Launch of Euro 6 - Penso Consulting Ltd · Launch of Euro 6 The all-new fuel-eficient ... achieve,...

Transcript of Launch of Euro 6 - Penso Consulting Ltd · Launch of Euro 6 The all-new fuel-eficient ... achieve,...

October 2016 / Issue No 2. / DRIVEN 1

T h e T e c h n o l o g y D r i v e n m a g a z i n e f r o m P e n s o G r o u p

Issue No 2. / October 2016

Launch of Euro 6The all-new fuel-eficient Vito Taxi by Mercedes-Benz

Transport Solutions ¡ High Security Studios ¡ Volume Production ¡ Composite Tailgate

DRIVEN / Issue No 2. / October 20162 October 2016 / Issue No 2. / DRIVEN 3

18

Over the last 12 months the automotive industry has faced significant headwinds, whether this is due to

CO2 emission challenges, slow down of the

Chinese market, Brexit, or new technology deployment. These headwinds have presented challenges to Penso and all of our key clients, and although they are improving, they will continue to challenge for some years to come.

In response to what has been a fluid market situation, Penso has rapidly diversified its composite revenue stream. Through diversification of Penso’s product and service range, client base and industry sectors, Penso has achieved sustained profitability whilst repositioning the group. This enables substantial future growth in both advanced technology, as well as high added value product and service offerings.

Penso are continuing to invest heavily into lightweight technologies, state-of-the-art facilities and manufacturing equipment.We have also developed new product opportunities and as a result we are delivering substantial export sales growth, especially in the field of carbon fibre composites.

Penso has further reinforced its technical capability in engineering; from project management through to test and validation, Penso can now truly offer a body engineering turnkey service. This has led to recent successes over the last 12 months, such as Tier-1 production supplier status with Mercedes-Benz, Jaguar Land Rover and London Underground. Penso is now well positioned to deliver sustainable revenue and profit growth through the international deployment of our products and services.

Penso’s ‘one team’ core value has been massively instrumental in the successful diversification of group activities. I would like to say a big thank you to the whole team for their perseverance and commitment over the last 12 months.

I sincerely hope you enjoy your insight into Penso, in this issue of Driven magazine.

DANIEL HURCOMBE

Group Managing Director

Director’s Corner In this Issue

The launch of the Mercedes-BenzEuro 6 Vito Taxi

Electrical & Electronics System Engineering

Composite Tailgate

Unique Engineering Data ManagementServices

Penso’s Brentwood Office

COMPOSITE TECHNOLOGIES

Three new High Security Studios

Chris Buckenham, Group Finance Director

BSI Audit Certification

Affordable Carbon Fibre Panels

06 04

04

10

14

NEWS

Lightweight Transport Solutions

Pioneering new ManufacturingSolutions

VARCITY Review

EVENTS

Advanced Engineering 2016

InnoTrans 2016

K-Show 2016

JEC World 2017

CONSULTING

SPECIAL OPERATIONS

04

06

10

14

18

EDITORIAL CONTENTS

DRIVEN / Issue No 2. / October 20164 October 2016 / Issue No 2. / DRIVEN 5

NEWS NEWS

Recently Penso Group has gained an extremely varied client base, each with different needs that require complete discretion and confidentiality.

As part of our client confidentiality criteria, we have procedures in place that ensure that information is secured and not disseminated outside of the designated area.

Admission is limited to authorised personnel only, which is restricted by access control and employee identification. All accessibility has to be authorised by the client. Both the entrance and the exit to the studio are controlled by airlock doors, confirming that only one person can pass through the door at one time.

The Penso facilities are under 24 hour surveillance; this allows the studios to be

monitored by CCTV at all times. The cameras are not directly angled onto the project, however capture all of the surrounding areas and entrances. This guarantees that confidential material is not filmed by any means unless instructed by the customer.

To protect intellectual property of the client, each person who holds access to the studio is forbidden to have any electronic devices on their person. Photography and filmography inside the secured area is strictly prohibited and monitored at all times.

We make customer confidentiality our priority; we are constantly in communication with our clients to satisfy that all requirements are met and ensure that all potential measures are available.

Three new High Security StudiosWe have invested into three state-of-the-art studios at Penso headquarters, each are windowless and equipped with high level security.

