Liscio's Bakery in Baking & Snack Report

-

Upload

hashtag-multimedia -

Category

Documents

-

view

531 -

download

4

description

Transcript of Liscio's Bakery in Baking & Snack Report

30 / Baking & Snack / May 2013 www.bakingandsnack.com

PROPERTY OF

SOSLAND P

ULISHIN

G

OPERATIONSLiscio’s Italian Bakery

May 2013 / Baking & Snack / 31 www.bakingandsnack.com

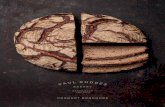

Foodservice’s hot new trend favoring sandwich cuisine takes Liscio’s Italian Bakery into growing markets for its ‘Philly bread’ and signature rolls.

Aby Laurie Gorton

Ask any Philadelphian: Nothing quite matches the thin, crispy crust and tender, soft crumb of a true hoagie roll. This sandwich style, especially the Philly cheesesteak, is as much a regional staple as the po-boy in New Orleans. Now, it is attracting menu attention outside the “hoagie zone,” and that spells opportunity for Liscio’s Italian Bakery, Glassboro, NJ.

The bakery specializes in hoagie rolls, called “Philly bread” by many customers. For nearly 20 years, sand-wich shops in the Philadelphia, New Jersey and New York region have made their menu favorites with Liscio’s bread and rolls. Today, however, the bakery also ships products as far away as Connecticut, Indiana, Texas and Oregon.

“Cheesesteak and hoagie shops find our breads better for their sandwiches,” explained Charles (Chad) Vilotti, Liscio’s co-owner and vice-president, “and Philly chees-esteak sandwiches are gaining interest in other areas of the country. We’ve been able to grow with some of the very best operators in the business.”

Several of the bakery’s key accounts are now national in scope. For example, one has 90 stores with four more about to open in Florida.

Such fare is big business. Menu trends throughout America favor sandwiches — all kinds of sandwiches — with a category incidence of 77% among all operators, according to the Foodservice Research Institute. These experts describe dynamic 14% growth of sandwich cuisine over 10 years as a historic gain and way ahead of every other menu category. Sandwiches show great di-versity. While grilled cheese sits atop the list with a 3.6%

menu share, the Philly cheesesteak comes in at No. 7, right after the corned beef reuben.

“The mom-and-pops are still good partners for us, but we’re changing the way we operate to be a larger producer in a more productive plant,” Mr. Vilotti said. Steps in this direction not only include the option of on-site freezing but also the adoption of British Retail Consortium (BRC) and Safe Quality Food (SQF) criteria and third-party inspections.

Continuing local demand and nascent national inter-est in the bakery’s products have stretched its sales nearly 300% in six years. The increased product volume and en-hanced food safety efforts that accompany such business push the bakery to operate better and more efficiently.

Expanding product platformsEmblazoned on each delivery truck, Liscio’s company motto states, “It all starts with the bread.” It certainly did for co-owners James Liscio and Chad Vilotti. Both come from a baking background, but when they first met, they sat on opposite sides of the desk.

Mr. Liscio started baking in high school, taking a job with a small mom-and-pop bakery-deli. During college, he worked in another bake shop before opening his own bakery in 1994, a retail location that quickly earned a wholesale following for its Italian bread specialties.

Mr. Vilotti’s great-grandfather opened one of the first Italian bakeries in South Philadelphia, and his grandfather developed a bakery ingredient distribution company while at the family bakery. Mr. Vilotti started working in that business while in college and later ran

PROPERTY OF

SOSLAND P

ULISHIN

G

32 / Baking & Snack / May 2013 www.bakingandsnack.com

LISCIO’S ITALIAN BAKERY

Make-Up Systems CUTTING EDGE SOLUTIONS FOR THE INDUSTRIAL BAKER

INNO•BAKE•TION

WWW.AMFBAKERY.COMAMF is a Markel Bakery Group Company

Do-Flex Divider• Excellent Scaling Accuracy, 1% Accuracy with

Virtually No Operator Adjustments Required

• Available as New Divider or a Retrofi t Kit for AMF HBD Dividers

• New Vector Auger System is 40% More Effi cient than old Twin Screw Augers, Less Work on Dough means More Control Over Grain Structure

• Very Low Pressure Dividing (less than 1 degree temperature rise)

• Easy to Maintain and Clean, No Tools Required for 100% Sanitation Inspection

• Capable of Running a Wide Range of Doughs from Stiff Roll Dough to Slack English Muffi n and Ciabatta Dough

• Eliminates ShearingFor more information, see Page 121

it for 20 years. After selling the in-gredient company in 2000, he joined Mr. Liscio, adding his business man-agement experience to his partner’s production expertise.

