MARPOL Annex I: Oil Polution Preventation

-

date post

18-Oct-2014 -

Category

Business

-

view

52.853 -

download

14

description

Transcript of MARPOL Annex I: Oil Polution Preventation

PREVENTING PREVENTING POLLUTION FROM SHIPSPOLLUTION FROM SHIPS

September 2009September 2009

V.Ship’s Mission StatementV.Ship’s Mission Statement

V.Ships aims to be recognised as the first choice V.Ships aims to be recognised as the first choice global supplier of the highest quality services to global supplier of the highest quality services to

the shipping industry with the shipping industry with absolute regard to absolute regard to safety and the marine environmentsafety and the marine environment

For V.Ships Environmental Policy full tFor V.Ships Environmental Policy full teext clickxt click here

V.Ship’s Environmental PolicyV.Ship’s Environmental Policy

V.Ships recognises environmental protection and V.Ships recognises environmental protection and management as one of its highest priorities and as a result, management as one of its highest priorities and as a result,

every effort is to be made to conserve and protect the every effort is to be made to conserve and protect the marine environment from all forms of pollution. marine environment from all forms of pollution.

V.Ships aim is to eliminate the possibility of pollution at source V.Ships aim is to eliminate the possibility of pollution at source by ensuring that high standards of safety and by ensuring that high standards of safety and environmental environmental awareness are maintained and that all relevant legislation awareness are maintained and that all relevant legislation

and conventions are followedand conventions are followed..

V.Ships is also committed to the V.Ships is also committed to the continuous improvementcontinuous improvement of of methods used to carry out this aim.methods used to carry out this aim.

DIRECTDIRECT SEA POLLUTION SEA POLLUTION CAUSESCAUSES

•• Almost all pollution incidents are avoidableAlmost all pollution incidents are avoidable• • Most discharges are via operational incidentsMost discharges are via operational incidents

FAILURE TO FOLLOW PROCEDURES CAUSES:FAILURE TO FOLLOW PROCEDURES CAUSES:

• • heavy fines and/or imprisonment for those involvedheavy fines and/or imprisonment for those involved

• • significant costs for Owners in case of all pollution actssignificant costs for Owners in case of all pollution acts

• • damage to V.Ships reputationdamage to V.Ships reputation

SHIPBOARD SEA POLLUTION SHIPBOARD SEA POLLUTION SOURCESSOURCES

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION((Marpol 73/78 Annex I)Marpol 73/78 Annex I)

Main Shipboard Oil Pollution Sources:Main Shipboard Oil Pollution Sources:

• • engine room bilges engine room bilges and fuel tanks ballastand fuel tanks ballast• • bunker operationsbunker operations• • tankers cargo operationstankers cargo operations• • tank washing and ballastingtank washing and ballasting operations on tankersoperations on tankers• • other operationsother operations• • tankers accidentstankers accidents

accidental oil spills contribute to less than 5 - 10% of all oil pollution.accidental oil spills contribute to less than 5 - 10% of all oil pollution.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

The history of main tanker accidents:The history of main tanker accidents:

1967 March 18, Cornwall,1967 March 18, Cornwall, Eng.:Eng.:

Torrey CanyonTorrey Canyon ran aground, spilling ran aground, spilling

her entire cargo of 120,000 tons of crude her entire cargo of 120,000 tons of crude

oil off the Scilly Islands while enteringoil off the Scilly Islands while entering

the English Channel.the English Channel.

This resulted in the biggestThis resulted in the biggest

oil pollution incident ever recorded up tooil pollution incident ever recorded up to

that time and was a result of poor that time and was a result of poor

navigational practices.navigational practices.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

1978 March 16, off Portsall, France1978 March 16, off Portsall, France: wrecked supertanker : wrecked supertanker Amoco CadizAmoco Cadiz spilled 68 million gallons, causing widespread spilled 68 million gallons, causing widespread environmental damage over 100 mi of Brittany coastenvironmental damage over 100 mi of Brittany coast

1979 July 19, Tobago1979 July 19, Tobago: the : the Atlantic EmpressAtlantic Empress and the and the Aegean Aegean CaptainCaptain collided, spilling 46 million gallons of crude. While being collided, spilling 46 million gallons of crude. While being towed, the Atlantic Empress spilled an additional 41 million towed, the Atlantic Empress spilled an additional 41 million gallons off Barbados on Aug. 2.gallons off Barbados on Aug. 2.

1983 Aug. 6, Cape Town, South Africa1983 Aug. 6, Cape Town, South Africa: the Spanish tanker : the Spanish tanker Castillo de BellverCastillo de Bellver caught fire, spilling 78 million gallons of oil off caught fire, spilling 78 million gallons of oil off the coastthe coast

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

In 1989 March 24, Prince William Sound, AlaskaIn 1989 March 24, Prince William Sound, Alaska: :

tanker tanker Exxon ValdezExxon Valdez hit an undersea reef and spilled 10 million hit an undersea reef and spilled 10 million gallons of oil into the water, causing the worst oil spill in U.S. history gallons of oil into the water, causing the worst oil spill in U.S. history and probably the one which gained the biggest media coverage to and probably the one which gained the biggest media coverage to date. The U.S. public demanded action - and duly got it.date. The U.S. public demanded action - and duly got it.

The United States introduced its The United States introduced its Oil Pollution ActOil Pollution Act of 1990 (OPA 90), of 1990 (OPA 90),

making it mandatory for all tankers calling at U.S. ports to have making it mandatory for all tankers calling at U.S. ports to have double hulls.double hulls.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

1991April 11, Genoa, Italy1991April 11, Genoa, Italy: : HavenHaven spilled 42 million gallons of oil in spilled 42 million gallons of oil in Genoa port.Genoa port.

May 28, AngolaMay 28, Angola: : ABT SummerABT Summer exploded and leaked 15–78 million exploded and leaked 15–78 million gallons of oil off the coast of Angola. It's not clear how much sank gallons of oil off the coast of Angola. It's not clear how much sank

or burned.or burned. 1993 Aug. 10, Tampa Bay, Fla1993 Aug. 10, Tampa Bay, Fla.: three ships collided, the barge .: three ships collided, the barge

Bouchard B155Bouchard B155, the freighter , the freighter Balsa 37Balsa 37, and the barge , and the barge Ocean 255Ocean 255. . The Bouchard spilled an estimated 336,000 gallons of No. 6 fuel oil The Bouchard spilled an estimated 336,000 gallons of No. 6 fuel oil into Tampa Bay.into Tampa Bay.

1996 Feb. 15, off Welsh1996 Feb. 15, off Welsh coast: supertanker coast: supertanker Sea EmpressSea Empress ran ran aground at port of Milford Haven, Wales, spewed out 70,000 tons of aground at port of Milford Haven, Wales, spewed out 70,000 tons of crude oil, and created a 25-mile slick.crude oil, and created a 25-mile slick.

1999 Dec. 12, French Atlantic coast1999 Dec. 12, French Atlantic coast: Maltese-registered tanker : Maltese-registered tanker ErikaErika broke apart and sank off Brittany, spilling 3 million gallons of broke apart and sank off Brittany, spilling 3 million gallons of heavy oil into the sea.heavy oil into the sea.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

2000 Nov. 28, Mississippi River2000 Nov. 28, Mississippi River south of New Orleans: oil tanker south of New Orleans: oil tanker Westchester Westchester lost power and ran aground near Port Sulphur, La., dumping lost power and ran aground near Port Sulphur, La., dumping 567,000 gallons of crude oil into lower Mississippi. The spill was the 567,000 gallons of crude oil into lower Mississippi. The spill was the

largest largest in U.S. waters since Exxon Valdez disaster in March 1989.in U.S. waters since Exxon Valdez disaster in March 1989.

2002 Nov. 13, Spain2002 Nov. 13, Spain: : PrestigePrestige suffered suffered a damaged hull and was towed to sea a damaged hull and was towed to sea and sank. The oil tanker “Prestige” sank and sank. The oil tanker “Prestige” sank

off Spain's NW coast, taking more than off Spain's NW coast, taking more than

70,000 tonnes of fuel into the Atlantic 70,000 tonnes of fuel into the Atlantic with it. with it.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

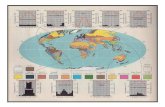

““Special Areas” * according to Marpol:Special Areas” * according to Marpol:

Mediterranean, Baltic, Black Sea, Mediterranean, Baltic, Black Sea, Red SeaRed Sea, Gulfs area,, Gulfs area,Gulf of AdenGulf of Aden,,Oman Area of the Arabian SeaOman Area of the Arabian Sea, **, **NW European waters, Southern South Africa waters NW European waters, Southern South Africa waters Any discharge into the sea of oil or oily mixtures into the Any discharge into the sea of oil or oily mixtures into the Antarctic Area (south of latitudeAntarctic Area (south of latitude 60°S60°S) ) is prohibited.is prohibited.