Penso Group, JE Engineering and Nottingham University combined their areas of expertise to develop a low investment process to produce low volume carbon fibre parts, along with their aligned technology partners. As a result, advanced and cost effective technologies for Carbon Fibre Reinforced Plastics (CFRP) have been developed for the UK niche vehicle sector.

CFRP panels are deemed as highly desirable in niche vehicles for reasons of customer appeal, individualisation, weight, appearance and prestige. The aim of the AffCAR project

was to reduce the cost of parts and tooling for lightweight structural body panels, and deliver a more robust and controlled process than the market norm of ‘autoclaving’.

Although autoclaving can offer low tooling costs, a cycle time of 3-10 hours per component is not necessarily suitable for volume manufacture. Penso Group seeks to lead the UK’s capability in the supply of out-of-autoclave, structural CFRP components and has developed an advanced press forming process. The unique procedure reduces cycle times to 4-6 minutes, however tooling costs

may be increased; this would be suitable for medium to large volume production, not necessarily for low volume production.

Thereby, the AffCAR project is the development of a new hybrid composite tooling technology known internally as ‘pressclaving’. This process demonstrates that CFRP components can be produced with lower tooling costs and reduced cycle times, with the potential to support the 2020 vehicle emission targets of 95 grams of CO

2 per kilometre and become a feasible

manufacturing process. Dave Roche, Technical Director of Penso

Group, commented: “This project is an illustration of Penso’s continued drive for innovation in order to make composite materials more accessible in low volume applications and more cost effective in high volume applications.”

The panel was tested and used on JE Engineering’s existing Defender Zulu vehicle. The weight of the panel with lacquer applied achieved a mass saving of 69% against the original steel bonnet. Debuted at the Automechanika event in Birmingham, the bonnet received a very positive reaction and intrigued a lot of people. The bonnet was also presented at the Goodwood Festival of Speed.

Affordable Carbon Fibre Panels (AffCAR)Affordable Carbon Fibre (AffCAR) Body Panels for Niche Vehicles is a project that targeted a series of technology innovations.

BSI Audit CertificationThe British Standard Institution (BSI) visited Penso for three days in April to conduct our three year re-certification audit ensuring compliance to ISO9001 and TS16949 standards.

It is critical for the business that our quality management system adheres to the requirements that both of these standards mandate. We understand that both are viewed as order qualifiers to Penso and a requirement from our customer base.

The audit that was conducted over a three day period went really well and Penso received positive feedback and results that we are extremely proud of. Only minor non-conformities were identified, which have since been closed off robustly to the requirements of the standards.

This has now ensured that we hold both of the certificates for a further two years subject to the annual audit plan.

Jacqueline Cox, Marketing Communications Manager at BSI, explained: “Penso have quality and safety at the heart of their business and

they have chosen to work with BSI to help demonstrate this to their customers.”

BSI are currently working on a new marketing campaign to promote successful businesses. The campaign focuses on the expertise of BSI staff and their customer first approach to help clients achieve certification. BSI asked Penso to support their brand across the UK. Jacqueline explained: “Penso were the perfect choice to support our new marketing campaign focusing on a people and partnership approach.”

James Healy, Head of Quality at Penso, was selected to take part in the campaign. He commented: “I must admit I was quite flattered when I was asked to be included in the campaign, it was a new experience for me. It felt a little surreal being directed and told how to stand, where to look and when to smile – which was a lot of times!

“If the campaign is successful and Penso receive the results that they set out to achieve, the photoshoot was most definitely worth it, even if I did have to wear make-up!”

High Security Studios

Defender Bonnet at Goodwood Festival of Speed

Chris Buckenham, Group Finance Director at Penso Q: Tell us about your career to date?

I achieved both AAT and ACCA qualifications whilst working at S R Howell & Co Chartered Certified Accountants & Registered Auditors. I stayed with the company for 11 years before moving on and becoming Lead Advisor.

In 2005 I joined CRP Print & Packaging as Finance Director. My aim was to support the company’s progression and help them grow. That was my last job before joining Penso.

Q: You have been in many industries in your career, is there a particular one you wanted to end up in?

