0L

XXX

LOCATING PINRETAINERS

APR010, 011, 012, 013 04/22/14

A

B

CODEAPR010APR011APR012APR013 E

D

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

NAAMSkgWT.

A MATERIALSteel / ASTM A-363/8-16 TAP

3/8-16 TAPSteel / ASTM A-3613/32SS type 303 or 30413/32

SS type 303 or 3040.320.320.320.32

C

SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHART

F

G

H

-

DISCO

NTINU

ED

G L O B A L S TA N D A R D C O M P O N E N T S

I 22

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.020

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACKNO BLACK OXIDE FINISH TO "SS TYPE" COMPONENTS.

OXIDE FINISH.

L

P.F. FOR 5/16 DOWEL(2) HOLES

3/8-16 TAP

15.00

12.5

49.0REF.

40.035.0

13.0

50.0REF.

9.0

5.0

30.000

12.5

0L

0L 0L

13.0

37.0

0

1.0 x 45

0L

25.0REF.

16.00 DIA.

10.0

0+0.0

3-0

.00

+0.015 -0.00

XXX

LOCATING PINRETAINERSAPR020, 021 04/22/14

A

CODEAPR020APR021

C

B

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

NAAMSkgWT.

MATERIALSteel / ASTM A-36SS type 303 or 304

0.320.32 D

SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHARTE

F

G

-

G L O B A L S TA N D A R D C O M P O N E N T S

I 23

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.020

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACKNO BLACK OXIDE FINISH TO "SS TYPE" COMPONENTS.

OXIDE FINISH.

L

P.F.FOR 5/16 DOWEL(2) HOLES (2) HOLES

64.0REF.

55.0

20.0

45.00

15.00

9.0

30.000

50.0REF.

37.0

50.0

13.0

13.0

0L

25.0

00

A

1.0 x 45

25.0REF.

12.50

12.50

0L

0L

16.00 DIA.

10.0

0+0.

03-0

.00

+0.015 -0.00

XXX

LOCATING PINRETAINERS

APR030, 031, 032, 033 04/22/14

A

CODEAPR030APR031APR032APR033

C

B

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

NAAMSkgWT.

A MATERIALSteel / ASTM A-363/8-16 TAP

3/8-16 TAPSteel / ASTM A-3613/32SS type 303 or 30413/32

SS type 303 or 3040.450.450.450.45 D

SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHART

E

DISCO

NTINU

EF

DISCO

NTINU

EF.FOR 5/16 DOWEL

DISCO

NTINU

E.FOR 5/16 DOWEL

(2) HOLES

DISCO

NTINU

E(2) HOLES

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E0

DISCO

NTINU

E00

DISCO

NTINU

E0 +

0.03

DISCO

NTINU

E+0

.03

-0.0

0

DISCO

NTINU

E-0

.00

DISCO

NTINU

EX

DISCO

NTINU

EXX

DISCO

NTINU

EXX

DISCO

NTINU

EX DDDD FG

-

DISCO

NTINU

ED

G L O B A L S TA N D A R D C O M P O N E N T S

I 24

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.020

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTE: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACKNO BLACK OXIDE FINISH TO "SS TYPE" COMPONENTS.

OXIDE FINISH.

3/8-16 TAP(2) HOLES

P.F. FOR 5/16 DOWEL(2) HOLES

45.00

15.00

9.0

30.000

13.0

50.0REF.

64.0REF.

55.050.0

20.0

12.5

12.5

0L0L0L

0L

13.0

37.0

0

1.0 x 45

25.0REF.

10.0

0+0.

03-0

.00

16.00 DIA.

+0.015 -0.00

XXX

LOCATING PINRETAINERSAPR040, 041 04/22/14

A

L

CODEAPR040APR041

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

NAAMSkgWT.

MATERIALSteel / ASTM A-36SS type 303 or 304

0.450.45 D

B

CSEE PAGE B-1.1 FORGLOBAL MATERIALS CHART

E

F

G

-

DISCO

NTINU

ED

G L O B A L S TA N D A R D C O M P O N E N T S

I 25

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.020BETWEEN DOWELS 0.015

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACKNO BLACK OXIDE FINISH TO "SS TYPE" COMPONENTS.

OXIDE FINISH.

L

P.F. FOR 5/16 DOWEL(2) HOLES

13/32 DIA.

35.0REF.

30.0

0

10.00

00.51 9.0

20.075.0REF.

15.0

0L

0L

1.0 x 45

12.50

25.0REF.

