GROUND FLOOR MECHANICAL SYMBOLS & NOTESmechanical symbols point of new connection to existing work...

Transcript of GROUND FLOOR MECHANICAL SYMBOLS & NOTESmechanical symbols point of new connection to existing work...

NEW YORK CITY BUILDING DEPARTMENT NOTES

MECHANICAL SCOPE OF WORK

RELOCATED SUPPLY DIFFUSER

RELOCATED RETURN GRILLE/ REGISTER

NEW RETURN GRILLE/ REGISTER

NEW SUPPLY DIFFUSER

M-202.00 GROUND LEVEL: MECHANICAL - SPECIFICATIONS II

M-201.00 GROUND LEVEL: MECHANICAL - SPECIFICATIONS I

SMOKE DAMPER

WIRE MESH SCREEN

TRANSFER DUCT

TYPE (REFER TO SCHEDULE)

BUILDING MANAGEMENT SYSTEM

CUBIC FEET PER MINUTE

FREE AREA

CONDENSATE DRAIN

CUBIC FEET PER MINUTE AND DIFFUSER

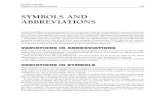

MECHANICAL ABBREVIATIONS

ACCESS DOOR

ACOUSTIC LINING

SD

WMS

TD

CD

F.A.

CFM

BMS

(550)A

AL

AD

SPACE SENSOR

A - SECTION DESIGNATION

B - DRAWING NO.

REFER TO PLANS FOR LOCATION.

REFER TO PLANS FOR LOCATION.

STARTER / DISCONNECT SWITCH

REMOVE AND PATCH EXISTING WORK

SECTION DESIGNATION ON DRAWING

SPOT TYPE LIQUID DETECTOR

SMOKE DETECTOR

REVISION SYMBOL

WHERE SECTION IS CUT

DRAWING NOTE TAG

EXISTING PIPING, DUCTWORK OR EQUIPMENT TO REMAIN

NEW PIPING, DUCTWORK OR EQUIPMENT

ELECTRIC ON/OFF THERMALLY PROTECTED SWITCH WITH PILOT LIGHT

HUMIDISTAT OR HUMIDITY SENSOR TO BE WALL OR DUCT MOUNTED.

THERMOSTAT OR TEMPERATURE SENSOR TO BE WALL OR DUCT MOUNTED.

MECHANICAL SYMBOLS

POINT OF NEW CONNECTION TO EXISTING WORK

MECHANICAL DRAWING NOTATIONS

GROUND LEVEL: MECHANICAL - SYMBOL & NOTES

MECHANICAL LINE REPRESENTATION

M-101.00

MECHANICAL DRAWING LIST

A. GENERAL

1. THERE IS A DRAWING SPECIFICATION AS PART OF THIS CONTRACT.

ON THE HVAC DRAWINGS.

FOR ALL THE COMPONENTS OF THE SYSTEM.

OUTLINED IN THE HVAC SPECIFICATIONS.

AND TESTING REQUIREMENTS.

AFFECTED BY REMOVALS OF THE BASE BUILDING WORK.

2. AIR LEAKAGE TESTING CONFORMING TO SMACNA STANDARDS OF ALL DUCTWORK IS REQUIRED AND

MUST BE OBSERVED BY THE ENGINEER. REFER TO DRAWING SPECIFICATIONS FOR SCHEDULING

5. DUCT DIMENSIONS SHOWN ON THE CONTRACT DRAWINGS ARE FOR AIR FLOW AREA. WHERE DUCTS

8. COORDINATE WITH BUILDING MANAGEMENT FOR ANY SERVICE INTERRUPTION OF EXISTING SYSTEMS

3. ALL AIR & WATER TESTING & BALANCING SHALL BE PERFORMED IN THE PRESENCE OF THE

5 YEARS OF EXPERIENCE AND WITH FULL FACTORY AUTHORIZATION AND CURRENT CERTIFICATION

4. ALL CONTROL WORK MUST BE PERFORMED BY TECHNICIANS AND ORGANIZATIONS WITH AT LEAST

ARE INDICATED AS ACOUSTICALLY LINED, THE DUCT DIMENSIONS SHALL BE INCREASED AS

6. BALANCE ALL DIFFUSERS/REGISTERS IN THE AREA OF WORK TO THE REQUIRED CFM'S AS INDICATED

7. CONTRACTOR TO CONTACT BUILDING MANAGEMENT AND TENANT REGARDING DEMOLITION/REMOVAL

SCOPE OF WORK TO ENSURE THAT OTHER TENANTS THAT ARE TO STAY OPERATIONAL ARE NOT

AND GIVE NOTICE AS REQUIRED BY BUILDING RULES AND REGULATIONS.

MECHANICAL GENERAL NOTES

ENGINEER. REFER TO DRAWING SPECIFICATIONS FOR REQUIREMENTS.

EXISTING SUPPLY DIFFUSER TO REMAIN

EXISTING RETURN GRILLE/ REGISTER TO REMAIN

EXISTING SUPPLY DIFFUSER TO BE DEMOLISHED

EXISTING RETURN GRILLE/ REGISTER TO BE DEMOLISHED

SITE PLAN: 375 BEACH 92ND STREET, QUEENS , NY

8.

5.

6.

7.

4.

a.

1.

2.

3.

b.

c.

d.

9.

10.

MECHANICAL DEMOLITION NOTES

PROVIDE ADDITIONAL SUPPORT FOR ALL EXISTING DUCTS AND PIPING TO REMAIN WHICH ARE

AFFECTED BY DEMOLITION OF EXISTING CEILING AND PARTITIONS.

ALL MATERIALS AND EQUIPMENT SHALL BE DISPOSED OF IN ACCORDANCE WITH APPLICABLE

LAWS AND ENVIRONMENTAL REGULATIONS.

COORDINATE WITH OWNER TO DETERMINE WHETHER EQUIPMENT IS TO BE TURNED OVER

FOR FUTURE USE AND STORED IN THEIR ASSOCIATED STORAGE LOCATIONS.

REMOVE ALL EXISTING BASE BUILDING SUPPLY AIR, RETURN AIR AND EXHAUST AIR

DUCTWORK WITH ALL ASSOCIATED DIFFUSERS, TERMINAL BOXES, CONTROLS,

COLLARS, DAMPERS, RETURN/EXHAUST GRILLES AND CONTROLS AND ALL ASSOCIATED

DEVICES BACK TO THE EXISTING SUPPLY, RETURN AND EXHAUST AIR SHAFTS, OR AS

NOTED ON DRAWINGS.

CONTRACTOR TO CONTACT BUILDING MANAGEMENT AND TENANT REGARDING

REMOVAL SCOPE OF WORK TO MAINTAIN CONTINUITY OF ALL SERVICES TO ALL

TENANTS WHO ARE TO REMAIN OPERATIONAL AND NOT BE AFFECTED BY DEMOLITION

WORK.