I wouldn’t say that I specialise in a particular industry. However, I do find the automotive sector extremely fascinating and it has always been of interest to me. Penso undertakes some exciting projects, and it is definitely an industry in which I am thrilled to be working in. Manufacturing is a different world when you go beyond the office doors.

Q: What have you been up to in your early stages at Penso?

I have been spending some time familiarising myself with the business and getting to know the team. It is a great place to work, friendly and very welcoming. Penso is an interesting and exciting business which the people reflect.

Q: Have you worked with any other departments other than Finance?

Whilst the title Finance Director will always have a higher time commitment to the accounting and financial areas, the role as I see

it will always be much wider and participate in all areas of the business to support and assist all colleagues as required. Working closely with Sales and Marketing, Purchasing, Human Resources and Operations is key to fully understanding a business and being able to positively assist and influence.

Q: How do you feel that your expertise will affect Penso on a whole?

I hope that my experience with private businesses and working with different clients will enable me to share my knowledge and input whatever I can into Penso. I have spent most of my years working with entrepreneurial individuals and other intermediaries to find the right solutions for businesses, making sure that any potential opportunities are known and fully exploited.

Q: What characteristics do you have that will drive Penso forward?

I think I have a fairly pragmatic and ‘can do’ approach. I hope to influence this and maintain a positive environment within my team and the rest of the business.

Q: Will you be involved with the expansion of the facilities at Penso?

The expansion will definitely require involvement from all areas at Penso. I know the guys have big plans for our new facilities and Jevon Thurston-Thorpe, Penso Group Operations Director, will lead this. It is my job to monitor the finances and support the company to achieve the results they are aiming for. I am excited!

Dawn Banner (BSI) auditing PensoBSI team (left) with James Healy

With over 25 years of experience in the finance sector,

Chris Buckenham joins Penso as the Group’s Finance Director.

“Manufacturing is a different world when

you go beyond the office doors.”

DRIVEN / Issue No 2. / October 20166 October 2016 / Issue No 2. / DRIVEN 7

Composite Tailgate

An extract of Penso’s technical paper on “Simulation Driven Design for Manufacture of a Pressed Composite Automotive Tailgate”. è

Services

Consulting

DRIVEN / Issue No 2. / October 20168 October 2016 / Issue No 2. / DRIVEN 9

CONSULTING

The EDM team is responsible for working closely with both Penso’s engineers and external clients, to ensure that the required product performance characteristics are achieved. They are accountable to plan and organise testing to make sure that each product satisfies the functional requirements specified by the client.

Paul Gillman, Manager of EDM, commented: “The EDM department provides a crucial synchronisation link between the many and varied engineering and project management activities that occur during the product creation and launch process.

“One of our significant strengths is the ability to focus on facilitating the immediate needs of our internal projects and external clients, whilst at the same time driving continuous enhancements throughout the business with process improvements and systems initiatives.”

An example of a project which the EDM team have worked on would be the Mercedes-Benz Vito Taxi. It was the EDM team’s responsibility to define product

performance requirements and supply a detailed test plan. EDM was then in charge of controlling the engineering releases and conducting the tests that were required, ensuring all the resources needed to do so were in place. They also tracked the Product Part Approval Process (PPAP).

Our EDM team provides a consultancy service for engineering suppliers. We can assist companies that might not have in-house systems or expertise to support the process from design to launch. We can also support the navigation of customer processes and product requirements.

Unique Engineering Data Management Services

Penso’s Brentwood Office

We are now based in an office which has been purpose built for Penso, a self-contained, open office area, capable of housing 40 people. The office is complete with separate meeting rooms and a Manager’s office.

Penso decided to open an office in Brentwood merely for new client acquisition. Having a second office located in the South of the UK enables us to be closer to some of our client bases. A second office also allows Penso to divide and allocate workload in an organised and structured manor.

Our team at Penso South is built up of engineers and CAD users. Most of the tasks currently involve supporting projects taking place at headquarters in Coventry, such as work for Jaguar Land Rover, Mercedes-Benz and other OEMs.

Simon Barton, Office Manager of Penso Brentwood, commented: “We have a very

skilled team with years of experience and knowledge from various backgrounds. This vast understanding allows the guys to challenge the engineering team as well as give guidance to get to the best engineering decisions. The team here pride themselves on being able to create exceptional quality CAD at rapid pace whilst solving any engineering issues that may occur.

