Hammer Tapping

-

Upload

joechengsh -

Category

Documents

-

view

289 -

download

4

Transcript of Hammer Tapping

Hammer tapping test

Principle of the test

When tapping test surface with a light hammer, near surface delaminated area will show “hollow sounding” comparing with that of the sound area.

Therefore, hammer tapping survey could identify near surface defects.

Application

Identify position of near surface defects, such as delaminated area.

Identify position of delamination between two layers of materials, e.g. tile/ concrete, rendering/ substrate, etc.

Equipment

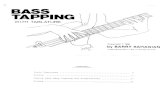

A light hammer or

Automatic hammer tapping void detector – consists of an electrical operated stainless steel ball creating tapping motion, a microphone for collecting responding sound after tapping and a colour lamp signal (green, orange and red) showing the test result. Green means no debonding, red means debonding, orange means doubtful.

Equipment

Test procedures

Tapping the test surface with a light hammer or the void detector.

Mark the suspended area with chalk or crayon immediately.

Measure the size of the suspended area and record to worksheet.

Reporting

Method of testing, e.g. by a light hammer or automatic hammer tapping void detector.

Type of surface being tested, e.g. concrete or tile surface.

Size and position of suspected areas.

Advantages

Non-destructive test.

Quick and simple.

Limitations - Traditional hammer

Need access to getting direct contact with the test surface.

Require well-trained and experienced technicians for performing the test.

Test results is subjective. It may vary against different technicians.

Limitations - Automatic void detector

Need access to getting direct contact with the test surface.

The equipment must be firmly contacted with test surface because it shows green lamp when the steel ball is not hitting to test surface.