International Union of Operating Engineers National Hazmat ......International Union of Operating...

Transcript of International Union of Operating Engineers National Hazmat ......International Union of Operating...

International Union of Operating Engineers National Hazmat Program

International Environmental Technology & Training Center

HUMAN FACTORS ASSESSMENT

REPORT FEBRUARY 2001

Mega-Tech Services, Inc. Blade Plunging Cutter

(BPC-4)TM

Research supported by the U.S. Department of Energy’s

National Energy Technology Laboratory under cooperative agreement DE-FC21-95MC32260 with the

Operating Engineers National Hazmat Program, 1293 Airport Road, Beaver, WV 25813,

Phone: 304-253-8674 , Fax (304) 253-7758. Email: [email protected]

Frank Hanley, General President This report was prepared with the support of the U.S. Department of Energy. However, any opinions, findings, conclusions, or recommendations expressed herein are those of the author(s) and do not necessarily reflect the views of the DOE.

i

Mega-Tech Services, Inc. Blade Plunging Cutter (BPC-4)™

Table of Contents

ACKNOWLEDGMENTS ...................................................................................... ii EXECUTIVE SUMMARY.................................................................................... iii SECTION 1 - SUMMARY Technology Description ..................................................................................1 Key Results ....................................................................................................1 SECTION 2 - SYSTEM OPERATION..................................................................1 SECTION 3 - SAFETY AND HEALTH EVALUATION General Safety and Health Concerns .............................................................2 Industrial Hygiene Monitoring .........................................................................3 Human Factors Interface ................................................................................6 Technology Applicability .................................................................................7 SECTION 4 - JOB SAFETY ANALYSIS (JSA) ....................................................8 SECTION 5 - FAILURE MODE AND EFFECTS ANALYSIS (FMEA) ................10 SECTION 6 - TECHNOLOGY SAFETY DATA SHEET (TSDS) ........................11 SECTION 7 - EMERGENCY RESPONSE/PREPAREDNESS ..........................17 SECTION 8 - REGULATORY/POLICY ISSUES................................................17 SECTION 9 - OPERATIONAL CONSIDERATIONS AND RECOMMENDATIONS ................................................................................18 APPENDIX A - REFERENCES .........................................................................20 APPENDIX B - NOISE SAMPLING ...................................................................21 APPENDIX C - ACRONYMS .............................................................................23

ii

ACKNOWLEDGEMENTS

The human factors assessment of the Mega-Tech Blade Plunging Cutter (BPC-4)TM conducted under support of the U.S. Department of Energy’s National Energy Technology Laboratory, under cooperative agreement DE-FC21-95MC32260 with the Operating Engineers National HAZMAT Program would like to thank the following people for their participation on the “research action team” and the professional expertise they provided for this assessment: Barbara McCabe Operating Engineers National Hazmat Program Pat Bell Operating Engineers National Hazmat Program David Curry Operating Engineers Local Union 280

iii

EXECUTIVE SUMMARY

The Mega-Tech Blade Plunging Cutter (BPC-4)TM is a high-pressure, hydraulically operated cutting system with spreaders and cutters that allow for rapid crimping, cutting, and shearing steel pipes and other structural shapes. The basic unit that supports the tools is a portable castor-wheeled HPU-12 hydraulic power cart, which can be moved with a crane or forklift. The cart is a heavy-duty customized unit built specifically for the application. The hydraulic power supply unit consists of a seven-gallon hydraulic oil reservoir, two immersed positive displacement gear pumps, and a 10 HP 3450 RPM motor that operates on either 440 or 220 V three-phase power and requires a 20-amp capacity power supply. The safety and health evaluation during the testing demonstration focused on noise, dust, ergonomics, and heat stress. Noise exposure was virtually non-existent. The noise readings were below the Occupational Safety and Health Administration’s (OSHA) permissible exposure limit (PEL). Dust measurements were also below the OSHA PEL and the and the American Conference of Governmental Industrial Hygienists (ACGIH) threshold limit value (TLV). Heat stress measurements indicated that further steps should be taken to assure that workers do not experience heat-related illnesses while conducting tests in the heat of Miami. Other safety and health concerns included ergonomics, tripping hazards, electrical hazards, lockout/tagout, and hazards associated with using hydraulically operated equipment. The BPC-4 represents a major improvement in human factors engineering with the absence of noise exposure. The choice of PPE will depend on the type and amount of contaminants generated by the surface contamination. Contaminants should be identified by the site characterization prior to the start of an actual decommissioning project. The amount of dust being generated will be identified by air sampling conducted during operation of the BPC-4. Of important note, total dust sampling was conducted during the Miami test because, in the absence of specific contaminants, it was the only approach available. Total dust measurements will be the least appropriate during actual operation of the BPC-4, however. Industrial hygiene samples will need to be collected for the contaminants present which can reasonable be expected to include lead from lead-based paint and coverings, other heavy metals, and radio nuclides. A major human factors issue is the ergonomic stressors placed on the worker from stooping, bending, twisting, kneeling, and lifting while supporting the weight of the BPC-4. Repetitive strain injuries are also possible from the wrist being in non-neutral positions for extended periods of time. The manufacturer recommends supporting the BPC-4 with a tension cable when working from scaffolding, a manlift, or a ladder. Consideration of this method also needs to be given to working at ground level. If the BPC-4 could be deployed robotically this would also give the added advantages of removing the worker from the

