Hydraulic Symbols

-

Upload

bhaskar-reddy -

Category

Documents

-

view

3 -

download

0

description

Transcript of Hydraulic Symbols

Section 35

Chapter 1

8-94372NH

How to Read Symbols in a Hydraulic Schematic

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

35-2

TABLE OF CONTENTS

HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC ........................................................................................... 35-3Introduction ......................................................................................................................................................... 35-3Circuit Diagrams .................................................................................................................................................. 35-3Symbol Systems .................................................................................................................................................. 35-3Using Schematic Symbols ..................................................................................................................................... 35-3

Reservoirs ........................................................................................................................................................ 35-3Lines, Tubes and Hoses ...................................................................................................................................... 35-4Crossing or Joining Lines .................................................................................................................................... 35-5Pump Symbols .................................................................................................................................................. 35-5Hydraulic Motor Symbols ..................................................................................................................................... 35-6Cylinder Symbols ............................................................................................................................................... 35-6

Pressure Control Symbols ..................................................................................................................................... 35-7Normally Closed ................................................................................................................................................ 35-7Normally Open ................................................................................................................................................... 35-7Relief Valve ....................................................................................................................................................... 35-7Pressure Reducing Valve .................................................................................................................................... 35-7Sequence Valve ................................................................................................................................................. 35-8

Directional Control Symbols ................................................................................................................................... 35-8Simplified Symbols ............................................................................................................................................. 35-8One Way Valve .................................................................................................................................................. 35-8By Pass Valve ................................................................................................................................................... 35-8

Composite Symbols ............................................................................................................................................. 35-8One Way Valves ................................................................................................................................................ 35-8Two Position Valves ........................................................................................................................................... 35-8Three Position Valves ......................................................................................................................................... 35-9Actuating Controls .............................................................................................................................................. 35-9

Flow Control Symbols ........................................................................................................................................... 35-9Restrictors ........................................................................................................................................................ 35-9

Accessories ...................................................................................................................................................... 35-10

SIMPLE SCHEMATIC ............................................................................................................................................ 35-12

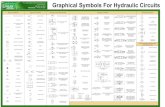

COMMON SYMBOLS ............................................................................................................................................. 35-14Lines and Line Functions .................................................................................................................................... 35-14Mechanical Devices ........................................................................................................................................... 35-14Pumps and Motors ............................................................................................................................................. 35-14Reservoirs ........................................................................................................................................................ 35-15Cylinders .......................................................................................................................................................... 35-15Valves .............................................................................................................................................................. 35-15Valve Actuators ................................................................................................................................................. 35-17Accessories ...................................................................................................................................................... 35-17

Template Name: SM_2_colTemplate Date: 1994_04_05

Alt= to hide template informationAlt+ to display template information

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

35-3

HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC

IntroductionAccurate diagrams of hydraulic circuits are essential to theman who must repair them. The diagram shows how thecomponents will interact. It shows the field technician how itworks, what each component should be doing and where theoil should be going so that he can diagnose and repair thesystem.

The purpose of this section is to show you how to find yourway around schematic circuit diagrams.

Circuit DiagramsThere are two types of circuit diagrams.

1. Cutaway Circuit Diagrams show the internal constructionof the components as well as the flow paths. By usingcolors, shades or var ious patterns in the l ines andpassages, t hey a re able t o show many d i f fe ren tconditions of flow and pressure. Cutaway diagrams takecons iderably longer t o p roduce because o f the i rcomplexity.

2. Schematic Circuit Diagrams the “shorthand” system ofthe industry, are usually preferred for troubleshooting. Aschematic diagram is made up of simple geometr icsymbols for the components and their controls andconnections.

Symbol Systems

There are several systems of symbols used when makingschematic diagrams. They are as follows:

I. S. O. = International Standards Organization

A. N. S. I. = American National Standards Institute

A. S. A. = American Standards Association

J. I. C. = Joint Industry Conference

A combination of these symbols are shown in this section.There are differences between the symbols but there isenough similarity so that if you understand the symbols in thissection you will be able to interpret other symbols as well.

Using Schematic Symbols

Reservoirs

A rectangle wi th the top removed represents a ventedreservoir. A rectangle with the top in place represents apressurized reservoir.

There are other schematic diagrams that show a slightlydifferent version of a pressurized reservoir, but the symbolsare similar and easily recognized. An oval with a short line ontop or a rectangle with curved sides represents a reservoirthat is pressurized.

