Kinetic resolution of 2-hydroxybutanoate racemic mixtures by NAD-independent l-lactate dehydrogenase

Transcript of Kinetic resolution of 2-hydroxybutanoate racemic mixtures by NAD-independent l-lactate dehydrogenase

Bioresource Technology 102 (2011) 4595–4599

Contents lists available at ScienceDirect

Bioresource Technology

journal homepage: www.elsevier .com/locate /bior tech

Kinetic resolution of 2-hydroxybutanoate racemic mixtures by NAD-independentL-lactate dehydrogenase

Chao Gao a,b, Wen Zhang a, Cuiqing Ma a,⇑, Peng Liu a, Ping Xu a,b,⇑a State Key Laboratory of Microbial Technology, Shandong University, Jinan 250100, People’s Republic of Chinab MOE Key Laboratory of Microbial Metabolism and School of Life Sciences & Biotechnology, Shanghai Jiao Tong University, Shanghai 200240, People’s Republic of China

a r t i c l e i n f o

Article history:Received 5 November 2010Received in revised form 4 January 2011Accepted 4 January 2011Available online 7 January 2011

Keywords:D-2-Hydroxybutanoate2-OxobutanoateNAD-Independent L-lactate dehydrogenaseKinetic resolutionIon exchange

0960-8524/$ - see front matter � 2011 Elsevier Ltd. Adoi:10.1016/j.biortech.2011.01.003

⇑ Corresponding authors. Address: School of LifeShanghai Jiao Tong University, Shanghai 200240, PeopTel.: +86 21 34206647; fax: +86 21 34206723 (P. Xu),+86 531 88369463 (C. Ma).

E-mail addresses: [email protected] (C. Ma), pingx

a b s t r a c t

Optically active D-2-hydroxybutanoate is an important building block intermediate for medicines andbiodegradable poly(2-hydroxybutanoate). Kinetic resolution of racemic 2-hydroxybutanoate may be agreen and desirable alternative for D-2-hydroxybutanoate production. In this work, D-2-hydroxybutano-ate at a high concentration (0.197 M) and a high enantiomeric excess (99.1%) was produced by anNAD-independent L-lactate dehydrogenase (L-iLDH) containing biocatalyst. 2-Oxobutanoate, anotherimportant intermediate, was co-produced at a high concentration (0.193 M). Using a simple ion exchangeprocess with the macroporous anion exchange resin D301, D-2-hydroxybutanoate was separated fromthe biotransformation system with a high recovery of 84.7%.

� 2011 Elsevier Ltd. All rights reserved.

1. Introduction electron donor NADH and thus is difficult to undertake on an indus-

2-Hydroxybutanoate is an important raw material for produc-tion of isoleucine, 2-oxobutanoate, and some kinds of medicines(Gao et al., 2010; Nakajima et al., 1994; Scheer et al., 1987,1988). In particular, highly optically pure 2-hydroxybutanoatecan be used as a feedstock monomer for production of poly(2-hydroxybutanoate), a polymer which is susceptible to hydrolyticdegradation and thus can be utilized as a biodegradable materialfor biomedical, pharmaceutical, and environmental applications(Tsuji and Okumura, 2009). As for D-2-hydroxybutanoate, it couldalso be used to produce azinothricin family of antitumour antibiot-ics (Karl et al., 1995; Nakagawa et al., 2007). Therefore, develop-ment of practicable techniques for production of optically activeD-2-hydroxybutanoate is desirable.

Chemical processes for 2-hydroxybutanoate production result ina racemic mixture of both stereospecific forms. Utilization of chem-ical catalysts has also made the green production of 2-hydroxybut-anoate difficult to accomplish. Several methods using biocatalystshave been reported for formation of optically active D-2-hydroxy-butanoate. For example, 2-oxobutanoate, the oxidation product of2-hydroxybutanoate, could be reduced to D-2-hydroxybutanoateby an NAD-dependent D-lactate dehydrogenase (D-nLDH) (Simonet al., 1989). This process depends on the addition of expensive

ll rights reserved.