* In Annexes I, II, V - MARPOL defines certain sea areas as "* In Annexes I, II, V - MARPOL defines certain sea areas as "special areasspecial areas" in which, " in which, for technical reasons relating to their oceanographic and ecological condition and to for technical reasons relating to their oceanographic and ecological condition and to their sea traffic a higher level of protection than other areas of the sea is required. their sea traffic a higher level of protection than other areas of the sea is required.

* * The Special Area requirementsThe Special Area requirements for these areas have not taken effect because of lack for these areas have not taken effect because of lack of notifications from MARPOL Parties whose coastlines border the relevant special of notifications from MARPOL Parties whose coastlines border the relevant special areas on the existence of adequate reception facilitiesareas on the existence of adequate reception facilities

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

1.Control of discharge of oil or oily mixtures from ships 1.Control of discharge of oil or oily mixtures from ships machinery space and from fuel tanksmachinery space and from fuel tanks

1.1.Outside “Special Area” 1.1.Outside “Special Area” Discharge may take place if Discharge may take place if ::• “• “en route” (discharge spread over great area)en route” (discharge spread over great area)• • processed through an oil filtering equipment (15 ppm)processed through an oil filtering equipment (15 ppm)• • the oil content without dilution <15 ppm (parts per million)the oil content without dilution <15 ppm (parts per million)

1.2. In a “Special Area” :1.2. In a “Special Area” :• oil filtering equipment (15 ppm) should have alarm (oil content meter) and oil filtering equipment (15 ppm) should have alarm (oil content meter) and automatic stopping device (3-way valve)automatic stopping device (3-way valve)

Oil residues which cannot be discharged into the sea in compliance with the Oil residues which cannot be discharged into the sea in compliance with the previous provisions shall be retained onboard for subsequent discharge to previous provisions shall be retained onboard for subsequent discharge to reception facilitiesreception facilities

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

1.3. For ships 1.3. For ships ≥ 4,000 GT and oil tankers 4,000 GT and oil tankers ≥ 150 GT (delivered after 31 150 GT (delivered after 31 December 1979) December 1979) no ballast waterno ballast water shall be carried in any oil fuel tank shall be carried in any oil fuel tank

Carrying large quantities of oil fuel and consequently ballastCarrying large quantities of oil fuel and consequently ballastwater, requires discharge to reception facilities orwater, requires discharge to reception facilities or into the sea following into the sea following procedures specified in 1.2.procedures specified in 1.2.

1.4. In a ship 1.4. In a ship ≥ 400 GT400 GT constructed after 1 July 1982, constructed after 1 July 1982, oil shall not be carried in a forepeak tank or a tank forward of the oil shall not be carried in a forepeak tank or a tank forward of the collision bulkhead.collision bulkhead.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

2. Construction requirements for 2. Construction requirements for

all ships machinery space: all ships machinery space:

• • sludge tanks of adequate capacitysludge tanks of adequate capacity with regard to the type of with regard to the type of machinery and length of voyagemachinery and length of voyage

• • standardstandard discharge connectiondischarge connection fitted to the ship’s discharge fitted to the ship’s discharge pipeline for residues from bilges and sludge tanks to enable pipeline for residues from bilges and sludge tanks to enable connection to reception facilitiesconnection to reception facilities

• • oil fuel tanks protection against collision/groundingoil fuel tanks protection against collision/grounding (i.e. double (i.e. double hull) for ships with an aggregate oil fuel capacity of 600 mhull) for ships with an aggregate oil fuel capacity of 600 m³³, , delivered on or after 1 August 2010. A max. capacity limit of mdelivered on or after 1 August 2010. A max. capacity limit of m³³ per oil fuel tank is 2,500per oil fuel tank is 2,500³³

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

3. Requirements for equipment of 3. Requirements for equipment of all ships machinery spaceall ships machinery space

• • All ships ≥400 GT must be fitted with oil filtering equipment All ships ≥400 GT must be fitted with oil filtering equipment (Oily Water Separator) producing an effluent with oil content <15ppm(Oily Water Separator) producing an effluent with oil content <15ppm

•• Ships ≥ 10000 GT shall be fitted with oil filtering equipment Ships ≥ 10000 GT shall be fitted with oil filtering equipment (15ppm) with alarm and automatic stopping device(15ppm) with alarm and automatic stopping device

• • Oily Water Separators (OWS) and Oil Content Meters (OCM) Oily Water Separators (OWS) and Oil Content Meters (OCM) (bilge alarms) shall be approved as per IMO resolutions: (bilge alarms) shall be approved as per IMO resolutions: A.393(X), MEPC.60 (33) or A.393(X), MEPC.60 (33) or since 01.012005 MEPC.107(49)since 01.012005 MEPC.107(49) which states that:which states that:

- OWS to be tested also with a stable emulsion- OWS to be tested also with a stable emulsion - OCM to include a recording function for date, time, alarm- OCM to include a recording function for date, time, alarm

and operating status. All records to be stored for 18 monthsand operating status. All records to be stored for 18 months

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

4. Control of discharge of oil or oily mixtures 4. Control of discharge of oil or oily mixtures from oil tankers cargo area from oil tankers cargo area

4.1. 4.1. Outside “Special Area” discharge may take place if:Outside “Special Area” discharge may take place if:

• • the instantaneous rate of discharge of oil content the instantaneous rate of discharge of oil content does note exceed 30 litres per nautical miledoes note exceed 30 litres per nautical mile• • proceeding on voyageproceeding on voyage• • more than 50 miles from land more than 50 miles from land • • discharge monitoring and control system is used to discharge residuedischarge monitoring and control system is used to discharge residue• • the total quantity of oil discharged into the sea does not exceedthe total quantity of oil discharged into the sea does not exceed 1/15,000 or 1/30,0001/15,000 or 1/30,000** of the total quantity of the particular cargo ofof the total quantity of the particular cargo of which the residue formed a part which the residue formed a part (( ** for tankers delivered after 31 December 1979 )

• • the tanker is equipped with Oil Discharge Monitoring and Control the tanker is equipped with Oil Discharge Monitoring and Control System and a Slop Tank arrangementSystem and a Slop Tank arrangement

4.2. 4.2. In “Special Area" only discharge of clean or segregated In “Special Area" only discharge of clean or segregated ballast is allowed (oil content in discharge<15 ppm)ballast is allowed (oil content in discharge<15 ppm)

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

5.Construction requirements for oil tankers cargo area5.Construction requirements for oil tankers cargo area

5.1. Every crude oil tanker of 20,000 dwt and above and 5.1. Every crude oil tanker of 20,000 dwt and above and every product carrier of 30,000 dwt and above delivered every product carrier of 30,000 dwt and above delivered after 1 June 1982, shall be provided with segregated ballast tanks after 1 June 1982, shall be provided with segregated ballast tanks

(SBT) (SBT)

5.2. In no case shall ballast water be carried in cargo tanks, except 5.2. In no case shall ballast water be carried in cargo tanks, except - weather conditions so severe that it is necessary to carry additional - weather conditions so severe that it is necessary to carry additional ballast water for the safety of the shipballast water for the safety of the ship - in exceptional cases where the particular character of the operation - in exceptional cases where the particular character of the operation of an oil tanker renders it necessary to carry ballast water of an oil tanker renders it necessary to carry ballast water

In case of crude oil tanker ,such cargo tanks have been crude oil washedIn case of crude oil tanker ,such cargo tanks have been crude oil washed (COW) (COW)Additional ballast water shall be processed and discharged in compliance Additional ballast water shall be processed and discharged in compliance with 1.4. and an entry shall be made in the Oil Record Book Part II with 1.4. and an entry shall be made in the Oil Record Book Part II

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

5.3.5.3. Crude oil tankers Crude oil tankers ≥ 40,000 dwt delivered 40,000 dwt delivered on or before 1 June 1982, shall comply with the requirements of 1.5.1. and on or before 1 June 1982, shall comply with the requirements of 1.5.1. and 1.5.2. or may in lieu SBT, operate with a cargo tank cleaning procedure 1.5.2. or may in lieu SBT, operate with a cargo tank cleaning procedure using crude oil washing (COW) using crude oil washing (COW)

5.4. Product carriers 5.4. Product carriers ≥ 40,000 dwt delivered on or before 1 June 1982 shall 40,000 dwt delivered on or before 1 June 1982 shall comply with the requirements of 1.5.1. and 1.5.2. or may in lieu SBT, comply with the requirements of 1.5.1. and 1.5.2. or may in lieu SBT, operate with dedicated clean ballast tanks (CBT).operate with dedicated clean ballast tanks (CBT). The product carrier shall The product carrier shall be equipped be equipped with an oil content meterwith an oil content meter, approved by the Administration to , approved by the Administration to enable supervision of the oil content enable supervision of the oil content in ballast water being discharged. in ballast water being discharged.