ALL EXISTING BUILDING FIRE DAMPERS, FIRE/SMOKE DAMPERS, DUCT MOUNTED

SMOKE DETECTORS AT SUPPLY AND RETURN AIR SHAFTS TO REMAIN.

ALL EXISTING WORK REQUIRED TO REMAIN BUT INTERFERING WITH PROPOSED NEW

MECHANICAL (AS WELL AS ELECTRICAL AND GENERAL CONSTRUCTION WORK) SHALL BE

RELOCATED AND RECONNECTED USING MATERIALS CONFORMING TO STANDARDS OF THIS

CONTRACT.

REMOVE ALL EXISTING AIR HANDLERS, CEILING AND FLOOR MOUNTED AIR CONDITIONING

UNITS WITH ALL ASSOCIATED DUCTWORK, TERMINAL BOXES, DIFFUSERS, GRILLES, HANGERS

AND ACCESSORIES.

REMOVE ALL EXHAUST, RETURN AND TRANSFER FANS AND ASSOCIATED DUCTWORK.

REMOVE ALL PIPING, VALVING AND HANGERS ASSOCIATED WITH PIPING TO BE REMOVED

BACK TO MAINS. IDENTIFY ALL PIPING BY SERVICE TYPE AND CAP AT MAINS.

REMOVE BASE BUILDING DUCTWORK AS INDICATED BELOW:

PRIOR TO PROPOSAL SUBMISSION. THIS CONTRACTOR SHALL VISIT THE SITE TO REVIEW THE

EXISTING CONDITIONS ASSOCIATED WITH THE SCOPE OF WORK AND ADJACENT AREAS TO

ASCERTAIN THE DIFFICULTIES WHICH WILL AFFECT THE EXECUTION OF THE WORK OF THIS

CONTRACT.

SUBMISSION OF A PROPOSAL WILL BE CONSTRUED AS EVIDENCE THAT THE ABOVE SITE

EXAMINATION HAS BEEN MADE AND LATER CLAIMS WILL NOT BE RECOGNIZED FOR EXTRA

LABOR, EQUIPMENT OR MATERIALS REQUIRED BECAUSE OF DIFFICULTIES ENCOUNTERED

WHICH COULD HAVE BEEN FORESEEN HAD SUCH AN EXAMINATION BEEN MADE.

DEMOLITION WORK SHALL INCLUDE ALL MATERIALS, LABOR, EXTENSIONS, CONNECTIONS,

CUTTING REPAIRING, ADAPTING AND OTHER MECHANICAL WORK REQUIRED TO MAINTAIN

SERVICE PENDING THE COMPLETION OF THE PERMANENT WORK. COORDINATE THE EXTENT

OF DEMOLITION WORK WITH THE ARCHITECT AND BUILDING MANAGEMENT.

H.

G.

F.

3.

2.

E.

D.

C.

B.

1.

A.

C.

SCOPE OF WORK.2.

B.

A.

GENERAL1.

1

2

3

4

5

TRADE DESCRIPTIONDWG. TITLESHEET#

NO

RTH

M-301.00

M-401.00GROUND LEVEL: MECHANICAL - DETAILS I

A TEST WILL BE CONDUCTED UNDER DIRECTION OF A LICENSED PROFESSIONAL ENGINEER OR ARCHITECT OR

OTHER PERSON HAVING NOT LESS THAN FIVE (5) YEARS EXPERIENCE SUPERVISING THE INSTALLATION OF THE

MECHANICAL SYSTEM. THE TEST WILL SHOW COMPLIANCE WITH 2008 BUILDING CODE REQUIREMENTS AS

OUTLINED IN SECTION [BC 1704].

THE LICENSED PROFESSIONAL ENGINEER OR ARCHITECT OR OTHER PERSON HAVING NOT LESS THAN FIVE (5)

YEARS EXPERIENCE SUPERVISING THE INSTALLATION OF MECHANICAL SYSTEMS AND CONDUCTING SUCH TESTS

WILL FILE DOCUMENTATION AND REPORT OF TEST THAT THE SYSTEM COMPLIES WITH THE CONSTRUCTION

DOCUMENTS AND APPLICABLE LAWS.

SPECIAL INSPECTIONS:

SMOKE CONTROL SYSTEMS INSPECTIONS SHALL BE PERFORMED IN ACCORDANCE WITH SECTION

[BC 1704.14] OF THE 2008 NYC BUILDING CODE.

ALL MECHANICAL SYSTEMS, EQUIPMENT AND MATERIALS INSPECTIONS SHALL BE PERFORMED IN

ACCORDANCE WITH SECTION [BC 1704.15] OF THE 2008 NYC BUILDING CODE.

FUEL OIL STORAGE EQUIPMENT AND ASSOCIATED FUEL-PIPING SYSTEMS AND EQUIPMENT

INSPECTIONS SHALL BE PERFORMED IN ACCORDANCE WITH SECTION [BC 1704.16] OF THE 2008 NYC

BUILDING CODE.

HIGH PRESSURE-STEAM PIPING AND ASSOCIATED EQUIPMENT INSPECTIONS SHALL BE PERFORMED IN

ACCORDANCE WITH SECTION [BC 1704.17] OF THE 2008 NYC BUILDING CODE.

SMOKE DETECTION SYSTEMS SHALL BE INSTALLED AND SEQUENCED TO FOLLOW CONTROLS OPERATIONS IN

ACCORDANCE WITH THE REQUIREMENTS OF SECTION [MC 606] OF THE 2008 NYC MECHANICAL CODE.

FIRE DAMPERS, SMOKE DAMPERS, COMBINATION FIRE/SMOKE DAMPERS AND CEILING DAMPERS LOCATED WITHIN

AIR DISTRIBUTION AND SMOKE CONTROL SYSTEMS SHALL BE INSTALLED IN ACCORDANCE WITH THE

REQUIREMENTS OF SECTION [MC 607] OF THE 2008 NYC MECHANICAL CODE.

ALL FIRE DAMPERS SHALL BE ACCEPTED FOR USE BY THE NEW YORK CITY DEPARTMENT OF BUILDINGS AND

SHALL BE MANUFACTURED AND INSTALLED IN ACCORDANCE WITH THE REQUIREMENTS OF UL 555.

SMOKE DAMPERS SHALL BE ACCEPTED FOR USE BY THE NEW YORK CITY DEPARTMENT OF BUILDINGS AND

SHALL BE MANUFACTURED AND INSTALLED IN ACCORDANCE WITH THE REQUIREMENTS OF UL 555S.

COMBINATION FIRE/SMOKE DAMPERS SHALL BE ACCEPTED FOR USE BY THE NEW YORK CITY DEPARTMENT OF

BUILDINGS AND SHALL BE MANUFACTURED AND INSTALLED IN ACCORDANCE WITH THE REQUIREMENTS OF BOTH

UL 555 AND UL 555S.

