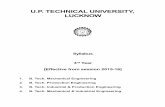

Kinematics and Dynamics Simulation of the Slider-crank Mechanism Based on Matlab / Simulink

Milwaukee Electric Tool Slider-Crank Analysis and test

description

Transcript of Milwaukee Electric Tool Slider-Crank Analysis and test

MILWAUKEE ELECTRIC TOOL

SLIDER-CRANK ANALYSIS AND TEST

Khaled Alaassmi and Majid Al Qutaim

Project Goal The goal of the project is to determine

the offset that provides the best cutting performance for M-18 Sawzall.

Cutting GeometryA=12.2mm= 0.4803 inB= 56.9 mm= 2.24 inC= 19.812 = 0.78 in

A C

B

Angle = z

Pin A

XOut

Drive Gear

Direction of Rotation

C = Offset

Displacement Analysis of Offset Slider Crank Mechanism Using a Vector Loop Closure Equation:O2A = O2D + DB + BA

D

a

bc

Velocity Analysis Equations

Acceleration Analysis Equations:

Analysis using the “Linkages” software from Robert L. Norton, Design of Machinery, 5ed

Analysis using linkages software Linkage software was used to make the

analysis at 3 different offsets Offset of 0.78 in Offset of 0 in Offset of -0.78 in

Analysis Using Linkages Software

At an offset of C=0.78 in

Analysis Using Linkages Software

At an offset of C=0 in

Analysis Using Linkages Software

At an offset of C = -0.78 in

Designing Slider Crank Using Pro-Engineer Wildfire 5

Pro E Analysis At offset of C= 0.78 ”

Pro E analysis At offset of C= 0 ”

Pro E analysis At offset of C= -0.78 ”

Physical Testing

Physical Testing 2 different offsets 10 runs each offset At an offset of 0.78 in and 0 in The average cutting time for each offset

was calculated Test was performed on 2 x 4” wood. The applied load on the blade was 7.4 lb

Physical testingCutting performance = Time required to cut through 2x4 pine board

At C = 0 in, Tavg = 8.9 s, sd= 1.4

At C = 0.78 in, Tavg = 6.3 s, sd= 0.3

Recommendation Use the Prototype Fixture to Design a

Metal Fixture.

Acknowledgements Roger Neitzell Milwaukee Electric Tool Corporation

Questions ?

![Structural design and analysis of a servo crank press · use of SolidWorks are also reported in design and analysis [14–18]. Crank presses are assembly of slider crank mechanisms](https://static.fdocuments.us/doc/165x107/603c71deca15bf020444e4ec/structural-design-and-analysis-of-a-servo-crank-press-use-of-solidworks-are-also.jpg)

![Ballscrew Efficiency Modeling in a Crank-Slider …embeddedlab.csuohio.edu/Prosthetics/media/HWarner.pdfbond graph modeling method can be found in [1]. ... Crank-Slider Prosthetic](https://static.fdocuments.us/doc/165x107/5b1c51377f8b9a1b688b7b63/ballscrew-efficiency-modeling-in-a-crank-slider-graph-modeling-method-can-be-found.jpg)