5.5. Oil tankers 5.5. Oil tankers ≥ 70,000 dwt delivered after 70,000 dwt delivered after 31 December 1979 shall comply with the requirements of 1.5.1. and 1.5.2. 31 December 1979 shall comply with the requirements of 1.5.1. and 1.5.2.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

5.6. Every crude oil tanker 5.6. Every crude oil tanker ≥ 20,000 dwt and every product 20,000 dwt and every product carrier carrier ≥ 30,000 dwt delivered after 1 June 1982, are required 30,000 dwt delivered after 1 June 1982, are required to be equipped with the to be equipped with the segregated ballast tankssegregated ballast tanks providing a measure providing a measure of protection against oil outflow in the event of grounding or collision.of protection against oil outflow in the event of grounding or collision.This regulation does not relate to tankers that meet double hull and This regulation does not relate to tankers that meet double hull and double bottom requirementsdouble bottom requirements

5.7. Every oil tanker 5.7. Every oil tanker ≥ 5,000 dwt delivered on or after 6 July 1996 shall be 5,000 dwt delivered on or after 6 July 1996 shall be fitted with fitted with double hulls double hulls ((the entire cargo tank length shall be protected by the entire cargo tank length shall be protected by ballast tanks or spaces other than tanks that carry oilballast tanks or spaces other than tanks that carry oil))

Such tankers delivered before 6 July 1996 shall comply with the 1.5.7.Such tankers delivered before 6 July 1996 shall comply with the 1.5.7.requirements not later than 5 April 2005 or the anniversary of the requirements not later than 5 April 2005 or the anniversary of the date of delivery of the ship on the date or in the year specified in the date of delivery of the ship on the date or in the year specified in the following statement:following statement:

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

The full timetable for the phasing out of single-hull tankersThe full timetable for the phasing out of single-hull tankers

Category Category

of oilof oil tankertanker

Date or yearDate or year

Category 1Category 1 5 April 2005 for ships delivered on 5 April 1982 or earlier5 April 2005 for ships delivered on 5 April 1982 or earlier

2005 for ships delivered after 5 April 19822005 for ships delivered after 5 April 1982

Category 2 Category 2 aandnd Category 3Category 3

5 April 2005 for ships delivered on 5 April 1977 or earlier5 April 2005 for ships delivered on 5 April 1977 or earlier

2005 for ships delivered after 5 April 1977 but before 2005 for ships delivered after 5 April 1977 but before

1 January 19781 January 1978

2006 for ships delivered in 1978 and 19792006 for ships delivered in 1978 and 1979

2007 for ships delivered in 1980 and 19812007 for ships delivered in 1980 and 1981

2008 for ships delivered in 19822008 for ships delivered in 1982

2009 for ships delivered in 19832009 for ships delivered in 1983

2010 for ships delivered in 1984 or later2010 for ships delivered in 1984 or later

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

IMO amendments to MARPOL 73/78 (adopted 12/2003, entry into IMO amendments to MARPOL 73/78 (adopted 12/2003, entry into

force 5/4/2005) - simplified statementforce 5/4/2005) - simplified statement

• Category 1 phase-out up to 2005Category 1 phase-out up to 2005• Categories 2&3 phase-out up to 2010Categories 2&3 phase-out up to 2010• Condition Assessment Scheme CAS Condition Assessment Scheme CAS

required for Categories 2&3 over 15 years oldrequired for Categories 2&3 over 15 years old

Oil Tanker CategorizationOil Tanker Categorization

Category 1Category 1 pre-MARPOL (pre-1982)pre-MARPOL (pre-1982)

Category 2Category 2 MARPOL (post-1982)MARPOL (post-1982)

Category 3Category 3 smaller tankers (5,000-20,000/30,000dwt)smaller tankers (5,000-20,000/30,000dwt)

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

BUTBUT

Flag state may extend Categories 2&3 up to 2015 or 25th anniversary Flag state may extend Categories 2&3 up to 2015 or 25th anniversary (whichever earlier) if satisfactory results of the CAS(whichever earlier) if satisfactory results of the CAS

Flag state may extend Categories 2&3 with only double bottoms Flag state may extend Categories 2&3 with only double bottoms (db)(db)or only or only double sides double sides (ds)(ds) which may trade up to 25th anniversary of delivery (even which may trade up to 25th anniversary of delivery (even past 2015)past 2015)

HOWEVERHOWEVER

Port state may deny entry of either of such flag-state-extended tankersPort state may deny entry of either of such flag-state-extended tankers

5.8. OIL TANKERS CARRYING HEAVY GRADE OIL 5.8. OIL TANKERS CARRYING HEAVY GRADE OIL AS CARGOAS CARGO

Double hullDouble hull is required from 5/4/05 for is required from 5/4/05 for Heavy Grade OilHeavy Grade Oil (HGO) (HGO) as cargo for as cargo for tankers 5,000 dwt and above, and for tankers 600 - 4,999 dwt (except tankers 5,000 dwt and above, and for tankers 600 - 4,999 dwt (except single-hulls built with single-hulls built with dbdb and and dsds) from anniversary date in 2008) from anniversary date in 2008

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

BUTBUT

Flag state may allow single-hull tkr ≥ 5,000 dwt with only Flag state may allow single-hull tkr ≥ 5,000 dwt with only db db or only or only dsds to continue with to continue with HGOHGO up to 25th anniversary (even beyond up to 25th anniversary (even beyond 2015)2015) Flag state may allow single-hull tkr ≥ 5,000 dwt to continue with Flag state may allow single-hull tkr ≥ 5,000 dwt to continue with HGOHGO between 900 and 945 kg/cubic meter until 25th anniversary or 2015 between 900 and 945 kg/cubic meter until 25th anniversary or 2015 whichever is earlier, if results of the CAS satisfy Administrationwhichever is earlier, if results of the CAS satisfy Administration

Flag state may allow single-hull 600-4,999 dwt to continue with Flag state may allow single-hull 600-4,999 dwt to continue with HGOHGO until 25th anniversary or 2015 whichever is earlieruntil 25th anniversary or 2015 whichever is earlier

HOWEVERHOWEVER

Port state may deny entry of any of the above Port state may deny entry of any of the above mentioned flag-state-extended tankers carrying mentioned flag-state-extended tankers carrying HGOHGO

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

5.9.Condition Assessment Scheme (CAS)5.9.Condition Assessment Scheme (CAS)

CAS (Applies to oil tankers CAS (Applies to oil tankers ≥ 5,000 dwt )5,000 dwt ) CAS will be performed at intervals of up to 5CAS will be performed at intervals of up to 5

years and 6 monthsyears and 6 months First CAS to be undertaken at first renewal First CAS to be undertaken at first renewal

(i.e. special) survey or intermediate survey (i.e. special) survey or intermediate survey

after 5/4/05 of every tanker which after 5/4/05 of every tanker which

has reached its fifteenth year has reached its fifteenth year CAS is to be harmonised CAS is to be harmonised

with ESP (Enhanced Special Survey)with ESP (Enhanced Special Survey)

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

5.10.On oil tankers 5.10.On oil tankers ≥ 5000 dwt constructed 5000 dwt constructed on or after 01.01.2007 the pump- room shall be provided on or after 01.01.2007 the pump- room shall be provided with with double bottomdouble bottom..