12.50

0L

10.00+0.03-0.00

0.66

16.00 DIA.00.55

+0.015 -0.00

XXX

LOCATING PINRETAINERSAPR050, 051 04/22/14

A

B

D

E

CCODE

APR050APR051

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

NAAMSkgWT.

MATERIALSteel / ASTM A-36SS type 303 or 304

0.410.41

SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHART F

G

H

-

DISCO

NTINU

ED

G L O B A L S TA N D A R D C O M P O N E N T S

I 26

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.020BETWEEN DOWELS 0.015

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACKNO BLACK OXIDE FINISH TO "SS TYPE" COMPONENTS.

OXIDE FINISH.

L

75.0REF.

30.0

0L

35.0

1.0 x 45

20.0

P.F. FOR 5/16 DOWEL(2) HOLES

A9.

0

12.530

.00

15.0

012.5

66.0

0L

0L

16.00 DIA.

25.0REF.

55.0

0+0.015 -0.00

XXX

10.00+0.03-0.00

LOCATING PINRETAINERS

APR060, 061, 062, 063 04/22/14

A

B

Drill & C/Bore for 3/8 SHCS

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

CODEAPR060APR061APR062APR063

NAAMSkgWT.

A MATERIALSteel / ASTM A-363/8-16 TAP

3/8-16 TAPSteel / ASTM A-36SS type 303 or 304

SS type 303 or 3040.410.410.410.41Drill & C/Bore for 3/8 SHCS

D

E

C

SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHART

F

G

H

-

DISCO

NTINU

ED

G L O B A L S TA N D A R D C O M P O N E N T S

I 27

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.020BETWEEN DOWELS 0.015

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: ALL DIMENSIONS METRIC UNLESS OTHERWISE NOTED.IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACKNO BLACK OXIDE FINISH TO "SS TYPE" COMPONENTS.

OXIDE FINISH.

L

P.F. FOR 5/16 DOWEL(2) HOLES

13/32 DIA.(2) HOLES

35.0REF.

30.0

0

10.00

00.51 9.0

20.090.0REF.

15.0

0L

0L

1.0 x 45 00. 5412.50

25.0REF.

0L12.50

81.0

16.00 DIA.

70.0

0+0.015 -0.00

XXX

10.00+0.03-0.00

LOCATING PINRETAINERSAPR070, 071 04/22/14

A

B

D

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

E

CCODE

APR070APR071

NAAMSkgWT.

MATERIALSteel / ASTM A-36SS type 303 or 304

0.450.45

SEE PAGE B-1.1 FOR GLOBAL MATERIALS CHART F

G

H

-

DISCO

NTINU

EDD

B RADIUS

C RADIUS

A

5.0

15.98

1.0 - 2.0 R

0.50 - 0.75 R

L REF.

28.0

1.0 X 45

3/8 x 16 TAP 17.0 mm DEEP24.0 MAX DRILL DEPTH

+0.00 -0.01

+0.00 -0.02

0.5 x 45

A

B

LEAVE THISEND SOFT

22.0

10.00TYP.

+0.00 -0.03

G

XXX

G L O B A L S TA N D A R D C O M P O N E N T S

I 28

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.015

ALL MACHINED SURFACES TO FLAT.

LOCATING PIN

6mm THRU 19mm DIAMETER 02/12/14

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

TABULATED INFORMATION ON FOLLOWING PAGE

o

o

PARALLEL AND PERPINDICULAR TO WITHIN0.015 T.I.R. TO DATUMS A AND B ANDCONCENTRIC TO WITHIN 0.03 T.I.R.