Sciences and Biotechnology,le’s Republic of China (P. Xu).tel.: +86 531 88364003; fax:

[email protected] (P. Xu).

trial scale. Racemic 2-hydroxybutanoate, which is much cheaperthan 2-oxobutanoate (Gao et al., 2010), can replace 2-oxobutanoatefor D-2-hydroxybutanoate production through kinetic resolution.The resolution can be performed through lipase-catalyzed enantio-selective acetylation or glycolate oxidase-catalyzed enantioselec-tive oxidation (Adam et al., 1997, 1998a, 1998b). Althoughoxidative resolution of the racemate produces low concentrationsof D-2-hydroxybutanoate, this process is promising because of itslow substrate price and exclusion of cosubstrate addition.

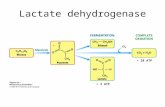

NAD-independent L-lactate dehydrogenase (L-iLDH), whichcould catalyze the oxidation of L-2-hydroxybutanoate with a fla-vin-dependent mechanism, has been documented in previousworks (Futai and Kimura, 1977; Gao et al., 2010; Jasso-Chávezet al., 2001; Ma et al., 2007). This enzyme might also be used inthe kinetic resolution of racemic 2-hydroxybutanoate into D-2-hydroxybutanoate. To identify the application potential of L-iLDHin D-2-hydroxybutanoate production, kinetic resolution of racemic2-hydroxybutanoate by L-iLDH containing biocatalyst was con-ducted in this work. The separation between D-2-hydroxybutano-ate and 2-oxobutanoate, another valuable product of the kineticresolution process, was also studied.

2. Methods

2.1. Chemicals

D-2-Hydroxybutanoate, L-2-hydroxybutanoate, racemic 2-hydroxybutanoate and 2-oxobutanoate were all purchased from

Table 1Substrate specificity of L-iLDH activity in P. stutzeri SDM.

Substrate Km (mM) Vmax (lmol min�1 mg�1)

L-Lactate 22.9 ± 1.1 13.2 ± 0.3

L-2-Hydroxybutanoate 62.7 ± 3.4 15.1 ± 0.2

Values are the average ± SD of three separate determinations.

4596 C. Gao et al. / Bioresource Technology 102 (2011) 4595–4599

Sigma. The adsorbents were provided by Shandong Lukang Phar-maceutical Co. Ltd. (PR China). All other chemicals were of reagentgrade.

2.2. Microorganism and growth conditions

Pseudomonas stutzeri SDM (China Center for Type Culture Col-lection No. M206010) isolated from soil was used in this study(Ma et al., 2007). The minimal salt medium (MSM) was supple-mented with 5.0 g 1�1

DL-lactate as the seed medium and with10.0 g 1�1

DL-lactate as the fermentation medium (Ma et al.,2007). P. stutzeri SDM cells were inoculated into 50 ml seed med-ium in a 300 ml flask and incubated with shaking at 30 �C for10 h. Then they were inoculated into a 5 l flask with 1 l fermenta-tion medium and cultivated at 30 �C for 16 h.

2.3. Biocatalyst preparation

The cells of strain SDM grown in MSM containing DL-lactate asthe carbon source were harvested at the late log phase. The har-vested cells were then washed and resuspended with distilledwater (pH 7.4). After preincubated at 55 �C for 15 min, the wholecells were used as the biocatalyst for kinetic resolution of DL-2-hydroxybutanoate.

2.4. Kinetic resolution of DL-2-hydroxybutanoate

For kinetic resolution of racemic 2-hydroxybutanoate, a 50 mlreaction mixture containing 6 g dry cell weight l�1 preincubatedP. stutzeri SDM and 0.4 M DL-2-hydroxybutanoate was incubatedin a 500 ml flask. Reactions were carried out at 30 �C and150 rpm on a reciprocating shaker. After stopping the reaction byadding of 1 M HCl, the final concentrations of 2-oxobutanoateand 2-hydroxybutanoate were determined.

2.5. Adsorbents tests

Adsorption was carried out with 20 ml reaction mixture at25 �C. The fresh resin was treated with 10 times the volume of1.0 M NaOH, water, 1.0 M HCl, and water in turn. Calculated capac-ities are based on the dry weights calculated from dried samples.