5.11. Tankers delivered on or after 01.01.2010 have to be 5.11. Tankers delivered on or after 01.01.2010 have to be constructed providing adequate constructed providing adequate protectionprotection against oil against oil pollution in the event of stranding or collision. (pollution in the event of stranding or collision. (Oil outflow Oil outflow performance in case of accident – collision or groundingperformance in case of accident – collision or grounding))

5.12. Oil tankers ≥ 150 GT shall be provided with 5.12. Oil tankers ≥ 150 GT shall be provided with slop tankslop tank arrangements of total capacity not less then 3% of total arrangements of total capacity not less then 3% of total carrying capacity. Oil tankers ≥ 70,000 delivered after carrying capacity. Oil tankers ≥ 70,000 delivered after

31.12.1979, shall be provided with at least two slop tanks.31.12.1979, shall be provided with at least two slop tanks.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

6. Equipment requirements for oil tankers cargo area 6. Equipment requirements for oil tankers cargo area

6.1. Oil tankers 6.1. Oil tankers ≥ 150 GT shall be equipped with Oil Discharge 150 GT shall be equipped with Oil Discharge Monitoring Equipment (ODME) approved by the Administration, Monitoring Equipment (ODME) approved by the Administration, which includes:which includes:

- a recording device to provide continuous record of the discharge in - a recording device to provide continuous record of the discharge in litres per nautical mile and total quantity discharged, orlitres per nautical mile and total quantity discharged, or

the oil content and rate of dischargethe oil content and rate of discharge.. Record shall be identifiable as to timeRecord shall be identifiable as to time and date and shall be kept for at least and date and shall be kept for at least three years; any discharge of oilythree years; any discharge of oily mixture is automatically stopped whenmixture is automatically stopped when exceeding the permitted instantaneous exceeding the permitted instantaneous rate of discharge of oil; rate of discharge of oil; Design of the oil content meter to be Design of the oil content meter to be incorporated in the system shall complyincorporated in the system shall comply with IMO requirements.with IMO requirements.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

6.2. Oil tankers ≥ 150 GT 6.2. Oil tankers ≥ 150 GT

shall be provided with effective shall be provided with effective oil/water interface detectors oil/water interface detectors approved by the Administration approved by the Administration for a rapid and accurate determination for a rapid and accurate determination of the oil/water interfaceof the oil/water interfacein slop tanks and shall be available in slop tanks and shall be available for use in other tanks where the for use in other tanks where the separation of oil and water is effected separation of oil and water is effected and from which it is discharged and from which it is discharged directly to the sea.directly to the sea.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

6.3. Every crude oil tanker 6.3. Every crude oil tanker ≥ 20,000 dwt 20,000 dwt

delivered after 1 June 1982 delivered after 1 June 1982

shall be fitted with a cargo tank cleaning system shall be fitted with a cargo tank cleaning system

using crude oil washing (COW) using crude oil washing (COW)

approved by Administration.approved by Administration.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

7.7. Oil Record Book requirementsOil Record Book requirements

• • Part I - Machinery space OperationsPart I - Machinery space Operations for tankers ≥ 150 GT for tankers ≥ 150 GT and for non tankers ≥ 400 GT and for non tankers ≥ 400 GT • • Part II - Cargo/ballast operations Part II - Cargo/ballast operations for oil tanker ≥ 150 GTfor oil tanker ≥ 150 GT

• • When making entries, the date, operational letter code When making entries, the date, operational letter code and item number must be inserted and item number must be inserted and the required details recorded and the required details recorded in the record of operationsin the record of operations

• • Each completed operation Each completed operation to be signed and dated by to be signed and dated by officer in charge as soon officer in charge as soon as the operation is over. as the operation is over.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

Entries in the Oil Record Book must be:Entries in the Oil Record Book must be:

accurateaccurate signed by person in charge signed by person in charge

of operation.of operation. entered without delay entered without delay signed by Master on each pagesigned by Master on each page available for inspectionavailable for inspection

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

Oil record book (cont.)Oil record book (cont.)

• • Mistakes to be struck through with a single line, the wrong Mistakes to be struck through with a single line, the wrong entry signed and followed by the correct entry. entry signed and followed by the correct entry.

• • No full empty lines between each recorded entry are permitted ,No full empty lines between each recorded entry are permitted ,

• • ORB is to remain onboard for min. three years from the date ORB is to remain onboard for min. three years from the date of last entryof last entry

• • Only an official ORB is to be kept. A rough or working copy is not Only an official ORB is to be kept. A rough or working copy is not permitted.permitted.

• • All entries recorded in ink.All entries recorded in ink.

• • ORB can be inspected by authorized authorities that may make copy ORB can be inspected by authorized authorities that may make copy of entries and require the Master to certify them as “true copy”of entries and require the Master to certify them as “true copy”

Proper record keeping is to be verified at each superintendent’s visit to the shipProper record keeping is to be verified at each superintendent’s visit to the ship

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

ORB is worthy of a special mention as this is ORB is worthy of a special mention as this is a particular area that Port State Controla particular area that Port State Controlinspectors frequently discover errors. inspectors frequently discover errors. It is also an area where a vessel can be fined It is also an area where a vessel can be fined heavily if the entries are wrong or have been heavily if the entries are wrong or have been deliberately falsifieddeliberately falsifiedRefer also to:Refer also to:

Fleet Operations Section 6.2.9

Safety & Environmental Procedures Section 9.4.4

INTERTANKO’s “A Guide for Correct Entries in INTERTANKO’s “A Guide for Correct Entries in the Oil Record Book”the Oil Record Book”

UK P&I Club Oil Record Book entries

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

8. Approved Shipboard Oil Pollution Plan (SOPEP)8. Approved Shipboard Oil Pollution Plan (SOPEP) required for oil tankers ≥ 150 GT and non-tankers ≥ 400 GT required for oil tankers ≥ 150 GT and non-tankers ≥ 400 GT SOPEP - based on IMO guidelinesSOPEP - based on IMO guidelines** is written in the is written in the working language of the master and officers.working language of the master and officers. The plan shall consist of: The plan shall consist of: - the procedure to be followed by the master or other - the procedure to be followed by the master or other persons having charge of the ship to report an oil persons having charge of the ship to report an oil pollution incident,pollution incident, - the list of authorities or persons to be - the list of authorities or persons to be contacted in the event of an oil pollution incident;contacted in the event of an oil pollution incident;

For ships fulfilling regFor ships fulfilling reg.. 17 of Marpol Annex II, SOPEP may be combined 17 of Marpol Annex II, SOPEP may be combined with the shipboard marine pollution emergency plan for noxious liquid with the shipboard marine pollution emergency plan for noxious liquid substances and the title is changed to “Shipboard marine pollution substances and the title is changed to “Shipboard marine pollution emergency plan”. SMPEPemergency plan”. SMPEP

* MEPC.54(32) as amended by resolution MEPC.86(44)* MEPC.54(32) as amended by resolution MEPC.86(44)**

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

The plan SOPEP shall consist of (cont.):The plan SOPEP shall consist of (cont.):

-- a detailed description of the action to be taken immediately by a detailed description of the action to be taken immediately by persons on board following the incidentpersons on board following the incident-- the procedures and point of contact on the ship for co-ordinating the procedures and point of contact on the ship for co-ordinating

shipboard action with national and local authorities. shipboard action with national and local authorities.

click here for click here for SOPEP Contact points updated as of 3SOPEP Contact points updated as of 300//0606/200/20099 for full txt of VMS SOPEP click herefor full txt of VMS SOPEP click here

Computerised, shore-based damageComputerised, shore-based damage stability and residual stability and residual

structural strength calculation programsstructural strength calculation programs shall be accessible shall be accessible on board all oil tankers ≥ 5,000 dwt .on board all oil tankers ≥ 5,000 dwt .

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

9. 9. Onboard Oil Spill EquipmentOnboard Oil Spill Equipment

should should comprisecomprise::

- protective clothing- protective clothing- emulsifiers for deck cleaning- emulsifiers for deck cleaning- s- sorbentsorbents- scupper plugs- scupper plugs- non-sparking hand scoops, shovels and buckets- non-sparking hand scoops, shovels and buckets- - a minimum of one non-sparking pump with hosesa minimum of one non-sparking pump with hoses

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

Onboard Oil Spill EquipmentOnboard Oil Spill Equipment (continued) (continued)

The full list of equipment and supplies The full list of equipment and supplies is tois to be listed in be listed in the vessel's SOPEP Manual.the vessel's SOPEP Manual.

Oil Spill Removal Equipment Oil Spill Removal Equipment is tois to be marked with two be marked with two red bands and kept in a red bands and kept in a marked marked storeroomstoreroom

During cargo operations and bunkering, the equipment During cargo operations and bunkering, the equipment and supplies should be ready for immediate use.and supplies should be ready for immediate use.