“Our aim for the future is to continue supporting various projects from the Coventry site. We also aim to gain some further work from our local based companies and continue to build the team in both numbers and engineering experience.”

“One of our significant strengths is the ability to focus

on facilitating the immediate needs of our clients.”

CONSULTING

The Engineering Data Management (EDM) team supports the core engineering functions. This is achieved by providing the necessary guidance and expertise needed to ensure project gateway deliverables are robustly achieved in a timely manner.

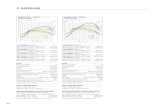

Status Report Pie Chart

Penso Brentwood Office

A current key automotive industry initiative is delivery of mass savings through the use of lightweight

materials, to reduce vehicle CO2 emissions.

Penso, a world leading manufacturing specialist, based in the UK and India, were commissioned by a European automotive OEM to design and manufacture a continuous fibre reinforced composite tailgate prototype. This would be a lightweight alternative to the current production tailgate which is moulded from Sheet Moulding Compound (SMC), a discontinuous-fibre reinforced composite material.

The new carbon fibre design had to meet all existing strength and stiffness targets, while maintaining existing A-surface geometry and all hardware. The three main parts of the tailgate considered for lightweighting were the tailgate inner panel, tailgate outer panel and spoiler mechanism carrier. The structural performance targets against which the tailgate would be evaluated were torsion, cantilevered bending, latch load and margin & flushness.

To perform the analysis a mesh was created on the A-surface, which corresponded to the preform tool surface, such that the laminate plies stacked from A to B surface. Each panel was meshed with first order conventional S4 and S3R shell elements, having a nominal element edge length of 5mm. Abaqus/Standard was then used for the non-linear static finite element analysis for the tailgate load cases.

To complete the tailgate model, the metallic mounting plates were modelled as shell elements referencing non-linear elastic-plastic material properties, while the rear screen glass was modelled with shell elements referencing isotropic elastic material properties. The adhesive was modelled using solid elements referencing isotropic elastic material properties. The adhesive elements connected to neighbouring panels using the distributing coupling constraints.

Once the finite element models were complete, two methods of optimisation were carried out on the tailgate, using a manual method and design optimisation software. These methods assisted in developing an optimised layup for the composite panels,

to comply with the structural performance targets, while also minimizing mass.

The Tsai-Wu Failure Measure and a user defined Inter-Laminar Failure Criterion were used as composite design metrics in post processing, to determine if ply failure or inter-laminar shear failure would occur between the laminate. These ply boundaries and material directions were updated in the FE model for further refinement of ply joint locations, prediction of finalized mass/performance and generation of layup manuals.

The design was then evaluated with Penso’s composite manufacturing team to develop preliminary ply shapes and overlap joint locations suitable for manual draping and Penso’s pressed composite technology. Once the ply layup and overlap locations had been developed for manufacture, the ply boundaries documented by the laminator in their draped configuration were sent to Penso’s analysis team along with information regarding fibre distortion. These ply boundaries, overlap locations and material directions were updated and modelled in the FE model for further refinement, for prediction of finalized mass/performance and generation of layup manuals.

Material directions gained from layup trials were compared to that in the analysis model and corrections made where large inconsistencies existed between the two sets of data. Since the parts will be manufactured using layup books generated directly from the FE models the laminates needed to be accurately defined.

The laminate tool within ANSA, from Beta CAE, was utilized for the ease of building, handling and modifying of all the layers of

the composite model, which exploits a special ANSA laminate property. This ANSA laminate property simplifies the number of layers the user has to manage during pre and post processing. Ply shapes of the final tailgate design were transferred to Penso’s design team by outputting ply boundaries as curves within an IGES file. By taking into account the ply shapes and ply thickness the B-Surface was generated for the composite parts of the tailgate, by modelling the layup from the A-Surface. The A and B-surfaces of the composite parts can then be used to create tool geometry for manufacturing.

Results gained from FE analysis of the tailgate showed that all strength and stiffness targets were achieved, while having equivalent or better structural performance to the production design. The final design of parts gave a combined mass savings of over 65% compared to the equivalent SMC/steel panels. The overall mass saving of the tailgate assembly was greater than this, due to the use of a new lightweight rear screen glass and removal of components such as the anti-pinch strips and interior trim.

