HFT PXL Mechanical July 2010

description

Transcript of HFT PXL Mechanical July 2010

1

HFT PXL Mechanical

July 2010

Howard Wieman LBNL

2

Topics

• PXL reminder• Tools for probe testing

thinned 50 m chips• PXL support with rapid

detector swapping

3

Pixel geometry. These inner two layers provide the projection precision

2.5 cm radius

8 cm radius

Inner layer

Outer layer

End view

One of two half cylinders

20 cm

coverage +-1

total 40 ladders

Some pixel features and specifications

Pointing resolution (12 19GeV/pc) mLayers Layer 1 at 2.5 cm radius

Layer 2 at 8 cm radiusPixel size 18.4 m X 18.4 m Hit resolution 8 m rmsPosition stability 6 m (20 m envelope)Radiation thickness per layer

X/X0 = 0.37%

Number of pixels 436 M

Integration time (affects pileup) 0.2 msRadiation requirement 20 to 90 kRad

2*1011 to 1012 1MeV n eq/cm2

Rapid detector replacement

< 8 Hours

criticalanddifficult

more than a factor of 3 better than other vertex detectors (ATLAS, ALICE and PHENIX)

5

Thinned MAPS performance

• Thinner and smaller pixels than a hybrid pixel detector

• Accumulates statistics for 0.5 GeV D0 36 times faster than a hybrid

• 200 times faster for 1.5 GeV

6

Mechanics Previously Reported

• Pointing requirements and a design to satisfy low multiple coulomb scattering plus high stability

• Detector assembly• Vibration tests• Cooling tests (Michal Szelezniak)

HFT PXL – fabrication and tooling

7

8

Vacuum chuck for probe station

handling of thinned siliconneeded new mechanics for probe testing

9

10

11

PXL support designed with emphasis on rapid replacement

• Motivation – most vertex detectors failed to produce because they could not be easily accessed and repaired

• Report on design progress on insertion and alignment– more involved mechanical design now practical

with modern 3D CAD software that was not available for the original STAR design

• Designs guided by Eric Anderssen

HFT PXL – installation design

• a well controlled method for installation of the pixel detector has been developed with emphasis on ease of operation and avoidance of detector risk

• The PXL assembly will be enclosed in a carrying box that is equipped for transfer of the detector assembly into the PXL support tube

• Once inserted on tracks the detector is guided into position locking kinematic mounts

12

13

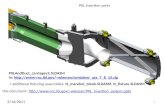

maneuvering the detector into the IP with cams and rails

PITPST

14

initial open position clears the wide region of the beam pipe

partially closed to fit into PST

operating position closed around the beam pipe

15

top two kinematic mounts

bottom not complete

16

hinge and carriagemachined aluminum2 mm thickcontoured to form light rigid structures

cam follower

rail bearings

cooling airhose adapterrapid prototype

1 mm thick carbon composite support tube and cooling air duct

17

testing of parts with CAD tools- work directly within CAD program

20 lb extended load for cables0.4 mm displacement

•less than 10 minutes to setup problem with constraints and loads•few seconds to mesh•12 seconds to solve

18

bending and breaking before building

19

system to test detector insertion with kinematic mounts

20

overlay of multi functional fixtures

• construct insertion test system•bond flanges on carbon composite support tubes•cut holes in support tubes•bond rails into support tubes•bond kinematic mounts into support tubes•support detector in kinematic mounts for spatial mapping in coordinate measuring machine•position SSD mounts on support tube for bonding

21

Coordinate Measuring Machine (CMM) configurationThe grand master fixture is also used to support the detector halves in the CMM for doing the spatial map of the pixels. The fixture is supported in the CMM with 3 point support on the tooling balls for all the required angular positions. The relative mapping of all the tooling balls provides the required cross referencing of all the angular positions.

The same kinematic supports are used here as are used in the STAR detector installation.

22

Status of parts

• Models and 60 pages of power point instructions submitted to LBNL main shop and University of Texas Austin machine shop – fabrication expected to start shortly

23

PIT flange attachment

• assemble PIT end plate fixture• load flanges on PIT and insert into the PIT end plate

fixture• bond flanges (middle flange?)• cut holes for rail mounts • ready for rail mounting

24

cut holes in PIT for rail supports

• install cutting guide, cut 4 holes• flip guide, cut 4 more• rotate PIT 180 deg, repeat for 8 more holes

25

apply glue and mount to rails with post passing through holesinsert rails with rail holder fixture

Bond rail supports

bonded rail support

26

remove post freeing rails and rail holder for removal

•remove rails and rail holder•release rails from rail holder•remove PIT from end fixtures (can’t remove with rails in place)•reattach rails to PIT with correctly identified posts

keep track of which post goes with which pad

27

PIT with rails attached

28

rail tester

rail_test_system.SLDASM (operation view)

29

tester rail attachment

• Assemble PIT flange mounting plates• Assemble tester frame

30

install rail holder with rails, posts and bond pads removed

spread glue attach post andbond pad

cams are removed so that cross bars (not shown) coupling rails constrain the rotation angle in the guides

31

remove posts

removing the posts allow that rails and rail holder to be removed.Rails without the rail holder can then be reattached to the rail tester by reinstalling the posts.

32

attach kinematic mounts to rail testerbutch plate

grand master with kinematic mounts

cross arms

base plate attached to grand master

•remove rails•mount butch plate•apply glue to cross arms and base plate•attach grand master to butch plate•after glue sets remove butch plate and separate rail tester from PIT end plates•reattach rails•tester is now complete•grand master can be detached from base plate for later use after testing is complete

33

PST flange attachment• Assemble PST end plate fixture• load flanges on PST and insert into the PST end plate fixture• bond flanges• cut holes (fixture yet to be designed)• Now ready for attaching the kinematic mounts

34

PST kinematic mount attachment

•remove east PST end plate•attach empty grand master to east PST end plate•attach PST end plate with grand master back on to the PST fixture

east PSTend plate

grand master

35

kinematic mount•assemble kinematic mounts with bond feet•attach mount with feet to cross bar•apply adhesive

adhesive

36

PST kinematic mount attachment• attach kinematic mounts to grand

master by securing cross bar to grand master

• allow setup and remove cross bars from feet and grand master

• detach grand master from east PST end plate and support the grand master so that it does not load PST

• Remove end plates and grand master• PST done

37

Summary of PST kinematic attachment

• remove east PST end plate• attach empty grand master to east PST end plate• attach PST end plate with grand master back on to the PST fixture• assemble kinematic mounts with bond feet• attach mount with feet to cross bar• apply adhesive• attach kinematic mounts to grand master by securing cross bar to grand

master• allow setup and remove cross bars from feet and grand master• detach grand master from east PST end plate and support the grand master

so that it does not load PST• Remove end plates and grand master• PST done

38

OSC fixture• The PIT fixture will also be used for the OSC since the OSC and PIT

are the same diameter. The base plate will be changed to set the correct length– fixture used for placing the OSC flanges– flats and reference groves used to position SSD supports. Up to 6 ladder supports

can be installed at one setting. The OSC is rotated in the fixture by 180 deg to do the remaining attachments.

39

backup

40

41

42