Lines connected to the reservoir usually are drawn from thetop, regardless of where the actual connection is.

If the hydraulic line terminates below the fluid level, it is drawnall the way to the bottom of the symbol.

710L8D710L8B

VENTED RESERVOIR PRESSURIZED RESERVOIR

710L8C 710L8A

PRESSURIZED RESERVOIR PRESSURIZED RESERVOIR

710L8E

RETURN LINE ABOVETHE OIL LEVEL

710L8F

SUCTION LINE OR RETURN LINE BELOW THE OIL LEVEL

Template Name: SM_2_colTemplate Date: 1994_04_05

Alt= to hide template informationAlt+ to display template information

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

35-4

A hydraulic line connected to the bottom of the reservoir maybe drawn from the bot tom of the symbol i f the bottomconnection is essential to the systems operation.

If the pump inlet must be charged or flooded with a positivehead of oi l above the inlet por t, we would posit ion thereservoir symbol above the pump symbol, and draw thesuction line out of the bottom of the reservoir symbol.

Every vehicle or system reservoir has at least two hydrauliclines connected to it, and some may have many more. Oftenthe components that are connected to the reservoir arespread all over the schematic. Rather than having a lot ofconfusing lines all over the schematic, it is customary to drawindividual reservoir symbols close to the components. Thereservoir is usually the only component symbol pictured morethan once.

Lines, Tubes and Hoses

A hydraulic line, tube, hose or any conductor that carries thefluid between components is shown as a line.

A working line, such as an inlet pressure or return, is shownas a solid line.

Working lines with arrows show direction of flow.

Pilot or control lines are broken into long dashes.

Drain lines for leakage oil are broken into short dashes.

A flexible line is shown as an arc between two dots and isalways represented by a solid line.

Quite often you will see an enclosure outline that indicatesthat there are several symbols that make up a componentassembly such as a valve or a valve stack. The enclosureoutline appears like a box and is broken with dashes on allsides.

7108GRESERVOIR WITH SUCTION LINE ATTACHED AT THE BOTTOM

749L8B

PUMP

710L8H

710L8JOIL FLOWS ONE WAY ONLY

710L8KOIL CAN FLOW EITHER WAY

710L8K

710L8B

710L8C

710L8D

Template Name: SM_2_colTemplate Date: 1994_04_05

Alt= to hide template informationAlt+ to display template information

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

35-5

Crossing or Joining Lines

The shor test distance between two components that areconnect is a straight line. There are lines that cross otherlines but are not connected. There are several ways to showcrossing lines.

Lines that are connected are shown with a dot that representsthe connection or shown as a tee connect ion. The dotconnect ion is the most commonly used when drawingschematic diagrams.

Pump Symbols

There are many bas ic pump des igns. A s imple f ixeddisplacement pump is shown as a circle with a black trianglethat is pointing outwards. The black triangle is like an arrowhead and points in the direction that the oil will flow. If thepump is reversible or designed to pump in either direction, itwill have two black triangles in it and they will be oppositeeach other.

A variable displacement pump is designated by drawing anarrow through the pump symbol at 45 degrees. To indicate avariable displacement pressure compensated pump, a smallbox with an arrow in it will be added to the side of the pumpsymbol.

If the pump is controlled by a lever or a pedal, it will be shownon the side of the pump.

A drive shaft is shown as two short parallel lines extendingfrom the side of the pump. If a curved arrow is shown on thedrive shaft, it will indicate the direction of rotation.

710L8M710L8L711L8E

LINES THAT ARE NOT CONNECTED

711L8H710L8P710L8N

DOT CONNECTION TEE CONNECTION

LINES THAT ARE CONNECTED

711L8J 711L8K

INLET

OUTLET

FIXED DISPLACEMENT

FIXED DISPLACEMENTREVERSIBLE

710L8T710L8s

VARIABLE DISPLACEMENTVARIABLE DISPLACEMENTPRESSURE COMPENSATED

710L8U710L8V

LEVER CONTROLLED PEDAL OR TREADLECONTROLLED

711L8L710L8W

PUMP WITH DRIVE SHAFT PUMP WITH DRIVE SHAFTAND DIRECTIONAL ARROW

Template Name: SM_2_colTemplate Date: 1994_04_05

Alt= to hide template informationAlt+ to display template information

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

35-6

Hydraulic Motor Symbols

Hydraulic motor symbols are circles with black triangles, butopposite a pump the triangles point inward to show the motoris a receiver of oil. One triangle is used in a nonreversiblemotor and two triangles are used for a reversible motor.