Hoagies account for the major-ity of Liscio’s business, but lately the

company finds itself venturing into “better burger” territory, the latest development in sandwich cuisine. And the results are tremendous.

“Burger rolls really blossomed,” said Mr. Liscio, the bakery’s presi-dent. “This is hoagie country, and

burgers have not been a big thing in this area. But they are now.” And they’re only get-ting bigger as upscale hamburgers go national.

Attentive to customer needs, bakery managers

accepted a challenge from a local operator of a quick-service restau-rant specializing in gourmet ham-burgers. “He wanted to set his sig-nature burger apart from others in the market,” Mr. Vilotti said. The customer asked the bakery to de-velop a rustic, pan-baked bun that would be crustier than the usual soft hamburger bun.

Mr. Liscio worked out the formu-lation and production details, and soon the customer had his new bun. Sales of the signature sandwich went through the roof.

Immediate feedbackLiscio’s Italian Bakery, Glassboro, NJ, specializes in supplying sandwich shops and foodservice operations, but it also has in-store supermarket and retail bakery accounts. And three of these retail shops carry the Liscio’s name. All are within six miles of the wholesale bakery, and all include deli sandwich operations.

“We treat our retail shops like any other account,” explained Chad Vilotti, the bakery’s vice-president, “but they do give us an immediate sense of what to expect from new product introductions.”

Such feedback also comes from Liscio’s manage-ment team. “We look at the product each day, and of course, we eat it, too!” Mr. Vilotti observed.

Liscio’s newest location, adjacent to the wholesale bakery, houses the company’s pastry production unit. Laura Casaletto, general manager of the retail business, described an active specialty operation employing four bakers and four decorators. “We do cakes of all sorts, birthday to weddings and more,” she said.

The bakery opted for an automatic peel board unloader to feed its newest tunnel oven.

PROPERTY OF

SOSLAND P

ULISHIN

G

May 2013 / Baking & Snack / 33 www.bakingandsnack.com

Turning

whole grains

into hearty sales

© 2012 Cargill Incorporated.

Innovative ingredients, like Horizon

Milling’s WheatSelect®white spring

whole wheat flour. It provides what

consumers prefer: a softer texture,

lighter color and milder taste. With

Cargill’s resources and our expertise

in traditional whole wheat and unique

ingredients with whole-grain nutrition,

we can help you develop hearty sales.

What does it take to turn

whole grains into products

consumers crave?

Discover how we can help you transform

whole grains into hearty sales. Visit

HorizonMilling.com or call 1-800-742-4506.

For more information, see Page 121

Spreading business reachLocated just about a half-hour outside Philadelphia, Liscio’s occu-pies a 10-acre site on New Jersey’s busy Route 47. Since moving to Glassboro in 2004, the company added 10,000 sq ft of retarder space in 2007, bringing the building up to 50,000 sq ft. By 2011, it was filled with additional production equip-ment to handle rising demand.

“We laid out the bakery to grow,” Mr. Vilotti said. “We took on tech-nology to fit the needs of these prod-ucts and allow our business to grow more aggressively.”

Recent capital equipment ad-ditions include upgraded double-spiral mixers supplying each pro-duction line, a new roll makeup

line, increased retarding capacity and efficient push-through proof-ers, two additional tunnel ovens and two more ambient-temperature spiral coolers. A new power plant was also installed.

During the same period, the com-pany acquired properties next to and behind the existing plant. Liscio’s built a new bakery-deli on one lot and relo-cated its 5,000-sq-ft pastry operation to the back shop there. It adapted the 6,000-sq-ft building on the other lot to warehouse bagged and boxed ingredi-ents and provide administrative offic-es. The company plans to connect the wholesale plant and warehouse soon.