CEILING RADITATION DAMPERS SHALL BE ACCEPTED FOR USE BY THE NEW YORK CITY DEPARTMENT OF

BUILDINGS AND SHALL BE MANUFACTURED AND INSTALLED IN ACCORDANCE WITH THE REQUIREMENTS OF UL

555C.

THESE PLANS ARE APPROVED ONLY FOR THE WORK INDICATED ON THE APPLICATION SPECIFICATION SHEET.

ALL OTHER MATTERS SHOWN ARE NOT TO BE RELIED UPON OR TO BE CONSIDERED AS EITHER BEING APPROVED

OR IN ACCORDANCE WITH APPLICABLE CODES.

ALL WORK SHALL COMPLY WITH APPLICABLE SECTIONS OF THE BULDING CODE, CITY OF NEW YORK,

EFFECTIVE JULY 1, 2008 AND ALL AMENDMENTS AND RULES AND REGULATIONS OF THE DEPARTMENT

OF BUILDINGS TO DATE.

6

BLOCK #: 16109

LOT #: 43

9

2

S

N

S

T

R

E

E

T

B

E

A

C

H

C

H

A

N

N

E

L

D

R

3

7

5

GROUND LEVEL: NYCECC COMCHECK COMPLIANCE CERTIFICATEM-102.00

BUILDING SUPPLY MAIN. THIS REPORT SHALL BE SUBMITTED TO THE ENGINEER FOR REVIEW & COORDINATION.

THE BASE BUILDING MAIN DUCTS (SUPPLY & RETURN) AND TAKE TRAVERSE READINGS AT EACH BASE

1. PRIOR TO START OF CONSTRUCTION, CONTRACTOR SHALL PERFORM EXISTING CONDITIONS SURVEY OF

A. GENERAL

1. FURNISH AND INSTALL ONE (1) GAS FIRED HEATING AND VENTILATING UNIT, AS INDICATED AND SCHEDULED ON

FOR PROPER OPERATION, TO INCLUDE BUT NOT LIMITED TO GAS PIPING, VALVES, GAUGES, HANGERS,

DUCTWORK CONNECTIONS, CONTROLS (WIRING T-STAT, SWITCHES), VIBRATION ISOLATORS, ETC. ["MAU-1"]

THE DRAWINGS. THE UNIT SHALL BE PROVIDED WITH THE ASSOCIATED ACCESSORIES

B. NEW ROOF MOUNTED MAKE-UP AIR UNIT (H+V UNIT)

THE UNITS SHALL BE PROVIDED WITH THE ASSOCIATED ACCESSORIES FOR PROPER OPERATION,

1. FURNISH AND INSTALL TWO (2) TOILET EXHAUST FANS TO BE INTERCONNECTED TO THE EXISTING BASE BUILDING SYSTEM.

2. CONTRACTOR TO VERIFY THE LOCATION(S) AND INTEGRITY OF THE EXISTING EXHAUST TAP IN EXISTING SHAFT.

PATCH AND REPAIR DAMGED DUCTWORK (AS REQUIRED) AND REBALANCE THE TOILET EXHAUST DUCT TO REQUIRED CFM'S.

D. NEW TOILET EXHAUST FAN SYSTEM

(WIRING T-STAT, SWITCHES), VIBRATION ISOLATORS, ETC. ["EF-B-1"]

TO INCLUDE BUT NOT LIMITED TO PIPING, VALVES, GAUGES, HANGERS, CONTROLS,

DUCT RISER SUPPORTS, CONTROLS (WIRING T-STAT, SWITCHES), VIBRATION ISOLATORS, ETC. ["KX-1"]

FOR PROPER OPERATION, TO INCLUDE BUT NOT LIMITED TO INSULATED DUCTWORK CONNECTIONS, HANGERS,

1. FURNISH AND INSTALL ONE (1) KITCHEN EXHAUST FAN, AS INDICATED AND SCHEDULED ON

C. NEW ROOF MOUNTED KITCHEN EXHAUST FAN

THE DRAWINGS. THE UNIT SHALL BE PROVIDED WITH THE ASSOCIATED ACCESSORIES

7

M-203.00 GROUND LEVEL: MECHANICAL - SPECIFICATIONS III

8 M-601.00 GROUND LEVEL: MECHANICAL - EQUIPMENT SCHEDULES

GROUND LEVEL: MECHANICAL - DUCTWORK PLAN & NOTES

J

A

M

A

I

C

A

B

A

Y

seal & signature

dwg title

twig

cadd

checked by

issue date

AS NOTED

drawn by

02/11/2011

project no.

dwg. no.

scale

cad file

t10-12-0230

375 Beach 92nd StreetQueens, NY 11693

SUBMISSIONS

DATE rev no issue

project

project

375 Beach 92nd StreetQueens, NY 11693

architect

231 West 29th Street - Suite 606, New York, NY 10001

Tel: 212 . 967 . TWIG / Fax: 212 . 967 . 8945

[email protected] www.twigcon.com

A Division of The Wall Consulting Group, Inc. All Rights Reserved. 2007- 2010©

375 Beach 92nd Street M-101.00.dwg

NYC dob#

sheetTHESE PLANS ARE APPROVED ONLY FOR THE WORK ON THE

BEING APPROVED OR IN ACCORDANCE WITH APPLICABLE CODES.

APPLICATION SPECIFICATION SHEET. ALL OTHER MATTERS SHOWN

ARE NOT TO BE RELIED UPON OR TO BE CONSIDERED AS EITHER

All Drawings And Written Material Herein Constitute The Original And Unpublished Work Of The Wall Consulting Group, Inc. and/or TWIG Consulting Engineers, P.C., And The Same May Not Be Duplicated, Used, Or Disclosed Without The Written Consent Of The Wall Consulting Group, Inc. and/or TWIG Consulting Engineers, P.C. © 2011.

NYCECC NOTES:

TO THE BEST OF MY KNOWLEDGE, BELIEF AND

PROFESSIONAL JUDGMENT, THESE PLANS AND

SPECIFICATIONS ARE IN COMPLIANCE WITH THE

NEW YORK CITY ENERGY CONSERVATION CODE.

02.14.11 1 FILING & PRICING

GROUND FLOORMECHANICALSYMBOLS & NOTES

1 of 8

NYCECC COMPLIANCE SHEETS

NYCECC COMPLIANCE: MECHANICAL

NYCECC COMPLIANCE: INTERIOR LIGHTING & POWER

1.

2.

08.31.10

02.17.11

J. Moorhead 02.17.11James Moorhead - SSK

J. MoorheadJames Moorhead - SSK

seal & signature

dwg title

twig

cadd

checked by

issue date

AS NOTED

drawn by

02/11/2011

project no.

dwg. no.

scale

cad file

t10-12-0230

375 Beach 92nd StreetQueens, NY 11693

SUBMISSIONS

DATE rev no issue

project

project

375 Beach 92nd StreetQueens, NY 11693

architect

231 West 29th Street - Suite 606, New York, NY 10001

Tel: 212 . 967 . TWIG / Fax: 212 . 967 . 8945

[email protected] www.twigcon.com

A Division of The Wall Consulting Group, Inc. All Rights Reserved. 2007- 2010©

375 Beach 92nd Street M-102.00.dwg

NYC dob#

sheetTHESE PLANS ARE APPROVED ONLY FOR THE WORK ON THE

BEING APPROVED OR IN ACCORDANCE WITH APPLICABLE CODES.

