Marie Lartigue -...

Transcript of Marie Lartigue -...

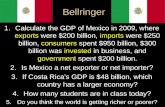

Erasmus (France)

Quality of hops in beer production

Marie Lartigue

Tutors: Heinrich Grausgruber, Johann Vollmann

2

Summary

INTRODUCTION

I) GET TO KNOW HOPS BETTER

1) Etymology

2) Botanical characteristics

3) Origin and history

4) Cultivation

5) Nutritional value and common uses

6) Beer processing

II) QUALITATIVE ASPECTS

1) Hop chemistry in beer flavor

2) Hop chemistry of the bitter taste

3) The lightstruck flavor of beer

4) Color of beer

5) Hop technology to control beer quality

6) Hops quality labels

III) HOP BREEDING AND SELECTION

1) What about selection in hop breeding?

2) Hops quality traits selection

3) Hop varieties

CONCLUSION

3

Table of acronyms and abbreviations

A.D.: Anno Domini

C4/C5: Carbon 4 / carbon 5

Ca: circa

CO2: Carbon dioxid

DNA: Deoxyribonucleic acid

EU: European Union

°F: Degree Fahrenheit

GMO: Genetically modified organism

IBU: International Bitterness Units

QTL: quantitative trait loci

PDO: Protected Designation of Origin

PGI: Protected Geographical Indication

Ppm: Part per million

TSG: Traditional Specialties Guaranteed

USDA: United States Department of Agriculture

4

Introduction

Austria is the second highest consumer of beer per capita worldwide, after Czech Republic,

with an average consumption of 206 large glasses of beer (or 106 liters) per head per year!

Indeed, the country has 214 breweries and the number is ever increasing. 1 In France, the

annual volume of beer consumed per capita amounts to 33 liters and is therefore at the 54th

position on the list of countries by beer consumption per capita. 2

This popular alcoholic beverage is produced by extracting raw materials with water, boiling,

and fermenting. Besides water, the ingredients are malt (kiln-dried germinated barley), yeast,

and hops. 3 This last ingredient is the one we are interested in.

In fact, the hop flower is added to beer to give it bitterness and aroma. It is a preservative and

it extends the life of beer. 4 The properties that hops give to the beer depend on how they

have been used during the brewing process but also on the hop varieties. In this report, we

want to know more about the quality of hops in beer production.

In food industry, product quality means that the product is conform to standards and free of

deficiencies or defects. To be considered as a quality product, it is also made depending on

what the consumer needs, wants and it must give him/she satisfaction. 5 It is the same for

beer, which must be conform to standards of technologies in the brewing process, or

standards required by labels. To satisfy the consumer, the beer must have a special taste, a

special color, a special level of bitterness, etc. Hops are a key ingredient that modifies and

adjusts a lot of quality parameters of beer. Quality of hops depends on what the brewer is

looking for in the hop plant. For that, many varieties exist. The utilization of a special variety

of hops and the strategic use of it can roughly modify the beer quality.

This report deals with the aspects of quality of hops in beer production. In a first part, the hop

plant will be described to get to know it better: its botanical characteristics, history,

cultivation, origins, and uses will be discussed. The brewing process will also be explained in

order to understand better how hops play a role in beer production and how to change some

parameters. The second part will be about the qualitative aspects that hops bring to beer: for

each chemical substance present in the hop plant, the effects they provide to beer will be

discussed. Finally, the different varieties of hops will be described in the third part: the

characteristics of each variety will be announced and a paragraph about the breeding and the

selection will be written as well.

1 https://www.austria.info/uk/things-to-do/food-and-drink/beer-culture 2 https://www.statista.com/statistics/447089/france-volume-beer-consumption-per-capita/ 3 https://www.britannica.com/topic/beer 4 http://allaboutbeer.com/learn/beer/hops/ 5 http://kalyan-city.blogspot.com/2013/05/what-is-product-quality-definition.html

5

I) Get to know hops better

1) Etymology

The scientific name of hops is Humulus lupulus. Lupulus comes

from the Latin lupus (wolf) because, as Pliny described in his

Naturalis Historia, “when the plant is produced among osiers,

it strangles them by its light, climbing embraces, as the wolf

does a sheep”. Humulus is thought to be derived from humus,

which is a rich organic matter of the soil in which the plant

grows. The English word hop comes from the Anglo-Saxon

word hoppan (to climb).