For VMS 9.4.5 Onboard Oil Spill Removal Equipment txt click hereFor VMS 9.4.5 Onboard Oil Spill Removal Equipment txt click here

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

10. 10. Oil loading terminals, repair ports and portsOil loading terminals, repair ports and ports

in which ships have oily residues toin which ships have oily residues todischarge, have to be equipped with discharge, have to be equipped with facilities for the reception of such facilities for the reception of such

residues andresidues and oily mixtures. Each Party oily mixtures. Each Party shall notify the Organization for shall notify the Organization for transmission to the Parties concerned transmission to the Parties concerned of all cases where the facilities of all cases where the facilities provided under this regulation are provided under this regulation are inadequate.inadequate.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

11. Surveys and Certification11. Surveys and Certification

- are required for ships ≥ 400 GT and oil tankers ≥ 150 GT. are required for ships ≥ 400 GT and oil tankers ≥ 150 GT. International Oil Pollution Prevention Certificate (IOPPC)International Oil Pollution Prevention Certificate (IOPPC) shall be issued:shall be issued:- after an initial or renewal surveyafter an initial or renewal survey- by the Administration or organization duly authorized by it.by the Administration or organization duly authorized by it.- for a period not exceeding five years.for a period not exceeding five years.

Certificate shall cease if the relevant surveys are not Certificate shall cease if the relevant surveys are not completed, if the certificate is not endorsed, upon transfer completed, if the certificate is not endorsed, upon transfer

of the ship to the flag of another Stateof the ship to the flag of another State..

Click here to open IOPPC example

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

11. Port State Control (PSC) on operational requirements*11. Port State Control (PSC) on operational requirements*

1.1. when in a port a ship is subject to inspection by authorized PSC officerswhen in a port a ship is subject to inspection by authorized PSC officers

2.2. if there are clear grounds for believing that the master or crew are not if there are clear grounds for believing that the master or crew are not familiar with essential shipboard procedures preventing pollution by oil,familiar with essential shipboard procedures preventing pollution by oil,

all steps are to be taken to ensure that the situation has been brought all steps are to be taken to ensure that the situation has been brought to order.to order.

3.3. if ships equipment is broken or missing or ship has suffered if ships equipment is broken or missing or ship has suffered damages en route, Port Authorities must be informed damages en route, Port Authorities must be informed accordingly and if remedies were agreed with the flag state,accordingly and if remedies were agreed with the flag state,

the ship is not to be detained.the ship is not to be detained.

** Refer to the Procedures for port State control resolutionRefer to the Procedures for port State control resolution A.787(19) as amended by resolution A.882(21);A.787(19) as amended by resolution A.882(21);

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

4.The most common MARPOL Annex I 4.The most common MARPOL Annex I deficienciesdeficiencies found by found by PSC PSC officers :officers :

•• filtering equipment OWS malfunctioningfiltering equipment OWS malfunctioning•• 15 ppm alarm arrangements (inoperative alarm and auto stop)15 ppm alarm arrangements (inoperative alarm and auto stop)•• illegal OWS bypass illegal OWS bypass •• SOPEPSOPEP•• retention of oil onboard ,quantity of oily water retained onboard not retention of oil onboard ,quantity of oily water retained onboard not

corresponding with ORB entries and OIPP Record of Construction corresponding with ORB entries and OIPP Record of Construction and equipment prevention of pollution by oil (IOPP)and equipment prevention of pollution by oil (IOPP)

•• quantity of oil residues landed ashore or incinerated contrary to quantity of oil residues landed ashore or incinerated contrary to quantity expected to be produced from machinery spacesquantity expected to be produced from machinery spaces

•• discharge violation noted by oil coating inside clean discharge pipes discharge violation noted by oil coating inside clean discharge pipes from OWSfrom OWS

•• indications of discharge pipe/valve removalindications of discharge pipe/valve removal•• inconsistent entries in ORBinconsistent entries in ORB

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

55. Certificates and documents to be carried onboard:. Certificates and documents to be carried onboard:

• • Oil Pollution Prevention Certificate (including the Record of Oil Pollution Prevention Certificate (including the Record of Construction and Equipment (Form A or B)Construction and Equipment (Form A or B)• • Statement of compliance for Condition Assessment SchemeStatement of compliance for Condition Assessment Scheme (Tankers only)(Tankers only)

Type of Approval Certificates:Type of Approval Certificates:

• • Oily Water SeparatorOily Water Separator• • 15 PPM Alarm15 PPM Alarm• • Oil Discharge Monitoring and Control SystemOil Discharge Monitoring and Control System (Tankers Only)(Tankers Only)• • Oil/Water Interface Detector (Tanker Only)Oil/Water Interface Detector (Tanker Only)

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

DocumentsDocuments

All ships:All ships:• • Oil Record Book (Part 1) Oil Record Book (Part 1) • • SOPEP *SOPEP *Tanker specific (Marpol Annex I):Tanker specific (Marpol Annex I):• • Oil Discharge Monitoring and Control System*– ODME Manual Oil Discharge Monitoring and Control System*– ODME Manual (recordings from ODME equipment to be kept onboard for at least 3 years)(recordings from ODME equipment to be kept onboard for at least 3 years)

• • Crude oil Washing Manual*, if applicableCrude oil Washing Manual*, if applicable• • Oil Record Book (part 2)Oil Record Book (part 2)• • Access to shore based damage stability and residual strengthAccess to shore based damage stability and residual strength CalculationsCalculations• • Dedicated Clean Ballast Tank Operation Manual*Dedicated Clean Ballast Tank Operation Manual*• • Damage Stability Approval*Damage Stability Approval*• • Vapour Emission Control System Procedure (Manual) *Vapour Emission Control System Procedure (Manual) *

* Should be approved by or on behalf of the Flag Administration* Should be approved by or on behalf of the Flag Administration

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

U.S. Regulation summary:U.S. Regulation summary:

MARPOL Annex I - the most frequently MARPOL Annex I - the most frequently violatedviolated

Over $200 million dollars in criminal fines Over $200 million dollars in criminal fines since 1998 as well as : restitution, since 1998 as well as : restitution, community service and probation with court community service and probation with court supervised environmental compliance supervised environmental compliance programs. programs.

Personal punishment : 17 years of Personal punishment : 17 years of imprisonment since 1998 for senior imprisonment since 1998 for senior shipboard officers and engineers. shipboard officers and engineers.

12. 12. Crime and penalty focusCrime and penalty focus

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

Direct causes of crimesDirect causes of crimes

Many cases constitute deliberate discharges of tons of waste oil, Many cases constitute deliberate discharges of tons of waste oil, sludge and other pollutants.sludge and other pollutants.

Crimes committed for financial motive.Crimes committed for financial motive. Deliberate crimes omitting pollution prevention equipment Deliberate crimes omitting pollution prevention equipment Cost saving, easiest & quickest method of performing taskCost saving, easiest & quickest method of performing task Discharges made at night, hiding of bypass equipment, use of Discharges made at night, hiding of bypass equipment, use of

dispersants, tricking of OCM, falsification of Oil Record Book and dispersants, tricking of OCM, falsification of Oil Record Book and Tank Sounding Log, etc. Tank Sounding Log, etc.

Faking of vessel records to mislead port Faking of vessel records to mislead port authorities.authorities. Most cases involve circumventing of justice Most cases involve circumventing of justice (destruction of evidence, alteration of documents, (destruction of evidence, alteration of documents, providing false witness, committing perjury). providing false witness, committing perjury).

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

illegal illegal bbypass exampleypass example

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

Each of these vessels Each of these vessels was ISM certified and was ISM certified and had passed Class, had passed Class, Flag and Port State Flag and Port State inspectionsinspections

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

European Ship Sourced Pollution DirectivesEuropean Ship Sourced Pollution Directives

■ ■ New EU legislation dealing with criminal liability in the form of Directive New EU legislation dealing with criminal liability in the form of Directive 2005/35/EC that came into force on 1 April 2007 imposes criminal 2005/35/EC that came into force on 1 April 2007 imposes criminal liabilities for ship-source pollution.liabilities for ship-source pollution.

■■ Unlike MARPOL, the Directive makes no distinction between Unlike MARPOL, the Directive makes no distinction between operational and accidental dischargesoperational and accidental discharges

■■ The Directive exposes not only ships’ crews, owners and operators The Directive exposes not only ships’ crews, owners and operators to liability but also any other party connected to the ship, including to liability but also any other party connected to the ship, including salvors and classification societies.salvors and classification societies.