Another essential step for Liscio’s was implementation of BRC and SQF food safety programs,

The bowl on this double-spiral mixer rises to bring ingredients into contact with mixing blades. Liscio’s recently added three of these larger-capacity systems to bring up output. PROPERTY O

F

SOSLAND P

ULISHIN

G

34 / Baking & Snack / May 2013 www.bakingandsnack.com

LISCIO’S ITALIAN BAKERY

For more information, see Page 121

important to attracting high-volume customers, including leading super-market chains. “In doing these pro-grams, we knew they would make us a better company and allow us to entertain those types of clients,” Mr. Vilotti said. “I knew from my previous distribution business the value of participating in programs such as those that AIB International offers. When we moved here, we decided we would run the cleanest, most efficient operation possible, and we get constant requests for third-party audits.”

Work with these formal food safety programs began in earnest three years ago. Efforts included onsite training for all staff mem-bers. The company became SQF-certified in 2012 by AIB and re-ceived a “Superior” rating on that group’s most recent inspection. Two employees currently hold HACCP certification, and separately, the company supports an in-house em-ployee safety committee.

“We continue to ‘climb the ladder’ on audits,” Mr. Vilotti reported.

Automating traditional artsHoagie sandwiches demand a spe-cial sort of bread. Its subtle flavor, paper-like crispy crust and soft interior crumb wouldn’t be pos-sible without retardation of the dough, according to Mr. Liscio. Accommodating such a long process presents challenges. “But we’ve tried to maintain the integrity of the pro-cess,” he said.

The bakery works hard to sustain traditional results while operating an automated process. “We don’t skip steps, and we strive to keep doing things as when we started,” Mr. Vilotti explained.

Now with a staff of 210, the bak-ery begins its day at 4 a.m., when bakers arrive to start up lines. Items made up the day before are just reaching the end of their retard pe-riod. Proofing, baking, cooling and

“We’re not the only game in town, so we have to play it better with quality

and consistency.”Chad Vilotti, Liscio’s Italian Bakery

When it comes to our pure natural sweeteners, you won’t find better quality, service or technical expertise. If you’re looking for a way to add a touch of sweetness and promote browning in your gluten free, non-GMO, natural or kosher formulations, Briess can help. Find out more at briess.com/sorghum

625 S Irish Rd | Chilton, WI 53014 | 920.849.7711briess.com/sorghum

©2013 Briess Industries, Inc.

BR

IESS. Your source for White Sorghum

and Tapioca Syrups, and Malt Extracts all M

AD

E IN TH

E USA

.

Ask us about our new contract packaging options: briess.com/packaging

PROPERTY OF

SOSLAND P

ULISHIN

G

May 2013 / Baking & Snack / 35 www.bakingandsnack.com

Turning

product

ideas into profits

© 2012 Cargill Incorporated.

At Horizon Milling, we know the answer:

food-technology and nutrition experts,

insightful knowledge of consumer

trends and ingredients that make

products healthier or more indulgent

— or both! And when you add

Cargill’s capabilities to the mix,

you’ve got the winning recipe.

What does it take to

turn new-product ideas

into revenue?

Discover how we can help you transform

product ideas into profits. Visit

HorizonMilling.com or call 1-800-742-4506.

For more information, see Page 121

order makeup take place simultane-ously with mixing and makeup of the next day’s products. Distribution activities begin at 8 p.m.

Liscio’s targeted the goal of con-sistent quality product starting on day one. “To drive out variability, every aspect of a baking business has to become more efficient, more effective,” Mr. Vilotti said.

Automation contributes to that consistency by steering away from routine manual tasks, but it’s not all about manpower reduction, accord-ing to Mr. Liscio. “There’s always the potential for labor savings,” he said, “but we redeploy individuals to better use their skills.”

Operators keep careful watch over products in progress and monitor machinery closely. Mr. Vilotti added, “In this business, the human element is a needed aspect to production, and the personal touch is important.”

Mr. Liscio and Mr. Vilotti rely on vendor support from their primary equipment and ingredient suppliers to guide them through the technol-ogy maze. “We frequently host other bakers from all over the country interested in evaluating our pro-cess and our processing and baking equipment,” Mr. Liscio said.

Making, baking rollsThe bakery’s original Pfening bulk flour system delivers flour to four mixers, although operators scale minor ingredients from scratch. The system routes batched flour from the outdoor 85,000-lb silo through a metal detector and into a stainless-steel sifter before it reaches four stainless-steel, 500-lb scale hoppers above the mixers.