A simple schematic diagram is shown with a hydraulic motorconnected to a hydraulic pump.

Cylinder Symbols

A cylinder symbol is a simple rectangle representing thebarrel. The piston and rod are represented by a tee that isinserted into the rectangle. The symbol can be drawn in anyposition.

If the cylinder is single acting there is only one port shown onthe symbol. The port is shown on the end of the cylinder thatreceives pressur ized f luid and the opposi te end of thecylinder is left open. A double acting cylinder symbol has bothends closed and has two ports on the symbol.

A double rod end cylinder has a rod extending from each endof the rectangle.

Some cylinders have cushions built into them. The cushionslows down the movement of the piston as it nears the end ofi ts st roke. Cyl inder cushions are shown as a smal le rrectangle on the piston. If the cushion has an adjustableorifice, a slanted arrow is drawn at 45 degrees across thesymbol.

711L8N711L8MNONREVERSIBLE MOTOR

REVERSIBLE MOTOR

711L8F

PUMP

MOTOR

711L8Q

TEERECTANGLE

711L8Q

711L8P

PORT

SINGLE ACTING CYLINDER

PORTS

DOUBLE ACTING CYLINDER

712L8ADOUBLE ROD END CYLINDER

749L8E

730L8E

SINGLE ROD ENDFIXED CUSHION BOTH ENDS

SINGLE ROD END ADJUSTABLECUSHION ROD END ONLY

Template Name: SM_2_colTemplate Date: 1994_04_05

Alt= to hide template informationAlt+ to display template information

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

35-7

Pressure Control Symbols

The basic symbol is a square (which is called an envelope)with external port connections and an arrow inside to showthe oil passage and direction of flow. Usually this type ofvalve operates by balancing the oil pressure against a spring,so a spring is shown on one side of the symbol and a pilotpressure line on the other side.

Normally Closed

A normally closed valve, such as a relief or sequence valve, isshown with the arrow offset from the ports and toward thepilot pressure line side of the square. The spring holds thevalve closed until the pilot line oil pressure is greater than thespring pressure. Mentally visualize a build up of pressure inthe pilot line and the square moving over, compressing thespring. The oil can now flow through the valve.

Normally Open

A normally open valve is shown with the arrow connecting thetwo ports. It closes when pressure overcomes spring force.Mentally visualize a build up of pressure in the pilot line andthe square moving over, compressing the spring. The oil flowthrough the valve is now blocked.

Relief Valve

A re l ie f valve is shown as a normal ly c losed symbolconnected between the pressure line and the reservoir. Theflow direction arrow points away from the pressure line portand toward the reservoir. This shows very graphically how are l ie f va lve opera tes. When pressu re i n t he sys temovercomes the valve spring, flow is from the pressure linethrough the relief valve to the reservoir.

Pressure Reducing Valve

A pressure reducing valve is shown as a normally opensymbol in a pressure line. This valve works opposite of arelief valve, since it senses outlet pressure versus inletpressure. As the outlet pressure builds, it works against apredetermined spring force. As the spring force is overcome,flow through the valve is modulated or shut off.

712L8C712L8B

ARROW OFFSETFROM PORTS

SPRING

OUTLET

PILOTLINE

ARROW ALIGNEDWITH PORTS

NORMALLY CLOSEDMENTALLY VISUALIZE SQUAREMOVING TOWARD SPRING

INLET

712L8E712L8D

SPRING

OUTLET

PILOTLINE

MENTALLY VISUALIZE SQUAREMOVING TOWARD SPRINGNORMALLY OPEN

INLET

712L8F

PRESSURE LINE

PUMP RELIEF VALVE

712L8H

HIGH PRESSURE INLET

PILOTLINE

REDUCED OUTLET PRESSURE

DRAIN LINE TORESERVOIR

Template Name: SM_2_colTemplate Date: 1994_04_05

Alt= to hide template informationAlt+ to display template information

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

35-8

Sequence Valve

The normally closed symbol is also used for a sequencevalve. The inlet port is connected to a primary cylinder andthe outlet port to the secondary cylinder line. When the pistonin the primary cylinder reaches the end of its stroke, thepressure in the supply line increases. The sequence valve isalso connected to the supply line and also feels the increasein p ressure. As pressure increases, the square anddirectional flow arrow moves over, connecting the inlet andoutlet ports allowing fluid to flow to the secondary cylinder.