2) Botanical characteristics

Hops are hardy, twining, herbaceous, perennial plants that

belong to the Cannabaceae family, which also contains the

genus Cannabis (hemp). They are made up of a rough stem

that produces a milky latex sap. The leaves are 3-5 lobed,

oppositely arranged, coarsely toothed. Hops plants either

have male or female (dioecious) flower cones

(inflorescences): male and female plants are separated. Male

inflorescences panicles and female inflorescences round

spikes have both papery bracts. Female plants’ cones are

called strobili. They are pollinated by wind and both pollinated

and unpollinated strobili only are harvested and used in

brewing. Much of the hop components desired for brewing

are found in the lupulin glands, which are located inside the base of the bracteoles, under the

small leaves of the strobili. They contain the resin humulone (alpha acids), lupulone (beta

acids), and the aromatic oils. Fruits are visibly much larger than inflorescences: they are

spherical and straw-colored. 6

3) Origin and history

The hop plant originally comes from Europe. There, it is best produced between April and

September. To get a very successful harvest, a lot of rain during the growing period coupled

with plentiful sunlight in the fruiting period are needed. The main crop producing regions in

the Northern Hemisphere are found in the United States, Germany, the Czech Republic and

England. Today, in the United States, roughly 50 million tons of hops are produced.

Throughout the 19th century, thanks to the ideal conditions for hop farming and the crop’s

geographic tendencies, Central New York was one of the America’s greatest producing

6 https://www.edenproject.com/learn/for-everyone/plant-profiles/hops

Figure 1 Hop plant classification (http://academics.hamilton.edu/foodforthought/Our_Research_files/hops.pdf)

6

regions. In fact, the widespread cultivation of hops, as case with much of its history is closely

associated with the making of beer. They became a popular additive in beer in medieval

Europe since they had been planted for the first time in 736 A.D. in Bavaria. During English

colonization, the crop was introduced to America in 1629.

4) Cultivation

The growing season of hops generally stretches from June to August and an average of 50-

66°F is ideal. Sunlight is also very important. It is better to plant after the possibility of frost

but not after May 18. Indeed, the hop plant is a perennial and lies dormant in the winter. That

is why summer is the natural time to grow hops. A minimum of 120 days is required to produce

a ripened crop of flowers. Even after the flowers ripen and are harvested, the vine will

continue to grow until the first frost in the fall in order to build up energy for winter. During

this growing stage, plants need water with an optimal degree of rainfall between 2,5 and 22,4

inches of precipitation. Indeed, the soil should be damp but proper drainage is necessary: hop

plants grow better on a well-drained soil that does not contain too much nitrogen and that

maintains a good soil structure. The use of chemical fertilizers can cause an excess of nitrogen,

which can harm the plant’s development. To use nitrogen-fixing legume crops as a type of

green manure ensures a slow release of nitrogen back into the soil as well as the accumulation

of calcium, potassium, and other essential micronutrients that the plant requires for growth.

The optimal pH is 6.0-6.2, which corresponds to a moderately acidic soil. However, hop plants

can grow anywhere in a range of 6.0-8.0. The soil must be free of weeds: to eliminate the

presence of unwanted plants, thorough tilling and addition of straw to the soil are important.

Concerning the possible diseases, downy mildew is entirely exclusive to the hop plant. It

occurs in humid conditions and stunts the growth of the plant. A soil that has not been well

drained increases the chance of causing disease. One solution is to plant the hops into hills

and to ditch the space between the rows. Against downy mildew, the farmer must remove all

the diseased shoot to prevent the loss of the entire crop. Pests is another problem for farmers:

hop aphids and spider mites are the most common insects. When the introduction of a

ladybug population is not efficient, farmers must use insecticides.

During their first year of growth, hop plants only grow about 6 feet tall because they spend

most of their energy expanding their root system. Indeed, they have a permanent root stock,

called a crown, that can grow over 12 feet deep into the soil and survive for over 25 years. A

mature plant can grow about 25-30 feet tall and produce up to 2 pounds of hops.

The time to harvest depends on the climate. The goal is to pick the hops when the lupulone

is the most aromatic, and the strobili are just starting to dry. It is to ensure the bitterness

and to ensure that the cones won’t be destroyed during processing.

5) Nutritional value and common uses

Hops are well-known beer’s major additive and preservative. The bitter taste given to beer is

due to the strobili’s content in alpha and beta acids. Alpha acids consist of a complex

hexagonal structure with several side chains that include ketone and alcohol groups. The

major types of different alpha acids are humulone, cohumulone, adhumulone, prehumulone,

7

and posthumulone. They differ in the makeup of side chains in their chemical structure. As

soon as the strobili are harvested, the levels of alpha acids begin to decline and if hops are

stored for a too long time, then the side chains can break down. In hops, 95% of the alpha

acids are humulone, cohumulone, and adhumulone. In addition to providing bitterness, these

compounds provide other characteristics to beer. Cohumulone is thought to increase head

retention and foam stability by forming cross linkages with specific proteins. Certain varieties

are selected to contain up to 19% alpha acids, called super-alpha-hops. Beta acids play the

same role in providing bitterness to beer, even if the compounds are not bitter. The bitterness

appears as the substances oxidize during storage. The main beta acids found in crops are

colupulone, lupulone, and adlupulone. They are structurally similar to the alpha acids.