To date, Liscio’s has been able to keep up with rising production demand by boosting the frequency of flour deliveries. However, in case

A ‘be prepared’ attitudeMother Nature certainly knows how to challenge businesses on the Eastern Seaboard. Hurricanes Irene and Sandy and several major winter storms recently blew through the region, spreading wide the damage.

“We did close one day for both Irene and Sandy but only once for a snowstorm a few years ago,” said Chad Vilotti, vice-president, Liscio’s Italian Bakery, Glassboro, NJ. “The main hurricane concern would have been our roof, but we’ve had emergency electrical power here from the start.”

The company recently replaced its first generator with a larger 700-kw system. “We could power half of Glassboro with it,” joked James Liscio, the bakery’s president. The company also inventories replacement motors for key equipment.

“We’ve only had one episode that required emergency electrical power since we moved here in 2004,” Mr. Liscio continued. “We lost about three hours of production then. But that experience was enough, and having back-up capacity satisfies our need to cover ‘what if’ situations.”

Advance planning paid off for Liscio’s Italian Bakery when Hurricane Sandy visited the East Coast on Halloween in 2012.NASA

PROPERTY OF

SOSLAND P

ULISHIN

G

May 2013 / Baking & Snack / 37 www.bakingandsnack.com

Turning risk

into prediction

© 2012 Cargill Incorporated.

Horizon Milling’s Performance Pricing

program. Our experts manage a portion

of your wheat futures exposure and

provide insights that help you

manage your other flour purchases.

With Cargill’s resources behind us, we

strive to help our customers beat the

market over time.

What does it take to turn

volatile markets into predictable

business opportunities?

Discover how we can help you transform

risk into predictability for your business.

Visit HorizonMilling.com or call

1-800-742-4506.

LISCIO’S ITALIAN BAKERY

For more information, see Page 121

of emergency, it stocks a supply of bagged flour equal to a full load. “Our middle name is ‘backup,’ ” Mr. Liscio said with a laugh.

The bakery now uses four Gemini/W&P dual-spiral-arm, high-speed mixers. Each can handle dough loads up to 500 lb per batch. Mix times range from six to 10 minutes, and the finished dough leaves the bowl through a bottom discharge port into a wait-ing dough trough.

The bakery’s automated bread and roll makeup lines have the ability to produce many different products from 1.5-oz rolls up to 15-oz stick bread. These include two Gemini/KB variety roll lines for moulded, round and Kaiser rolls and one Craft Master low-stress combination bread and roll moulding line. Each employs a trough lift to unload dough, thus eliminating the need to manually feed dough into the 700-lb dough reservoirs above the Gemini TWL dividers. The newest line makes stamped Kaiser rolls and moulded rolls weighing 1.5 to 7.5 oz. The auto-matic loader on each line can deposit round and moulded dough pieces directly onto peel boards supplied by an integrated board feeder.

Operators place boards filled with dough pieces into mobile racks and wheel them into the refrigerated 38°F retarding room. To fill the next day’s production schedule, operators move racks to the two roll-through rack proofers.

All racks feature a top plate. “These act as lids to prevent con-densation or dust falling onto the dough pieces,” Mr. Liscio ex-plained. The company embraced this recommendation made during an AIB inspection.

The bakery is now equipped with three tunnel ovens supplied by Gemini Bakery Equipment. The first two are manually loaded, but the newest 77-ft tunnel oven — in-stalled in 2011— operates with an automatic peel board oven loading system. “That way, the oven is al-ways full, which aids efficiency and enables a more consistent bake,” Mr. Liscio observed.

Baked rolls and buns slide down a transfer plate as they leave the oven and move onto a conveyor taking them to three G&F ambient- temperature spiral cooling systems.

The partners are considering add-ing an automatic oven loader to one of the two smaller tunnel ovens;

Liscio’s supplies the Philadelphia Phillies’ ball park with rolls and merchandises the relationship with delivery truck graphics.