2.6. Adsorption characteristics of resin

A column (20 cm � 16 mm) packed with 15 ml wet resin wasused for column separation at room temperature. The columnwas washed with water after the resin was regenerated with1.0 M HCl. Different pH values of reaction mixture were chosento determine the effect of pH on D-2-hydroxybutanoate and 2-oxo-butanoate adsorption. The initial pH value of the solution was ad-justed by 1.0 M HCl.

2.7. Analytical procedures

The activity of L-iLDH was determined at 30 �C in 1 ml of 50 mMTris–HCl, pH 7.5, 0.2 mM 3-(4,5-dimethylthiazol-2-yl)-2,5-diphe-nyltetrazolium bromide (MTT), and 0.02–0.05 dry cell weight l�1

whole cells of P. stutzeri SDM. The reaction was started by additionof 10 mM L-lactate or L-2-hydroxybutanoate, and the rate of MTTreduction was determined by measuring the absorbance changesat 578 nm in 1 minute (Ma et al., 2007). One unit of enzyme activ-ity is defined as the amount of iLDH required to catalyze 1 lmol ofsubstrate oxidation per minute.

Accurate concentrations of 2-oxobutanoate and 2-hydroxybut-anoate were analyzed by high-performance liquid chromatography(HPLC, Agilent 1100 series, Hewlett–Packard, USA) using an

Aminex HPX-87H column (Bio-Rad) and the eluent using 10 mMH2SO4 solution at 1 ml min�1 flow-rate (Hao et al., 2007).Stereoselective assays of D-2-hydroxybutanoate and L-2-hydroxy-butanoate were performed by HPLC analysis using a chiral column(MCI GEL CRS10 W, Japan) and a tunable UV detector at 254 nm(Gao et al., 2009). The mobile phase was a mixture of water andacetonitrile (90:10), containing 2 mM copper sulphate. The opticalpurity of D-2-hydroxybutanoate was expressed as enantiomericexcess which was defined as the ratio of

ðD� 2� hydroxybutanoateÞ � ðL� 2� hydroxybutanoateÞðD� 2� hydroxybutanoateÞ þ ðL� 2� hydroxybutanoateÞ � 100

3. Results and discussion

3.1. Identification of D-2-hydroxybutanoate production feasibility

Addition of DL-lactate in culture medium induced the expressionof L-iLDH and NAD-independent D-lactate dehydrogenase (D-iLDH)in P. stutzeri SDM (Ma et al., 2007). Different thermostabilities ofL-iLDH and D-iLDH have been documented in previous work. L-iLDHis more thermostable than D-iLDH (Ma et al., 2007). Thus, the bio-catalyst with only L-iLDH activity, could be prepared through pre-incubation of P. stutzeri SDM under proper temperature (seeSupplementary Material).

Lactate is taken up into the Escherichia coli cell either by theL-lactate permease or by the glycolate permease in previousreports (Núñez et al., 2002). Because of the similar structure of2-hydroxybutanoate and lactate, we expected that the 2-hydroxy-butanoate might also be transported into P. stutzeri SDM by thosetransporters. On the other hand, iLDHs often play their essentialrole in the aerobic utilization of lactate through electron transportchain (Castro-Guerrero et al., 2005; Moreno-Sánchez et al., 2000;Philippe et al., 2004). The L-lactate oxidation activity with oxygenas the electron acceptor (including the L-iLDH and some compo-nents of electron transport chain) is also not affected by heat pre-incubation under proper temperature (see SupplementaryMaterial). As shown in Table 1, L-iLDH in P. stutzeri SDM alsoexhibited stereospecific NAD-independent L-2-hydroxybutanoatedehydrogenase (L-iBDH) activity. Thus, the preincubated wholecells of P. stutzeri SDM might have the ability to enantioselectivelyoxidize racemic 2-hydroxybutanoate into D-2-hydroxybutanoateand 2-oxobutanoate.

Kinetic resolution of racemic 2-hydroxybutanoate was con-ducted with preincubated whole cells of P. stutzeri SDM as the bio-catalyst. As shown in Fig. 1, D-2-hydroxybutanoate, which was notoxidized in the biocatalytic process, accumulated with a high con-centration (0.197 M) and a high enantiomeric excess (99.1%) (seeSupplementary Material). Reaction with higher concentrations ofracemic 2-hydroxybutanoate would result in a much lower enan-tiomeric excess of D-2-hydroxybutanoate (see supplementarymaterial).