iv

contaminated area, thereby decreasing the possibility of heat stress and exposure to contaminants. The BPC-4 offers the major advantage of virtually no noise exposure while having the ability to cut metal structures that fit within the anvil. There also appears to be no significant dust generated during cutting. Recommendations for improved safety and health of the BPC-4 and HUP-12 include: 1) Review the maintenance procedures for checking hose connectors, 2) keeping electrical and hydraulic lines as orderly as possible to avoid injury due to tripping, 3) training in ergonomics to assure proper techniques in lifting, bending, stooping, etc., 4) deploying the BPC-4 robotically or at the least with a tension cable, 5) putting larger wheels on the unit would provider smoother and easier movement, 6) putting a barrier or wall around the tool storage area on the top of the HPU-12, 7) keeping with the mushroom-shaped emergency stop button red and the HPU-12 another color, 8) using proper hand protection to handle cut metal which is sharp, 9) stabilize pieces as they are cut, and 10) using hydraulic hoses that are rated for a PSI above the maximum potential pressures.

1

Figure 1. Blade Plunging Cutter (BPC-4)™ and Hydraulic Power

Cart (HPU-12).

Mega-Tech Services, Inc. Blade Plunging Cutter (BPC-4)TM

Human Factors Assessment

SECTION 1 – SUMMARY

TECHNOLOGY DESCRIPTION The Mega-Tech Blade Plunging Cutter (BPC-4)TM is a high-pressure, hydraulically operated cutting system with spreaders and cutters that allow for rapid crimping, cutting, and shearing steel pipes and other structural shapes. The basic unit that supports the tools is a portable castor-wheeled HPU-12 hydraulic power cart, which can be moved with a crane or forklift. The cart is a heavy-duty customized unit built specifically for the application. The system is shown in Figure 1. The hydraulic power supply unit consists of a seven-gallon hydraulic oil reservoir, two

immersed positive displacement gear pumps, and a 10 HP 3450 RPM motor that operates on either 440 or 220 V three-phase power and requires a 20-amp capacity power supply. KEY RESULTS The safety and health evaluation during the testing demonstration focused on noise, dust, ergonomics, and heat stress. Noise exposure was virtually non-existent. The noise readings were below the Occupational Safety and Health Administration’s (OSHA) permissible exposure limit (PEL). Dust measurements were also below the OSHA PEL and the and the American Conference of Governmental Industrial Hygienists (ACGIH) threshold limit value (TLV). Heat stress measurements indicated that further steps should be taken to assure that workers do not experience heat-related illnesses while conducting tests in the heat of Miami. Other safety and health concerns included ergonomics, tripping hazards, electrical hazards, lockout/tagout, and hazards associated with using hydraulically operated equipment.

2

SECTION 2 – SYSTEM OPERATION

The Mega-Tech Blade Plunging Cutter (BPC-4)TM is a high-pressure, hydraulically operated cutting system with spreaders and cutters that allow for rapid crimping, cutting, and shearing steel pipes and other structural shapes. The BPC-4 required a minimal radial clearance of 2-inches and has a 2-feet stand off distance. The BPC-4 cycles in a total of 22 seconds. The blade automatically disengages from the work on the return portion of the cycle. Blade plunging cutter design and performance data: § Weight (in pounds) – 28 § Length (in inches) – 28 § Lateral Clearance required (in inches) – 2.5 § Opening Capacity (in inches) – 4.5 § Shear point pressure (in 1,000 pounds) – 300 § Cycle Time (in seconds) – 20 § Design operating life (in 1,000 cycles) – 250 The unit’s pump and hoses are rated at 10,000 PSIG while nominal operating pressure is 5,000 to 6,500 PSIG. The pump and fluid is controlled by a patented demand-type valve, which uses minimal pressure to move the tool piston. If the tool stalls, an internal relief valve opens to relieve the pressure. The HPU-12 connects to the tools by two small diameter hoses, one supply and one return, which have low-leakage check valves installed. Hydraulics power unit and cart design and performance data: § Power Unit § Size (in inches) – 20.5H X 16W X 16L § Capacity (in gallons) – 7 § Weight (in pounds) – 150 § Power requirements – 440 VAC/20 AMPS § Speed (RPM) – 3,450 to 3,600 § Pressure rating (PSIG) – 6,500 §

SECTION 3 – SAFETY AND HEALTH ASSESSMENT GENERAL SAFETY AND HEALTH CONCERNS The following safety and health issues were identified during the evaluation of the Mega-Tech Blade Plunging Cutter (BPC-4)TM: § Struck by hazards – When a piece of metal that fits in the anvil under the

blade is cut, it can fall or be thrown (by the pressure of the cut) and strike a worker in the area. An additional worker, or even better, a mechanical means to stabilize the piece until it is cut may need to be considered.