In addition to the properties given to beer, hops’ components also provide benefits for the

human health. It has been an herbal remedy for a very long time. Hops are believed to possess

sedative, hypnotic, and topical bactericidal properties. They have traditionally been used for

neuralgia, insomnia, excitability, priapism, mucous colitis, ulcers, restlessness associated with

nervous tension headache and indigestion. They also show antibacterial properties against

gram-positive bacteria. Lupulin produced from the female strobili increases milk production

in nursing mothers. Flavonoids found in hops are well known for their antioxidant activities in

neutralizing free radicals within the body. In fact, free radicals can damage cells and cause

cancer. Hops are the major source of the flavonoid xanthohumol in the human diet. In addition

to its antioxidant properties, this flavonoid has been shown to prevent the growth of tumor

cells and in particular prostate cancer. Xanthothumol is also an antiinfective substance

efficient against bovine diarrhea virus, cytomegalovirus, herpes simplex virus, and human

immunodeficiency virus. It possesses a strong response against the replication of Plasmodium

falciparum, the causative agent of malaria. Other flavonoids show positive effects on human

cancer cells as they have chemoprotective activity against breast and ovarian cancer.

However, a person would have to drink 120 gallons of beer a day to experience any significant

biological effect of the xanthohumol. 7

7 http://academics.hamilton.edu/foodforthought/Our_Research_files/hops.pdf

Figure 2 Chemical structures of humulones and lupulones (http://academics.hamilton.edu/foodforthought/Our_Research_files/hops.pdf)

8

6) Beer processing

MILLING: The first step in beer processing is the milling of the brewing grain, barley. The goal

is to crush the grains enough so that it exposes the starchy center of the barley seed without

damaging the grain hulls that encase them. If the crush is too strong, not enough of the starch

will be converted to fermentable sugars. However, if it is too fine, the husks, which act as a

filter bed for the brew will be destroyed, and the brew will become gummy and unusable.

MASHING: Once the grains have been milled, they are

added to a large vessel called the mash tun and mixed with

hot water to form the mash. The water must be hot, and

the heat activates the enzymes within the barley: they

convert the starches into sugars. There are several

different types of enzymes within barley and each of them

has a preferred temperature at which they work.

Therefore, by raising or lowering the temperature of the

mash, brewers can control what types of sugars are

produced by the enzymes. To produce highly fermentable sugars, lower temperatures are

needed. At higher temperatures, the sugars are not easily digested by the yeast, resulting in a

beer with some sugars left unfermented, and thus a sweeter, more full-bodied end product.

Within about an hour, enzymes will have worked and be done converting starch to sugar. At

this point, the brewer will end the enzymatic activity by raising the temperature of the mash

to over 200 degrees Fahrenheit. This process is called the mashing out.

LAUTERING: During this step, the goal is to take the mash

and separate out the spent grain from the sugary liquid

known as wort. To begin, the mash must be transferred to a

vessel with a false-bottom called a lauter tun. Then, the

clear wort is drained away from the hulls and barley grist. In

order to extract even more of the fermentable sugars from

the grain, water is added: this is called the sparging. It must

be done very gradually as to not disrupt the grain bed that

acts as a natural filter for the wort. Typically, brewers add

sparge water at the same rates as the wort is being drained below. Some English methods

completely drain the wort, then add water and do it all over again. This method is called

second runnings and was basically used for small beers. Brewers must be very careful not to

sparge for too long because the bitter tannins could be stripped away.

Figure 3 Milling step(http://craftbeertemple.com/videoblog/brewing-process/)

Figure 4 Mashing step (http://craftbeertemple.com/videoblog/brewing-process/)

Figure 5 Lautering step (http://craftbeertemple.com/videoblog/brewing-process/)

9

BOIL: At this step, the wort is sweet and has been separated from the grains. It is now brought

to a boil for one to two hours. This step is very important since it sterilizes the beer. Moreover,

once hops are introduced to boiling water, they will break down or isomerize. This will alter

the composition of the acids within the hops and release bitterness into the beer. The longer

the hops are boiled, the more of their alpha acids will be isomerized in order to lend bitterness

to the brew. Hops added to the boiling water to provide bitterness are called early hop

additions, and they generally boil in the beer for an hour or more. If hops are added later, they

don’t bitter the beer that much, but instead they give flavor and aroma. This is due to highly

volatile and pungent oils that hops contain in addition to alpha acids. These oils break down

quickly in boiling water as well. To extract flavor, brewers add hops about 10-15 minutes

before the end of the boil. For aroma, they are added even later, no more than 2 minutes

before the end of the boil. It often happens that aromatic hops are added just after the end

of the boil. After the boil ended, it is sent to a whirlpool to collect any accumulated hop matter

and coagulated proteins. Then it is immediately cooled, since the beer will begin to oxidize

and produce off flavors almost immediately at these temperatures.