As shown in Table 2, different biocatalysts such as lipase, glyco-late oxidase, 4-chloro-3-hydroxybutanoate hydrolase, and horse-radish peroxidase have been used in production of opticallyactive D-2-hydroxybutanoate (Adam et al., 1995, 1997, 1998a ,

0 2 4 6 8 10 12

0.00

0.05

0.10

0.15

0.20

Con

cent

rati

on (

M)

Time (h)

Fig. 1. Time course of kinetic resolution of racemic 2-hydroxybutanoate bypreincubated whole cells of P. stutzeri SDM. (h) L-2-hydroxybutanoate; (d)2-oxobutanoate; (j) D-2-hydroxybutanoate. Accurate concentrations of 2-oxobut-anoate and 2-hydroxybutanoate in the reaction mixture were analyzed by HPLC atthe indicated times. Values are the average ± SD of three separate determinations.

Table 3Screening of adsorbents for D-2-hydroxybutanoic acid and 2-oxobutanoic acidseparation.

Adsorbent Type Adsorption capacity (mmol g�1)

D-2-hydroxybutanoic acid 2-oxobutanoic acid

D315 Acrylic 0.247 ± 0.006 0.321 ± 0.009D301 Styrene 0.528 ± 0.019 0.711 ± 0.015D345 Phenolic 0.354 ± 0.009 0.404 ± 0.012335 Epoxy 0.351 ± 0.014 0.433 ± 0.013318 Acrylic 0.274 ± 0.009 0.379 ± 0.007330 Epoxy 0.364 ± 0.013 0.476 ± 0.010D941 Acrylic 0.259 ± 0.011 0.341 ± 0.008CAD45 Styrene 0.041 ± 0.002 0.034 ± 0.002CAD40 Styrene 0.042 ± 0.001 0.064 ± 0.003D311 Acrylic 0.159 ± 0.007 0.100 ± 0.005

Adsorption capacities of 10 sorts of adsorbents were studied in reaction mixture(pH 7.0) at 25 �C. The ratio of the solution volume to the adsorbent was 20 ml to 5 g.Values are the average ± SD of three separate determination.

C. Gao et al. / Bioresource Technology 102 (2011) 4595–4599 4597

1998b; Nakagawa et al., 2007). The process utilizing 4-chloro-3-hydroxybutanoate hydrolase resulted in the highest product(D-2-hydroxybutanoate ester) concentration and has been used inpractical production of D-2-hydroxybutanoate (Nakagawa et al.,2007). The kinetic resolution catalyzed by L-iLDH also producedhigh concentration of D-2-hydroxybutanoate at a high enantio-meric excess. This route excluded the hydrolysis of D-2-hydroxy-butanoate ester for preparation of D-2-hydroxybutanoate. Thus,practical production of D-2-hydroxybutanoate might be also per-formed using L-iLDH catalyzed kinetic resolution.

On the other hand, the kinetic resolution process also produced0.193 M 2-oxobutanoate, which was an important raw material insynthesis of chiral 2-aminobutyric acid, isoleucine, and some kindsof medicines (Eggeling et al., 1987; Furuyoshi et al., 1991; Gaoet al., 2010 ). This process used the cheap starting material racemic2-hydroxybutanoate and produced two important block interme-diates with high concentrations. Thus, it is a promising alternativefor the biotechnological production of D-2-hydroxybutanoate and2-oxobutanoate.

3.2. Screening for adsorbents

In order to simplify the isolation of D-2-hydroxybutanoate and2-oxobutanoate, a distilled water system was used in the kineticresolution of DL-2-hydroxybutanoate. Due to the simple composi-tion of the resultant reaction mixture, D-2-hydroxybutanoate and2-oxobutanoate were the main components needing separation(see Supplementary Material). In this work, ion exchange, a

Table 2Comparison of the processes for D-2-hydroxybutanoate production.

Enzyme Substrate

Horseradish peroxidase Racemic 2-hydroperoxy esters4-Chloro-3-hydroxybutyrate hydrolase Racemic 2-hydroxybutanoate esterGlycolate oxidase Racemic 2-hydroxybutanoateGlycolate oxidase and D-nLDH Racemic 2-hydroxybutanoateLipase Racemic 2-hydroxybutanoatel-iLDH Racemic 2-hydroxybutanoate

practical method in industry because of its economy and facility,was utilized in the D-2-hydroxybutanoate recovery process.