“This is hoagie country.”James Liscio, Liscio’s Italian Bakery

PROPERTY OF

SOSLAND P

ULISHIN

G

38 / Baking & Snack / May 2013 www.bakingandsnack.com

Call 1-800-538-7721 to discover the difference.www.ndmill.com

ISO 22000 C ERT I F I E D

Discover the North Dakota Difference

Call 1-800-538-7721 to discover the difference.www.ndmill.com

Standard Patent Flour: Dakota ChampionThe standard of excellence for the baking industry, Dakota Champion fl ours are suitable for a wide variety of breads, rolls and specialty products.

Outstanding Mixing Characteristics

ISO 22000 / PAS 220 C ERT I F I E D

LISCIO’S ITALIAN BAKERY

For more information, see Page 121

however, floor space is too tight and production rates too low to justify one on the company’s original 60-ft tunnel oven. Liscio’s kept a few of its original single-rack ovens to handle low-volume items.

Packing, shipping productsFinished products depart Liscio’s loaded loosely into white corrugated boxes. Such boxes are standard for fresh local distribution of hoagie rolls and Italian breads because they maintain the bread’s crisp crust texture.

“Most bakers in this region use brown boxes,” Mr. Liscio explained, “but we use only white ones print-ed with our name. This helps differentiate us.”

The corrugated boxes return to the bakery where they are dumped to remove any debris and thoroughly inspected before reuse.

As the company expanded distribution into other markets, it began to offer different packaging styles. In Delaware, for example, customers want their products in sealed plastic bags. Liscio’s added a Cavanna packaging and bagging line to accommodate such requests.

“The next step will be to automatically pack hamburger buns and other rolls,” Mr. Vilotti said.

Liscio’s assembles its product for distribution in a

Chad Vilotti (left), Liscio’s Italian Bakery vice-president, and James Liscio, president, invested capital in processing equipment and food safety programs to better serve the bakery’s growing roster of clients.

PROPERTY OF

SOSLAND P

ULISHIN

G

May 2013 / Baking & Snack / 39 www.bakingandsnack.com

Turning

sustainability

goals into solutions

© 2012 Cargill Incorporated.

Horizon Milling’s EcoFlour™ program

includes it all: innovative ingredients

made from our identity-preserved

wheat, cutting-edge agricultural

technologies that respect the Earth

and custom-tailored plans that meet

your business goals. And fortified

with Cargill’s capabilities, EcoFlour™

solutions deliver.

What does it take to turn

sustainability goals into

brand-building results?

Discover how our eco-friendly programs can

help you transform goals into solutions. Visit

HorizonMilling.com or call 1-800-742-4506.

For more information, see Page 121

dedicated part of the main building, placing orders into a bank of locked cages assigned to individual drivers.

Supermarkets represent another flourishing part of the bakery’s market. Liscio’s now serves more than 90 area stores using direct store delivery (DSD) methods. Like the sandwich shop business, fresh DSD to supermarkets involves loose rolls.

With a good number of national accounts, the company is being pulled into the frozen side to grow along with its customers. It recently acquired a liquid nitrogen flash freezer. Currently in storage, the freezer will be installed on the next build-out.

Everyday consistencyMr. Liscio and Mr. Vilotti credit their bakery’s success to its abil-ity to produce consistent product day in and day out. “Customers want consistency,” Mr. Vilotti said. “Samples are all fine and well, but the everyday product has to be the same every day.”

They acknowledged the role that their staff plays in support-ing such performance. “Our

employees are the backbone of our system,” Mr. Liscio said. “The entire team is dedicated to pro-ducing a great product, and they know the importance of this to our customers.”

Mr. Vilotti added, “Machines can only do so much. It’s the people who run them that make the difference.”

Looking ahead, the partners expect further DSD expansion. “Our category — fresh Italian bread and rolls — is not yet saturated,” Mr. Vilotti observed. “We also have a future in products distributed out-side the region. That’s based on our customers wanting ‘Philly bread’ for their operations.”

The future may bring more competition, but Liscio’s is ready for it. “We have the variety of product enabled by use of machine and man-ual methods — variety that many of our competitors lack,” Mr. Vilotti said. “We’re not the only game in town, so we have to play it better with quality and consistency.”

Mr. Liscio confirmed this com-mitment. “Consistency is a product issue and a service issue, but consis-tency is our strength,” he said. •

The bakery’s newest makeup line offers both Kaiser stamping and soft bun capacity.

PROPERTY OF

SOSLAND P

ULISHIN

G