Directional Control SymbolsSimplified SymbolsOne Way Valve

A simple ball check valve is shown. When oil pressure isexerted on the left side of the ball, the ball is forced into the Vand no oil can flow past it. When oil pressure is applied to theright side of the ball, the ball moves away from the V and oilcan flow past it.

By Pass Valve

A by pass valve is shown as a one way valve with a spring onthe ball end of the symbol. This shows that a pressurized flowwill be necessary to overcome the spring force and allow flowaround the ball

Composite SymbolsOne Way Valves

A more complex one way valve is now shown. This directionalcontrol symbol uses a multiple envelope (square) system thathas a separate square for each position. Remember all of thepor t connections are made to the envelope that shows theneutral condition of the valve. Within each envelope arearrows showing the flow paths when the valve is shifted tothat position.

Two Position Valves

A simple control valve has two envelopes (representing thespool) if it is a two position valve. The envelopes show theflow conditions when they are in one position. The aboveschematic is showing that oil is being supplied to the rod endof the cylinder. If we mentally visualize the directional controlvalve moved to the other position, it would be as shownbelow.

Here, pressurized oil is being supplied to the piston end ofthe cylinder and oil from the rod end of the cylinder is allowedto flow to the reservoir.

712L8G

SUPPLY LINE

RELIEFVALVE PUMP

TO PRIMARYCYLINDER

TO SECONDARYCYLINDER

SEQUENCEVALVE

712L8J

NO FLOW

FREE FLOW

712L8K

SPRING

714L8A

NOFLOW

FREEFLOW

ONE WAY VALVE SHOWN INTHE CLOSED POSITION

MENTALLY VISUALIZE A BUILDUP OF PRESSURE ON THERIGHT SIDE OF THE VALVE

714L8B

PUMP

RELIEFVALVE

CONTROLVALVE

CYLINDERROD END

CYLINDERPISTON END

714L8C

Template Name: SM_2_colTemplate Date: 1994_04_05

Alt= to hide template informationAlt+ to display template information

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

35-9

Three Position Valves

Three position valves will have a centered (neutral) position.The centered position can be either open or closed to flow.The open center is usually used with a fixed displacementpump and the closed center is usually used with a variabledisplacement pump.

Actuating Controls

Valve spools are controlled by levers, pedals, pilot oil, electricsolenoids, etc., which are called actuating controls. Theseactuating controls are shown by symbols placed on the endsof the envelopes.

To show that a valve is spring centered, a spring symbol isplaced at each end of the envelope. The above schematicshows that an electrical solenoid and pilot pressure assist arerequired to overcome spring force to move the valve spool.

Flow Control SymbolsRestrictors

The basic f low contro l symbol is a representation of arestrictor. If the restrictor is adjustable, a slanted arrow isdrawn across the symbol. The restrictor could be a specialfitting with a small hole in it or a small drilled passagewaywithin a valve. If it is an adjustable restriction, it could bethought of as a water faucet that can be controlled by turningthe handle to regulate the flow. Restrictors can be applied tometer out, meter in and bleed off circuits.

The r e a re ad jus tab l e re s t r i c to r s t h a t a re p res su recompensated. That means that the size of the opening in therestr ictor wi l l change with increases and decreases inpressure. A per pend icu la r a r row ind ica tes pressurecompensat ion. I f the restr ictor has both pressure andtemperature compensation, the symbol for a thermometer willalso be shown.

713L8B

713L8AOPEN CENTER THREE POSITION VALVE

CLOSED CENTER THREE POSITION VALVE

713L8G 713L8FLEVER PEDAL

713L8D 713L8E

713L8D

TWO POSITION, CONTROLLED BYEXTERNAL PILOT PRESSURE

TWO POSITION, CONTROLLEDBY SOLENOIDS

THREE POSITION, SOLENOID CONTROLLEDWITH INTERNAL PILOT ASSIST PRESSURE

713L8C

SOLENOID CONTROL WITHINTERNAL PILOT PRESSURE

SPRINGSPRINGTHREE POSITION, SPRING CENTERED

716L8B716L8A

NON ADJUSTABLE RESTRICTOR ADJUSTABLE RESTRICTOR

716L8D716L8C

ADJUSTABLE RESTRICTORPRESSURE COMPENSATED

ADJUSTABLE RESTRICTORPRESSURE ANDTEMPERATURE COMPENSATED

Template Name: SM_2_colTemplate Date: 1994_04_05

Alt= to hide template informationAlt+ to display template information

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

35-10

Accessories

Filters, strainers and heat exchangers are represented assquares that are turned 45 degrees and have the por tconnection at the corners.