As shown in Table 3, the macroporous anion exchange resinD301 resin had higher adsorption capacity than other adsorbents.Its capacities were 0.528 mmol g�1 for D-2-hydroxybutanoate and0.711 mmol g�1 for 2-oxobutanoate, respectively.

3.3. Adsorption characteristics of D301 under different pHs

Both D-2-hydroxybutanoic acid and 2-oxobutanoic acid areweak acids and have different pKa. The dissociation of D-2-hydroxybutyric acid and 2-oxobutyric acid can be shifted underdifferent pHs. The pH value of reaction mixture would have signif-icant effect on the adsorption property of ion exchange adsorbent.A column (20 cm � 16 mm) packed with 15 ml wet resin was usedfor separation of D-2-hydroxybutyric acid and 2-oxobutyric acid.

The breakthrough curves of D-2-hydroxybutyric acid and 2-oxobutyric acid at pH 2.4, 3.5, and 4.6 were shown in Fig. 2.Selectivity is the critical factor in the separation process of D-2-hydroxybutyric acid and 2-oxobutyric acid. Compared with the re-sults at pH 2.4 and 4.6 (Figs. 2a and c), the operation at pH 3.5(Fig. 2b) got the best separation of D-2-hydroxybutyric acid and2-oxobutyric acid. Thus, the following work was conducted at pH3.5.

3.4. Separation of D-2-hydroxybutyric acid and 2-oxobutyric acid

Reaction mixtures (40 ml, pH 3.5) were applied on the D301 ex-change resin column at a flow rate of 0.5 ml min�1. Then the col-umn was washed with 60 ml of water at a flow rate of0.5 ml min�1 for elution of D-2-hydroxybutyric acid. Loaded 2-oxobutyric acid was eluted by 1.0 M HCl at a flow rate of0.5 ml min�1.

D-2-Hydroxybutanoateconcentration (mM)

Enantiomericexcess (%)

Reference

1.5 97 Adam et al., 1995s 340 98.5 Nakagawa et al., 2007

0.025 >99 Adam et al., 19970.4 95 Adam et al. 1998a0.05 77 Adam et al., 1998b197 99.1 This study

0 10 20 30 40 50-0.1

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

Rel

ativ

e co

ncen

trat

ion

(C/C

0)

Volume (ml)

0 10 20 30 40 50

0.0

0.2

0.4

0.6

0.8

1.0

Rel

ativ

e co

ncen

trat

ion

(C/C

0)

Volume (ml)

0 10 20 30 40 50

0.0

0.2

0.4

0.6

0.8

1.0

Rel

ativ

e co

ncen

trat

ion

(C/C

0)

Volume (ml)

b

c

a

Fig. 2. Breakthrough curve of D-2-hydroxybutanoic acid and 2-oxobutanoic acid onmacroporous anion exchange resin D301. After the pH was adjusted to a desired pH,reaction mixtures containing 0.197 M D-2-hydroxybutanoic acid and 0.193 M2-oxobutanoic acid were applied on the column at a flow rate of 0.5 ml min�1.Effluent was collected and the D-2-hydroxybutanoic acid and 2-oxobutanoic acidconcentrations were measured by HPLC. (a) pH 2.4; (b) pH 3.5; (c) pH 4.6. (j) D-2-hydroxybutanoic acid; (d) 2-oxobutanoic acid. Values are the average ± SD of threeseparate determinations.

0 20 40 60 80 100 120 140 160 180

0.0

0.5

1.0

1.5

2.0

2.5

Rel

ativ

e co

ncen

trat

ion

(C/C

0)

Volume (ml)

Fig. 3. Column separation of D-2-hydroxybutanoic acid and 2-oxobutanoic acid onmacroporous anion exchange resin D301. Accurate concentrations of D-2-hydrox-ybutanoic acid and 2-oxobutanoic acid in the effluent were analyzed by HPLC. (j)D-2-Hydroxybutanoic acid; (d) 2-oxobutanoic acid. Values are the average ± SD ofthree separate determinations.