MATERIAL: S.A.E. 8620 STEELHARDNESS: 58 - 62 Rc TO A DEPTH OF 0.5 - 0.7 mm

AFTER GRINDINGNOTE: IDENTIFY WITH NAAMS CODE NUMBER AS

SHOWN XXX.SEE PAGE B-1.1 FORGLOBAL MATERIALS CHART

F

A

H

D

D

B

E

C

G

I

-

DISCO

NTINU

ED

04/22/14

I-29

Assembly

TMLOCATING PIN

6 mm THRU 19 mm DIAMETER

NAAMSCODE A L

WT.kg

APS061

APS062

APS063

APS064

APS065

APS066

15.0

20.0

30.0

40.0

50.0

60.0

51.8

56.8

66.8

76.8

86.8

96.8

0.05

0.05

0.05

0.05

0.06

0.06

6 mm Round HoleB Rad = 1.0C Rad = 18.0D = 5.85

8 mm Round HoleB Rad = 1.0C Rad = 24.0D = 7.85

NAAMSCODE A L

WT.kg

APS081

APS082

APS083

APS084

APS085

APS086

15.0

20.0

30.0

40.0

50.0

60.0

55.1

60.1

70.1

80.1

90.1

100.1

0.05

0.05

0.06

0.06

0.06

0.07

APS087

APS088

70.0

80.0

110.1

120.1

0.07

0.08

10 mm Round HoleB Rad = 2.0C Rad = 30.0D = 9.85

NAAMSCODE A L

WT.kg

APS101

APS102

APS103

APS104

APS105

APS106

15.0

20.0

30.0

40.0

50.0

60.0

57.4

62.4

72.4

82.4

92.4

102.4

0.06

0.06

0.07

0.07

0.08

0.08

APS107

APS108

70.0

80.0

112.4

122.4

0.09

0.10

APS109

APS100

90.0

100.0

132.4

142.4

0.10

0.11

13 mm Round HoleB Rad = 2.0C Rad = 39.0D = 12.85

NAAMSCODE A L

WT.kg

APS131

APS132

APS133

APS134

APS135

APS136

15.0

20.0

30.0

40.0

50.0

60.0

62.4

67.4

77.4

87.4

97.4

107.4

0.07

0.07

0.08

0.09

0.10

0.11

APS137

APS138

70.0

80.0

117.4

127.4

0.12

0.13

APS139

APS130

90.0

100.0

137.4

147.4

0.14

0.15

16 mm Round HoleB Rad = 2.0C Rad = 48.0D = 15.85

NAAMSCODE A L

WT.kg

APS161

APS162

APS163

APS164

APS165

APS166

15.0

20.0

30.0

40.0

50.0

60.0

67.5

72.5

82.5

92.5

102.5

112.5

0.09

0.09

0.11

0.13

0.14

0.16

APS167

APS168

70.0

80.0

122.5

132.5

0.17

0.19

APS169

APS160

90.0

100.0

142.5

152.5

0.20

0.22

19 mm Round HoleB Rad = 2.0C Rad = 38.0D = 18.85

NAAMSCODE A L

WT.kg

APS191

APS192

APS193

APS194

APS195

APS196

15.0

20.0

30.0

40.0

50.0

60.0

66.8

71.8

81.8

91.8

101.8

111.8

0.10

0.12

0.14

0.16

0.18

0.20

APS197

APS198

70.0

80.0

121.8

131.8

0.22

0.24

APS199

APS190

90.0

100.0

141.8

151.8

0.27

0.29

A

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

B

TiNCODE

APS061T

APS062T

APS063T

APS064T

APS065T

APS066T

TiNCODE

APS081T

APS082T

APS083T

APS084T

APS085T

APS086T

APS087T

APS088T

TiNCODE

APS101T

APS102T

APS103T

APS104T

APS105T

APS106T

APS107T

APS108T

APS109T

APS100T

TiNCODE

APS131T

APS132T

APS133T

APS134T

APS135T

APS136T

APS137T

APS138T

APS139T

APS130T

TiNCODE

APS161T

APS162T

APS163T

APS164T

APS165T

APS166T

APS167T

APS168T

APS169T

APS160T

TiNCODE

APS191T

APS192T

APS193T

APS194T

APS195T

APS196T

APS197T

APS198T

APS199T

APS190T

C

-

2.0 RADIUS

50.0 RADIUS

1.0 X 45

3/8 X 16 TAP 17.0 mm DEEP24.0 MAX DRILL DEPTH

28.0

6.0

0.50 - 0.75 R

15.98+0.00 -0.01

A

B

G L REF.

LEAVE THISEND SOFT

XXX

24.85+0.00 -0.02

10.00TYP.

+0.00 -0.03

0.5 x 45 A

G L O B A L S TA N D A R D C O M P O N E N T S

I 30

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.015

ALL MACHINED SURFACES TO FLAT.

LOCATING PIN 25mm DIAMETER

02/12/14

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

PARALLEL AND PERPINDICULAR TO WITHIN0.015 T.I.R. TO DATUMS A AND B ANDCONCENTRIC TO WITHIN 0.03 T.I.R.