3

§ Electrical – The HPU-12 is electrically powered by a 440 or 220 V three-phase power supply. Electrical shock could occur if proper precautions, such as grounding, are not taken. In addition, proper lockout/tagout procedures need to be followed when conducting maintenance and repair on the HPU-12 and/or BPC-4.

§ Tripping hazards – The BPC-4/HPU-12 has electrical and hydraulic lines that need to be neatly laid out to avoid becoming a tripping hazard. In addition, any hydraulic fluids that leak or spill need to be cleaned up immediately to avoid a slippery walking surface.

§ Ergonomics – In order to manipulate the BPC-4 to cut high and low objects,

the worker is exposed to ergonomic stressors, such as stooping, bending, twisting, kneeling, and lifting, while supporting the weight of the BPC-4. There is also the potential for repetitive strain injuries from the wrist being in a non-neutral position for extended periods.

§ Pinch points – The area where the blades come together to cut presents a

severe pinch point. Worker’s hands must be kept from this area during operation. A partially sheared piece of metal also provides pinch points.

§ Heat stress – The personal protective equipment (PPE) that the worker must

wear in a contaminated area contributes to the heat load. This could lead to a severe heat stress hazard is possible and must be evaluated. Heat stress training is advisable.

§ Hydraulic hazards – Hydraulic operated equipment operates under

pressure. The hydraulic lines could present severe struck by hazards if they were to rupture or disconnect. All hoses and connections need to be inspected on a regular basis and connectors with safety pins used. In addition, the proper PPE to avoid contact with the hydraulic fluid needs to be worn.

INDUSTRIAL HYGIENE MONITORING METHODS Noise Personal noise monitoring was conducted using Metrosonics db-3100 data logging noise dosimeters. Calibration was conducted pre- and post-monitoring using a Metrosonic CL304 acoustical calibrator. Dust Dust monitoring was conducted by drawing air with a MSA Escort Elf air sampling pump through a pre-weighted PVC 37 mm filter in an open-faced cassette. Sampling and analysis followed the NIOSH 0500 gravimetric method for total dust. The cassettes were preweighed and analyzed by Galson Laboratories, and AIHA-Accredited lab. Pre- and post-sampling calibration was

4

accomplished using a BIOS International DryCal DC1 primary calibration system. The level of quantification reported by the lab was 0.05 mg. Heat Stress Heat stress was measured using a QuestTemp°15 Heat Stress Monitor. The wet-bulb globe temperature (WBGT) was used to determine the work/rest regimen in accordance with the ACGIH recommendations. The wet-bulb globe temperature was adjusted for the type of clothing, including PPE, that the worker was wearing in accordance with ACGIH guidelines.

5

RESULTS Noise Area sample Area sample 31002 31003 Sampling Location Inside enclosed Inside enclosed work area (approx. work area (approx. 5-feet from cutting 5-feet from cutting operation). Operation). Sampling period 30 30 (minutes) Avg. exposure 74.4 74.5 (dBA) Percent dose 0.73% 0.73% Projected percent 11.46% 11.56% dose over 8 hrs. Max exposure 100 99.7 (dBA) Peak Exposure 126.9 124.2 (dBA) The “average exposure” above reflects the noise levels averaged for each one-minute period of time. The maximum exposure during one of those periods is listed in the table above as “maximum exposure”. These are lower than “peak exposure” which has the highest instantaneous readings. The OSHA “action limit” for noise under 29 CFR 1910.95 is 85 dBA, averaged over an 8-hour time period. From OSHA’s Hearing Conversation Amendment of 1983, exceeding this level means the employer must administer a continuing, effective hearing conservation program. OSHA also requires that workers exposed above 90 dBA as an 8-hour time weighted average (TWA) must be protected – preferably through engineering or administrative controls. If neither is feasible, personal protective equipment must be provided by the employer. The noise levels measured were below the OSHA action limit and the permissible exposure limit.

