HEALTH & SAFETY - Marathon Petroleum Corporation · HEALTH & SAFETY DISCUSSION: As MPC grows, we...

Transcript of HEALTH & SAFETY - Marathon Petroleum Corporation · HEALTH & SAFETY DISCUSSION: As MPC grows, we...

MPC CITIZENSHIP REPORT 2013 21

HEALTH & SAFETY

An operator at MPC’s Galveston Bay refinery in Texas City, Texas

MPC CITIZENSHIP REPORT 201322

We are uncompromising in our approach to health and safety, and to our vision: that every day is accident-free, and every employee and contractor at our facilities goes home injury-free. Health and safety are therefore built into our daily work, whether it’s in office buildings, at refineries and terminals, on marine vessels or in vehicles.

Health and safety are important to our success as a company; if our employees and contractors are not safe, then other measures of success lose their meaning. We track the metrics reported in this section as a matter of accountability to our employees and contractors and to the communities in which we live. We want you to know how we’re doing.

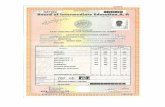

FATALITIES TIER 1 PROCESS SAFETY EVENTS

(PSEs)*

MPC SAFETY* SPEEDWAY SAFETY*

0

5

10

15

20

20132012201120102009

10

8

11

3

16

}Galveston Bay re�nery (acquired Feb. 1, 2013)

* Prior-year PSEs have been recalculated to comply with current standards and to exclude assets no longer owned by MPC, including a refinery in St. Paul Park, Minn., which MPC sold in 2010. These PSEs do not include Speedway.

*Includes employees and contractors

0

500

1,000

1,500

2,000

2,500

3,000

20132007

2 or Fewer Health Risks

3-4 Health Risks

5+ Health Risks

850

1,335

576

571

1,208

982

33% reduction in the number of employees with the most health risks

}

EMPLOYEE WELLNESS ASSESSMENT*

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

20132012201120102009

MPC OSHA Recordable Incident Rate

MPC Days Away Rate

0.080.12

0.03

0.45

0.61

0.45

0.03

0.24

0.03

0.32

0.00

0.50

1.00

1.50

2.00

2.50

3.00

3.50

20132012201120102009

Speedway OSHA Recordable Incident Rate

Speedway Days Away Rate

3.263.13

2.96

1.66 1.71 1.78

2.71

1.68

2.71

1.61

2.69

*Includes contractors; excludes Speedway *Excludes contractors

0

1

2

3

4

5

20132012201120102009

MPC* (excluding Speedway)

Speedway (excluding contractors)

2

1 1

0 00 0

0.0

0.1

0.2

0.3

0.4

0.5

0.6

20132012

0.38

0.55

MPC SAFETY PERFORMANCE INDEX (MSPI)*

DISCUSSION: The 2013 Wellness Assessments revealed a 33 percent reduction in the number of employees with the largest number of health risks compared to a baseline survey conducted in 2007. In order to ensure statistically valid comparability, MPC selects the assessment population each year to control for attrition and other changes in the group over time.

* The MSPI is a safety metric similar to the OSHA Recordable Incident Rate and Days Away Rate metrics reported in this section, but is weighted for severity. 2012 was the first year that the MSPI was used as one of the criteria to determine a portion of employee compensation.

DISCUSSION: The increase in process safety events in 2013 is a concern that MPC is addressing. For each process safety event that takes place in the company, an in-depth analysis is conducted to determine the causes and how to avoid them in the future. These analyses are then provided to all impacted employees to ensure widespread awareness, and changes are made to processes and procedures as necessary. MPC also is involved in an industry-wide effort to share process safety lessons for continual improvement.

Metrics

HEALTH & SAFETY

DISCUSSION: As MPC grows, we work to ensure every aspect of our business performs to our high safety standards and continually improves. The increase in our MSPI in 2013 is due primarily to the expansion of our business, and our target remains continual improvement in health and safety.

*Excludes Speedway

For more information about any of the terms on this page, please see the Glossary on page 44.

DISCUSSION: The OSHA Recordable Incident Rate represents the number of incidents per 200,000 hours of work. The Days Away Rate represents injuries that caused at least one missed day of work, also per 200,000 hours of work.

DISCUSSION: The OSHA Recordable Incident Rate represents the number of incidents per 200,000 hours of work. The Days Away Rate represents injuries that caused at least one missed day of work, also per 200,000 hours of work.

MPC CITIZENSHIP REPORT 2013 23

◗ MPC’s refineries in Garyville, La.; Detroit, Mich.; Robinson, Ill.; Catlettsburg, Ky.; Texas City, Texas; and Canton, Ohio, earned the Meritorious Safety Performance Award from the American Fuel and Petrochemical Manufacturers. The award recognized the plants’ excellent safety records.

◗ A seven-member MPC pipeline construction and maintenance crew accrued more than 1,000 workdays with no OSHA recordable injuries, a significant milestone for a crew that conducts excavation work with heavy equipment in all kinds of weather.

◗ MPC’s Marathon Pipe Line subsidiary hosted members of the Tallahatchie County Local Emergency Planning Committee for a pipeline safety and awareness meeting in Charleston, Miss. Topics addressed by MPC

technicians included what to do in the event of a pipeline emergency and what products are shipped through local pipeline systems.