MATERIAL: S.A.E. 8620 STEELHARDNESS: 58 - 62 Rc TO A DEPTH OF 0.5 - 0.7 mm

AFTER GRINDINGNOTE: IDENTIFY WITH NAAMS CODE NUMBER AS

SHOWN XXX.SEE PAGE B-1.1 FORGLOBAL MATERIALS CHA0RT

F

A

I

D

D

E

B

C

G

o

o

APS251 15.0 74.8 0.15APS252 20.0 79.8 0.17APS253 30.0 89.8 0.21APS254 40.0 99.8 0.24APS255 50.0 109.8 0.28APS256 60.0 119.8 0.32APS257 70.0 129.8 0.36APS258 80.0 139.8 0.39APS259 90.0 149.8 0.43APS250 100.0 159.8 0.47

NAAMSCODE A L

WTkg

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E2.0 RADIUS

DISCO

NTINU

E2.0 RADIUS

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

A DISCO

NTINU

E

A

24.85

DISCO

NTINU

E 24.85

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E+0.00

DISCO

NTINU

E+0.00-0.02

DISCO

NTINU

E-0.02

0.5 x 45DISCO

NTINU

E

0.5 x 45

D

H

J

-

DISCO

NTINU

ED

3/8 x 16 TAP 17.0 mm DEEP24.0 MAX DRILL DEPTH

D 25.0

B RADIUS

C RADIUS

A

5.0

15.98

1.0 - 2.0 R

0.5 - 0.75 R

L REF.

28.0

1.0 X 45 +0.00 -0.01

5.0(MAX)0.5 x 45

A

B

GG

XXX

+0.30 -0.00

EFLAT

+0.00 -0.02

G

G

10.00 TYP.+0.00 -0.03

LEAVE THISEND SOFT

G L O B A L S TA N D A R D C O M P O N E N T S

I 31

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.015

ALL MACHINED SURFACES TO FLAT.

LOCATING PIN FOR 6 x 12 THRU 19 x 25 mm

02/12/14

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

TABULATED INFORMATION ON FOLLOWING PAGE

o

PARALLEL AND PERPINDICULAR TO WITHIN0.015 T.I.R. TO DATUMS A AND B ANDCONCENTRIC TO WITHIN 0.03 T.I.R.