6

Dust Sample number 091399-FIU-004 091399-FIU-005 Instrument MSA 003 MSA 002 Serial # Sampling Location Inside enclosed Inside enclosed work area (approx. work area (approx. 2-feet (0.61 meters) 2-feet (0.61 meters) from cutting from cutting operation). operation). Sampling period 15 15 (minutes) Sampling rate 2.0 2.0 (liters/minute) Volume collected 30 30 (liters) Mass (mg) <0.05 <0.05 Concentration <1.7 <1.7 (mg/m3) These dust concentrations are all well below the OSHA permissible exposure limit of 15 mg/m3 for total dust and the ACGIH threshold limit value of 10 mg/m3. Other contaminants such as radiation may need to be monitored and should be based on the site characterization. Heat Stress The WBGT represents the integration of all the key physical indicators of heat stress: the wet bulb (WB) reflects the effect of humidity, the globe (GT) indicates the degree of radiant heating, and the dry bulb (DB) corresponds to the ambient temperature. These measurements are combined in the following formula for indoor readings or outdoor readings with no solar load: WBGT = 0.7 WB + 0.3 GT For outdoor exposures, the effect of the black globe temperature is reduced by including the ambient, dry bulb reading as indicated: WBGT = 0.7 WB + 0.2 GT + 0.1 DB The ACGIH TLVs for heat stress are based on the WBGT readings, the intensity of the work being performed, and the type of clothing being worn. The need to

7

wear protective clothing will need to be considered and the work/rest regime based on the WBGT determined. HUMAN FACTORS INTERFACE The BPC-4 represents a major improvement in human factors engineering with the absence of noise exposure. The choice of PPE will depend on the type and amount of contaminants generated by the surface contamination. Contaminants should be identified by the site characterization prior to the start of an actual decommissioning project. The amount of dust being generated will be identified by air sampling conducted during operation of the BPC-4. Of important note, total dust sampling was conducted during the Miami test because, in the absence of specific contaminants, it was the only approach available. Total dust measurements will be the least appropriate during actual operation of the BPC-4, however. Industrial hygiene samples will need to be collected for the contaminants present which can reasonably be expected to include lead from lead-based paint and coverings, other heavy metals, and radionuclides. A major human factors issue is the ergonomic stressors placed on the worker from stooping, bending, twisting, kneeling, and lifting while supporting the weight of the BPC-4. The manufacturer recommends supporting the BPC-4 with a tension cable when working from scaffolding, a manlift, or a ladder. Consideration of this method also needs to be given to working at ground level. If the BPC-4 could be deployed robotically this would also give the added advantages of removing the worker from the contaminated area, thereby decreasing the possibility of heat stress and exposure to contaminants. TECHNOLOGY APPLICABILITY The BPC-4 offers the major advantage of virtually no noise exposure while having the ability to cut metal structures that fit within the anvil. There also appears to be no significant dust generated during cutting.

8

SECTION 4 – JOB SAFETY ANALYSIS

JOB SAFETY ANALYSIS MEGA-TECH SERVICES, INC.

Blade Plunging Cutter (BPC-4)TM

HAZARD CORRECTIVE ACTION SETUP AND TEARDOWN

Pinch Points * Use of hand protection. * Use of proper hand tools for the job.

Slips/Trips/Falls * Awareness of the specific hazards. * Organization of materials (housekeeping). * Walking around areas that are congested when possible. * Walking around tripping hazards when possible. * Marking, isolating, and/or bunching together tripping hazards.

Muscular/Back Injury * Ergonomic training. * Use of mechanical lifting devices. * Larger wheels on the HPU-12 for easier maneuverability over rough/uneven surfaces.

CUTTING OPERATION Muscular/Back Injury (from stooping, bending, awkward arm positions)

* Ergonomic training. * Use tension cable to maneuver even when working at ground level.

Slips/Trips/Falls * Awareness of site specific hazards (electrical cords and hydraulic lines). * Job site organization of materials (housekeeping). * Walk around hazards when possible. Marking, isolating, and/or bunching together tripping hazards.

Pinch Points * Assure worker training in the proper operation of the BPC-4. *Assure operator always keeps hands from cutting end of BPC-4.

9

HAZARD CORRECTIVE ACTION

CUTTING OPERATION (CONTINUED) Cut/Laceration Hazard * Assure worker training in the proper operation

of the BPC-4. * Always assure workers hands/fingers are not in the area of the blade when a cut is being made.

Struck by (hydraulic hose) *Use safety line to male and female end of fitting.

Exposure to Contaminants * Assure workers are aware of the hazards in the area where they are using the BPC-4. * Use of proper PPE, including respiratory protection. * Worker training to use good work practices that will enable worker to avoid contact with any contaminated surfaces, i.e. the floor, walls, other structures in the area.

Exposure to Hydraulic Fluid * Assure Hazard Communication training for workers. * Assure proper maintenance of equipment.

MAINTENANCE Exposure to Contaminant * Wear proper PPE, including respiratory

protection. Accidental Activation of Moving Parts

* Use proper lockout/tagout techniques, tool and hydraulic power unit.

Pinch Points * Use of hand protection. * Use of hand tools appropriate for the job. * Use of appropriate lockout/tagout procedures.

Slips/Trips/Falls * Awareness of the specific hazards. * Organization of materials (housekeeping). * Walking around areas that are congested when possible. * Walking around tripping hazards, when possible.