APPLICATION SPECIFICATION SHEET. ALL OTHER MATTERS SHOWN

ARE NOT TO BE RELIED UPON OR TO BE CONSIDERED AS EITHER

All Drawings And Written Material Herein Constitute The Original And Unpublished Work Of The Wall Consulting Group, Inc. and/or TWIG Consulting Engineers, P.C., And The Same May Not Be Duplicated, Used, Or Disclosed Without The Written Consent Of The Wall Consulting Group, Inc. and/or TWIG Consulting Engineers, P.C. © 2011.

NYCECC NOTES:

TO THE BEST OF MY KNOWLEDGE, BELIEF AND

PROFESSIONAL JUDGMENT, THESE PLANS AND

SPECIFICATIONS ARE IN COMPLIANCE WITH THE

NEW YORK CITY ENERGY CONSERVATION CODE.

02.14.11 1 FILING & PRICING

GROUND FLOORMECHANICALNYCECCCERTIFICATES

2 of 8

2.02 INSULATION

A. ALL INSULATION SHALL MEET THE REQUIREMENTS OF ASTM, NFPA NEW YORK STATE ENERGY CODE AND ALL

AUTHORITIES HAVING JURISDICTION. ALL MECHANICAL INSULATION, (JACKETING, COVERINGS, ADHESIVES,

MASTICS, FACINGS, TAPES, ETC.), SHALL HAVE RATINGS NOT EXCEEDING A "FLAME SPREAD" OF 25 OR LESS AND

"SMOKE DEVELOPED" INDEX OF 50 OR LESS.

B. BEFORE APPLYING INSULATION, ALL PRESSURE AND LEAK TESTS SHALL BE COMPLETED AND APPROVED. FURNISH

AND INSTALL AS PER MANUFACTURERS REQUIREMENTS.

C. INSULATION FOR FITTINGS OR ACCESSORIES REQUIRING SERVICING OR INSPECTION SHALL HAVE INSULATION

REMOVABLE AND REPLACEABLE WITHOUT DAMAGE.

D. DUCT INSULATION:

1. GENERAL

a. INSULATION SHALL BE APPLIED WITH MASTICS, ADHESIVES, COATINGS, WITH COVERS, WEATHER-

PROTECTION AND OTHER WORK AS REQUIRED BY MANUFACTURER'S RECOMMENDATIONS. DO NOT

INSULATE SOUND LINED DUCTWORK. MATERIALS SHALL MEET REQUIREMENTS OF ADHESIVE AND

SEALANT COUNCIL STANDARDS AND SMACNA.

1. KITCHEN EXHAUST

a. KITCHEN EXHAUST DUCTWORK SHALL HAVE A MINIMUM INSULATION COVERING OF TWO INCHES OF

CALCIUM SILICATE BLOCK, ATTACHED WITH 1" HIGH RIB COPPER STEEL LATH. FINISHED WITH

TWO COATS OF CEMENT. INSURE THAT THE INSULATION EXTENDS THROUGH ALL WALL PENETRATIONS

TO SEPARATE THE DUCTS FROM THE BUILDING CONSTRUCTION.

PART 1 - GENERAL

1.01 GENERAL REQUIREMENTS:

A. WORK INCLUDES ALL HVAC WORK FOR THAI ROCK RESTAURANT, AT 375 BEACH 92ND STREET,

QUEENS, NY 11693

B. INSTALL ALL NEW WORK IN A NEAT WORKMANLIKE MANNER READILY ACCESSIBLE FOR OPERATION, MAINTENANCE AND

REPAIR.

C. CODES, PERMITS AND INSPECTIONS:

1. ALL WORK SHALL COMPLY WITH REQUIREMENTS OF NYC BUILDING CODE, NYC BUILDING DEPARTMENT,

BUILDING MANAGEMENT, AND ALL AUTHORITIES HAVING JURISDICTION AND APPLICABLE NATIONAL, STATE

AND LOCAL CODES, LAWS AND REGULATIONS GOVERNING OR RELATING TO ANY PORTION OF THIS WORK SHALL

BE INCORPORATED INTO AND MADE A PART OF THESE SPECIFICATIONS. CONTRACTOR IS TO INFORM

ENGINEER OF ANY EXISTING WORK OR MATERIALS WHICH VIOLATE ANY OF THE ABOVE LAWS AND

REGULATIONS. ANY WORK DONE BY THE CONTRACTOR CAUSING SUCH VIOLATION SHALL BE CORRECTED AT

CONTRACTOR'S EXPENSE BY THIS CONTRACTOR AND AT NO EXPENSE TO THE OWNER.

3. ALL APPLICABLE EQUIPMENT SHALL HAVE AN "M.E.A. OR B.S.A. NUMBER."

D. SITE VERIFICATION:

1. PRIOR TO SUBMISSION OF THE BID, THIS CONTRACTOR SHALL VISIT THE JOB SITE TO ASCERTAIN THE

ACTUAL FIELD CONDITIONS AS THEY RELATE TO THE WORK INDICATED ON THE DRAWINGS AND DESCRIBED

HEREIN. DISCREPANCIES, IF ANY, SHALL BE BROUGHT TO THE ENGINEER'S ATTENTION PRIOR TO

SUBMISSION OF THE BID, AND IF NOT RESOLVED TO SATISFACTION, SHALL BE SUBMITTED AS A WRITTEN

QUALIFICATION OF THE BID. SUBMISSION OF A BID SHALL BE EVIDENCE OF SITE VERIFICATION HAS

BEEN PERFORMED AS DESCRIBED ABOVE.

E. CONTRACT DOCUMENTS:

2. PRIOR TO SUBMISSION OF A FORMAL BID, THIS CONTRACTOR SHALL REVIEW ALL DRAWINGS OF THE ENTIRE

PROJECT INCLUDING GENERAL CONSTRUCTION, DEMOLITION, ARCHITECTURAL, MECHANICAL, ELECTRICAL,

PLUMBING AND SPRINKLER AND SHALL INCLUDE ANY WORK REQUIRED IN THE BID WHICH IS INDICATED OR

IMPLIED TO BE PERFORMED BY THIS TRADE IN OTHER SECTIONS OF THE WORK.