FERMENTATION: Once the wort has been cooled, it is moved to a

fermentor. Then, yeast is added and begins to eat the sugars that had

been created during the mash. In the same time, it expels carbon

dioxide and alcohol, as well as a variety of flavor compounds. The time

of fermentation vary from a few days for a simple ale to over a month

for lagers. The majority of beers is an ale. This style requires ale yeast

that will be added to the beer and the temperature of the fermenting

beer will rise to 65-76 degrees. If brewing a lager, the beer must be

much cooler, between 45 and 55 degrees.

CONDITIONNING: Once the yeast has consumed all the available

sugars, primary fermentation is over. However, some off flavors

associated with under-conditioned or “green” beer are created:

sulfur, butter, green apples. Luckily, yeast will absorb these off

flavors. Once fermentation is over, yeast finally become dormant

and begins to settle to the bottom of the fermentation vessel. It is

easily removed to leave only bright, clear beer. Brewers can either

use a filter or add filtering agents which help collect the yeast into

larger groups, which then fall out of suspension at a faster rate.

Figure 6 Boiling step (http://craftbeertemple.com/videoblog/brewing-process/)

Figure 7 Fermentation step (http://craftbeertemple.com/videoblog/brewing-process/)

Figure 8 Conditionning step (http://craftbeertemple.com/videoblog/brewing-process/)

10

PACKING: Finally, beer is packed into bottles, can, and kegs. Most of the time, brewers force

carbonating their beer just prior packing, since they’ve allowed any CO2 developed during

fermentation to escape into the atmosphere. Without this step, the tanks could rupture from

the pressure build-up. Some brewers, instead of force carbonating, add yeast and sugars to

bring a second fermentation inside the bottle, thereby adding depth flavor, as well as

carbonation. 8

II) Qualitative aspects

Hops are one of the most important ingredients of beer. They bring bitterness to beer but also

flavor and aroma. In addition, they contribute to the color and clarity of the beer. Originally,

hops were added to beer to preserve it.

Hops contain many components that are responsible for bitterness, flavor, aromas, and color.

1) Hop chemistry in beer flavor

As mentioned above, hops are responsible for the hoppy flavor in beer. It results from many

different volatile compounds found in hops that act in synergism. During the boiling of hops

in wort, many constituents are volatilized or oxidized, and the hop-derived constituents

present in beer are different from the original molecules present in hops. The very intricate

composition of the hop oils becomes even more complex during wort boiling.

8 http://craftbeertemple.com/videoblog/brewing-process/

Figure 9 Hops chemical composition (http://www.uvm.edu/extension/cropsoil/wp-content/uploads/2014HopsConference_Shellhammer_brewersperspective.pdf)

11

Brewers often try to conserve the original composition by adding precious hop varieties near

the end of the boiling period. This method is called late hopping and allows some original hop

constituents to be directly transferred to beer to give it a discrete hoppy character.

Hops are also rich in polyphenols as they can represent one third of the total amount of

polyphenols in beer. They are found as monomers, dimers, trimers, and more complex forms

associated with nitrogenous components. They combine slowly with proteins to form chill

haze when cooled, which dissolves when warmed up. As they polymerize and grow larger,

they become insoluble at room temperature to form irreversible haze. Hops polyphenols have

interesting effects on taste and taste stability of beers. Moreover, polyphenols are known to

have anti-oxidant properties very beneficial in human diet. That is why in the future, more

attention will be focused on the various roles of polyphenols in brewing.

Hop oils are mainly terpenes and susquiterpenes. Due to the fact that they are highly volatile

and easily evaporate, most of them are lost during wort boiling. However, trace amounts of

them remain, and provide many of the beer’s positive flavor and aroma attributes.

2) Hop chemistry of the bitter taste

The most well-known role of hops in beer production is the bitterness it provides. Naturally,

before introducing hops, beer is sweet. Hops balance and help counteract this sweetness.

The most important class of hops compounds is the class of hop acids, which includes the

alpha-acids, or humulones, and beta-acids or lupulones. The two series comprise, in fact, three

constituents differing in the nature of the side chain, which is derived from the hydrophobic

amino acids, leucine, valine, and isoleucine, for humulone/lupulone, cohumulone/colupulone,

and adhumulone/adlupulone, respectively. The relative proportions of the individual

constituents depend strongly on the hop variety and, for a given variety, on the conditions of

growing. The hop aids occur as pale-yellowish solids in the pure state, are weak acids, exhibit

very poor solubility in water and have almost no bitter taste.

Hop acids have the particularity to have a strong bacteriostatic activity; it means they inhibit

the growth of Gram-positive bacteria. It is due to the interaction between the prenyl group of

the side chains of the acids, with the cell plasma membrane. The more prenyl groups are

Figure 10 Structures of humulones and lupulones (http://www.scielo.br/scielo.php?script=sci_arttext&pid=S0100-40422000000100019)

12

present, the stronger the bacteriostatic action is. It is very important for killing micro-

organisms during wort boiling, which ultimately leads to a sterile beer.