4598 C. Gao et al. / Bioresource Technology 102 (2011) 4595–4599

Column separation curves of D-2-hydroxybutyric acid and 2-oxobutyric acid are shown in Fig. 3. After the loading stage, wash-ing the column with water resulted in a D-2-hydroxybutyric acidrecovery of 84.7%. The 2-oxobutyric acid was eluted from the resinby 1 M HCl with yield of 95.7%. Although the purity of 2-oxobutyricacid was not high (81.5%), the ion exchange process got a good sep-aration of D-2-hydroxybutyric acid from the reaction mixture (withthe purity of 98.7%, see Supplementary Material).

2-Hydroxycarboxylic acids and 2-oxocarboxylic acids could beproduced by biotechnological routes (Adam et al., 1997, 1998a,1998b; Causey et al., 2003; Furuyoshi et al., 1991; Gao et al.,

2009; Gao et al., 2010; Qin et al., 2009; Qin et al., 2010; Wanget al., 2010; Zhao et al., 2010a,b). Separation methods such as reac-tive extraction, ion exchange, and electro-dialysis have been usedin recovery of those carboxylic acids (Cao et al., 2002; Ma et al.,2006; Thang and Novalin, 2008; Zelic et al., 2004). Most of thosemethods face the separation of the target product from the minor-ity impurities and might be used in recovery of 2-oxobutyric acidfrom the effluent gotten in this work. On the other hand, enantio-selective oxidation of racemic 2-hydroxycarboxylic acids has beenextensively studied for production of optically pure 2-hydroxy-carboxylic acids. (Adam et al., 1997, 1998a; Gao et al., 2009). Thoseprocesses would result in a mixture of 2-hydroxycarboxylic acidsand 2-oxocarboxylic acids with approximate concentrations. Theion exchange process using the resin D301 gave a good examplefor separation of optically pure 2-hydroxycarboxylic acids fromits relevant 2-oxocarboxylic acids. Thus, it might be coupled withother enantioselective oxidation processes.

4. Conclusions

A simple kinetic resolution process was utilized to produce D-2-hydroxybutanoate from racemic 2-hydroxybutanoate. Using bio-catalyst which exhibited L-iLDH activity, D-2-hydroxybutanoate ata high concentration (0.197 M) and a high enantiomeric excess(99.1%) was produced. The separation of D-2-hydroxybutanoatewith 2-oxobutanoate, another important intermediate, was real-ized by the ion exchange process using resin D301. The green con-version system should be a promising one for the practicalproduction of D-2-hydroxybutanoate, because it uses the cheaperstarting material DL-2-hydroxybutanoate and brings higher yieldsof two building block intermediates (D-2-hydroxybutanoate and2-oxobutanoate) by a one-pot biotransformation method.

Acknowledgements

The work was supported by National Natural Science Foundationof China (31000014, 31070062), Major State Basic ResearchDevelopment Program of China (2007CB714303), China Postdoc-toral Science Foundation (20100480600) and Research Fundfor the Doctoral Program of Higher Education of China(20090131110036).

C. Gao et al. / Bioresource Technology 102 (2011) 4595–4599 4599

Appendix A. Supplementary data

Supplementary data associated with this article can be found, inthe online version, at doi:10.1016/j.biortech.2011.01.003.

References

Adam, W., Fell, T., Hoch, U., Saha-Möller, C.R., Schreier, P., 1995. Kinetic resolution ofchirai a-hydroperoxy esters by horseradish peroxidase-catalyzedenantioselective reduction to a-hydroxy esters. Tetrahedron Asymmetr. 6,1047–1050.

Adam, W., Lazarus, M., Boss, B., Humpf, H.-U., Saha-Moller, C.R., Schreier, P., 1997.Enzymatic resolution of chiral 2-hydroxy carboxylic acids by enantioselectiveoxidation with molecular oxygen catalyzed by the glycolate oxidase fromspinach (Spinacia oleracea). J. Org. Chem. 62, 7841–7843.

Adam, W., Lazarus, M., Saha-Moller, C.R., Schreier, P., 1998. Quantitativetransformation of racemic 2-hydroxy acids into (R)-2-hydroxy acids byenantioselective oxidation with glycolate oxidase and subsequent reductionof 2-keto acids with D-lactate dehydrogenase. Tetrahedron Asymmetr. 9, 351–355.