■■ Satellite monitoring – Satellite monitoring – Clean Sea Net Clean Sea Net provides monitoring provides monitoring of illegal discharges of illegal discharges with oil spill alert within 30 min, with oil spill alert within 30 min, including slick position, its extent, shape , including slick position, its extent, shape , as well as wind and wave data.as well as wind and wave data.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

13. Equipment and Best Management Practices13. Equipment and Best Management Practices

VMS water pollution prevention (Fleet Operations, VMS water pollution prevention (Fleet Operations, Safety & Environmental Procedures, Tanker Operation Instructions)Safety & Environmental Procedures, Tanker Operation Instructions)

1. General1. General

• • necessary precautions are to be taken and procedures are to be necessary precautions are to be taken and procedures are to be strictly followed during all oil transfer operations, which must not be leftstrictly followed during all oil transfer operations, which must not be left unattendedunattended

• • every ship is to be supplied with posters regarding the every ship is to be supplied with posters regarding the prohibition of the discharge of any pollutants. Anyone sighting a prohibition of the discharge of any pollutants. Anyone sighting a pollutant around or near the vessel has to inform the Master pollutant around or near the vessel has to inform the Master immediatelyimmediately

Click here for water pollution posterClick here for water pollution poster

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

General (cont.)General (cont.)

• • inert gas generators should be started before entering restrictedinert gas generators should be started before entering restricted waters to avoid the possibility of pollution.waters to avoid the possibility of pollution.

2. Bilges2. Bilges

• • Bilges must be kept dry at all times utilizing bilgeBilges must be kept dry at all times utilizing bilge holding holding tank. tank. All oil and water leaks must be stopped or reducedAll oil and water leaks must be stopped or reduced..

• • Engineer officer is to examine bilges regularly, leaks and spillages Engineer officer is to examine bilges regularly, leaks and spillages must be identified and eliminated (no oil leak collecting tins etc are must be identified and eliminated (no oil leak collecting tins etc are allowed)allowed)

• • Cleansing agents, emulsifiers, solvents or surfactants used for Cleansing agents, emulsifiers, solvents or surfactants used for cleaning purposes are to be minimized in the bilges of a ship, cleaning purposes are to be minimized in the bilges of a ship, to limit emulsion formation. to limit emulsion formation.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

2. Bilges (cont)2. Bilges (cont)

• • The contents of the bilge holding tank(s) are to be discharged viaThe contents of the bilge holding tank(s) are to be discharged via the vessel’s oily water separation system, ensuring that the oil the vessel’s oily water separation system, ensuring that the oil content of the effluent does not exceed 15 ppmcontent of the effluent does not exceed 15 ppm

3. The Oily Water Separator (OWS) 3. The Oily Water Separator (OWS)

• • personnel is to be fully familiar with its operation and testing personnel is to be fully familiar with its operation and testing

• • on no account is the OWS to be by-passed on no account is the OWS to be by-passed • • any faults and incorrect operating practices found by port any faults and incorrect operating practices found by port state inspection can lead to the detention of a vessel.state inspection can lead to the detention of a vessel. operation manual for the OWS is to be studied by the relevant operation manual for the OWS is to be studied by the relevant personnel in order to become fully conversant with it.personnel in order to become fully conversant with it.• • crew is to be familiar with the approved cleaning chemicals that do not crew is to be familiar with the approved cleaning chemicals that do not form emulsionform emulsion

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

3. The Oily Water Separator (OWS) cont.3. The Oily Water Separator (OWS) cont.

• • any flanges located at or near the OWS and overboard discharge valvesany flanges located at or near the OWS and overboard discharge valves that are not used, should be blanked off that are not used, should be blanked off

• • all flanges connected to any flexible hoses maintained on board which mayall flanges connected to any flexible hoses maintained on board which may create the wrong impression or suspicion that an illegal by-pass is being create the wrong impression or suspicion that an illegal by-pass is being used should be removed.used should be removed.

• • alarms and recording devices must be fully operationalalarms and recording devices must be fully operational

• • oil Record Book and the Deck Log can be closely checked for discrepancies oil Record Book and the Deck Log can be closely checked for discrepancies by the inspectorsby the inspectors

• • Pumping capacities can be scrutinisedPumping capacities can be scrutinised

• • OWS discharge valve is to be closed and locked when the vessel is in port OWS discharge valve is to be closed and locked when the vessel is in port or in a Special Area as defined by MARPOLor in a Special Area as defined by MARPOL

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

3. (OWS) cont.3. (OWS) cont.

•• It is to be noted that it is illegal to sail from a port without It is to be noted that it is illegal to sail from a port without a functioning OWS and it is a requirement that sufficient sparesa functioning OWS and it is a requirement that sufficient spares for the unit are carried onboard. for the unit are carried onboard.

•• The Chief Engineer is fully responsible for the maintenanceThe Chief Engineer is fully responsible for the maintenance and operation of the OWS and its operation must only be and operation of the OWS and its operation must only be carried out by officers fully familiar with the equipment carried out by officers fully familiar with the equipment

•• When the equipment is not in use, the Chief Engineer is to When the equipment is not in use, the Chief Engineer is to ensure that a system is in place to lock-out the equipment ensure that a system is in place to lock-out the equipment to avoid unauthorized operation with keys being held by the C/Eto avoid unauthorized operation with keys being held by the C/E

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

3. (OWS) cont.3. (OWS) cont.

• • Operating instructions and an operating diagram are to be Operating instructions and an operating diagram are to be posted on or next to the OWS unit.posted on or next to the OWS unit.

• • Regular operational tests and checks of the OWS and associated Regular operational tests and checks of the OWS and associated equipment must be carried out in accordance with the PMP and equipment must be carried out in accordance with the PMP and also no later than 24 hours before arrival in port where possible also no later than 24 hours before arrival in port where possible

• • Minimum recommendations are that full inspection andMinimum recommendations are that full inspection and cleaning of the OWS is to be carried out at least every twocleaning of the OWS is to be carried out at least every two months with filters cleaned on a monthly basis. All tests months with filters cleaned on a monthly basis. All tests must be recorded in the engine log book and oil record bookmust be recorded in the engine log book and oil record book However it is advisable that filters clearing should not be carried outHowever it is advisable that filters clearing should not be carried out immediately prior to entering port, as it may be interpreted as immediately prior to entering port, as it may be interpreted as

suspicious by PSC or MARPOL inspectors. suspicious by PSC or MARPOL inspectors.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

3. (OWS) cont.3. (OWS) cont.

•• The tank from which the OWS takes suction should be cleaned on a two The tank from which the OWS takes suction should be cleaned on a two monthly basis. A sample is to be landed yearly for testing in a shore monthly basis. A sample is to be landed yearly for testing in a shore laboratory; the test standard is to be USEPA 1664.laboratory; the test standard is to be USEPA 1664.

• • The Oil Content Monitor is to be calibrated yearly. Where possible an The Oil Content Monitor is to be calibrated yearly. Where possible an interlock deviceinterlock device preventing discharge overboard whilst flushing water preventing discharge overboard whilst flushing water supplied to the Oil Content Monitor (OCM) is to be fitted.supplied to the Oil Content Monitor (OCM) is to be fitted.

• • Any defects discovered with the OWS and associated equipment must Any defects discovered with the OWS and associated equipment must be rectified without delay. Where a defect cannot be repaired on board be rectified without delay. Where a defect cannot be repaired on board for want of spare parts or the need for specialist service, for want of spare parts or the need for specialist service, the the management office must be notifiedmanagement office must be notified and a remedial action plan agreed and a remedial action plan agreed upon. If the vessel is about to enter port knowing that the OWS is upon. If the vessel is about to enter port knowing that the OWS is defective, defective, the fact must be reported in the pre-arrival notices via agentsthe fact must be reported in the pre-arrival notices via agents according to local regulations.according to local regulations. for for RESOLUTION MEPC.107(49) „Revised guidelines and specifications for pollution prevention Revised guidelines and specifications for pollution prevention

equipment for machinery space bilges of ships.” Click equipment for machinery space bilges of ships.” Click herehere These Guidelines relate to equipment installed on or after 01.01.05

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

3. (OWS) cont.3. (OWS) cont.