“We have a very skilled team with years of experience

and knowledge from various backgrounds.”

Parts considered for lightweighting

Strain energy plot for torsion load case

The work presented in this publication was undertaken as part of the VARCITY project. This project was co-funded by Innovate UK as part of the IDP7 programme. The project partners in this R&D project were Penso Group, Jaguar Land Rover, Solvay, Sika, AMRC (Boeing), Avdel (Stanley), Expert and WMG. Penso were the VARCITY manufacturing project lead.

By Andy Ngai, Senior Engineer and Dr. Mark Arnold, Chief Technical Specialist

Penso’s second office is based in Brentwood, Essex. The office opened in April 2014 and currently has a team of 10 employees: an Office Manager and nine engineers and CAD users. We are very keen to grow the team as new projects start.

6 Sigma DMAIC Model

DRIVEN / Issue No 2. / October 201610 October 2016 / Issue No 2. / DRIVEN 11

Lightweight Transport Solutions

Penso’s unique lightweight composite rail door is receiving an increasing amount of interest. è

Technologies

Composite

DRIVEN / Issue No 2. / October 201612 October 2016 / Issue No 2. / DRIVEN 13

The vehicle utilises the structural performance and weight advantages of advanced Carbon Fibre Reinforced Plastic (CFRP) based composites, whilst delivering a sustainable and economically viable proposition for volume production.

The consortium includes: Penso Group, Jaguar Land Rover, Solvay, Expert Tooling, Advanced Manufacturing Research Centre, Warwick Manufacturing Group, Stanley Avdel and Sika.

VARCITY has driven the technical capability developments of the fully integrated UK supply chain that was involved, and has delivered major commercial benefits for the wider market. The project also acted as a catalyst to stimulate the science, engineering and technology base to support the CO

2

and sustainability challenges facing the UK’s automotive industry.

Penso supported the manufacture of demonstrator vehicle assemblies using fast cure adhesive bonding technology from Sika and other joining and fixing methods and strategies developed during the project.

Alongside the VARCITY project, Penso and Solvay developed a fast cure High Pressure Resin Transfer Moulding (HP-RTM) resin

using a KraussMaffei metering machine onsite at Penso, as well as a snap cure pre-preg resin system suitable for hot compression moulding. These materials produced medium to large sized parts for the use in VARCITY demonstrators, as well as exploiting the learning from partners and niche sectors.

Press tooling was designed and manufactured by Penso to create eight different press formed panels with the remaining parts sourced from third party autoclavers. These were assembled into complete Body-in-White structures, for driveable demonstrator vehicles suitable for crash testing and NVH durability assessments.

The technology used for VARCITY has created inspiration for work in other sectors. The learning has been accelerated due to innovate funding. VARCITY has fast-tracked opportunities to exploit the learning overseas. We are excited to develop our knowledge further and continue to use the technology developments discovered across other industry areas.

Since the initial design and manufacture of the original lightweight rail door, developments have been made and 21

prototypes have now been produced.Currently, the prototypes are undergoing

testing and have been fitted to powered-up trains in the process. We are extremely optimistic that our unique rail door will be fully-certified and we look forward to an updated status in the near future.

Penso’s design creates a mass saving of >10kg from the current aluminium incumbent door. This has the potential to improve the speed of the doors opening and closing, it will also reduce the wear on components leading to longer intervals between services. With the potential of an overall lighter train, the track and wheel wear could be reduced, as well as

the running costs and energy usage lowered.The door is designed to have a new window

cassette system. This allows any damaged glass to be replaced in up to one hour, as opposed to replacing the whole door. Existing bonded glass solutions can take between 7 and 24 hours.

In order to be compliant to Fire, Smoke and Toxicity requirements (BS6853 Category 1A and GMRT 2100), Penso has used phenolic resin materials to achieve this.

Another benefit of our rail door is that it has been designed to have a foam core. This not only has the potential to improve noise ingress through the door aperture, but a significant reduction in the risk of water penetration too.

The door is also engineered to have better dimensional stability. Due to the door leaf being a completely enclosed part manufactured in one pressing process, it has a greater dimensional accuracy than aluminium honeycomb sandwich assemblies. This could

reduce shimming allowance, resulting in faster fitment times during service.