3. DRAWINGS ARE DIAGRAMMATIC AND INDICATE GENERAL ARRANGEMENT OF WORK AND APPROXIMATE LOCATION

OF EQUIPMENT. REFER TO ARCHITECTURAL DRAWINGS FOR ALL DIMENSIONS AND COORDINATE FINAL

LOCATIONS OF DIFFUSERS, GRILLES, REGISTERS, THERMOSTATS, SENSORS, SWITCHES AND ANY WALL

MOUNTED DEVICES. ALL WORK SHALL BE COORDINATED WITH OTHER TRADES TO AVOID CONFLICT.

4. IF A CONFLICT OCCURS IN THE SPECIFICATIONS AND/OR ON THE DRAWINGS, THE MORE STRINGENT

SITUATION SHALL APPLY.

5. ANY EQUIPMENT, PARTS, MATERIALS, ACCESSORIES, OR LABOR THAT IS NECESSARY FOR PROPER

PERFORMANCE OF THE MECHANICAL WORK ALTHOUGH NOT SPECIFICALLY MENTIONED HEREIN OR SHOWN ON THE

DRAWINGS, SHALL BE FURNISHED AND INSTALLED WITHOUT ADDITIONAL COSTS.

F. GUARANTEE:

6. ALL MATERIALS AND WORKMANSHIP SHALL BE GUARANTEED FOR A PERIOD OF ONE YEAR FROM DATE OF FINAL

ACCEPTANCE OF THIS WORK. FINAL ACCEPTANCE SHALL BE DEFINED AS THE TIME AT WHICH THE

MECHANICAL WORK IS TAKEN OVER AND ACCEPTED BY THE OWNER, AND IS UNDER CARE, CUSTODY, AND

CONTROL OF THE OWNER. ENGAGE THE SERVICES OF VARIOUS MANUFACTURERS SUPPLYING THE EQUIPMENT

FOR THE PROPER STARTUP AND OPERATION OF ALL SYSTEMS INSTALLED. INSTRUCT THE OWNERS PERSONNEL

IN THE PROPER OPERATION AND SERVICING OF THE SYSTEM.

7. THE CONTRACTOR SHALL GUARANTEE TO REPLACE OR REPAIR PROMPTLY AND ASSUME RESPONSIBILITY FOR

ALL EXPENSES INCURRED FOR ANY W0RKMANSHIP AND EQUIPMENT IN WHICH DEFECTS DEVELOP WITHIN THE

GUARANTEE PERIOD. THIS WORK SHALL BE DONE AS DIRECTED BY THE OWNER. THIS GUARANTEE SHALL

INCLUDE RESPONSIBILITY FOR ALL EXPENSES INCURRED IN REPAIRING AND REPLACING WORK OF OTHER

TRADES AFFECTED BY DEFECTS, REPAIRS OR REPLACEMENTS IN EQUIPMENT SUPPLIED BY THIS CONTRACTOR.

8. THIS CONTRACTOR IS RESPONSIBLE FOR THE MAINTENANCE AND OPERATION OF ALL SYSTEMS UNTIL THE

FINAL ACCEPTANCE OF THE WORK.

9. ALL AIR CONDITIONING UNIT COMPRESSORS AND REFRIGERATION COMPONENTS SHALL HAVE A 5-YEAR

WARRANTY.

G. THE "GENERAL CONDITIONS OF THE CONTRACT FOR CONSTRUCTION" AIA DOCUMENT A201, LATEST EDITION, OR AS

REQUIRED BY THE ARCHITECT DOCUMENTS, AND/OR THE STRUCTURAL ENGINEER'S DOCUMENTS, AS APPLICABLE, ARE

PART OF THIS CONTRACT.

H. DEFINITIONS:

10. MECHANICAL CONTRACTOR, "THIS CONTRACTOR" - THE PARTY OR PARTIES HAVE BEEN DULY AWARDED THE

CONTRACT FOR AND ARE THEREBY MADE RESPONSIBLE FOR THE MECHANICAL WORK AS DESCRIBED HEREIN.

11. "THIS CONTRACT", "THE CONTRACT" - THE AGREEMENT COVERING THE WORK TO BE PERFORMED BY "THIS

CONTRACTOR".

12. "APPROVED", "EQUAL", "SATISFACTORY", "ACCEPTED", "ACCEPTABLE", "EQUIVALENT" - SUITABLE FOR

USE ON THE PROJECT, AS DETERMINED BY THE ENGINEER BASED ON DOCUMENTS PRESENTED FOR SUCH

DETERMINATION.

13. "THESE SPECIFICATIONS", "THIS SECTION, PART, DIVISION" (OF THE SPECIFICATION) - THE DOCUMENT

SPECIFYING THE WORK TO BE PERFORMED BY "THIS CONTRACTOR".

14. "THE MECHANICAL WORK", "THIS WORK", - ALL LABOR MATERIALS, EQUIPMENT, APPARATUS, CONTROLS,

ACCESSORIES, AND OTHER ITEMS REQUIRED FOR A PROPER AND COMPLETE INSTALLATION BY THE

MECHANICAL CONTRACTOR.

15. "ARCHITECT", "ENGINEER", "OWNER'S REPRESENTATIVE" - THE PARTY OR PARTIES RESPONSIBLE FOR

INTERPRETING, ACCEPTING AND OTHERWISE RULING ON THE PERFORMANCE UNDER THIS CONTRACT.

16. "FURNISH" - PURCHASE AND DELIVER TO THE PROJECT SITE COMPLETE WITH EVERY NECESSARY

APPURTENANCE AND SUPPORT, ALL AS PART OF THE MECHANICAL WORK.

17. "INSTALL" - UNLOAD AT THE DELIVERY POINT AT THE SITE AND PERFORM EVERY OPERATION NECESSARY

TO ESTABLISH SECURE MOUNTING INSTALLATION AND CORRECT OPERATION AT THE PROPER LOCATION IN THE

PROJECT, ALL AS PART OF THE MECHANICAL WORK.

18. "PROVIDE" - "FURNISH" AND "INSTALL".

19. "NEW" - MANUFACTURED WITHIN THE PAST TWO YEARS AND NEVER BEFORE USED.

20. "RELOCATE" - MOVE EXISTING EQUIPMENT AND ALL ACCESSORIES AS REQUIRED.

21. "REMOVE" - DISMANTLE AND CART AWAY FROM SITE INCLUDING ALL RELATED ACCESSORIES. ALL ITEMS

SHALL BE LEGALLY DISPOSED OF. ALL OTHER EQUIPMENT AND OPERATIONS IN ANY WAY EFFECTED BY THE

REMOVAL IS TO REMAIN IN FULL OPERATION. PROVIDE ALL NECESSARY COMPONENTS TO MAINTAIN SUCH

OPERATION.

