Instrument Hook-up Drawing Intro

-

Upload

nikhil-kautilya -

Category

Documents

-

view

595 -

download

20

description

Transcript of Instrument Hook-up Drawing Intro

CONTENTS

� Introduction

� Hook-up drawing for Pressure/Differential pressure measurement instruments

� Hook-up drawing for Flow measurement instruments

� Hook-up drawing for Temperature measurement instruments

� Hook-up drawing for Level measurement instruments

� Hook-up drawing for Instrument Air supply

Instrument Installation or Hook-up

� Hook-up drawing for Instrument Air supply

� Impulse Pipe and Tube

What is Instrument hook-up drawing?

Instrument hook-up drawing gives the detail of the connection from the tappingpoint in the process line up to the sensing instrument.

So, while Piping and Instrumentation Diagram (P&ID) shows the instruments thatare to be connected to a process line, the Instrument Hook-up gives detailinformation about how that is to be done during actual installation.

Introduction

Why do we need Instrument Hook-up drawing?

- To make measurements accurate and reliable - To make measurement systems safe- To be used at site for correct instrument erection & installation

Type of instrument

Accessories

Bill of MaterialScope of work

Tapping orientation

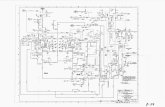

Introduction: How does a typical hook-up drawing look like?

S

Fittings

Impulse line Sensing instrument/transmitter withvalve manifolds

Figure: Typical Instrument Hook-up Drawing for a Pressure Transmitter

Input documents required for making Instrument Hook-up drawings:

� Contract Requirement and Project Design Criteria � Piping and Instrument Diagrams (P&ID)� Instrument List (with Instrument Datasheet)� Piping Material Classification (PMC) or Piping Material Specification (PMS)� Instrument Rack grouping, elevation of tapping and rack� Control Valve List (for Instrument Air)� Tank and Heat Exchanger GA drawings

Output documents from Hook-up drawing:

�Bill of Material (erection and installation)

Introduction: Engineering Process & Interface

Support drawings along with Hook-up drawing:

� Pipe Support drawing� Piping Isometric Drawing

General check-points:

� Check Instrument Installation material specification with Boiler/Turbine group for maintaining uniformity across plant.� Instrument/Rack location and drain connections to be informed to related departments for proper end connections.� Elevation of rack provides enough scope for requisite slope for instrument mounting.� Cross-check the connections of materials at interface points.

Hook-up drawing for Pressure/Differential pressure measurement instruments

a) Tapping points - Preferred angle of tapping point in horizontal line:

� Gas service: within 45 degree around vertical centre-line� Steam service: within 45 degree around horizontal centre-line� Liquid service: within 45 degree of horizontal centre-line in lower half, preferred horizontal because taps

below the centre-line can accumulate solids, while taps above the centre-line can accumulate air ornon-condensing gases.

� For differential pressure measurement, both tapping points should be at same elevation.

b) Root valve

- Root (isolation or block) valves are required to separate the entire measurement system from the mainpipeline when necessary, but they should not affect the pressure signal.

For gas service

For steam service

For liquid service

- Root valves are to be located as close as possible to tap connections.

- Root valves shall be designed for maximum design pressure and temperature of the piping system

- For process pressure greater than 40 bar(g) (or as specified in contract), two nos. of root valves to be used.

c) Preferred Location of measuring instrument (secondary) with respect to process tapping (primary)

� Gas service - secondary above primary

� Liquid service- secondary below primary

Root valves

For gas service, secondary above primary

For liquid service, secondary above primary

Lesson learnt (Root valve): To provide accessibility, Root valves were brought to floor levelwhich caused a potential safety issue (high steam application) and slope issues which couldlead to inaccurate measurement. The valve was moved near to tapping point.

d) Impulse tube/pipe and fittings

� The required diameter of the impulse line depends on the service conditions. Internal diameter of tube/pipe should be adequate to allowgas bubbles to flow up and out of a liquid system, and to allow liquid drops to flow down (ISO 2186:2007 does not allow diameter lessthan 6mm, prefers 10mm and specifies a maximum of 25mm).

� It is always recommended that the shortest possible impulse-line lengths be used. The diameter is given as per the length for theimpulse as per the service in ISO 2186:2007, Table A.1

� Material of Impulse line should be as per service, process conditions.