As you can see, the black triangles point in the direction thatthe heat is dissipated. Or in the case of the control unit, theyshow that the heat can be regulated.

An oval with details inside indicate an accumulator. Thedetails inside will tell you what type of accumulator it is;spring loaded, gas charged, or other features.

A dotted line perpendicular to the flowline indicates a filter or strainer.

FILTER OR STRAINER716L8E

A solid line perpendicular to the flowwith black t r iangles poin t ing outindicates a cooler.

COOLER716L8F

The symbol for a heater is like thesymbol for a cooler, except the blacktriangles point in.

HEATER731L8G

Two sets of triangles pointing in andout indicates a temperature controlunit

TEMPERATURECONTROL UNIT

731L8H

716L8H

716L8G

GAS CHARGED

SPRING LOADED

The divider line indicates there is aseparator between the charge and theoil. A hollow triangle indicates gas.

A spring shows that the accumulator isspring loaded.

35-11

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

NOTES

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

35-12

SIMPLE SCHEMATIC

Now that you have completed hydraulic symbols, we have put some of the symbols together to form a simple hydraulic schematic.See if you can find your way around the schematic without reading the text for each valve. The text explains the function of each valvein the hydraulic system.

A

A

D

C

D C B

B

715L8

DETENT

FLOAT

35-13

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

Valve AThis valve is a three position valve. The spool is lever operatedand spring centered. It is an open center valve. Visually placethe envelopes into the center position and you will see that thevalve will direct oil into one end or the other of cylinder A. Whenthe spool in valve A is moved out of the centered position, thevalves downstream will receive no oil.

Valve B

Valve B is similar to valve A but it is a four position valve. Thefourth position is a float position and is held into that positionwith a detent. With this valve the cylinder B can be extend,retracted, or placed in the float position. Visualizes the envelopefor the float position in the inlet passageway.

You will see that oil can continue to flow to the next valvedownstream and that the rod in cylinder B could be pushed backand forth. The oil could move from one end of the cylinder to theother via the valve. Both ends of the cylinder are also connectedto the return line to the reservoir.

Valve C

This valve is also similar to valve A but is designed to control asingle acting cylinder. When you visualize placing the upperenvelope in the center position you will see that oil can drainback to the reservoir from cylinder C.

At the same time, oil from the pump can flow through valve C tothe next valve.

Valve D

Valve D is a lever operated, spr ing centered valve and isdesigned to control a hydraulic motor. If a hydraulic motor wasturning a flywheel and the oil supply and return were shut offabruptly, this would cause damage to the hydraulic lines, themotor, or whatever it was powering. Therefore when the valvesupplying the motor is shut off, the motor should be able to slowdown gradually. The center (neutral) position of valve D willallow that to happen by letting oil from the outlet of the motorreturn to the inlet side.

As you have seen, this brief information is all you need to readhydraulic schematics. The more you use it, the more you will becomfortable using hydraulic schematics as a troubleshootingguide.

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

35-14

COMMON SYMBOLSLines and Line Functions Mechanical Devices

Pumps and Motors

711L8A

710L8H

711L8B

SOLID LINEMAIN LINE

DASHED LINEPILOT LINE

DOTTED LINEEXHAUST OR DRAIN

729L8M

ENCLOSURE OUTLINE

711L8E

710L8M

LINES CROSSING

LINES JOINING

710L8P

729L8N

729L8P

LIQUID DIRECTIONOF FLOW

GASEOUS DIRECTIONOF FLOW

711L8C

FLEXIBLE LINE

730L8G

MECHANICAL CONNECTIONSTWO PARALLEL LINES(SHAFTS, LEVERS, ECT)

730L8H

VARIABLE COMPONENT (RUN ARROWTHROUGH SYMBOL AT 45 DEGREES

730L8JSPRING

729L8D

HYDRAULIC PUMPFIXED DISPLACEMENT

729L8E

HYDRAULIC PUMPVARIABLE DISPLACEMENT

729L8F

PRESSURE COMPENSATEDVARIABLE DISPLACEMENT PUMP

711L8K

FIXED DISPLACEMENTHYDRAULIC PUMP(TWO DIRECTIONAL FLOW)