Ergonomics/Bending/Kneeling/Lifting

*Use proper lifting techniques. * Ergonomic training to include proper lifting techniques. * Consider engineering controls to eliminate non-neutral wrist positions.

Exposure to Hydraulic Fluid * Assure Hazard Communication training for workers. * Assure proper PPE is used during maintenance activities.

10

SECTION 5 – FAILURE MODE AND EFFECTS ANALYSIS

FAILURE MODE AND EFFECTS ANALYSIS

MEGA-TECH SERVICES, INC. Blade Plunging Cutter (BPC-4)TM

FAILURE MODE EFFECT Hydraulic line punctures/ruptures/disconnects

* Potential for injury to worker from being struck by hydraulic line. * Exposure to hydraulic fluid.

Hydraulic line fitting fails * Potential for injury to worker from being struck by hydraulic line. * Exposure to hydraulic fluid.

Shear binds during cut * Worker exposed to ergonomic stressors from having to pull, push, or twist tool to free it from the material caught in it when it bound.

11

SECTION 6 – TECHNOLOGY SAFETY DATA SHEET

TECHNOLOGY SAFETY DATA SHEET

MEGA-TECH SERVICES, INC. Blade Plunging Cutter (BPC-4)TM

SECTION 1: TECHNOLOGY IDENTITY

Emergency Contact: Jon Stouky 888-522-5185 Information Contact: Jon Stouky 888-522-5185

Manufacturer’s Name and Address: Mega-Tech Services, Inc. 2804 Woodley Court James Town, NC 27282

Date Prepared: February 2001

Other Names: BPC-4 Portable Piston-Operated Hydraulic Tool

Signature of Preparer: Operating Engineers National Hazmat Program 1293 Airport Road, Beaver, WV 25813 phone: 304-253-8674 fax: 304-253-7758 Under cooperative agreement DE-FC21-MC32260

12

SECTION 2: PROCESS DESCRIPTION The Mega-Tech Blade Plunging Cutter (BPC-4)TM is a high-pressure, hydraulically operated cutting system with spreaders and cutters that allow for rapid crimping, cutting, and shearing steel pipes and other structural shapes. The BPC-4 required a minimal radial clearance of 2-inches and has a 2-feet stand off distance. The BPC-4 cycles in a total of 22 seconds. The blade automatically disengages from the work on the return portion of the cycle. Blade plunging cutter design and performance data: § Weight (in pounds) – 28 § Length (in inches) – 28 § Lateral Clearance required (in inches) – 2.5 § Opening Capacity (in inches) – 4.5 § Shear point pressure (in 1,000 pounds) – 300 § Cycle Time (in seconds) – 20 § Design operating life (in 1,000 cycles) – 250 The unit’s pump and hoses are rated at 10,000 PSIG while nominal operating pressure is 5,000 to 6,500 PSIG. The pump and fluid is controlled by a patented demand-type valve which uses minimal pressure to move the tool piston. If the tool stalls, an internal relief valve opens to relieve the pressure. The HPU-12 connects to the tools by two small diameter hoses, one supply and one return, which have low-leakage check valves installed. Hydraulics power unit and cart design and performance data: § Power Unit § Size (in inches) – 20.5H X 16W X 16L § Capacity (in gallons) – 7 § Weight (in pounds) – 150 § Power requirements – 440 VAC/20 AMPS § Speed (RPM) – 3,450 to 3,600 § Pressure rating (PSIG) – 6,500

13

SECTION 3: PROCESS Photos

Blade Plunging Cutter (BPC-4)™ and Hydraulic Power Cart (HPU-12).

Piece of metal being cut by BPC-4.

14

SECTION 4: CONTAMINANTS AND MEDIA Dust generation does not appear to be a concern with the BPC-4. Consideration does need to be given to the metal being cut and contamination in the area where the BPC-4 is being used for D&D activities. An air sampling plan will need to be developed as appropriate for the site where the BPC-4 is used. SECTION 5: ASSOCIATED SAFETY HAZARDS Probability of Occurrence of Hazard:

1 Hazard may be present but not expected over background level 2 Some level of hazard above background level known to be present 3 High hazard potential 4 Potential for imminent danger to life and health