� Wall thickness of impulse line to be as per ANSI B31.1 for a given temperature and pressure rating.

� Fitting material should conform to ANSI B16.11 and should match with the impulse line material (for e.g. SS fittings for SS tubing). Anexception to this is brass fittings with copper tubing. Different materials could cause Galvanic corrosion due to different electrodepotentials of dissimilar metals.

Hook-up drawing for Pressure/Differential pressure measurement instruments

potentials of dissimilar metals.

� For gas application: slope from process line to measuring instrument to be upwards with gradient of minimum 8% for self-draining(otherwise low-point drain to be provided)

� For steam: slope for impulse line to be downwards from tapping point to measuring instrument, with gradient of minimum 8% for self-venting of non-condensing gases (otherwise high-point vent to be provided)

� For liquid: downwards slope of minimum 8% (otherwise high-point vent to be provided)

Lesson learnt: In case of tube fittings, compression fittings (double ferrule type) for pressure greater than 40 bar (g) caused leakage. To correct, welded fittings were used for all high pressure application.

Accessories:

a) Instrument Isolation Valve and Valve manifolds: Valves/valve manifolds are installed to permit operation, calibration andtroubleshooting of the secondary device (measuring instrument) without removing it. An assembly of two, three, or more valves, oftenin one package, used to facilitate calibration and maintenance is called valve manifold. These valves are used to:

� Isolate the secondary device from the impulse lines� Open a path between the high and low pressure sides of the secondary device. The secondary device zero (no flow signal) can be

adjusted at operating pressure with one block valve closed and the bypass valve(s) open� Drain or vent the secondary device and/or the impulse piping to the drain or to atmosphere.

2-valve manifold: One valve connects the process to secondary instrument, another valve allows testing, venting and calibration (when the first valve is closed).

3-valve manifold: Two block valves provide instrument isolation, and one equalize valve is positioned between the high and low

Hook-up drawing for Pressure/Differential pressure measurement instruments

3-valve manifold: Two block valves provide instrument isolation, and one equalize valve is positioned between the high and low transmitter process connections. Equalizing valve provides a means to check for 0 PSI differential pressure when both Isolation valves are closed and only equalizing valve is left open. Such valves are used for d/p type measurement.

5-valve manifold: Two block valves provide instrument isolation and one equalize valve is positioned between the high and low transmitter process connections. In addition, two drain/vent valves allow for venting/draining, and in-process calibration capability.

2-valve manifold 3-valve manifold 5-valve manifold

Accessories:

b) Remote Seal:

This arrangement of an Remote Isolating diaphragm at the tapping point and acapillary tube containing a fill-fluid which combine to transfer the pressure fromthe process to the measuring instrument without allowing the process fluid tocome directly in contact with the secondary instrument is called Remote Seal.This is employed when,� There is a need to protect transmitter sensor from harsh process fluid� Process fluid is viscous or might get frozen in the impulse tube because of

temperature fall� Process fluid might clog the impulse line with contaminants� Process fluid is to be prevented from getting contaminated (as in food

processing systems)

Hook-up drawing for Pressure/Differential pressure measurement instruments

processing systems)

c) Condensate Pots (Seal Pots or Reservoirs):

To measure the pressure of high-temperature steam without damaging thepressure transmitter sensor, Condensate Pot is used which has a small volumeof liquid which creates a barrier for steam which prevents it from reaching thesensing element.Pigtail Siphon: It is a loop of tube which serves the same purpose as the condensatepot. The condensed steam will accumulate and create a barrier for steam.

Condensate pot

In situations where the flow measurement is done by measuring differential pressure, all sections of Differential Pressure measurement are to be followed.

Magnetic flow meter:The magnetic flow meter must be electrically grounded to the process liquid. This is because the magnetic meter is part of the path for any stray current traveling down the pipeline or through the process liquid. Bonding, by grounding the meter at both ends to the process fluid, provides a short circuit for stray currents, routing them around the flow-tube instead of through it. If the system is not properly grounded, these currents can

Flow measurement (on the basis of installation type)

By measuring differential-pressure (e.g. Orifice, nozzle)

By In-line Mechanical or Electrical flow meters (e.g. Positive Displacement meter, Ultrasonic meter)

Hook-up drawing for Flow measurement instruments

short circuit for stray currents, routing them around the flow-tube instead of through it. If the system is not properly grounded, these currents can create a zero shift in the magnetic flow meter output.