The developments throughout this project and the results that have been demonstrated have highlighted certain attributes here at Penso and driven interest from many other industry sectors. Michael Collins, Marketing and Sales Director of Penso Group, commented: “We believe our door is a world first. Not only does it demonstrate Penso’s seamless engineering and manufacturing, but also how quickly Penso can get to market.

“The use of lightweight composite materials can provide further significant opportunities within the rail transport sector, this will help the CO

2 reduction, energy consumption and

general wear and tear. After unveiled this door at JEC World in 2016, we are now reaping the benefits of our Research and Development investment with enquires from the UK, France and North America.”

Penso showcased the composite rail door at the InnoTrans 2016 exhibition in September on the Rail Alliance stand. The door received an increasing amount of interest and we are very proud to have been able to showcase our project at the leading international trade fair for transport technology.

Pioneering new Manufacturing Solutions

VARCITY Review

COMPOSITE TECHNOLOGIES

Following years of sustained R&D, we have developed processes that can produce carbon fibre components with a better performance than existing technologies, such as autoclaving, which can take several hours.

This unique process has reduced manufacturing times to just minutes, making the use of carbon fibre material very competitive against the traditional steels, aluminum and mixed materials commonly used in the automotive sector.

We have invested over £7m in developing our existing building and installing a new state-of-the-art carbon fibre high volume factory, a new plant for lightweight structures and machining centres for rapid tooling.

Taking the weight out of the equation is one of the engineering sector’s biggest drivers and we are pioneering new engineering processes and manufacturing solutions.

This technology opens up lightweight structures for the

high volume market.

Displacement contour plot

Hot Compression Moulding

Exploded view of VARCITY parts using Hot Compression Moulding and HP-RTM technologyRail door in final inspection booth

Pressing of train door

“We believe our door is a world first.”

Hot Compression Moulding¡ Medium cost tooling¡ Process cycle times (<10 minutes)¡ Suitable for low to medium volume production¡ Double A surface part; accurate geometry¡ Aluminum or Steel tooling modifications easily introduced

High Pressure RTM¡ Higher cost tooling & plant CAPEX¡ Process cycle times (4-15 minutes)¡ Suitable for medium to high volume production¡ Good part integration¡ Tool design process more involved to determine clamping force, cure window and tool temperature on a part-by-part basis ¡ Difficult to incorporate design changes

High Pressure RTM

The Vehicle Architectures for City Cars (VARCITY) Research Programme, co-funded by Innovate UK and the Office for Low Emission Vehicles, has developed carbon fibre composite technology and delivered new vehicle body architectures.

“Penso’s design creates

mass saving of more than

COMPOSITE TECHNOLOGIES

10kg.

DRIVEN / Issue No 2. / October 201614 October 2016 / Issue No 2. / DRIVEN 15

The launch of the Mercedes-Benz Euro 6 Vito Taxi

Mercedes-Benz has launched the all new fuel-efficient Euro 6 Vito Taxi, and Penso are the general contractors. è

Operations

Special

DRIVEN / Issue No 2. / October 201616 October 2016 / Issue No 2. / DRIVEN 17

Penso previously worked as an engineering partner for Mercedes-Benz when developing the Euro 4 and 5 Vito Taxi.

We contributed to the engineering, Rear Wheel Steer (RWS) system development, new rear arm, full interior, Electronic Distribution System (EDS) prototype and upgrade, Electronic Control Unit (ECU) upgrades, electronics upgrades, homologation and testing. For the Euro 5 we also worked on designing the system, software, EDS and electronics hardware.

After working with Mercedes-Benz for the last eight years, we are now extremely proud to be the general contractor of the new taxi. Finance Birmingham has recently provided Penso with funding which will be invested into tools for the taxi production.

The Vito Taxi offers unrivalled levels of space and refined comfort for the driver and up to six passengers. Jevon Thurston-Thorpe, Operations Director of Penso, commented:

“I think the key attribute of the Vito is the level of accessibility which the taxi offers. Not only accessible to able-bodied people, but wheelchair bound, semi-ambulant, arthritic, elderly, partially sighted and hard of hearing. What we deliver with the new Mercedes-Benz Vito is a socially inclusive taxi.”