Adam, W., Lazarus, M., Schmerder, A., Humpf, H.-U., Saha-Möller, C.R., Schreier, P.,1998b. Synthesis of optically active a-hydroxy acids by kinetic resolutionthrough lipase-catalyzed enantioselective acetylation. Eur. J. Org. Chem., 2013–2018.

Cao, X., Yun, H.S., Koo, Y.M., 2002. Recovery of L-(+)-lactic acid by anion exchangeresin Amberlite IRA-400. Biochem. Eng. J. 11, 189–196.

Castro-Guerrero, N.A., Jasso-Chávez, R., Moreno-Sánchez, R., 2005. Physiological roleof rhodoquinone in Euglena gracilis mitochondria. Biochim. Biophys. Acta. 1710,113–121.

Causey, T.B., Shanmugam, K.T., Yomano, L.P., Ingram, L.O., 2003. EngineeringEscherichia coli for efficient conversion of glucose to pyruvate. Proc. Natl. Acad.Sci. USA 101, 2235–2240.

Eggeling, I., Cordes, C., Eggeling, L., Sahm, H., 1987. Regulation of acetohydroxy acidsynthase in Corynebacterium glutamicum during fermentation of a-ketobutyrateto L-isoleucine. Appl. Microbiol. Biotechnol. 25, 346–351.

Furuyoshi, S., Nawa, Y., Kawabata, N., 1991. Microbial production of 2-oxobutyricacid from crotonic acid. Agric. Biol. Chem. 55, 123–128.

Futai, M., Kimura, H., 1977. Inducible membrane-bound L-lactate dehydrogenasefrom Escherichia coli: purification and properties. J. Biol. Chem. 252, 5820–5827.

Gao, C., Qiu, J.H., Li, J.C., Ma, C.Q., Tang, H.Z., Xu, P., 2009. Enantioselective oxidationof racemic lactic acid to D-lactic acid and pyruvic acid by Pseudomonas stutzeriSDM. Bioresour. Technol. 100, 1878–1880.

Gao, C., Zhang, W., Lv, C.J., Li, L.X., Ma, C.Q., Hu, C.H., Xu, P., 2010. Efficientproduction of 2-oxobutyrate from 2-hydroxybutyrate using whole cells ofPseudomonas stutzeri strain SDM. Appl. Envrion. Microbiol. 76, 1679–1682.

Hao, J.R., Ma, C.Q., Gao, C., Qiu, J.H., Wang, M., Zhang, Y.N., Cui, X., Xu, P., 2007.Pseudomonas stutzeri as a novel biocatalyst for pyruvate production from DL-lactate. Biotechnol. Lett. 29, 105–110.

Jasso-Chávez, R., Torres-Márquez, M.E., Moreno-Sánchez, R., 2001. The membrane-bound L- and D-lactate dehydrogenase activities in mitochondria from Euglenagracilis. Arch. Biochem. Biophys. 390, 295–303.

Karl, J., Jia, C., Soraya, M., Andrew, P., 1995. Synthetic studies on the azinothricinfamily of antibiotics. 4. Enantioselective synthesis of the northern half ofantitumour antibiotics A83586C and citropeptin. Tetrahedron Lett. 36, 6965–6968.

Ma, C.Q., Gao, C., Qiu, J.H., Hao, J.R., Liu, W.W., Wang, A.L., Zhang, Y.N., Wang, M., Xu,P., 2007. Membrane-bound L- and D-lactate dehydrogenase activities of anewly isolated Pseudomonas stutzeri strain. Appl. Microbiol. Biotechnol. 77,91–98.

Ma, C.Q., Li, J.C., Qiu, J.H., Wang, M., Xu, P., 2006. Recovery of pyruvic acid frombiotransformation solutions. Appl. Microbiol. Biotechnol. 70, 308–314.

Moreno-Sánchez, R., Covián, R., Jasso-Chávez, R., Rodríguez-Enríquez, S., Pacheco-Moisés, F., Torres-Márquez, M.E., 2000. Oxidative phosphorylation supported byan alternative respiratory pathway in mitochondria from Euglena. Biochim.Biophys. Acta. 1457, 200–210.