MATERIAL: S.A.E. 8620 STEELHARDNESS: 58 - 62 Rc TO A DEPTH OF 0.5 - 0.7 mm

AFTER GRINDINGNOTE: IDENTIFY WITH NAAMS CODE NUMBER AS

SHOWN XXX.SEE PAGE B-1.1 FORGLOBAL MATERIALS CHART

SLOTTED HOLES

E

A

G

D

B

C

F

o

H

-

DISCO

NTINU

ED

04/22/14

I-32

Assembly

TM

LOCATING PINFOR 6 x 12 THRU 19 x 25 mm

SLOTTED HOLES

NAAMSCODE A L

WT.kg

APE061

APE062

APE063

APE064

APE065

APE066

15.0

20.0

30.0

40.0

50.0

60.0

52.9

57.9

67.9

77.9

87.9

97.9

0.05

0.05

0.05

0.06

0.06

0.06

6 x 12 Slotted HoleB Rad = 1.0C Rad = 18.0D = 7.09E = 5.85

8 x 14 Slotted HoleB Rad = 1.0C Rad = 24.0D = 8.81E = 7.85

NAAMSCODE A L

WT.kg

APE081

APE082

APE083

APE084

APE085

APE086

15.0

20.0

30.0

40.0

50.0

60.0

56.0

61.0

71.0

81.0

91.0

101.0

0.05

0.06

0.06

0.07

0.07

0.08

APE087

APE088

70.0

80.0

111.0

121.0

0.08

0.08

10 x 16 Slotted HoleB Rad = 2.0C Rad = 30.0D = 10.63E = 9.85

NAAMSCODE A L

WT.kg

APE101

APE102

APE103

APE104

APE105

APE106

15.0

20.0

30.0

40.0

50.0

60.0

58.2

63.2

73.2

83.2

93.2

103.2

0.06

0.06

0.07

0.08

0.08

0.09

APE107

APE108

70.0

80.0

113.2

123.2

0.10

0.10

APE109

APE100

90.0

100.0

133.2

143.2

0.11

0.12

13 x 19 Slotted HoleB Rad = 2.0C Rad = 39.0D = 13.46E = 12.85

NAAMSCODE A L

WT.kg

APE131

APE132

APE133

APE134

APE135

APE136

15.0

20.0

30.0

40.0

50.0

60.0

63.1

68.1

78.1

88.1

98.1

108.1

0.07

0.08

0.09

0.10

0.11

0.12

APE137

APE138

70.0

80.0

118.1

128.1

0.13

0.14

APE139

APE130

90.0

100.0

138.1

148.1

0.16

0.17

16 x 22 Slotted HoleB Rad = 2.0C Rad = 48.0D = 16.35E = 15.85

NAAMSCODE A L

WT.kg

APE161

APE162

APE163

APE164

APE165

APE166

15.0

20.0

30.0

40.0

50.0

60.0

68.0

73.0

83.0

93.0

103.0

113.0

0.09

0.10

0.11

0.13

0.15

0.16

APE167

APE168

70.0

80.0

123.0

133.0

0.18

0.20

APE169

APE160

90.0

100.0

143.0

153.0

0.21

0.23

19 x 25 Slotted HoleB Rad = 2.0C Rad = 38.0D = 19.27E = 18.85

NAAMSCODE A L

WT.kg

APE191

APE192

APE193

APE194

APE195

APE196

15.0

20.0

30.0

40.0

50.0

60.0

67.2

72.2

82.2

92.2

102.2

112.2

0.11

0.12

0.14

0.16

0.19

0.21

APE197

APE198

70.0

80.0

122.2

132.2

0.23

0.25

APE199

APE190

90.0

100.0

142.2

152.2

0.28

0.30

A

B

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

C

TiNCODE

APE061T

APE062T

APE063T

APE064T

APE065T

APE066T

TiNCODE

APE081T

APE082T

APE083T

APE084T

APE085T

APE086T

APE087T

APE088T

TiNCODE

APE101T

APE102T

APE103T

APE104T

APE105T

APE106T

APE107T

APE108T

APE109T

APE100T

TiNCODE

APE131T

APE132T

APE133T

APE134T

APE135T

APE136T

APE137T

APE138T

APE139T

APE130T

TiNCODE

APE161T

APE162T

APE163T

APE164T

APE165T

APE166T

APE167T

APE168T

APE169T

APE160T

TiNCODE

APE191T

APE192T

APE193T

APE194T

APE195T

APE196T

APE197T

APE198T

APE199T

APE190T

D

-

DISCO

NTINU

ED

G L O B A L S TA N D A R D C O M P O N E N T S

I 33

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.015

ALL MACHINED SURFACES TO FLAT.

LOCATING PIN FOR 25 x 31 mm

02/12/14

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

PARALLEL AND PERPINDICULAR TO WITHIN0.015 T.I.R. TO DATUMS A AND B ANDCONCENTRIC TO WITHIN 0.03 T.I.R.

MATERIAL: S.A.E. 8620 STEELHARDNESS: 58 - 62 Rc TO A DEPTH OF 0.5 - 0.7 mm

AFTER GRINDINGNOTE: IDENTIFY WITH NAAMS CODE NUMBER AS

SHOWN XXX.SEE PAGE B-1.1 FORGLOBAL MATERIALS CHART

SLOTTED HOLES

E

A

J

B

D

C

F

G

APE251 15.0 75.1 0.15APE252 20.0 80.1 0.17APE253 30.0 90.1 0.21APE254 40.0 100.1 0.25APE255 50.0 110.1 0.29APE256 60.0 120.1 0.33APE257 70.0 130.1 0.37APE258 80.0 140.1 0.40APE259 90.0 150.1 0.44APE250 100.0 160.1 0.48

NAAMSCODE A L

WTkg

H

o

3/8-16 TAP17.0 DEEP24.0 MAXDRILL DEPTH

2.0 RADIUS

50.0RADIUS

1.0 X 45

28.0

6.0

A

0.50 - 0.75 R

15.98+0.00 -0.01

5.0 MAX

A

B

G

25.1724.85FLAT

+0.00 -0.02

XXX

G

G

+0.00 -0.02

G

10.00+0.00 -0.03

10.00+0.00 -0.03

L REF.

LEAVE THISEND SOFT

0.5x45

o

I

K

-

2.0 RADIUS

50.0 RADIUS

1.0 X 45

M10 X 1.5 x 17.0 DEEP24.0 MAX DRILL DEPTH

28.0

6.0

0.50 - 0.75 R

15.98+0.00 -0.01

A

B

G L REF.

LEAVE THISEND SOFT

24.72+0.00 -0.02

10.00TYP.

+0.00 -0.03

0.5 x 45 A

G L O B A L S TA N D A R D C O M P O N E N T S

I 34

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.015

ALL MACHINED SURFACES TO FLAT.