• quantity of water discharged overboard in any logged period must quantity of water discharged overboard in any logged period must not exceed the certificated capacity of the OWS unit. If any such not exceed the certificated capacity of the OWS unit. If any such discrepancy occurs, a full explanation must be recorded in the ORB.discrepancy occurs, a full explanation must be recorded in the ORB.

•• consistent units of measurement of volumes, rates and capacities consistent units of measurement of volumes, rates and capacities used in the engine room should be used. used in the engine room should be used. (For example the units of measurement used in tank (For example the units of measurement used in tank sounding tables should be the same as those used in sounding tables should be the same as those used in recording volumes processed in the OWS)recording volumes processed in the OWS)

•• tank and equipment titles used in the ORB and in log books must tank and equipment titles used in the ORB and in log books must match those of tanks and equipment identified in the ship’s IOPP match those of tanks and equipment identified in the ship’s IOPP certificate. Bilge tanks must be identified by their location certificate. Bilge tanks must be identified by their location (e.g. frame number) and capacity as well as their correct title(e.g. frame number) and capacity as well as their correct title

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

3. (OWS) cont.3. (OWS) cont.

•• failure to comply with above instructions can lead to failure to comply with above instructions can lead to prosecution and authorities such as the USA have made it prosecution and authorities such as the USA have made it clear that they will seek jail sentences for senior officers of clear that they will seek jail sentences for senior officers of ships breaching pollution regulations.ships breaching pollution regulations.

•• USA officials are to scrutinise the E/R alarm book and USA officials are to scrutinise the E/R alarm book and compare the times recorded for bilge /sludge tank alarms and compare the times recorded for bilge /sludge tank alarms and subsequent pumping out with the ORB times of pumping subsequent pumping out with the ORB times of pumping bilges overboard, checking for any discrepancies.bilges overboard, checking for any discrepancies.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

3. (OWS) cont.3. (OWS) cont.

The The MasterMaster must be advised, before the OWS is used, to ensure must be advised, before the OWS is used, to ensure

that the operation is in compliance with MARPOL and that all that the operation is in compliance with MARPOL and that all risks have been fully considered. The bridge team is to be risks have been fully considered. The bridge team is to be advised when the equipment is in use in order that they can keep advised when the equipment is in use in order that they can keep a watch astern to ensure that no oily sheen is sighted on the a watch astern to ensure that no oily sheen is sighted on the water. If such a sheen is sighted then the operation must be water. If such a sheen is sighted then the operation must be immediately stopped. Where possible, consideration should be immediately stopped. Where possible, consideration should be given to limiting the use of the oil water separator to daylight given to limiting the use of the oil water separator to daylight hours. Where possible, consideration should be given to posting hours. Where possible, consideration should be given to posting a watch (additional to the navigation watch) to visually monitor a watch (additional to the navigation watch) to visually monitor the sea surface in way of the discharge.the sea surface in way of the discharge.

For more details on OWS click here Ref. is also to be made to the Fleet Operations Section 6.5.5. e and Safety & Environmental Procedures Section 9.4.3

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

4.4. Disposal and handling of sludgeDisposal and handling of sludge

• • sludge is to be considered as “contaminated, hazardous and toxic”.sludge is to be considered as “contaminated, hazardous and toxic”. There is a significant danger of explosion and fire as well as theThere is a significant danger of explosion and fire as well as the dangers associated with toxic chemicals. Therefore it must be dangers associated with toxic chemicals. Therefore it must be handled with care by competent staff using appropriate equipment handled with care by competent staff using appropriate equipment and protective clothing. and protective clothing.

• • sludge containing oil or petroleum wastes from the engine room sludge containing oil or petroleum wastes from the engine room must be disposed of in full compliance with MARPOL .must be disposed of in full compliance with MARPOL .

• • expected sludge generation should be around 0,8 – 1,0 % of HFOexpected sludge generation should be around 0,8 – 1,0 % of HFO

plus 0,5% of DO consumption.plus 0,5% of DO consumption.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

Disposal and handling of sludge (cont.)Disposal and handling of sludge (cont.)

Disposal will be:Disposal will be:

direct to shore facilities or with the use of onboard incinerators or direct to shore facilities or with the use of onboard incinerators or by by other means covered by supplement to the IOPP Certificate other means covered by supplement to the IOPP Certificate “ “Form A/B”Form A/B”

if not stated in the IOPP Supplement Form A/B and the vessel if not stated in the IOPP Supplement Form A/B and the vessel hashas insufficient free capacity onboard to reach shore reception insufficient free capacity onboard to reach shore reception facilities, the transfer of engine-room sludge to the cargo facilities, the transfer of engine-room sludge to the cargo system slop tanks may only be carried out after contact system slop tanks may only be carried out after contact with the management office and flag authorisation.with the management office and flag authorisation.

a Risk Assessment (SAF03) and Critical Operations Checklist (SAF16) a Risk Assessment (SAF03) and Critical Operations Checklist (SAF16) must be created by the vessel and reviewed by the management office must be created by the vessel and reviewed by the management office prior to any such transfer.prior to any such transfer.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

55. Other procedures. Other procedures that, that, if followed correctlyif followed correctly, will help prevent, will help prevent pollution from engine room sourcespollution from engine room sources

FO 6.3.4 FO 6.3.4 Planned Maintenance System Planned Maintenance SystemFO 6.3.5 FO 6.3.5 Defects and Damages Defects and DamagesFO 6.3.13 FO 6.3.13 Pipeline Identification, Valves Pipeline Identification, ValvesFO 6.3.18 FO 6.3.18 Calibration CalibrationFO 6.9.5 FO 6.9.5 Completion of Dry-docking Completion of Dry-dockingS&E 3.0S&E 3.0 Risk Assessments & Critical Operations Risk Assessments & Critical OperationsS&EP 4.4.4 (h) Use of DetergentsS&EP 4.4.4 (h) Use of DetergentsS&EP 4.6.3S&EP 4.6.3 Lock Out – Tag Out Procedures Lock Out – Tag Out ProceduresS&EP 9.4S&EP 9.4 Water Pollution Water PollutionS&EP 9.7S&EP 9.7 Disposal and Handling of Sludge Disposal and Handling of Sludge

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

6. Tankers Cargo Operations 6. Tankers Cargo Operations - the main oil pollution sources:- the main oil pollution sources:

• • Failure to monitor operations correctlyFailure to monitor operations correctly• • Poor use of checklistsPoor use of checklists• • Responsibilities delegated from officers to crewResponsibilities delegated from officers to crew• • Failure of equipment Failure of equipment • • Insufficient planning Insufficient planning • • ComplacencyComplacency• • Failure to follow proceduresFailure to follow procedures

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

6.1. PLANNING 6.1. PLANNING (Oil Tanker Operating Instruction)(Oil Tanker Operating Instruction)

Cargo Loading/Discharge PlanCargo Loading/Discharge Plan (Form MAR08) includes as a (Form MAR08) includes as a minimum: final ullages, correct sequence of loading/discharge with minimum: final ullages, correct sequence of loading/discharge with expected times, ballasting, stress, stability and draft conditions at expected times, ballasting, stress, stability and draft conditions at each stage, operating envelope of loading arms.each stage, operating envelope of loading arms.

The Chief Officer The Chief Officer in conjunction with another officer in conjunction with another officer ensure that all ensure that all valves are correctly set.valves are correctly set.

Plan is to be approved by the Master and signed by each officer and Plan is to be approved by the Master and signed by each officer and pumpman. Junior officers are encouraged to take part in planning.pumpman. Junior officers are encouraged to take part in planning.

Plan is to be discussed and agreed in writing with the terminal Plan is to be discussed and agreed in writing with the terminal personnel.personnel.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

6.2. COMMENCING OPERATIONSCOMMENCING OPERATIONS

Before any operation proper procedures must be adopted in Before any operation proper procedures must be adopted in accordance with Oil Tanker Operating Instruction accordance with Oil Tanker Operating Instruction

4.64.6 Cargo PlanningCargo Planning 4.16 Commencing Operations4.16 Commencing Operations 6.36.3 Precautions Before and During LoadingPrecautions Before and During Loading 8.58.5 Precautions Before DischargePrecautions Before Discharge 11.4.1. Tank Cleaning Plan11.4.1. Tank Cleaning Plan All or parts of the above refer to the blanking of manifolds not in All or parts of the above refer to the blanking of manifolds not in

use, checking valves and lines, the use of checklists, scuppers in use, checking valves and lines, the use of checklists, scuppers in place, trips and alarms tested, commencing loading slowly, place, trips and alarms tested, commencing loading slowly, checking valves and lines again once cargo operations underway, checking valves and lines again once cargo operations underway, checking cargo going into/out of correct tanks, proper watch keeping checking cargo going into/out of correct tanks, proper watch keeping and communications as well as the readiness of salvage pumps and and communications as well as the readiness of salvage pumps and clean-up equipment in case of a spill.clean-up equipment in case of a spill.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

6.3. MONITORING OF OPERATIONS6.3. MONITORING OF OPERATIONS

Monitoring of all cargo operations is essential for the purpose of safetyMonitoring of all cargo operations is essential for the purpose of safetyand the avoidance of pollution. and the avoidance of pollution.