Beta-acids are very sensitive to oxidative decomposition and most oxidation reaction products

possess unpleasant organoleptic characteristics. They may protect beer against oxidation but

in general, they are not appreciated and thus, brewers select hop varieties that are poor in

beta-acids.

The major component of the alpha-acids is humulone. While the relative amounts of

humulone and cohumulone are variety-dependent (20-50%), adhumulone constitutes

invariably ca. 15% of the mixture. Cohumulone has been associated with a poor hop quality

but the reason has not been clearly given.

The most important chemical conversion

overall during the brewing process in the

thermal isomerization of the alpha-acids or

humulone to the iso-alpha-acids or

isohumulones via an acyloin-type ring

contraction. The IBU (International Bitterness

Units) is a relative scale that

spectrophotometrically determines iso-alpha-

acids in beer. IBUs can be utilized to not only

compare the bitterness between two different beers but can also be used as a quality control

measure to ensure a consistent level of bitterness.

Each humulone gives two epimeric isohumulones: cis-isohumulones and trans-isohumulones.

These two forms depend on the spatial arrangement of the tertiary alcohol function at C4 and

the prenyl side chain at C5. Trans and cis mean that these two groups point to opposite faces

and to the same face of the five-membered ring, respectively. Because humulone is

isomerized to cis-isohumulone and trans-alphahumulone, six major iso-alpha-acids are

present in beer: cis-isohumulone and trans-isohumulone, cis-isocohumulone and trans-

isocohumulone, cis-isoadhumulone and trans-isoadhumulone. They result from the

conversion of the three major alpha-acids humulone, cohumulone and adhumulone,

respectively.

Figure 12 Conversion of the humulones to the isohumulones (http://www.scielo.br/scielo.php?script=sci_arttext&pid=S0100-40422000000100019)

Figure 11 The most important reaction in hop chemistry

13

The ratio of isohumulones depends on the reaction conditions. It is normally 68:32 in favor of

the cis-compounds, which are much more stable (half-life over 5 years) than the trans-isomers

(half-life of ca. 1 year). This affects the cis:trans ratio and has significant consequences on taste

and flavor stability. Brewers try to have the highest content of cis-isohumulones possible in

the mixture.

Iso-alpha-acids are very bitter, almost equivalent to quinine, the reference compound for

comparisons of bitterness. Their concentrations vary from 15 ppm in typical American lager

beers to nearly 100 ppm in very bitter English ales. However, the real taste perceived by

consumers is modified and more complex because of the residual sugars, and thus, the

bitterness is evaluated as pleasant bitterness.

In addition to the bitter taste iso-alpha-acids provide to the beer, they exhibit other interesting

features such as tensioactive properties, thereby stabilizing the beer foam, and inhibit the

growth of Gram-positive bacteria, thus protecting beer against these micro-organisms.

3) The lightstruck flavor of beer

Iso-alpha-acids and phenolic compounds are key components for beer stability. Iso-alpha-

acids are partly responsible for production of ageing off-flavors, including stale and cardboard

flavors: volatile aldehydes, such as trans-non-2-enal, are formed during storage of bottles beer

from various precursors, including hop lipids. It is also known that beer decomposes on

exposure to light, thereby generating an offending skunky flavor. This is due to the

vulnerability of the iso-alpha-acids to light. The resulting decomposition leads to formation of

the “lightstruck flavor”. The light-sensitive chromophore in the isohumulones is the acyloin

group composed of the tertiary alcohol function at C4 and the carbonyl group of the side chain

at C4. That is the reason why beer must be stored, either in opaque cans, or in green or brown

bottles, in order to prevent light from being transmitted through the glass.

4) Color of beer

The color of beer is also a characteristic of quality and hops affect this indicator of quality.

Their content in polyphenols plays a role in beer color and clarity when they are release into

the beer. The older the hops, the more color will be imparted to the beer.

5) Hop technology to control beer quality

The following part is about some technologies applied to the brewing process or directly to

the hops in order to get full utilization of hops and to get the best quality of beer.

The isomerization of alpha-acids to iso-alpha-acids during wort boiling unluckily gives low

yields, which are seldom higher than 30%. Critical factors are the transfer of the alpha-acids

from vegetative hop, the low solubility of the alpha-acids and the neutral wort (pH 5-5.5). To

get a better yield (40-50%), hop extracts are used. To extract both the hop acids and the hop

oil from hops, liquid or supercritical carbon dioxide are excellent medium. The goal of new

technologies is to exploit the full potential of hops and optimize their utilization in the brewing

process.

14

Fractionated hops give hop products based on liquid or supercritical carbon dioxide.