35-15

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

Reservoirs

Cylinders

Valves

711L8M

HYDRAULIC MOTORFIXED DISPLACEMENT

730L8B

HYDRAULIC MOTORVARIABLE DISPLACEMENT

730L8C

HYDRAULIC OSCILLATOR

710L8B

RESERVOIROPEN TO ATMOSPERER

710L8A

PRESSURIZED RESERVOIR

710L8F

LINE TO RESERVOIRBELOW FLUID LEVEL

710L8E

LINE TO RESERVOIRABOVE FLUID LEVEL

711L8P

SINGLE ACTING

711L8P

730L8E

749L8EP

712L8A

DOUBLE ACTINGSINGLE ROD END

DOUBLE ACTINGDOUBLE ROD END

SINGLE ROD ENDFIXED CUSHION BOTH ENDS

SINGLE ROD ENDADJUSTABLE CUSHIONROD END ONLY

730L8F

DIFFERENTIAL CYLINDER

731L8A

731L8B

712L8J

CHECK VALVE

PILOT OPERATED CHECK

ON - OFFMANUAL SHUT OFF

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

35-16

729L8L

729L8K

731L8E

731L8C

749L8F749L8A

REGULATING ORSELECTOR VALVES

2 POSITION - 2 WAY VALVE

2 POSITION - 4 WAY VALVE

3 POSITION - 4 WAY VALVE

2 POSITION - 4 WAYOPEN CENTER CROSS OVER

749L8C

VALVE CAPABLE OF INFINITEPOSITIONING (INDICATED BYHORIZONTAL LINES DRAWNPARALLEL TO THE ENVELOPE)

712L8B

PRESSURE RELIEF VALVE

731L8D

2 POSITION - 3 WAY VALVE

PRESSURE REDUCING VALVE

712L8H

716L8H

NON - ADJUSTABLE RESTRICTOR

716L8B

ADJUSTABLE RESTRICTOR

716L8C

ADJUSTABLE RESTRICTORPRESSURE COMPENSATED

716L8D

ADJUSTABLE RESTRICTOR(TEMPERATURE ANDPRESSURE COMPENSATED)

35-17

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

Valve Actuators

Accessories

G731L8L

729L8A

729L8

730L8J

729L8B

729L8C

SOLENOID

DETENT

SPRING

MANUAL

PUSH BUTTON

PUSH PULL LEVER

713L8F

PEDAL

729L8G

MECHANICAL

729L8H

PRESSURE COMPENSATED

731L8F

PILOT PRESSUREREMOTE SUPPLY

731L8M

LIQUID SUPPLY

716L8E

FILTER

716L8F

COOLER

731L8G

HEATER

731L8H

TEMPERATURECONTROLLER

716L8G

ACCUMULATORHYDRO - PNEUMATIC

SECTION 35 - HOW TO READ SYMBOLS IN A HYDRAULIC SCHEMATIC - CHAPTER 1

35-18

730L8K

REVERSING MOTOR

730L8M

PRESSURE INDICATOR

730L8N

TEMPERATURE INDICATOR

730L8L

STATION OR TEST POINT

730L8P

PRESSURE SWITCH

731L8K

731L8J

QUICK DISCONNECTS(DISCONNECTED)

QUICK DISCONNECTS(CONNECTED)

![Quantifiers, Unit Symbols, Chemical Symbols and Symbols ...[Technical Data] Quantifiers, Unit Symbols, Chemical Symbols and Symbols of Elements Excerpts from JIS Z 8202 Calculation](https://static.fdocuments.us/doc/165x107/613ff166b44ffa75b8048971/quantifiers-unit-symbols-chemical-symbols-and-symbols-technical-data-quantifiers.jpg)

![Quantifiers, Unit Symbols, Chemical Symbols and Symbols of … · 2019-02-26 · [Technical Data] Quantifiers, Unit Symbols, Chemical Symbols and Symbols of Elements Excerpts from](https://static.fdocuments.us/doc/165x107/5ea0ef282df5855ac23d36fb/quantifiers-unit-symbols-chemical-symbols-and-symbols-of-2019-02-26-technical.jpg)