A. ELECTRICAL (LOCKOUT/TAGOUT) RISK RATING: 3 The UPH-12 is powered by a 440 or 220 V three-phase power supply. Electrical shock could occur if proper precautions, such as grounding are not taken. It does have ground straps and covered connectors. Proper lockout/tagout procedures need to be followed when conducting maintenance and repair on the HPU-12 and/or the BPC-4. B. FIRE AND EXPLOSION RISK RATING: 1 Technology does not pose this hazard in and of itself but could not be used in an explosive environment due to potential sparking and because it is not intrinsically safe. C. CONFINED SPACE ENTRY RISK RATING: 1 Not part of this technology unless the specific location where the system is being used is a confined space. In this case, confined space procedures would need to be followed. D. MECHANICAL HAZARDS RISK RATING: 4 Assembling and adjusting the BPC-4 may pose pinch points. Severe pinch points at the point where the blades come together during a cut. In addition, a partial sheared piece of metal could cause pinch points. E. PRESSURE HAZARDS RISK RATING: 4 When the shear stops during operation hydraulic pressure was noted to increase 400 PSI above the PSI rating of the hoses (hoses rated at 5,000 PSI). During difficult cuts pressure can be adjusted to 2,500 PSI above the hose rating. Hydraulic hoses that are used must be rated for a PSI above the maximum potential pressures. Hydraulic hoses can become dangerous struck by hazards if released when under pressure, therefore, all hydraulic hoses and connections must be inspected before use. F. TRIPPING AND FALLING RISK RATING: 3 Electrical lines and hydraulic hoses present tripping hazards. In addition, hydraulic fluid leaks or spills could cause walking surfaces to become slippery. G. LADDERS AND PLATFORM RISK RATING: N/A Not part of this technology.

15

SECTION 5: ASSOCIATED SAFETY HAZARDS (CONTINUED) H. MOVING VEHICLE RISK RATING: N/A Not part of this technology. I. BURIED UTILITIES, DRUMS, AND TANKS RISK RATING: N/A Not part of this technology. J. PROTRUCING OBJECTS RISK RATING: N/A Not part of this technology. K. GAS CYLINDERS RISK RATING: N/A Not part of this technology. L. TRENCHING AND EXCAVATIONS RISK RATING: N/A Not part of this technology. M. OVERHEAD LIFTS RISK RATING: N/A Not part of this technology. N. OVERHEAD HAZARDS RISK RATING: 3 May be part of this technology if the piece being cut is overhead. At a minimum, anyone working in the area should be wearing a hard hat. It needs to be assured that all workers in the area are aware of the overhead work being done and avoid the area when possible. SECTION 6: ASSOCIATED HEALTH HAZARDS Probability of Occurrence of Hazard:

5 Hazard may be present but not expected over background level 6 Some level of hazard above background level known to be present 7 High hazard potential 8 Potential for imminent danger to life and health

A. INHALATION HAZARD RISK RATING: 2 Technology does not appear to produce dust during operation. Consideration needs to be given to the metal being cut. Contaminants that may be present in the area will be identified from the site characterization. B. SKIN ABSORPTION RISK RATING: 2 This would be dependent on the contaminants at the site and would be identified by the site characterization. Consideration needs to be given to the hydraulic fluid. C. HEAT STRESS RISK RATING: 1-4 Ambient conditions, work rates, and PPE levels must be considered. D. NOISE RISK RATING: 1 The technology does not appear to present a noise hazard. E. NON-IONIZING RADIATION RISK RATING: N/A Not part of this technology. F. IONIZING RADIATION RISK RATING: N/A Not part of this technology. G. COLD STRESS RISK RATING: 1-4 Technology does not produce a hazard but ambient conditions need to be considered.

16

SECTION 6: ASSOCIATED HEALTH HAZARDS (CONTINUED) H. ERGONOMIC HAZARDS RISK RATING: 3 In order to manipulate the BPC-4 to cut high and low objects, the worker is exposed to ergonomic stressors, such as stooping, bending, twisting, kneeling, and lifting, while supporting the weight of the BPC-4. I. OTHER RISK RATING: N/A None noted at this time. SECTION 7: PHASE ANALYSIS A. CONSTRUCTION/START-UP The set-up/start-up phase presents several hazards including pinch points, laceration hazards, slips/trips/falls, struck by, electrical hazards, hazards from hydraulic fluids, and muscular/back injury. B. OPERATION The operation phase presents several hazards including exposure to contaminant, muscular/back injury, pinch points, laceration hazards, slips/trips/falls, electrical hazards, ergonomic stressors, and hazards from hydraulic fluids. C. MAINTENANCE The maintenance phase presents several hazards including pinch points, laceration hazards, slips/trips/falls, muscular/back injury, exposure to contaminants, electrical hazards, hazards from hydraulic fluids, and accidental activation of moving parts. D. DECOMMISSIONING The decommissioning phase presents several hazards including exposure to contaminants, pinch points, laceration hazards, slips/trips/falls, electrical hazards, hazards from hydraulic fluids, and muscular/back injury. SECTION 8: HEALTH AND SAFETY PLAN REQUIRED ELEMENTS A. AIR MONITORING Dust does not appear to be a concern during operation of the BPC-4. Monitoring may need to be conducted for the metal the pieces are made of and the contaminants in the area where the D&D activities take place. This will be determined by the site characterization prior to the initiation of the D&D project.