Monitoring comprisesMonitoring comprises::

the cross checking of fixed with portable gaugesthe cross checking of fixed with portable gauges the calculation of loading/discharge rates – unplanned the calculation of loading/discharge rates – unplanned deviations in the loading rate must be investigated immediatelydeviations in the loading rate must be investigated immediately checking pressures at the manifoldchecking pressures at the manifold ensuring cargo is being loaded/discharged from the correct ensuring cargo is being loaded/discharged from the correct spaces and that spaces not involved in the spaces and that spaces not involved in the operation are checkedoperation are checked check of mooringscheck of moorings

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

6.3. MONITORING OF OPERATIONS (cont.)6.3. MONITORING OF OPERATIONS (cont.)

effective manifold and deck watch looking for leaks both on effective manifold and deck watch looking for leaks both on the ship and over-sidethe ship and over-side

checking stress and stabilitychecking stress and stability checks of IGchecks of IG checks of the pump roomchecks of the pump room careful topping offcareful topping off ensuring cargo is fully stopped after loadingensuring cargo is fully stopped after loading the use checklists!the use checklists!

ENSURE THAT THE CARGO PLAN IS FOLLOWED BY ALL!ENSURE THAT THE CARGO PLAN IS FOLLOWED BY ALL!VMS Ref. = VMS Ref. = Oil Tanker Operating InstructionsOil Tanker Operating Instructions : all chapters! : all chapters!

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

6.4. CHECKLISTS 6.4. CHECKLISTS

Checklists are an essential and useful tool in safe operation and if used Checklists are an essential and useful tool in safe operation and if used correctly they help prevent an incident. However they do not detract from an correctly they help prevent an incident. However they do not detract from an officers responsibility to follow the fully laid down procedure.officers responsibility to follow the fully laid down procedure.

There are references to particular checklists in almost every chapter of the There are references to particular checklists in almost every chapter of the tanker manual to accompany procedures and the relevant checklists are tanker manual to accompany procedures and the relevant checklists are held within the forms manual. All checklists must be signed and a log entry held within the forms manual. All checklists must be signed and a log entry made once completed.made once completed.

Where a checklist does not exist for a specific and critical operation (e.g. Where a checklist does not exist for a specific and critical operation (e.g. tank cleaning) then a critical operations checklist (SAF 16) is to be made tank cleaning) then a critical operations checklist (SAF 16) is to be made and used onboard for such an operation. (ref .Sand used onboard for such an operation. (ref .S&&EEP P 3.7)3.7)

Over and above Company checklists, the tanker manual references the Over and above Company checklists, the tanker manual references the Ship-Shore and Ship-to-Ship Transfer checklists as contained within Ship-Shore and Ship-to-Ship Transfer checklists as contained within ISGOTT (tanker manual refs 3.7, 3.8, 3.30.4, 3.30.5, 4.14, 6.3 and 8.5). ISGOTT (tanker manual refs 3.7, 3.8, 3.30.4, 3.30.5, 4.14, 6.3 and 8.5). Another non-Company checklist to be used is for crude oil washing. Such Another non-Company checklist to be used is for crude oil washing. Such

a form will be available in the COW operating manual carried onboard (ref .a form will be available in the COW operating manual carried onboard (ref . Oil Tanker Operating Instructions 11.9).Oil Tanker Operating Instructions 11.9).

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

6.5. RESPONSIBILITIES6.5. RESPONSIBILITIES

Section 2 of Oil Tanker Operating Instructions defines the responsibilities Section 2 of Oil Tanker Operating Instructions defines the responsibilities (in relation to tanker operations) of the following personnel:(in relation to tanker operations) of the following personnel:

Master:Master: e.g. supervision of cargo system and checking cargo plans e.g. supervision of cargo system and checking cargo plans Chief Officer:Chief Officer: e.g. preparing the cargo plan, monitoring and control e.g. preparing the cargo plan, monitoring and control of of

cargo operations, personal supervision, producing written instruction cargo operations, personal supervision, producing written instruction and checking stress/stability. and checking stress/stability.

2nd & 3rd Officers:2nd & 3rd Officers: e.g. monitoring of cargo operations as instructed by e.g. monitoring of cargo operations as instructed by the Chief Officer and ensuring that a proper watch is maintained.the Chief Officer and ensuring that a proper watch is maintained.

Chief Engineer:Chief Engineer: e.g. maintenance of equipment and advising the Chief e.g. maintenance of equipment and advising the Chief Officer of any bunker or other transfer to take place.Officer of any bunker or other transfer to take place.

Pump man and Ratings: Pump man and Ratings: assisting in cargo operations as required by the assisting in cargo operations as required by the Chief OfficerChief Officer

There are examples of incidents occurring where the Chief Officer has delegated There are examples of incidents occurring where the Chief Officer has delegated various responsible tasks to ratings instead of the deck officer.various responsible tasks to ratings instead of the deck officer.

The use of the word “assist” in relation to the pump man and ratings is not intended to detract The use of the word “assist” in relation to the pump man and ratings is not intended to detract from the responsibility of the officers who are trained and experienced in cargo handling.from the responsibility of the officers who are trained and experienced in cargo handling.

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

6.6. FAILURE OF EQUIPMENT6.6. FAILURE OF EQUIPMENT

There are many important items of equipment that are used in cargo There are many important items of equipment that are used in cargo operations. If one or more of these were to fail or not be operated correctly a operations. If one or more of these were to fail or not be operated correctly a pollution incident could easily occur. These items have two or more things in pollution incident could easily occur. These items have two or more things in common with each other that directly effect their operation:common with each other that directly effect their operation:

Planned Maintenance (effectively carried out)Planned Maintenance (effectively carried out) Routine Testing (part of PMP or as required before operations)Routine Testing (part of PMP or as required before operations) CalibrationCalibration Understanding the correct use (read the instruction manuals)Understanding the correct use (read the instruction manuals) Following procedures correctly (read the relevant sections of the VMS)Following procedures correctly (read the relevant sections of the VMS)

Reference to the above is to be found throughout the VMSReference to the above is to be found throughout the VMS

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

7. 7. Bunker OperationsBunker Operations

the main problems refer to:the main problems refer to:

•• Insufficient planning Insufficient planning •• Failure to monitor operations correctlyFailure to monitor operations correctly•• Poor use of checklistsPoor use of checklists•• ResponsibilitiesResponsibilities•• Failure of equipment Failure of equipment •• ComplacencyComplacency

All bunker procedures are contained in the Fleet Operating Manual, Ch 6, SectAll bunker procedures are contained in the Fleet Operating Manual, Ch 6, Sect..7.2 7.2

For further details of bunkering operations including specific responsibilities, For further details of bunkering operations including specific responsibilities, bunkering plan andbunkering plan and checklist pleasechecklist please click here click here

(Some key points (Some key points related to Oil Pollutionrelated to Oil Pollution PreventionPrevention are listed in the following are listed in the following slides)slides)::

OIL POLLUTION PREVENTIONOIL POLLUTION PREVENTION

Bunker filling limits :Bunker filling limits : Tanks up to 700m3 = 90%Tanks up to 700m3 = 90% Tanks over 700m3 = 95%Tanks over 700m3 = 95% Tanks with known air-locking difficulties = 90%Tanks with known air-locking difficulties = 90%

Responsibilities:Responsibilities: MasterMaster; to ensure all regulations complied with; to ensure all regulations complied with Chief OfficerChief Officer; to deploy pollution prevention equipment; to deploy pollution prevention equipment Chief EngineerChief Engineer: to plan and supervise as well as ensure all : to plan and supervise as well as ensure all equipment is in good order. equipment is in good order. This responsibility cannot be This responsibility cannot be delegated. delegated. He must also ensure the He must also ensure the designated persondesignated person is aware is aware