Depending on the temperatures and pressures we can obtain an extract rich in hop acids or

an extract rich in hop oil. Then, the hop volatiles can be separated from the oil-rich extract to

give hop essences. To extract the alpha-acids, a pH-controlled solvent extraction may be used

on the acids-rich extract. A concentrate of alpha-acids is obtained, and they can easily

isomerize to iso-alpha-acids, which are the main beer bitter constituents.

These isohumulones are not produced by brewers but by hop processors who formulate them

as potassium salts in concentrated solution. These innovative hop products can easily be

added at any stage during the brewing process to give and adjust bitterness within the beer.

To get better organoleptic results, they are added at the end of the wort boiling. However, in

order to make these “advanced” beers indistinguishable from traditional beers, very small

amounts of hop oil must be added in addition to isohumulones, before packing. Thus, yields

of isohumulones exceed 80%. 9 10

6) Hops quality labels

Producers of high-quality specialties have always paid attention to quality, tradition, and

origins. Various quality labels were used to indicate this. Nowadays, consumers strongly pay

attention to these characteristics and as protection for the growers, the EU introduced three

different labels that are obviously subject to strict regulations. The labels can only be carried

by products that are distinguished by regional origins and traditional production methods.

In the EU, concerning the geographical indication, there

are two designations: The Protected Designation of Origin

(PDO), which is assigned to products that are produced,

processed, and prepared in specific regions or at a specific

location. All raw materials and ingredients must be from

this region and even the processing is restricted to this

region.

The second label is the Protected Geographical Indication (PGI), which also deals with the

geographical origins. It is assigned to products that are produced, processed, or prepared in a

specific region or location using traditional methods. The raw material used, or the processing

methods can be from this region or take place in this region, but it is not a requirement.

The third label is the Traditional Specialties Guaranteed (TSG), which refers to a special

production method that lends the product its specific character, making it a specialty. 11

9 https://www.gastrograph.com/blogs/gastronexus/beer-quality-control-raw-hops.html 10 http://www.scielo.br/scielo.php?script=sci_arttext&pid=S0100-40422000000100019 11 http://www.deguopijiuhua.eu/?p=88

15

III) Hop breeding and selection

1) What about selection in hop breeding?

Hop breeding and selection is the process by which plant breeders develop new hop cultivars.

At the beginning of hop cultivation, cultivars were not the product of deliberate breeding

efforts but careful selections by hop growers of indigenous wild hops until they have found

varieties that were suited for local growing conditions. A few cultivars became dominant

because they possessed some characteristics that growers and brewers were looking for.

Since the late 19th century, plant breeding programs have been set up to replace the simple

local selection practices of hop growers.

The first known organized breeding work took place in Germany in 1894 and again in 1898.

Between 1904 and 1908, the United States Department of Agriculture (USDA) attempted to

establish a hop breeding program but it was abandoned because of budgets cuts, the World

War I, and prohibition. However, it established a hop research program in 1931 in Oregon and

this program is still in operation. In England, breeding program started in 1904, at Wye College

in Kent, where many of the bittering varieties were created. Other early hop breeding

programs sprang up in Denmark, Sweden and the Czech Republic.

Cultivated hop is dioecious. It means that male and female reproductive organs are located

on separate plants. Only female hop plants are used in commercial cultivation because they

produce the cones used in brewing. Males are only used in plant breeding because they don’t

produce these ones.

The cross-pollinated breeding is the method used to select hops. It relies on the understanding

of relatedness among individuals so that appropriate crosses can be planned to minimize

inbreeding. The mating of related individuals (inbreeding) can uncover negative traits that

may result in agronomically unacceptable individuals. Breweries prefer replacement hop

cultivars that behave functionally or organoleptically like the ones they currently use. That’s

why hop breeders must work within narrow genetic confines when developing new cultivars.

But this approach can be dangerous since cultivars can be too closely related, which can hinder

future breeding efforts and render the pool of currently grown cultivars susceptible to

catastrophic events such as devastating outbreak of disease or pests. Thus, breeders assess

the genetic diversity among the genotypes in their breeding collection by evaluating pedigree

records and variation in plant traits and using molecular biology tools such as genetic markers.

This allows breeders to select unrelated parents for crossing in the hope that they will produce

genetically diverse progeny. However, pedigree records are not perfectly reliable because of

the origins of certain hops that are not known. Then, some cultivars were naturally selected

by open pollination (the male pollen source is not known because pollination occurs naturally

and randomly).

Recently, DNA extracted from different cultivars, breeding lines, and male genotypes was

analyzed in order to understand the ancestry of the current breeding stock. It has been shown

that, in general, modern hop accessions fall into one of two categories: those with a European-

16

based ancestry and those that are hybrids between European and wild American ancestry.

Within these two large groups there are subgroups based on traits such as sex or regional

adaptation.