Nakagawa, A., Kato, K., Shinmyo, A., Suzuki, T., 2007. Asymmetric hydrolysis of 2-hydroxy-carboxylic esters using recombinant Escherichia coli. TetrahedronAsymmetr. 18, 2394–2398.

Nakajima, T., Sawai, S., Sato, S., Nakahara, T., 1994. Production of 2-hydroxybutyricacid from 1,2-butanediol by resting cells of Rhodococcus sp. strain. TB-42. Biosci.Biotechnol. Biochem. 58, 683–686.

Núñez, M.F., Kwon, O., Wilson, T.H., Aguilar, J., Baldoma, L., Lin, E.C., 2002. Transportof L-lactate, D-lactate, and glycolate by the LldP and GlcA membrane carriers ofEscherichia coli. Biochem. Biophys. Res. Commun. 290, 824–829.

Philippe, G., Frédérique, L., Michiel, K., Pascal, H., 2004. Major role of NAD-dependent lactate dehydrogenases in aerobic lactate utilization inLactobacillus plantarum during early stationary phase. J. Bacteriol. 186,6661–6666.

Qin, J., Wang, X., Zheng, Z., Ma, C., Tang, H., Xu, P., 2010. Production of L-lactic acidby a thermophilic Bacillus mutant using sodium hydroxide as neutralizingagent. Bioresour. Technol. 101, 7570–7576.

Qin, J., Zhao, B., Wang, X., Wang, L., Yu, B., Ma, Y., Ma, C., Tang, H., Sun, J., Xu, P., 2009.Non-sterilized fermentative production of polymer-grade L-lactic acid 14 by anewly isolated thermophilic strain Bacillus sp. PloS ONE 4, e4359.

Scheer, E., Cordes, C., Eggeling, L., Sahm, H., 1987. Regulation of acetohydroxy acidsynthase in Corynebacterium glutamicum during isoleucine formation from a-hydroxybutyric acid. Arch. Microbiol. 149, 173–174.

Scheer, E., Eggeling, L., Sahm, H., 1988. Improved D, L-a-hydroxybutyrate conversionto L-isoleucine with Corynebacterium glutamicum mutants with increased D-lactate utilization. Appl. Microbiol. Biotechnol. 28, 474–477.

Simon, E.S., Plante, R., Whitesides, G.M., 1989. D-lactate dehydrogenase. Substratespecificity and use as a catalyst in the synthesis of homochiral 2-hydroxy acids.Appl. Biochem. Biotechnol. 22, 169–179.

Thang, V.H., Novalin, S., 2008. Green biorefinery: separation of lactic acid from grasssilage juice by chromatography using neutral polymeric resin. Bioresour.Technol. 99, 4368–4379.

Tsuji, H., Okumura, A., 2009. Stereocomplex formation between enantiomericsubstituted poly(lactide)s: blends of poly[(S)-2-hydroxybutyrate] and poly[(R)-2-hydroxybutyrate]. Macromolecules 42, 7263–7266.

Wang, L., Zhao, B., Liu, B., Yu, B., Ma, C., Su, F., Hua, D., Li, Q., Ma, Y., Xu, P., 2010.Efficient production of L-lactic acid from corncob molasses, a waste by-productin xylitol production, by a newly isolated xylose utilizing Bacillus sp. Strain.Bioresour. Technol. 101, 7908–7915.

Zelic, B., Gostovic, S., Vuorilehto, K., Vasic-Racki, D., Takors, R., 2004. Processstrategies to enhance pyruvate production with recombinant Escherichia coli:from repetitive fed-batch to in situ product recovery with fully integratedelectrodialysis. Biotechnol. Bioeng. 85, 638–646.

Zhao, B., Wang, L., Li, F., Hua, D., Ma, C., Ma, Y., Xu, P., 2010a. Kinetics of D-lactic acidproduction by Sporolactobacillus sp. Strain CASD using repeated batchfermentation. Bioresour. Technol. 101, 6499–6505.

Zhao, B., Wang, L., Ma, C., Yang, C., Xu, P., Ma, Y., 2010b. Repeated open fermentativeproduction of optically pure L-lactic acid using a thermophilic Bacillus sp. Strain.Bioresour. Technol. 101, 6494–6498.