Laminar Flow Inc. is a trusted name in the industry for ...

Transcript of Laminar Flow Inc. is a trusted name in the industry for ...

Laminar Flow, Inc102 Richard RdWarminster, PA 18974Tel: (215) 672-0232

Find out more at laminarflowinc.com

Laminar Flow Inc. is the leading manufacturer of the mostdiverse products available, both standard and custom,for the Pharmaceutical, Biotech, and Electronics industries.

We engineer and manufacture all of our products, so youdeal directly with the manufacturer. With our experiencein innovative designs, thousands of our systems have beenvalidated, certi�ed and placed into productive service.

Companies around the world place their trust in our abilityto deliver quality products. They rely on our reputationof standing behind every product 100% and o�ering thebest quality and service in the industry - guaranteed!

Trust LFI to provide systems that will perform as promised.

Discover why Laminar Flow Inc. is the leader with themost comprehensive product line.

Laminar Flow Inc.is a trusted name

in the industryfor one reason -

We stand behindeverything

we manufacture.

LFI Series 5000 Downflow Booths

54 th1969

- 2014 Anniversary

SETTING THE STANDARD

Laminar Flow Inc. has been in the business of providing high quality solutions for the Pharmaceutical process industry for over 45 years. Our reputation for quality, value, and on-time deliveries is world renowned.

The LFI Down�ow Booth is a self-contained systemdesigned to control potent or nonpotent compounds / powders during sampling, weighing, or other manual processes. The Ceiling plenum provides up to an average of 135 FPM of Laminar HEPA �ltered air which is then exhausted at the rear of the booth through high-e�ciency primary HEPA �lters, Bag-In / Out optional, and then recirculated down through secondary HEPA �lters housed in the ceiling grid. A percentage of fresh makeup air, typically 10% of volume, is induced into the recirculation cycle as the corresponding amount is bled o� through adjustable dampers located in the Ceiling plenum. Operator protection is provided to 50 ug / m3. The system includes full stainless steel construction, instrumentation, air �ow control, and easy �lter changeout.

LFI Series 5000 Downflow BoothsLFI Series 5000

FEATURES

- All stainless steel cGMP construction with optional stainless steel side wall panels- Unique Gel-Seal HEPA �lter mounting system, replaceable room-side- Direct Drive Inverter-duty Motors- Modular design allows for ease of installation with minimal components- Full booth illumination - teardrop or recessed �uorescent lighting- Available options include various electrical con�gurations, perf worktables, NEMA 4X control panels, strip curtains and more- Single-point production - complete system is designed and manufactured at our facility- Bag-In/Bag-Out safe-change housing available- PLC Control Panel- Cooling Coils- Sloped exhaust plenum assisting wash down/air �ow- Fully sealed ceiling plenum- cGMP Fabrication throughout- 5D Screen for enhanced operator protection (optional)

This highly-customized Lamabooth was constructed with

many added features for use w/ potent compounds, and

features multiple cutouts for owner equipment, a rigid

front wall for roll-up door mount, �ltered intakes, and 3 stage

safe - change �ltration.

An innovative PLC-based booth monitoring and

control system are utilized in this application. Side

walls and custom cut-outs in the rear bulkhead panel completed the functional

requirements for this Lamabooth.

Unique side-access to the workspace and t-5 teardrop

lighting were design considerations on this Lamabooth.

Note the bleed return grilles mounted on the side of the ceiling

plenum.

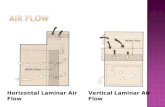

WORKING PRINCIPALS - LAMINAR FLOW BOOTH

The Down�ow Booth operates on a recirculatory push-pull air�ow principle providing containment by air movement. A clean, constant, turbulence-free down�ow of air is supplied from the ceiling, suppressing any dust clouds generated during powder processing, removing and capturing airborne particles from the operator's breathing zone.

Exhaust air grilles with �lters at the base of the back panel wall capture the airborne contaminants generated. The exhaust air�ow then passes through a series of �ltration stages before returning through the booth ceiling plenum. A small percentage of air (approx 10%) is discharged from the booth through a HEPA-�ltered bleed exhaust port to maintain the working space under negative pressure, minimizing airborne contamination breakout.

The down�ow booth is primarily classi�ed as an engineering control, for the purpose of operator protection. A secondary function of the booth is protection against product cross-contamination as the recirculating air�ow contains the product within the con�nes of the booth while in operation.