RESPOT PIN 25mm DIAMETER

05/05/14

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

PARALLEL AND PERPINDICULAR TO WITHIN0.015 T.I.R. TO DATUMS A AND B ANDCONCENTRIC TO WITHIN 0.03 T.I.R.

MATERIAL: S.A.E. 8620 STEELHARDNESS: 58 - 62 Rc TO A DEPTH OF 0.5 - 0.7 mm

AFTER GRINDINGNOTE: IDENTIFY WITH NAAMS CODE NUMBER AS

SHOWN XXX.SEE PAGE B-1.1 FORGLOBAL MATERIALS CHART

(FULL METRIC)

C

F

B

A

D

o

o

E

XXXH

G

I

J

ARP251M ARP251MT 15.0 74.8 0.15

ARP252M ARP252MT 20.0 79.8 0.17

ARP253M ARP253MT 30.0 89.8 0.21

ARP254M ARP254MT 40.0 99.8 0.25

ARP255M ARP255MT 50.0 109.8 0.29

ARP256M ARP256MT 60.0 119.8 0.33

ARP257M ARP257MT 70.0 129.8 0.37

ARP258M ARP258MT 80.0 139.8 0.40

ARP259M ARP259MT 90.0 149.8 0.44

ARP250M ARP250MT 100.0 159.8 0.48

NAAMSCODE A L

WTkg

TiNCODE

-

DB RADIUS

C RADIUS

A

5.0

15.98

1.0 - 2.0 R

0.50 - 0.75 R

L REF.

28.0

1.0 X 45

M10 X 1.5 x 17.0 DEEP24.0 MAX DRILL DEPTH

+0.00 -0.01

h6

0.5 x 45

A

B

LEAVE THISEND SOFT

22.0

10.00TYP.

+0.00 -0.03

G

XXX

G L O B A L S TA N D A R D C O M P O N E N T S

I 35

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.015

ALL MACHINED SURFACES TO FLAT.

LOCATING PIN 8mm THRU 20mm DIAMETER

08/29/07

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

TABULATED INFORMATION ON FOLLOWING PAGE

o

o

PARALLEL AND PERPINDICULAR TO WITHIN0.015 T.I.R. TO DATUMS A AND B ANDCONCENTRIC TO WITHIN 0.03 T.I.R.

MATERIAL: S.A.E. 8620 STEELHARDNESS: 58 - 62 Rc TO A DEPTH OF 0.5 - 0.7 mm

AFTER GRINDINGNOTE: IDENTIFY WITH NAAMS CODE NUMBER AS

SHOWN XXX.SEE PAGE B-1.1 FORGLOBAL MATERIALS CHART

(FULL METRIC)

A

C

B

-

02/12/14

I-36

Assembly

TM

LOCATING PIN8 mm THRU 20 mm DIAMETER

(FULL METRIC)