1.02 SCOPE OF WORK

A. PROVIDE ALL LABOR, MATERIALS, EQUIPMENT, AND CONTRACTOR'S SERVICES NECESSARY FOR COMPLETE, SAFE

INSTALLATION OF ALL MECHANICAL WORK. THE SCOPE OF WORK SHALL INCLUDE BUT NOT BE LIMITED TO THE

FOLLOWING:

1. DEMOLITION AND REMOVAL OF ITEMS AS REQUIRED.

2. DUCTWORK AND DUCTWORK ACCESSORIES.

3. AIR DISTRIBUTION SYSTEM (AIR OUTLETS, ETC.).

4. PIPING AND PIPING ACCESSORIES INCLUDING ALL VALVING.

5. EQUIPMENT (PUMPS, AIR CONDITIONING UNITS, FANS, VFD'S, ETC.)

6. INSULATION OF PIPING, EQUIPMENT AND DUCTWORK.

7. SOUND ATTENUATORS AND SOUND LINING.

8. AUTOMATIC TEMPERATURE CONTROLS.

9. TESTING AND BALANCING.

10. CUTTING AND PATCHING.

11. SHOP DRAWINGS.

12. AS-BUILT DRAWINGS.

13. OPERATING AND MAINTENANCE MANUALS.

14. FULL COORDINATION WITH OTHER TRADES.

15. WARRANTY AND GUARANTY.

16. PHASING AS REQUIRED BY OWNER, CONSTRUCTION MANAGER, GENERAL CONTRACTOR OR BUILDING

MANAGEMENT.

17. PREMIUM TIME FOR WORK TO BE PERFORMED AFTER-HOURS AS REQUIRED BY BUILDING MANAGEMENT AND/OR

OWNER.

18. FILING, PERMITS, CONTROLLED INSPECTIONS.

19. FULL TESTING AND STARTUP OF ALL SYSTEMS.

B. SECURE CERTIFICATES, PAY ALL FEES AND CHARGES FOR ALL WORK INSTALLED, CERTIFYING COMPLIANCE WITH ALL

AUTHORITIES AND ARTICLES 27-132 (C26-106.3), 27-778 (C26-1301.1), 27-779 (C26-1301.2,) 27-780 (C26-

1301.3),27-781 (C26-1301.4). CONTRACTOR TO PERFORM REQUIRED CONTROLLED INSPECTION AND OBTAIN ALL

EQUIPMENT USE PERMITS. DELIVER CERTIFICATES TO OWNER FOR SIGNING BEFORE FILING.

1.03 COORDINATION WITH BUILDING MANAGEMENT

A. THIS CONTRACTOR IS TO OBTAIN A COPY OF THE BUILDING RULES AND REGULATIONS PRIOR TO BID SUBMISSION

TO DETERMINE REQUIREMENTS AND THE EXTENT OF PREMIUM TIME WORK REQUIRED BY BUILDING.

B. THIS CONTRACTOR IS RESPONSIBLE FOR ADHERING TO THE BUILDING OWNER'S RULES AND REGULATIONS. ANY

DISCREPANCIES BETWEEN THE CONTRACT DOCUMENTS AND THE BUILDING RULES AND REGULATIONS SHALL BE

SUBMITTED IN WRITING TO THE ARCHITECT/ENGINEER FOR REVIEW, WITH BID SUBMISSION.

C. COORDINATE WITH BUILDING OWNER FOR ANY SERVICE INTERRUPTION OF EXISTING SYSTEMS AND GIVE NOTICE AS

REQUIRED BY BUILDING RULES AND REGULATIONS OR A MINIMUM OF TWO (2) DAYS PRIOR TO ANY WORK, WHICHEVER

IS MORE STRINGENT. CONTRACTOR IS TO PERFORM WORK ON PREMIUM TIME, IF SO DIRECTED BY BUILDING

OWNER, SO AS NOT TO DISTURB EXISTING TENANTS ON OTHER FLOORS.

1.04 SHOP DRAWINGS

A. SUBMIT SHOP DRAWINGS CERTIFIED BY ALL TRADES THAT COORDINATION HAS BEEN COMPLETED. SUBMIT ALL

CERTIFIED EQUIPMENT CUTS WITH CONSTRUCTION WIRING DIAGRAMS AND AUTOMATIC TEMPERATURE CONTROL

REQUIREMENTS. SHOP DRAWINGS SUBMISSION SHALL INCLUDE, BUT NOT BE LIMITED TO, THE FOLLOWING:

1. DUCTWORK - PROVIDE DUCT SHOP STANDARDS AND LEAKAGE TEST CERTIFICATION, AS REQUIRED, AND 3/8

SCALE DUCT LAYOUT.

2. PIPING LAYOUT AND APPURTENANCES - PROVIDE PIPING, VALVING, CHEMICAL TREATMENT, SHOP STANDARDS

AND 3/8 SCALE PIPING LAYOUT WITH ALL VALVING.

3. INSULATION FOR DUCTWORK, PIPING AND EQUIPMENT.

4. CERTIFIED AIR AND WATER BALANCING REPORT

5. EQUIPMENT CATALOG CUTS FOR ALL ITEMS TO BE UTILIZED ON PROJECT (FANS, PUMPS, AC UNITS,

VARIABLE FREQUENCY DRIVES, ETC.)

6. AIR OUTLETS (DIFFUSERS, REGISTERS, GRILLES, ETC.)

7. AUTOMATIC TEMPERATURE CONTROL DIAGRAMS, DEVICES AND SEQUENCE OF OPERATION

8. AS-BUILT DRAWINGS AT PROJECT COMPLETION OF THE INSTALLED CONDITION OF WORK.

B. THE QUANTITY OF SHOP DRAWINGS SHALL AS A MINIMUM BE FOUR (4) COPIES OF 8-1/2"x11" SUBMISSIONS AND

ONE (1) REPRODUCIBLE AND ONE (1) PRINT OF ALL DRAWINGS. SPECIFIC JOB REQUIREMENTS MAY BE MORE

STRINGENT AND CONTRACTOR IS RESPONSIBLE TO OBTAIN REQUIREMENTS FROM CONSTRUCTION MANAGER, GENERAL

CONTRACTOR OR ARCHITECT.

1.05 MAINTENANCE MANUALS

A. SUBMIT FOUR (4) LOOSE-LEAF BOUND OPERATING AND MAINTENANCE MANUALS WITH INDEX AND INDEX TABS TO

INCLUDE THE FOLLOWING:

1. OPERATING AND MAINTENANCE INSTRUCTIONS ON ALL SYSTEMS.

2. MANUFACTURERS' CATALOG CUTS ON ALL EQUIPMENT.

3. AUTOMATIC TEMPERATURE CONTROL SYSTEMS WITH SEQUENCE OF OPERATIONS, CATALOG CUTS OF ALL

DEVICES AND POINT-TO-POINT WIRING DIAGRAMS.

4. CERTIFIED FINAL AIR AND WATER BALANCING REPORT.

5. DUCT AND PIPING AS-BUILT DRAWINGS WITH VALVE CHART AND KEY PLAN DRAWINGS INSERTED IN BINDER.

6. ALL ITEMS SUBMITTED FOR REVIEW IN SHOP DRAWING SECTION.

1.06 AS-BUILT DRAWINGS

A. CONTRACTOR SHALL MAINTAIN RECORD DRAWING PRINTS ON JOB SITE AND RECORD, AT TIME OF OCCURRENCE,

DEVIATIONS FROM CONTRACT DOCUMENTS DUE TO FIELD COORDINATION, BULLETINS, OR ADDENDA.