Grounding when pipe is conductive Grounding when pipe is non-conductive

Typical hook-up drawing for Positive Displacement type flow meter

Hook-up drawing for Temperature measurement instruments

� Connection type of the thermo-well: flanged, weld, threaded etc should be indicated as per the instrument selected.

� Thermo-well drawing to be reviewed with respect to Isometric drawing to avoid thermowell diameter mismatch.

� ASME PTC 19.3 2010 does not recommend velocity collar as a rigid support for the purposes of shortening the unsupported length.

Typical hook-up drawing for Test Well (Flange type) with Velocity collar Typical hook-up drawing for Test Well (Threadolet type)

� In case of Level measurement by D/P method, all the points of Differential Pressure measurement apply as it is.� In DP type Level Measurement for avoiding density variation in one Leg Wet leg Calibration is performed� Root valve and impulse pipe shall have a minimum of 1” (DN 25 mm) diameter� From Tank tapping point to stand pipe and further from stand pipe tapping to instrument � Impulse routing shall be always straight with minimum bends.� For Displacer type Level transmitter, side-side and side-bottom criteria should be checked with instrument selected.� For Tanks Level Gage, center-to-center (C-C) distance should be checked with application requirement.� For a Tank multiple Level Gauges can be used with overlapping C-C length.� For Ultrasonic and Radar Type Level Transmitters Signal transmission angle to be checked of nozzle.

Hook-up drawing for Level measurement instruments

Typical installation method for Level transmitters/gauge. Wecan see the side-bottom configuration of the transmitter.Also, can be seen are multiple level gauges with overlappingC-C length.

GL: Gauge lengthSL: Sigh length (Visible length)ME: Center-to-center (C-C) distance

Hook-up drawing for Ultrasonic method for level measurement

Hook-up drawing for Instrument Air supply

� This hook-up contains the connection from the instrument air source to the instrument requiring the air for its working.

� Air line tube material (Copper/SS), size and thickness to be considered as per requirement

Typical hook-up drawing for Instrument Air supply to Modulating Type Control Valve

Connector: tube fitting designed to connect tube to pipe.

Union: tube fitting designed to connect tube to tube. If union joins tubes of different sizes, it is called reducing union. To connect two pipes, Coupling is used.

Bulkhead fittings: Connectors and

Pipe and Tube, both are hollow structures designed to provide an enclosed pathway for fluids to flow.

� Essential difference is that both are manufactured with different standards.

� Pipes are thick-walled, tubes are thin-walled.

� Tube is never threaded (like a pipe) and a tube fitting is a must to join ends.

� Tube is specified by OD (Outer diameter) and wallthickness.

Impulse Pipe and Tube

Bulkhead fittings: Connectors and fittings designed to fit through holes drilled in panels or enclosures. Similar to Connectors and Union except long length of central ‘barrel’ piece and a nut to lock the piece into the place.

Elbow: Fittings with a bend

Tee fittings: Fittings that are used to join three fluid lines.

�Pipe is denoted by NB (Nominal bore) or NPS (Nominal Pipe Size) [both in inches] or DN (translated to Nominal Diameter) [in mm] and Schedule (wall thickness). NB, NPSor NB are equivalent in their meaning, but different in dimensions used.

�NPS (or DN or NB) are closely related to internal diameter but are not exactly same as the internal diameter.

� For a given NPS, OD gets fixed. As the Schedule changes the wall thickness increases (thereby changing the Internal Diameter).

Impulse Pipe and Tube: Connection types

Considering hook-up, pipes are connected to another pipe or a component by:

�Socket weld�Threaded connection�Flanged connection

Tubes are connected to other tubes or a component by:

� Socket weld� Compression fittings

� Tubes are too weak to support threads or flanges.

Socket

The left end is Socket end in which a tube is inserted and welded at the joint. The right end is threaded for Pipe connection as it is a male connector.

Flanged connection Compression fitting with double ferrule

Thank You