NAAMSCODE A L

WT.kg

APQ081

APQ082

APQ083

APQ084

APQ085

APQ086

TiNCODE

TiNCODE

APQ081T

APQ082T

APQ083T

APQ084T

APQ085T

APQ086T

15.0

20.0

30.0

40.0

50.0

60.0

55.4

60.4

70.4

80.4

90.4

100.4

0.05

0.05

0.06

0.06

0.07

0.07

8 mm Round HoleB Rad = 1.0C Rad = 24.0D = 8

10 mm Round HoleB Rad = 1.0C Rad = 30.0D = 10

NAAMSCODE A L

WT.kg

APQ101

APQ102

APQ103

APQ104

APQ105

APQ106

15.0

20.0

30.0

40.0

50.0

60.0

58.7

63.7

73.7

83.7

93.7

103.7

0.06

0.06

0.07

0.07

0.08

0.09

APQ107

APQ108

APQ101T

APQ102T

APQ103T

APQ104T

APQ105T

APQ106T

APQ107T

APQ108T

70.0

80.0

113.7

123.7

0.09

0.10

13 mm Round HoleB Rad = 2.0C Rad = 30.0D = 13

NAAMSCODE

TiNCODE A L

WT.kg

APQ131

APQ132

APQ133

APQ134

APQ135

APQ136

15.0

20.0

30.0

40.0

50.0

60.0

60.2

65.2

75.2

85.2

95.2

105.2

0.07

0.07

0.08

0.09

0.10

0.12

APQ137

APQ138

APQ131T

APQ132T

APQ133T

APQ134T

APQ135T

APQ136T

APQ137T

APQ138T

70.0

80.0

115.2

125.2

0.13

0.14

16 mm Round HoleB Rad = 2.0C Rad = 48.0D = 16

NAAMSCODE

TiNCODE A L

WT.kg

APQ161

APQ162

APQ163

APQ164

APQ165

APQ166

15.0

20.0

30.0

40.0

50.0

60.0

67.7

72.7

82.7

92.7

102.7

112.7

0.08

0.09

0.11

0.12

0.14

0.15

APQ167

APQ168

APQ161T

APQ162T

APQ163T

APQ164T

APQ165T

APQ166T

APQ167T

APQ168T

70.0

80.0

122.7

132.7

0.17

0.19

18 mm Round HoleB Rad = 2.0C Rad = 38.0D = 18

NAAMSCODE

TiNCODE A L

WT.kg

APQ181

APQ182

APQ183

APQ184

APQ185

APQ186

15.0

20.0

30.0

40.0

50.0

60.0

66.3

71.3

81.3

91.3

101.3

111.3

0.10

0.11

0.13

0.15

0.17

0.19

APQ187

APQ188

APQ181T

APQ182T

APQ183T

APQ184T

APQ185T

APQ186T

APQ187T

APQ188T

70.0

80.0

121.3

131.3

0.21

0.23

20 mm Round HoleB Rad = 2.0C Rad = 38.0D = 20

NAAMSCODE A L

WT.kg

APQ201

APQ202

APQ203

APQ204

APQ205

APQ206

15.0

20.0

30.0

40.0

50.0

60.0

67.6

72.6

82.6

92.6

102.6

112.6

0.11

0.13

0.15

0.17

0.20

0.22

APQ207

APQ208

TiNCODE

APQ201T

APQ202T

APQ203T

APQ204T

APQ205T

APQ206T

APQ207T

APQ208T

70.0

80.0

122.6

132.6

0.25

0.27

Ah6 h6 h6

h6 6h6h

B

C

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

-

G L O B A L S TA N D A R D C O M P O N E N T S

I 37

AssemblyTM

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.015

ALL MACHINED SURFACES TO FLAT.

LOCATING PIN 25mm THRU 40mm DIAMETER

08/29/07

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

o

PARALLEL AND PERPINDICULAR TO WITHIN0.015 T.I.R. TO DATUMS A AND B ANDCONCENTRIC TO WITHIN 0.03 T.I.R.

MATERIAL: S.A.E. 8620 STEELHARDNESS: 58 - 62 Rc TO A DEPTH OF 0.5 - 0.7 mm

AFTER GRINDINGNOTE: IDENTIFY WITH NAAMS CODE NUMBER AS

SHOWN XXX.SEE PAGE B-1.1 FORGLOBAL MATERIALS CHART

(FULL METRIC)

B

D

C

A

2.0 RADIUS

50.0 RADIUS

1.0 X 45

M10 X 1.5 x 17.0 DEEP24.0 MAX DRILL DEPTH

28.0

6.0

0.50 - 0.75 R

15.98+0.00 -0.01

A

B

G L REF.

LEAVE THISEND SOFT

XXX

10.00TYP.

+0.00 -0.03

0.5 x 45 A

Dh6

o

-

02/12/14

I-38

Assembly

TM

LOCATING PIN25 mm THRU 40 mm DIAMETER

(FULL METRIC)

