Material Science Lab

-

Upload

mehul-bansal -

Category

Documents

-

view

13 -

download

3

Transcript of Material Science Lab

Material Science

Laboratory 1

Iron Microstructure Identification

Aim: To identify sample types of iron from there microstructure under a microscope.

Equipment: Microscope, and Struers Metallographic Sample Selection.

Procedure: Place each sample provided under the microscope and compare the microstructure to that shown on the identification cards.

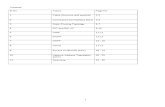

Results:

Sample B

1. Specimen No . 21142. Material type : Iron

Steel Non- alloyed steel, C 60, heat- treatment steel, Din 17200, Material No. 1.0601, Round bar, 22mm diameter, normalized.

3. Composition : 0.61% C, 0.21% Si, 0.65% Mn, 0.45% P and S4. Properties : Suited for heat treatment, Ultimate Tensile Strength 70-90 KP/mm2

Hardness BHN 30 = 243 KP/mm2

5. Applications : Clamps, parts of switch tracks, sheet iron (hard surface)6. Structure : This specimen has compared with specimen number 2113 a high content of

carbide and therefore the amount of pearlite are greater than of ferrite. The pearlite is in some areas formed very fine and is only partly to be seen in the light microscope.

7. Sketch of microstructure:

Conclusion:

Comparison with the example on the card : The microstructure looked very similar to that on the card. But, there was a higher concentration of pearlite as compared to that on the identification card.

Grains of ferrite, pearlite and graphite were visible in the microstructure.

The grains of ferrite, pearlite and graphite were randomly scattered throughout the microstructure. The grains are more refined because of normalising.

Sample D:

1. Specimen No . 21152. Material Type : Iron

Steel Non alloyed steel, D85-2, DIN 1740, Material No. 1.0616, rod section, 105 x 18mm, normalized.

3. Composition : 0.81%C, 0.27%Si, 0.69%Mn, 0.018%P, 0.014%Al, 0.0047%N4. Properties : Suitable for stamp tools, chisels, punch tongs, wire5. Structure : the structure comprises of pearlite(eutectic). This is fine precipitated and only

partly, visible in the light microscope. Furthermore, isolated longitudinal Mn- sulphide are present.

6. Sketch of microstructure :

Conclusion:

Comparison with the example on the card : The microstructure looked very similar to that on the card.

Grains of ferrite, pearlite and graphite were visible in the microstructure. The grains of ferrite, pearlite and graphite were randomly scattered throughout the

microstructure. The grains are more refined because of normalising.

Sample E:

1. Specimen No . 22132. Material Type : Iron

Steel Cast Iron Raw iron, hypereutectic, not standardized after DIN, Cast pig

3. Composition : 5.5%C, 1.35%Si, 0.6Mn, 0.15%S4. Properties : For hard materials.5. Structure : The structure comprises primary of precipitated cementite needles like and burite

( + Fe3C). Due to high content of carbon the eutectic part is the greatest in the structure. The specimen demonstrates furthermore scratches, compared with specimen No. 2211 and 2212.

6. Sketch of microstructure :

Conclusion:

Comparison with the example on the card : The microstructure looked very similar to that on the card.

Grains of ferrite, pearlite and graphite were visible in the microstructure. The specimen demonstrates scratches.

Since, the specimen contains a high concentration of carbon, the grains are brittle and cracked.