17

SECTION 8: HEALTH AND SAFETY PLAN REQUIRED ELEMENTS (CONTINUED) B. WORKER TRAINING Training that may apply in this case may include but not be limited to: § HAZWOPER § HAZCOM § Respiratory Protection § Personal Protective Equipment § Electrical Safety § Lockout/Tagout § Ergonomics (proper lifting, bending, stooping, kneeling, and static postures) § Heat stress (learning to recognize signs and symptoms) § CPR/First Aid/Emergency Response § Bloodborne Pathogens § Working with hydraulic systems § Construction Safety (OSHA 500) and/or General Industry Safety (OSHA 501) C. EMERGENCY RESPONSE Emergency response planning for a site needs to assure adequate coverage for hazards described in the TSDS. Having at least one person per shift trained in CPR and first aid is recommended. D. MEDIAL SURVEILLANCE Evaluation of personnel’s general health with emphasis on the cardiovascular and respiratory system and back. In addition, medical surveillance as required by OSHA standards must be conducted. SECTION 9: COMMENTS AND SPECIAL CONSIDERATIONS Only personnel who have been adequately trained in the operation of this technology should be permitted to operate and/or work the equipment.

18

SECTION 7 -- EMERGENCY RESPONSE/PREPAREDNESS

The use of the BPC-4 and UHP-12 technology does not present any serious concerns for generating emergency situations that would affect the surrounding operations or communities. Emergency response/preparedness should be part of every hazardous waste site safety and health plan. In addition to credible site emergencies, site personnel must plan for credible emergencies in connection with the BPC-4 and UHP-12.

SECTION 8 – REGULAORY/POLICY ISSUES

The site safety and health personnel where the BPC-4 and UHP-12 technology is being used need to be concerned with safety and health regulations applicable to the issues discussed above. The following OSHA regulations may apply to the operation of the BPC-4 and UHP-12 and should be reviewed. § OSHA 29 CFR 1926.25 Housekeeping § OSHA 29 CFR 1910.141 Sanitation (1910.141(a)(3) covers housekeeping) § OSHA 29 CFR 1926 Subpart Z Toxic and Hazardous Substances § OSHA 29 CFR 1910 Subpart Z Toxic and Hazardous Substances § OSHA 29 CFR 1910.1200 Hazard Communication § OSHA 29 CFR 1926.59 Hazard Communication § OSHA 29 CFR 1926 Subpart K Electrical § OSHA 29 CFR 1910 Subpart S Electrical § OSHA 29 CFR 1910.147 The Control of Hazardous Energy (Lockout/Tagout) § OSHA 29 CFR 1926 Subpart I Tools – Hand and Power § OSHA 29 CFR 1910 Subpart P Hand and Portable Powered Tools § OSHA 29 CFR 1926.103 Respiratory Protection § OSHA 29 CFR 1910.134 Respiratory Protection § OSHA 29 CFR 1926.102 Eye and Face Protection § OSHA 29 CFR 1910.28 Personal Protective Equipment Worker training is essential to safe operation. The following training may be required and, it not required, should be considered to ensure the protection of workers. § HAZWOPER § HAZCOM § Respiratory Protection § Personal Protective Equipment § Electrical Safety § Lockout/Tagout § Ergonomics (proper lifting, bending, stooping, kneeling, and static postures) § Heat stress (learning to recognize signs and symptoms) § CPR/First Aid/Emergency Response § Bloodborne Pathogens § Working with hydraulic systems

19

§ Construction Safety (OSHA 500) and/or General Industry Safety (OSHA 501)

SECTION 9 – OPERATIONAL CONSIDERATIONS & RECOMMENDATIONS

§ Review the maintenance procedures for checking hose connectors. The

constant high pressure on the hoses can weaken the connections, releasing a hose under pressure. The resulting whipping action could lead to serious injuries and expose workers to hydraulic fluids.

§ Workers must be aware of the tripping hazards associated with electrical lines

and hydraulic hoses. Keeping these as orderly as possible in compliance with good housekeeping regulations will help avoid injury due to tripping.

§ The workers need to have training in ergonomics to assure proper techniques

in lifting, bending, stooping, twisting, etc. during equipment set-up, operation, maintenance, tear-down, and decontamination.

Operating the BPC-4 has the potential to cause the operator to assume positions which place stress on the back, neck, shoulders, arms, knees, and legs. This is in part due to the position in which the BPC-4 has to be held to access the piece to be cut. Pre-planning to place the operator in the best position, for both ergonomic and safety considerations, needs to be done before the start of the project and periodically as the project progresses. Additional concerns are raised due to the static posturing that must be assumed while at the same time balancing the weight of the BPC-4 during a cut. The manufacturer recommends supporting the BPC-4with a tension cable when working from a scaffolding, a manlift, or a ladder. Consideration of this method also needs to be given to working at ground level. If the BPC-4 could be deployed robotically, this would not only alleviate ergonomic stressors but would also remove the worker from the contaminated area, thereby decreasing the possibility of heat stress and exposure to contaminants.