◗ When contractors performing MPC pipeline right of way work incurred four OSHA recordable injuries in 2011, MPC decided to hold a safety summit. In 2012, there were no OSHA recordables. In 2013, the safety summit continued, bringing together MPC employees and contractors working on right of way clearing to engage in hazard-awareness training and receive copies of the new “Best Practices Right of Way Handbook: Think, then Act.”

◗ MPC’s Safe Digging School Program in 2013 reached hundreds of students, their teachers and parents at schools in areas where the company has significant pipeline operations. Through the

program, MPC employees teach children the importance of calling 811 before digging to protect their families, the environment and underground utilities.

◗ To recognize the safety practices of locations with more than 20,000 exposure hours worked, the American Chemistry Council presents Certificates of Excellence to member companies that have no fatalities, no injuries resulting in missing a day of work, and no injuries resulting in restricted duty. MPC earned these certificates at 42 of its operations locations.

◗ MPC earned Norfolk Southern railroad’s Thoroughbred Chemical Safety Award in 2013, in recognition of MPC’s rail operations resulting in zero non-accident releases. A non-accident release is one that is not associated with a train accident.

Behind theNumbers

HEALTH & SAFETY

MPC firefighters at the company’s Galveston Bay refinery in Texas City, Texas, participate in a training exercise.

MPC CITIZENSHIP REPORT 201324

Behind theNumbers

HEALTH & SAFETY

◗ The American Heart Association (AHA) recognized MPC with the Fit Friendly Company Award in 2013 for our efforts to champion the health of employees and create a culture of physical activity and health in the workplace. MPC is one of fewer than 300 companies nationwide to receive the platinum level of recognition – the AHA’s highest for the award.

◗ At MPC’s Eisenhower terminal in Port Everglades, Fla., MPC conducted a day-long emergency drill with other companies from the area, local firefighters and other emergency responders.

◗ MPC’s refinery in Canton, Ohio, achieved Gold Level Certification from the Cambridge Center for Behavioral Studies in recognition of the plant’s behavioral-based safety program’s comprehensiveness, success and dedication to continual improvement.

◗ MPC’s refinery in Detroit, Mich., collaborated with the Federal Bureau of Investigation to provide training to Special Weapons and Tactics and Special Response Teams from 11 U.S. states and territories. The refinery provided access to MPC-owned buildings, allowing the trainers to demonstrate techniques for forcing entry into buildings in order to rescue victims of hostage situations.

◗ MPC’s Terminal, Transport and Rail organization earned the Platinum Safety Award from the International Liquid Terminals Association (ILTA) for its exemplary safety performance. ILTA represents 80 companies and partnerships that operate bulk liquid storage terminals in 49 countries.

◗ MPC’s Marine Transportation organization was recertified by the American Waterways Operators as a Responsible Carrier after successfully

being audited by a third-party auditor to ensure compliance with the program’s requirements.

◗ MPC’s Marine Transportation organization in Catlettsburg, Ky., participated in a joint confined-space rescue drill with the Boyd County, Ky., Emergency Management Services and the Grayson, Ky., Fire Department.

◗ MPC’s Marine Transportation organization was recognized by the Chamber of Shipping America with 13 Jones F. Devlin Awards. The award recognizes vessels that have operated for at least two years without a seafarer involved in a lost-time injury.

◗ MPC’s refinery in Canton, Ohio, earned the Responsible Care® Certificate of Achievement Award, which recognizes facilities with zero fatalities and zero days-away incident cases for employees.

MPC employees working on a pipeline project in Kentucky

MPC CITIZENSHIP REPORT 2013 25

◗ MPC was recognized by Union Pacific Railroad with its Pinnacle Award for chemical transportation safety. The award recognizes Union Pacific customers that implemented successful prevention and corrective plans, and achieved a rate of zero non-accident releases for regulated hazardous materials shipments. Non-accident releases are those not due to a rail accident.

◗ MPC’s refinery in Robinson, Ill., was awarded with the Cambridge Center for Behavioral Studies’ Outstanding Behavior-Based Safety Outreach Award. The award recognizes the plant’s efforts

to extend behavior-based safety principles and practices to contractor companies that work at the refinery.

◗ MPC’s refinery in Robinson, Ill., was recognized by OSHA with its National Voluntary Protection Program Participants’ Association (VPPA) Outreach Award for outstanding efforts in mentoring nine contracting companies to achieve behavior-based safety accreditation. The refinery also received the Region 5 VPPA Outreach Award for its efforts to grow and promote the Voluntary Protection Program.

◗ MPC’s refinery in Robinson, Ill., held a Behavior-Based Safety Conference, attracting more than 400 participants from local industry and contracting companies to hear from safety experts on behavior-based safety practices used at the refinery.

◗ MPC’s refinery in Garyville, La., hosted its annual firefighting training for more than 50 local volunteer firefighters, providing classroom and hands-on instruction on fighting flammable gas and liquid fires.

“MARATHON PETROLEUM HAS ALWAYS BEEN VERY OPEN AND WILLING TO REPORT ANY SAFETY AND ENVIRONMENTAL INFORMATION AT OUR MONTHLY MEETINGS. THE MANAGER READILY ANSWERS ANY QUESTIONS POSED BY THE COMMUNITY ADVISORY PANEL MEMBERS.”SYLVIA BOTTOLFS Community Advisory Panel memberGaryville, La.

MPC employees participate in a Corporate Emergency Response Team drill, in which they practice working with federal, state and local emergency responders to address a simulated incident.