Heterosis is another technique considered to have some merit for hop breeding. In fact, it is

the genetic concept where progeny from a cross outperforms both parents for a given trait. It

occurs when unrelated genotypes are mated and produce diverse progeny with unique gene

combinations. The unique alleles that are brought together interact in such a way as to

enhance the expression of the desired trait. Such traits can be yield, vigor, disease resistance.

Genetic linkage maps have been created by hop research programs to physically locate

important traits on hop chromosomes.

Concerning traits that are governed by the expression of many genes in combination, the

markers used are called quantitative trait loci (QTL). They allow hop breeders to select

individuals in the seedling stage that contain clusters of genes important for expressing the

complex trait of interest.

Genetic modification can also contribute to hop new varieties creation. Generating a

genetically modified organism (GMO) involves inserting a piece of DNA into the host plant.

The inserted DNA may be from an entirely different organism of from the host species itself

but with some modification to its function. This technique is very useful in the case of an

individual that is deficient in a specific trait. If a known resistance gene is available, it can be

inserted into the desired individual which gains disease resistance to the target pathogen.

However, consumers don’t like the aim of the GMO method and would not appreciate drinking

a beer made with GMO hops. Therefore, it remains an open question whether this technology

will find use in hop breeding. 12

2) Hops quality traits selection

As we could see in the previous part of the report, the chemical components found in hops

are important quality characteristics. They are therefore criteria used for selecting the parents

in breeding and creating new hop varieties. Concerning bitterness, it is easy to select for the

desired trait. However, for aromas, since only little is known about the relationship between

the chemical composition and flavor in beer, these criteria are not very useful. In aroma hop

breeding, these criteria only provide a similarity index that helps comparing new varieties with

preexisting varieties and find desirable characteristics similarities. This index has been made

by studies in which the classification of hop varieties from chemical composition was found to

be related in part to the classification obtained from the sensory evaluation scones for beer

brewed with each hop variety. Because of the lack of theoretical knowledge regarding hop

quality inheritance, the mating design is based mainly on the breeder’s experience and it is

not always possible to obtain the desired traits. 13

12 https://beerandbrewing.com/dictionary/zIlgUHefML/ 13 https://onlinelibrary.wiley.com/doi/epdf/10.1002/j.2050-0416.1999.tb00013.x

17

3) Hops varieties

There are different varieties of hops with different amounts in alpha- and beta-acids and

therefore different flavors and aromas:

- Amarillo hops have a flowery and citrus-like aroma and are not too bitter.

- Cascade hops have been developed by Oregon State University’s breeding program in

1956 (United States). Just like Amarillo, they have a flowery and citrus-like aroma but

also a spicy one and a slight grapefruit characteristic.

- The Chinook hop plant comes from a pine forest washed with exotic spice infused with

grapefruit. It is a green bine cultivar release in 1985 in the United States as well

(Washington State). It is characterized by its slightly spicy and very piney flavor and is

present in most beer styles. Its alpha acid content can reach 14%.

- Citra hops, as their name suggests, provides strong citrus and tropical fruit aromas to

beer. Developed by the Hop Breeding Company, it was released in 2007. The other

characteristic of these hops is their fairly high alpha acids (up to 16%) and total oil

contents with a low percentage of cohumulone.

- Crystal hops are an American triploid variety developed in 1993 from Hallertau,

Cascade, Brewer’s Gold and Early Green varieties. It provides a delicate blend of spices

and flowers with a low bittering value.

- Columbus hops, contrary to crystal hops, are very bitter! They are also interesting for

their oil content which creates sharpness and herbal aroma.

- The Fuggle variety provides wood and fruit aromas and its bittering value is moderate.

- Golding hops are said to have produced some of England’s best bitter thanks to their

flowery tones.

- The Hop Hash is a blend of about 10 varieties.

- The Lambic variety is a Belgian one that has been cultivate near Brussels in the 19th

and 20th centuries. It is used in lambics thanks to its very low bittering level (alpha acids

maximum 2%).

- In contrast, Magnum hops have the high bittering value (alpha acids up tp 15%). They

also offer spicy and citrus aromas.

- The Mosaic brand contains high alpha-acids amounts, tropical, blueberry, tangerine,

floral, and earthy aromas.

- The Mt. Hood hops are triploid hybrids that offer flower and spice aromas with a

woody characteristic. They also have a good yield and vigor.

- In combination with other hops, the Northern Brewer variety is used for bittering and

gives a woody, earthy, and fruity flavor to beer.

- The Nugget hops has a strong herbal and slight spice aroma with a high bittering value

(14%). Thus, it is mainly use for bittering beers.

- The Perle hop plant is often used with other hops as well. Its bittering value is

moderate, and its aromas are refreshing, floral, fruity and spicy.

- Saaz possesses an aromatic blend of earth and spice with a low bittering value.

