Introduction to GeneticExpression Introduction to Genetic Expression.

Introduction to RamLog

-

Upload

corrietaljaard -

Category

Technology

-

view

279 -

download

0

Transcript of Introduction to RamLog

1

Introduction R&M Technologies

and RamLog

2

Agenda

• Introduction to R&M Technologies

• R&M Technologies - Capabilities

• RamLog Overview

• Demonstration

• Summary

3

Introduction to R&M Technologies

• Established in 1990 (19 years old) Specializing in Reliability, Maintainability and Logistic Support Analysis

• Start to develop RamLog in 1992

(16 years old)

4

R&M Technologies Capabilities

• LSA Data Development and Management

• RamLog Software

• R&M Engineering

• Logistic Support Analysis

• Modeling (LCC, RAM, Spare Part, Logistic Support)

• FRACAS

5

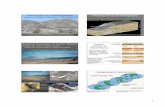

Early Design

Production/Construction

Phase Out

Development

Operational Phase

System Baseline InformationRamLog Information Management

Edition

Maintenance Management System (Transactional Database)

RAMLOG.NET

Decision Making ModelRamLog Simulation Edition

Whole Life Management

6

Information Management Edition

7

Support Analysis Process

Phase BFailure Analysis

Phase ASystem Definition

Phase CTask

Identification

Phase DDetail Task

Analysis

Develop a System

Breakdown FBS / PBS

Perform FMECA / RCM

analysis

Identify the tasks and

the task level

Identify the tasks requirements and develop detail task description

What does the system consist of ?

How can it fail ?What is the

failure criticality ?How can it

be detected ?Can the failure be prevented ?

Should it be redesigned ?

What tasks are required to correct/ prevent a failure ?

Who is going to do these tasks ?(at what level ?)

What is the most cost effective

support concept ?(last opportunity

before detail analysis)

What is required to perform

these tasks? (all support elements)

How, in detail will the task been performed ?

(for TMs)

8

Early Design

Production/Construction

Phase Out

Development

Operational Phase

PBS/FBS

Functional and/or Physical Breakdown Structure

Internal and External LCN Structure which provide flexibility (i.e. floating nodes and reference nodes)

csv file Import/Export

Data Checking and Data Checker

9

Early Design

Production/Construction

Phase Out

Development

Operational Phase

FMECA

Functional and/or Physical FMECA can be performed

10

Early Design

Production/Construction

Phase Out

Development

Operational Phase

RCM Analysis

MSG-3 logic but user have the ability to built its own logic

11

Early Design

Production/Construction

Phase Out

Development

Operational Phase

Detail Task Analysis

Task Documentation Editor for procedural tasks linked with imbedded figures and photos

12

Early Design

Production/Construction

Phase Out

Development

Operational Phase

Task Network Model

Task Network Diagrams to define the task sequence for simulation purposes

13

Early Design

Production/Construction

Phase Out

Development

Operational Phase

Illustrated Parts Breakdown (IPB) Editor

IPB Editor with “hot spots” and imbedded figures linked to the PBS

14

Early Design

Production/Construction

Phase Out

Development

Operational Phase

Interactive Electronic Technical Manual/Publication IETM/P

chm (windows help)

html (web based, publish to RAMLOG.NET or intranet)

MS Word (2007) - RSA-MIL-STD-122 printable copy format)

Information sets and data modules (based on AECMA S1000D)

15

Simulation Edition

16

Early Design

Production/Construction

Phase Out

Development

Operational Phase

Simulation Planner

Event planner to schedule events for simulation purposes (acquisitions, operations, etc)

17

Early Design

Production/Construction

Phase Out

Development

Operational Phase

Operational Model

Operational Model to simulation the operation, life cycle of the system/plant

System Groups into clusters

Operational phases, parameters distribution based

18

Early Design

Production/Construction

Phase Out

Development

Operational Phase

Deploy & Support Model

Deploy & Support Model to simulate the flow of Work Orders, Job Cards, Item Orders and Delivery Notes

19

Early Design

Production/Construction

Phase Out

Development

Operational Phase

RBD and FTA

RBDs and FTAs linked to the failure modes to simulation Reliability and Availability

Reliability and Availability Culprit Identification

20

Early Design

Production/Construction

Phase Out

Development

Operational Phase

Animation Model

Animation Model to assist during the model verification process

21

Early Design

Production/Construction

Phase Out

Development

Operational Phase

Simulation Results

Life Cycle Cost Results

22

Early Design

Production/Construction

Phase Out

Development

Operational Phase

Simulation Results Continue

Statistical results including Availability, Reliability, Spare Parts Requirements, Delay Times - Histograms and Distributions

23

RAMLOG.NET

24

Early Design

Production/Construction

Phase Out

Development

Operational Phase

RAMLOG.NET

Job Card

Item Orders

Delivery Notes

web based IETM/P

Work Orders

Configuration AdministratorAdministrator

System ManagerSupervisorMaintainer

Stores PersonnelData Capture

25

RAMLOG.NET

It provides System Managers, Supervisors, Maintainers and Store Personnel thee ability to manage equipment assets, with respect to:

• stock and inventory control

• system utilisation and operational tracking

• as-maintained configuration control (i.e. configuration control during maintenance and serial number tracking)

• collect system and equipment failure data

• collect maintenance and repair data

• collect supply and turn-around times/data

• implementation of a Failure Recording Analysis and Corrective Action System (FRACAS)

26

Early Design

Production/Construction

Phase Out

Development

Operational Phase

Whole Life Management

Estimations Reality