The wheelchair access is positioned at the side of the vehicle as opposed to loading at the rear of the vehicle. This is a safer and more convenient option for both the passenger and the driver due to reducing the amount of space the vehicle needs to park and load passengers on the street.

Customers can choose from the front wheel-drive 109CDI model, with an 88hp Euro 6 engine, or the 114CDI with a 114hp Euro 6 engine, which drives the rear wheels. Both come with manual gearboxes and in Compact or Long body lengths, the 114CDI is also available with an automatic gearbox.

A London specification version of the taxi will also be available towards the end of 2016, incorporating the RWS system that allows the taxi to meet the 25ft turning circle requirement by Transport for London to enable the execution of a U-turn in London’s congested streets.

The design for the RWS system has been improved ready for the Euro 6. The steering geometry has been developed to maximise tyre life, optimise passenger ride comfort and improve the turning circle. Re-design of mechanical interface of solenoid towers allows easy access for service and replacement.

Electrical & Electronic System Engineering Penso has a highly skilled electrical and electronics department who are able to provide turnkey solutions for both internal and external projects.

From requirement analysis and design, to testing, verification and validation, we can offer support and solutions on-site at Penso for electrical enquiries.

What we offer:¡ System Design: Analysing customer needs and specifying full system requirements using SysML modelling or traditional textual requirements.¡ Hardware Design: Electronic Control Unit (ECU) schematic design and simulation through to Printed-Circuit Boards (PCB) layout and production. We have developed modules for high current body control, audio and steering.¡ Harness Design: Electrical distribution for complete vehicles including circuit analysis, signal specification and 3D routing.

¡ Software Development: Software is designed through simulation in MathWorks Simulink/Stateflow, then the production code is auto-generated with Mathworks Embedded Coder und unit tested. Automated tests are developed and run on our Hardware-in-the-Loop systems.¡ Communications: We design communication systems using technologies such as CAN, LIN and Unified Diagnostic Services (UDS).¡ Concept Prototypes: Not only do we develop systems for production, we also design and develop complete electro-mechanical benchtop concept demonstration systems for vehicle manufacturer clients.¡ Verification and Validation: We manage the verification and validation at every stage in the development process, from software unit testing through to ECU and full vehicle validation.¡ Harness Manufacture: Our in-house harness manufacturing team can produce high quality wiring harnesses at short lead times.

Electric Growth

“I think the key attribute of the Vito is the level of

accessibility which the taxi offers... What we deliver with

the new Mercedes-Benz Vito is a socially inclusive taxi.”

Passenger safety improved by using side wheelchair access

SPECIAL OPERATIONS SPECIAL OPERATIONS

“Improved quality,

lower CO2 emissions and

maximised comfort.

The London alternative is available with the more powerful engine as standard together with the 7G-Tronic seven-speed automatic gearbox, which is now controlled by using a steering column-mounted lever. This offers easy gear selection allowing the driver to remain aware of their busy surroundings.

Standard equipment on both versions includes the fuel-saving BlueEFFICIENCY measures which features engine Start/Stop

function for the 114CDI models, air conditioning for the driver and passengers, electric folding mirrors, electrically operated sliding doors on both sides and electrical nearside step. The London variant offers an additional off-side step.

Being a Tier-1 supplier for Mercedes-Benz is extremely exciting for Penso, especially with the Vito Taxi receiving interest from outside of the UK; such as Europe, North America and Australia. This allows us to expand our knowledge globally and enter the new stimulating markets.

Comfortably seats six passengers

Installation of the new taxi light

Mercedes-Benz Case Study

¡ We started by analysing the customer needs and Transport for London regulations. We then disassembled the detailed system requirements for a set of ECUs and their interfaces which would deliver the taxi features.

¡ We designed and developed hardware and software for: intercom; body control; locking system; Rear Wheel Steer (RWS) ECUs and LED lighting modules. They successfully passed Electro Magnetic Compatibility (EMC), shock and vibration and life cycle testing.

¡ The body features include: driving steps; interior and exterior lighting; locking; controlling the air conditioning.

¡ We designed and manufactured a modular, multi-variant vehicle wiring harness in-house, including 3D wire routing.

¡ We integrated the ECUs and the harness with the base vehicle and the communication systems to provide a seamless experience to the customers, taxi drivers and their passengers.