§ The operating lever acts as a “dead-man” switch; if the operator releases pressure on the control the BPC-4. Therefore, the control should never be held down by anything other than the operator’s fingers.

§ The HPU-12 has wheels for easier maneuverability but the small wheels do

not move smoothly on rough surfaces such as gravel. Putting larger wheels on the unit would provider smoother and easier movement.

§ The HPU-12 has a storage area for tools on the top of the unit. This is an

excellent idea and helps keep tools organized and readily available. A barrier or wall around this area would help keep tools from slipping onto the control panel.

20

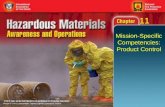

Figure 2. HPU-12 colored red with red emergency stop button.

§ There is a mushroom shaped knob-type emergency stop button located to the

left of the control panel of the HPU-12. The emergency stop is red as is the HPU-12. This can make the emergency stop button difficult to see especially during the confusion that often accompanies an emergency. See Figure 2. In keeping with the stereotype for an emergency related button, the emergency stop should remain red and the rest of the HPU-12 should be another color.

§ The edge of the metal piece being cut can

be jagged and very sharp. Proper hand protection to prevent cuts and punctures needs to be worn.

§ When a piece of metal that fits in the anvil

under the blade is cut, it can fall or be thrown (by the pressure of the cut) and strike a worker in the area. An additional worker, or even better, a mechanical means to stabilize the piece until it is cut may need to be considered.

§ When the shear stops during operation

hydraulic pressure was noted to increase 400 PSI above the PSI rating of the hoses (hoses rated at 5,000 PSI). During difficult cuts pressure can be adjusted to 2,500 PSI above the hose rating. Hydraulic hoses that are used must be rated for a PSI above the maximum potential pressures.

§ Hydraulic hoses can become dangerous struck by hazards if released when

under pressure, therefore, all hydraulic hoses and connections must be inspected before use. In addition, a safety line should be used between the male and female connections.

§ The BPC-4 twists and turns while a cut is being made. This often makes it

difficult for the operator to retain control of the cutter. During the demonstration, the operators felt that the best practice was to allow the cutter to twist along with the metal being cut. This needs to be taken into consideration when operators are trained and only trained should be allowed to use the cutter. Robotic deployment or supporting the BPC-4 with a tension cable would also help with this problem.

§ During the demonstration, the operators felt it was difficult to estimate when

the cut was completed which could cause the operator to have difficulty determining when to stop applying pressure. This presents the potential for striking the helper when the cut is complete. Extra care needs to be taken by the operator to watch the cut he/she is making and to be aware of the position of the helper.

21

APPENDIX A REFERENCES

Occupational Safety and Health Standards for General Industry, 29 CFR Part 1910, Occupational Safety and Health Administration United States Department of Labor Occupational Safety and Health Standards for the Construction Industry, 29 CFR Part 1926, Occupational Safety and Health Administration United States Department of Labor Threshold Limit Values (TLVs) for Chemical Substances and Physical Agents and Biological Exposure Indices (BEIs), American Conference of Governmental Industrial Hygienists, 1995-1996 The NIOSH compendium of hearing protection devices, U.S. Department of Health and Human Services, Public Health Service, Center for Disease Control and Prevention, October 1994

22

APPENDIX B NOISE SAMPLING

31002

The percentage of time spent at each decibel level can be obtained from the graph. As shown, 91.987% of the time the noise exposure level was at or less than 85 dBA, which means 8.013% of the time, was spent at sound levels above 85 dBA. OSHA requires that a hearing conservation program be initiated if the 8-hour TWA is 85 dBA. The high peaks around the 106 dBA level can be attributed to the scoring.

23

NOISE SAMPLING 31003

The percentage of time spent at each decibel level can be obtained from the graph. As shown, 91.788% of the time the noise exposure level was at or less than 85 dBA, which means 8.212% of the time, was spent at sound levels above 85 dBA. OSHA requires that a hearing conservation program be initiated if the 8-hour TWA is 85 dBA. The high peaks around the 106 dBA level can be attributed to the scoring.

24

APPENENDIX C ACRONYM SHEET

ACGIH - American Conference of Governmental Industrial Hygienists AIHA - American Industrial Hygiene Association CFR - Code of Federal Regulations dBA - Decibel (on the “A” weighted scale) D&D - Decontamination and decommissioning DOE - Department of Energy FIU - Florida International University HAZCOM - Hazard communication HAZWOPER - Hazardous Waste Operations HP - Horse power mg - Milligram m3 - Cubic meter MSDS - Material Safety Data Sheet NIOSH - National Institute of Safety and Health OSHA - Occupational Safety and Health Administration PEL - Permissible exposure limit PPE - Personal protective equipment PSIG - Pressure per square Inch gauge RPM - Revolutions per minute TLV - Threshold limit value TSDS - Technology Safety Data Sheet TWA - Time weighted average V - Volt WBGT - Wet-bulb globe temperature