B. CONTRACTOR SHALL REVISE SHOP DRAWINGS TO CONFORM TO RECORD DRAWINGS AND SUBMIT AN AS-BUILT CONDITION

(PIPING AND DUCTWORK) DRAWINGS UPON COMPLETION OF THE PROJECT. FINAL SUBMISSION OF REPRODUCIBLE AS-

BUILT DRAWINGS ARE TO BE SIGNED AND CERTIFIED BY INSTALLING CONTRACTOR THAT THIS IS THE AS-BUILT

CONDITION OF THE WORK.

1.07 SERVICE AND WARRANTY (MAINTENANCE CONTRACT)

A. THIS CONTRACTOR SHALL PROVIDE AS AN ADD ALTERNATE PRICE, A FULL ONE YEAR SERVICE AND WARRANTY OF ALL

MECHANICAL COMPONENTS AND SYSTEMS, WITH PRICES FOR YEARS 2, 3 AND 4 FOLLOWING THIS FIRST YEAR. AT

THE TIME OF ACCEPTANCE OF PROJECT, THE TENANT OR OWNER'S REPRESENTATIVE WILL DECIDE TO ACCEPT WHICH

ALTERNATE, IF ANY.

1.08 SUBSTITUTIONS

A. NO SUBSTITUTE MATERIAL OR MANUFACTURER OF EQUIPMENT SHALL BE PERMITTED WITHOUT A FORMAL WRITTEN

SUBMITTAL TO THE ENGINEER WHICH INCLUDES ALL DIMENSIONAL, PERFORMANCE AND MATERIAL SPECIFICATIONS.

ANY CHANGES IN LAYOUT, ELECTRICAL CHARACTERISTICS, STRUCTURAL REQUIREMENTS, OR DESIGN DUE TO THE USE

OF A SUBSTITUTION SHALL BE SUBMITTED TO THE ENGINEER AS PART OF THIS PROPOSAL. THE CONTRACTOR TAKES

FULL RESPONSIBILITY FOR THE SUBSTITUTION AND ALL CHANGES RESULTING FROM SUBSTITUTION. ALL ITEMS

SHALL BE SUBMITTED FOR REVIEW IN CONJUNCTION WITH THE SUBMITTAL OF THE SUBSTITUTION. ANY

SUBSTITUTION MUST BE SUBMITTED WITH AN EXPLANATION WHY A SUBSTITUTION IS BEING UTILIZED. IF THE

SUBSTITUTED ITEM DEVIATES FROM THE SPECIFIED ITEM, THOSE DEVIATIONS ARE TO BE IDENTIFIED ON A LINE

BY LINE BASIS. IF THE SUBSTITUTE IS BEING UTILIZED FOR FINANCIAL REASONS, THE ASSOCIATED CREDIT MUST

BE SIMULTANEOUSLY SUBMITTED.

B. ALL SUBSTITUTED EQUIPMENT SHALL CONFORM TO SPACE REQUIREMENTS AND PERFORMANCE REQUIREMENTS SHOWN ON

CONTRACT DOCUMENTS. CONTRACTOR SHALL REPLACE ANY EQUIPMENT THAT DOES NOT MEET THESE REQUIREMENTS AT

HIS OWN EXPENSE. ANY MODIFICATIONS TO ASSOCIATED SYSTEMS OR ADDITIONAL COSTS ATTRIBUTED TO THIS

SUBSTITUTION SHALL BE AT THIS CONTRACTOR'S EXPENSE.

C. CONTRACTOR SHALL SUBMIT BID BASED ON SPECIFIED ITEMS AND SHALL SUPPLY AS AN ALTERNATE PRICE ANY

SUBSTITUTIONS.

1.09 ACCESS DOORS IN GENERAL CONSTRUCTION

A. THIS CONTRACTOR SHALL SUBMIT TO THE ARCHITECT FOR APPROVAL A PLAN INDICATING THE SIZE AND LOCATION

OF ALL ACCESS DOORS REQUIRED FOR OPERATION AND MAINTENANCE OF ALL CONCEALED EQUIPMENT, DEVICES,

VALVES, DAMPERS AND CONTROLS. CONTRACTOR SHALL ARRANGE FOR FURNISHING AND INSTALLATION OF ALL

ACCESS DOORS IN FINISHED CONSTRUCTION AND INCLUDE COSTS IN THE BID. ACCESS DOORS SHALL BE OF ADEQUATE

SIZE TO PROVIDE ACCESS TO CONCEALED ITEMS FOR OPERATIONS AND MAINTENANCE, WITH A MINIMUM SIZE OF

18"x18".

PART 2 - PRODUCTS/APPLICATIONS

2.01 DUCTWORK AND ACCESSORIES

A. ALL DUCTWORK SHALL BE FABRICATED AND INSTALLED IN ACCORDANCE WITH SMACNA HVAC DUCT CONSTRUCTION

STANDARDS - METAL AND FLEXIBLE, 1995 OR LATEST EDITION, SMACNA HVAC AIR DUCT LEAKAGE TEST MANUAL,

1991 OR LATEST EDITION, NFPA 90A LATEST EDITION, AND NEW YORK CITY BUILDING CODE. THE MORE STRINGENT

REQUIREMENT OF ANY CODES SHALL APPLY.

B. PROVIDE ALL SUPPORTING AND HANGING DEVICES IN ACCORDANCE WITH NEW YORK CITY BUILDING CODE AND SMACNA.

C. DUCTWORK LAYOUT AND ROUTING IS SCHEMATIC AND THE MECHANICAL CONTRACTOR IS RESPONSIBLE FOR ALL DUCT

SIZE CHANGES AND RELOCATIONS TO ACCOMMODATE SPACE AND STRUCTURAL CONDITIONS. OFFSETS AND TRANS-

FORMATIONS SHALL PRESERVE THE FULL INSIDE CROSS-SECTIONAL AREA OF DUCTWORK SHOWN ON THE DRAWINGS.

D. DUCTWORK SHALL HAVE PRESSURE CLASSIFICATION, SEALING REQUIREMENTS AND LEAKAGE TESTING IN ACCORDANCE

WITH SMACNA AND AS LISTED BELOW UNLESS OTHERWISE SPECIFIED OR SHOWN ON THE DRAWINGS:

1. 3" CLASS: ALL SUCTION AND DISCHARGE OF KITCHEN HOOD, AND SMOKE EXHAUST DUCTWORK. SEAL

CLASS "B", LEAKAGE CLASS 12 (RECTANGULAR) OR CLASS 6 (ROUND).

2. 2" CLASS: ALL OTHER LOW PRESSURE DUCTWORK. SEAL CLASS "C", LEAKAGE CLASS 24 (RECTANGU

LAR) OR CLASS 12 (ROUND).