- Simcoe is a variety known for the many aromas it provides to beer: passion fruit, pine,

erath, citrus. It is also a very bitter variety with its high content of alpha acids (14%).

18

- The Triumph hop plant is a new variety released in 2016 by the USDA Hop Breeding

Program in Corvallis, OR. Not much is available regarding the flavor profile of this hop

plant for now.

- Willamette hops are triploid hybrids released in 1976 by the USDA Breeding Program.

In the U.S. it is the best aroma hop thanks to its modest bittering value (6%) and its

blend of flowers, fruits, earth and spice.

In fact, hops varieties can be divided in three categories, depending on their bittering value

and the aromas they possess:

The aroma hops, as their name suggests, provide a good aroma to beer thanks to their oil

profile and their lower alpha acid percentage. In the brewing process, they are generally used

as a finishing or conditioning hop.

Bitter hops are used in the boiling process to extract their bitterness given by their high alpha

acid level.

Dual-purpose- hops, such as Northern Brewer, are both aromatic and bittering hops. 14

There are actually many other hop varieties, especially aroma hops.

They are also classified depending of the type of beer they are used for.

14 https://freshops.com/hop-variety-descriptions/

19

Conclusion

To conclude about the topic “Quality of hops in beer production” we can first say that hops

are one of the most important ingredients in beer. They help balance and counteract the

natural sweetness of beer. Indeed, the main role of hops in beer is to give it bitterness. They

do not only provide bitterness but also aromas and flavors.

Bitterness, aromas and flavors are beer quality traits influenced by the brewing process and

the ingredients as well. Thus, the hop plant quality influences the beer quality. Hops quality

depends on the varieties and the cultivars.

Depending on these factors, hops possess different aromas and flavors and different bittering

values. Aromas are due to the content in essential oils: hops contain high amounts of oils, but

they are highly volatile, and they easily evaporate. However, trace amounts of them remain.

Bitterness is brought by alpha acids found in hops; they are the primary bitter compounds.

Beta acids are not bitter but are responsible for bitterness too. The main reaction is he

isomerization of alpha acids into iso-alpha-acids during the boiling of wort in the brewing

process. This is what makes hops bring bitterness to beer. The International Bitterness Units

(IBU) is a relative scale that spectrophotometrically determines iso-alpha-acids in beer. IBUs

can be utilized to not only compare the bitterness between two different beers but can also

be used as a quality control measure to ensure a consistent level of bitterness. The higher the

percentage of alpha-acids (14-16%), the more bitter the beer is.

Science has been creating and developing new cultivars for hop breeders and beer makers. To

help brewers make a choice, indexes are available, in which all the varieties are mentioned,

and alternatives are given. They are classified function of the aromas they give to beer and

their content in acids (alpha and beta) to determine their bittering value. Some brewers use

two different varieties for the same beer to give it different aromas.

However, it is still hard nowadays to find pertinent information about hop quality. Indeed,

concerning flavors and aromas, not many studies have been conducted yet. Most of them

concern the bitterness. Moreover, we have to pay to get access to the results.

In the future, studies about hop quality will probably continue to be conducted and science

will clarify the link between hop quality and beer quality. The understanding of this link will

help select hops according to the aromas they provide and not only on their bittering value.

20

Table of illustrations

Figure 1 Hop plant classification ................................................................. 2

Figure 2 Chemical structures of humulones and lupulones ........................ 2

Figure 3 Milling step ................................................................................... 2

Figure 4 Mashing step ................................................................................ 2

Figure 5 Lautering step ............................................................................... 2

Figure 6 Boiling step ................................................................................... 2

Figure 7 Fermentation step ........................................................................ 2

Figure 8 Conditionning step ....................................................................... 2

Figure 9 Hops chemical composition .......................................................... 2

Figure 10 Structures of humulones and lupulones ..................................... 2

Figure 11 The most important reaction in hop chemistry .......................... 2

Figure 12 Conversion of the humulones to the isohumulones ................... 2

21

Table of contents

SUMMARY 2

TABLE OF ACRONYMS AND ABBREVIATIONS 3

INTRODUCTION 4

I) GET TO KNOW HOPS BETTER 5

1) Etymology 5

2) Botanical characteristics 5

3) Origin and history 2

4) Cultivation 6

5) Nutritional value and common uses 6

6) Beer processing 8

II) QUALITATIVE ASPECTS 10

1) Hop chemistry in beer flavor 10

2) Hop chemistry of the bitter taste 11

3) The lightstruck flavor of beer 13

4) Color of beer 13

5) Hop technology to control beer quality 13

6) Hops quality labels 14

III) HOP BREEDING AND SELECTION 15

1) What about selection in hop breeding? 15

2) Hops quality traits selection 16

3) Hop varieties 17

CONCLUSION 19

TABLE OF ILLUSTRATIONS 20