30 mm Round HoleB Rad = 2.0C Rad = 50.0D = 30

NAAMSCODE A L

WT.kg

APQ301

APQ302

APQ303

APQ304

APQ305

APQ306

15.0

20.0

30.0

40.0

50.0

60.0

77.8

82.8

92.8

102.8

112.8

122.8

0.22

0.24

0.30

0.35

0.41

0.46

APQ307

APQ308

TiNCODE

APQ301T

APQ302T

APQ303T

APQ304T

APQ305T

APQ306T

APQ307T

APQ308T

70.0

80.0

132.8

142.8

0.52

0.57

35 mm Round HoleB Rad = 2.0C Rad = 50.0D = 35

NAAMSCODE A L

WT.kg

APQ351

APQ352

APQ353

APQ354

APQ355

APQ356

15.0

20.0

30.0

40.0

50.0

60.0

80.3

85.3

95.3

105.3

115.3

125.3

0.29

0.33

0.41

0.48

0.55

0.63

APQ357

APQ358

TiNCODE

APQ351T

APQ352T

APQ353T

APQ354T

APQ355T

APQ356T

APQ357T

APQ358T

70.0

80.0

135.3

145.3

0.70

0.78

40 mm Round HoleB Rad = 2.0C Rad = 50.0D = 40

NAAMSCODE

TiNCODE A L

WT.kg

APQ401

APQ402

APQ403

APQ404

APQ405

APQ406

15.0

20.0

30.0

40.0

50.0

60.0

82.5

87.5

97.5

107.5

117.5

127.5

0.39

0.43

0.53

0.63

0.73

0.82

APQ407

APQ408

APQ401T

APQ402T

APQ403T

APQ404T

APQ405T

APQ406T

APQ407T

APQ408T

70.0

80.0

137.5

147.5

0.92

1.02

25 mm Round HoleB Rad = 2.0C Rad = 50.0D = 25

NAAMSCODE A L

WT.kg

APQ251

APQ252

APQ253

APQ254

APQ255

APQ256

15.0

20.0

30.0

40.0

50.0

60.0

75.0

80.0

90.0

100.0

110.0

120.0

0.15

0.17

0.21

0.25

0.29

0.32

APQ257

APQ258

TiNCODE

APQ251T

APQ252T

APQ253T

APQ254T

APQ255T

APQ256T

APQ257T

APQ258T

70.0

80.0

130.0

140.0

0.36

0.40

C

D

h6 h6

h6

h6

B

A

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

-

G L O B A L S TA N D A R D C O M P O N E N T S

I 39

AssemblyTM

LOCATING PIN RETAINER(FULL METRIC) 20 mm SERIESAPR310M, 311M, 312M, 313M

Tolerances: 1 PLACE 0.32 PLACE 0.033 PLACE 0.020

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACKNO BLACK OXIDE FINISH TO "SS TYPE" COMPONENTS.

OXIDE FINISH.

L

6F7 (2) HOLES

15.00

9.0

30.000

49.0REF.

48.0REF.

0.53

0.51

0. 31

35.040.0

5.0

000.52

A

0L

0L1.0 x 45

30.00REF.

10.0

0+0.

03-0

.00

+0.015 -0.00

16.00

0L

0L

XXX

15.00

15.00

04/22/14

CODEAPR310MAPR311MAPR312MAPR313M

B

A

1997 Auto/Steel Partnership www.naamsstandards.org This document is Uncontrolled when printed.

NAAMSkgWT.

A MATERIALSteel / ASTM A-36M8 x 1.25

M8 x 1.25Steel / ASTM A-369.0SS type 303 or 3049.0

SS type 303 or 3040.410.410.410.41

SEE PAGE B-1.1 FORGLOBAL MATERIALS CHART C

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

49.0

DISCO

NTINU

E

49.0RE

DISCO

NTINU

E

REF

DISCO

NTINU

E

F.

DISCO

NTINU

E

.

DISCO

NTINU

E

35.0

DISCO

NTINU

E

35.040.0

DISCO

NTINU

E

40.0

DISCO

NTINU

E0

DISCO

NTINU

E00

DISCO

NTINU

E0L

DISCO

NTINU

E

LL

DISCO

NTINU

E

L0L0

DISCO

NTINU

E0L00L0

DISCO

NTINU

E0L0

DISCO

NTINU

E

DISCO

NTINU

E

1.0 x 45

DISCO

NTINU

E

1.0 x 45

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E30.00

DISCO

NTINU

E30.00RE

DISCO

NTINU

EREF

DISCO

NTINU

EF.

DISCO

NTINU

E.

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E

DISCO

NTINU

E10

.00

DISCO

NTINU

E10

.00

L

DISCO

NTINU

EL

DD

E

D

-

G L O B A L S TA N D A R D C O M P O N E N T S

I 40

AssemblyTM

6F7(2) HOLES

M8 x 1.25

15.00

12.5

49.0REF.

40.035.0

15.0

48.0REF.

9.0

5.0

30.000

12.5

0L

0L 0L

13.0

35.0

0

1.0 x 45

0L

25.0REF.

16.0010

.00+0

.03

-0.0

0+0.015 -0.00

XXX

LOCATING PIN RETAINER(FULL METRIC) 20 mm SERIES

APR320M, 321MTolerances: 1 PLACE 0.3

2 PLACE 0.033 PLACE 0.020

SURFACES TO BE FLAT, PARALLEL &PERPENDICULAR TO O WITHIN 0.015 T.I.R.

NOTES: IDENTIFY WITH NAAMS CODE NUMBER AS SHOWN XXX.BLACKNO BLACK OXIDE FINISH TO "SS TYPE" COMPONENTS.

OXIDE FINISH.

L

04/22/14

B

ACODEAPR320MAPR321M