LJ04 CZ FZ Processes Aug2010

-

Upload

rishabh-kumar -

Category

Documents

-

view

216 -

download

0

Transcript of LJ04 CZ FZ Processes Aug2010

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

1/26

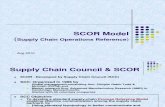

August 2010S. K. Bhatnagar 1

CZ and FZProcesses

Dr. S. K. Bhatnagar

Professor and Head,

R & D Center for Engg. and Science,

J. E. C. Kukas

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

2/26

August 2010S. K. Bhatnagar 2

Mono-crystal Silicon Growth

Crystal PullingCZ Method

Floating Zone Method

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

3/26

August 2010S. K. Bhatnagar 3h103

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

4/26

August 2010S. K. Bhatnagar 4

Surface Tension

Weight of the liquid silicon pulled up is supported

by the surface tension of the melt.For 300 mm diameter wafer and 1 mm pulledmelt, weight = 165 gm

Weight of 1 meter long crystal = 165 Kg.

It is important that the pulled liquid solidifiesquickly and does not melt again.

The temp. gradient across the pulled crystal shouldbe very large.

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

5/26

August 2010S. K. Bhatnagar 5

Czochralski (CZ) crystal growth

It involves the crystalline solidification of

atoms from a liquid phase at an interface.

The process consists of the following steps:

1. A fused silica crucible is loaded with a

charge of undoped EGS together with a

precise amount of diluted silicon alloy.

2. Evacuate the growth chamber.

3. Back-fill with inert gas prevent

atmospheric gases from entering the

chamber.

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

6/26

August 2010S. K. Bhatnagar 6

Czochralski (CZ) crystal growth

4. Heat Crucible to 1421o C to melt Silicon.

5. Introduce seed crystal in molten silicon.

Seed crystal is slim ( 5 mm dia) and 100300

mm long with precise orientation6. The seed crystal is then withdrawn at a very

controlled rate.

7. The seed crystal and the crucible are rotatedin opposite directions while this withdrawal

process occurs.

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

7/26

August 2010S. K. Bhatnagar 7

Crystal Growing Theory

Every impurity has a solid solubility in Siliconand a different equilibrium solubility in the

melt.

Segregation Coefficient k0 = Cs / ClCs , Cl = equilibrium concentrations of the

impurity in the solid and melt near the

interface

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

8/26

Distribution of impurity in the grown crystal

Freezing Relation

Where

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

9/26

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

10/26

h104

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

11/26

August 2010S. K. Bhatnagar 11q410

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

12/26

August 2010S. K. Bhatnagar 12

Pull Rate and Growth Rate

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

13/26

August 2010S. K. Bhatnagar 13

Float Zone Cystal Growth

S. K. Bhatnagar 13

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

14/26

August 2010S. K. Bhatnagar 14S. K. Bhatnagar 14q411b

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

15/26

August 2010S. K. Bhatnagar 15S. K. Bhatnagar 15h105

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

16/26

August 2010S. K. Bhatnagar 16

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

17/26

August 2010S. K. Bhatnagar 17

The FZ Process consists of the following steps:

1. A polysilicon rod is mounted vertically inside a chamber,

which may be under vacuum or filled with an inert gas.2. A needle-eye coil that can run through the rod is

activated to provide RF power to the rod, melting a 2 cm

long zone in the rod. This molten zone can be maintained

in stable liquid form by the coil.

3. The coil is then moved through the rod, and the molten

zone moves along with it.

4. The movement of the molten zone through theentire length of the rod melts the polysilicon and

solidifies it into a single crystal.

S. K. Bhatnagar 17

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

18/26

August 2010S. K. Bhatnagar 18

Alternative

Alternatively the coil can be kept stationary

and the rod can be moved up or down

through the coil.

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

19/26

August 2010S. K. Bhatnagar 19S. K. Bhatnagar 19Wafers from the ingot

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

20/26

August 2010S. K. Bhatnagar 20S. K. Bhatnagar 20Thank You

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

21/26

August 2010S. K. Bhatnagar 21

Schematic of a Float Zone

System for growing large

diameter boules

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

22/26

August 2010S. K. Bhatnagar 22S. K. Bhatnagar 22

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

23/26

August 2010S. K. Bhatnagar 23S. K. Bhatnagar 23

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

24/26

August 2010S. K. Bhatnagar 24S. K. Bhatnagar 24

Mark identificationsFig:q422

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

25/26

August 2010S. K. Bhatnagar 25

-

7/31/2019 LJ04 CZ FZ Processes Aug2010

26/26

August 2010S. K. Bhatnagar 26S K Bhatnagar 26

![Tadzkirah aug2010 fasting[slideshare]](https://static.fdocuments.us/doc/165x107/548e17b9b4795975218b45f6/tadzkirah-aug2010-fastingslideshare.jpg)