DRIVEN / Issue No 2. / October 201618 October 2016 / Issue No 2. / DRIVEN 19

JEC World is the largest international gathering of composite professionals, Penso are extremely proud to be part of it.

The exhibition represents, promotes and expands composite markets by providing global or local networking and information services. JEC supports the development of composite materials by fostering knowledge transfer and exchanges it between suppliers and users.

To date, the JEC network connects more than 250,000 professionals from a hundred countries. A strongly user-oriented strategy JEC informs composite professionals about major events, economic, technical and technological developments, new products and applications.

Penso is excited to be attending the event and will be taking with us some of our latest composite technology parts.

www.jeccomposites.com

Visit Penso on Stand O141 Hall 3A

The world’s premier fair for the plastics and rubber industry will again be presenting everything the sector has to offer in 2016. Everything from the latest state of the art and trailblazing innovations, to development visions. The K-Show will host over 3,000 exhibitors from over 50 nations, the ideal exhibition for businesses to discover inspirational ideas and forward-looking decisions.

For decades, K in Düsseldorf has been setting the benchmark on the highest international level. In 19 halls and on over 171,000 sqm of exhibition space, it will be presenting the best that engineers, chemists and scientific researchers have investigated and developed over the last 3 years: solutions, innovations and visions.

Penso will showcase some lightweight composite panels on the KraussMaffei stand.

www.k-online.com

K 2016

19th-26th Oct 2016

Düssseldorf, Germany

Visit Penso on the KraussMaffei stand C24 & C27, Hall 15

www.advancedengineeringuk.com

Bringing together OEMs and Tier 1 manufacturers to meet and do business with all levels of the engineering supply

chain, Advanced Engineering addresses the supply chain needs of the following sectors: aerospace; automotive; motorsport; transport; civil engineering and more.

The Advanced Engineering show launched in 2009 with just 80 exhibitors and 1,200

attendees, the exhibition has grown year on year to become the UK’s largest annual meeting of advanced engineering professionals and supply chain organisations. Since its move to the NEC in Birmingham it has become one of the venue’s fastest-growing events, hosting over 700 exhibitors and record 13,000 2-day attendance in 2015.

The show provides expert industry intel,

latest technology and innovations case studies, and supply chain opportunities delivered by OEM programme managers and industry experts. Growth is set to continue for 2016 as the UK continues to meet national and international requirements in the high value manufacturing sector.

InnoTrans is the leading international trade fair for transport technology and takes place every two years in Berlin. The event is sub-divided into five segments: Railway Technology, Railway Infrastructure, Public Transport, Interiors and Tunnel Construction. InnoTrans occupies all 41 halls available at Berlin Exhibition Grounds.

The InnoTrans Convention, the event’s top level supporting programme, complements the trade fair.

Penso were proud to exhibit at InnoTrans 2016. We showcased our composite lightweight rail door and received an increasing amount of interest.

www.innotrans.de

JEC World 2017

14th - 16th March 2017Paris Nord Villepinte, Paris, France

The largest international gathering of composite professionals

InnoTrans

20th-23rd Sept 2016Messe Berlin, Germany

Penso exhibited on the Rail Alliance stand 206G, Hall 2.2

EVENTS

Penso GroupWoodhams RoadCoventryCV3 4FXUnited Kingdom

Tel: +44 (0)2476 217760Fax: +44 (0)2476 217769

OnlineWeb: www.penso.co.ukE-mails: [email protected],[email protected]

Social Mediawww.linkedin.com/company/pensowww.twitter.com/PensoGroupwww.facebook.com/PensoGroup

Penso Coventry

Penso Brentwood

Penso Pune

Contact

EditorMichael Collins

EditorialRachael Davies

LayoutAndrea Czapova

ReproductionAll rights reserved. Not to be reproduced, copied or duplicated, in full or in part, without written permission.

Image copyrights in this issue belong to: Penso Group, Mercedes-Benz, Pixabay, Public Domain Pictures, BSI, NVN,Finance Birmingham.

Editorial

The UK’s largest meeting place for advanced engineering professionals

www.penso.co.uk

Penso Group ¡ Woodhams Road ¡ Coventry ¡ Warwickshire ¡ CV3 4FX ¡ United Kingdom