3. LEAKAGE TESTING

ALL TESTING SHALL BE DONE IN THE PRESENCE OF THE ENGINEER OR OWNER'S REPRESENTATIVE. THE

CONTRACTOR IS RESPONSIBLE FOR PROVIDING ALL COLLARS, CAPS, ELECTRIC POWER, ETC. NECESSARY TO

PERFORM THE TESTS. THE CONTRACTOR IS ALSO RESPONSIBLE FOR SCHEDULING THE TEST NO LESS THAN

THREE (3) BUSINESS DAYS PRIOR TO ITS INTENDED OCCURRENCE. LOW PRESSURE DUCTWORK (2"CLASS)

SHALL BE TESTED ON AN AS-NEEDED BASIS AT THE ENGINEER'S DIRECTION. LEAKAGE TEST PROCEDURES

SHALL FOLLOW THE OUTLINES AND CLASSIFICATIONS IN THE SMACNA HVAC DUCT LEAKAGE TEST MANUAL.

IF SPECIMEN FAILS TO MEET ALLOTTED LEAKAGE LEVEL, THE CONTRACTOR SHALL MODIFY TO BRING IT

INTO COMPLIANCE AND SHALL RETEST IT UNTIL ACCEPTABLE LEAKAGE IS DEMONSTRATED. TESTS AND

NECESSARY REPAIR SHALL BE COMPLETED PRIOR TO CONCEALMENT OF DUCTS.

E. MATERIALS:

1. SHEET METAL: UNLESS OTHERWISE SPECIFIED OR INDICATED, DUCTS SHALL BE CONSTRUCTED OF HOT-

DIPPED GALVANIZED SHEETMETAL WITH G60 COMMERCIAL COATING ACCORDING TO ASTM 653 & A924.

2. BLACK IRON (CARBON STEEL): PROVIDE DUCTWORK OF BLACK IRON (CARBON STEEL), WHERE INDICATED.

DUCTWORK SHALL BE BLACK IRON (CARBON STEEL) SHEET COMPLYING WITH ANSI/ASTM 415. PROVIDE FOR

ALL KITCHEN EXHAUST AND FIELD FABRICATED LOW TEMPERATURE CHIMNEYS, BREECHING AND KITCHEN HOOD

SYSTEMS.

3. IN WELDED CASES FOR ALL METAL DUCTWORK, THE FILLER ROD MATERIAL SHALL EQUAL OR EXCEED THE

BASE METAL PROPERTIES.

4. WELDED DUCTWORK SHALL BE SEALED AIR, WATER AND GAS TIGHT.

5. FLEXIBLE CONNECTIONS AT FANS SHALL BE NEOPRENE COATED, FLAME RETARDANT GLASS FABRIC

(COMPLYING WITH NFPA 90 AND 96), 30 OZ./SQ. YD. WITH SEWED AND CEMENTED SEAMS.

6. FLEXIBLE DUCTWORK SHALL NOT BE USED ON THIS PROJECT.

F. FABRICATION:

1. CONFORM TO SMACNA REQUIREMENTS FOR METAL THICKNESS, REINFORCING, JOINTS, AND SEALING FOR

MAXIMUM STATIC PRESSURES INVOLVED. ALL SEAMS AND JOINTS SHALL BE SEALED AND TAPED.

2. ELBOWS SHALL CONFORM TO SMACNA REQUIREMENTS AND THE FOLLOWING:

a. PROVIDE LONG RADIUS TYPE WITH CENTERLINE RADIUS MINIMUM 1.5 TIMES DUCT WIDTH.

PROVIDE SHORT RADIUS OR SQUARE ELBOWS WHERE INDICATED OR WHERE REQUIRED TO FIT

RESTRICTED SPACES. PROVIDE DOUBLE THICKNESS TURNING VANES ON ALL SHORT RADIUS AND

MITERED ELBOWS. CONFORM TO SMACNA FOR THE NUMBER OF VANES FOR FITTINGS.

3. BRANCH CONNECTIONS: PROVIDE 45 DEGREE ENTRY OR CONICAL TAPS. PROVIDE RADIUS TYPE FITTINGS FOR

DIVIDED FLOW BRANCHES.

G. ACOUSTICALLY LINED DUCTWORK:

1. PROVIDE MAT-FACED GLASS DUCT LINER, 1-INCH THICK -2 LB/CF DENSITY. DUCT DIMENSIONS INDICATED

ARE CLEAR (NET) INSIDE DIMENSIONS. FOR DUCT VELOCITIES GREATER THAN 2,000 FPM, FACE

DUCTLINER WITH 24 GAUGE PERFORATED ALUMINUM OR GALVANIZED STEEL, FULLY COVERING DUCTLINER,

AND SUPPORTED 12" ON CENTER. DO NOT EXTERNALLY INSULATE ACOUSTICALLY LINED DUCTWORK.

CONFORM TO SMACNA REQUIREMENTS FOR INSTALLATION. PROVIDE ACOUSTICALLY LINED DUCT WHERE LISTED

BELOW AND/OR SHOWN ON THE DRAWINGS:

a. ALL TRANSFER DUCTS

b. WITHIN MINIMUM 20 FEET OF ALL AC UNIT DISCHARGES

c. WITHIN MINIMUM 20 FEET OF FAN INLET AND DISCHARGES

H. DUCT ACCESS DOORS:

1. CONFORM TO SMACNA WITH PIANO HINGES, TWO SASH LOCKS AND DOOR GASKETS. SCREWED ACCESS PANELS

ARE NOT PERMITTED. PROVIDE REMOVABLE ACCESS DOORS WHERE DOOR SWING CAN NOT BE ACCOMMODATED.

2. SIZE: MINIMUM 20" X 14" EXCEPT DUCTS LESS THAN 16", ONE DIMENSION 20" AND THE OTHER

DIMENSION, 2" LESS THAN THE DUCT WIDTH.

3. PROVIDE ACCESS DOORS: AT ENTERING AND LEAVING SIDES OF COILS IN DUCTS; AUTOMATIC DAMPERS ON

LINKAGE SIDE, MANUAL VOLUME DAMPERS 2 SQ. FT. AND LARGER, FIRE DAMPERS, SMOKE DAMPERS,

COMBINATION FIRE/SMOKE DAMPERS, SMOKE DETECTION HEADS, FAN BEARINGS ENCLOSED IN DUCTS,

SUCTION AND DISCHARGE SIDES OF CEILING MOUNTED FANS, FILTERS, REHEAT COILS, AT ALL EQUIPMENT

REQUIRING ACCESS AND AS INDICATED ON DRAWINGS.

MECHANICAL SPECIFICATIONS - I

THIS CONTRACTOR SHALL PROCURE THE SERVICES OF A THIRD PARTY INSPECTION COMPANY TO PERFORM ALL SPECIAL

INSPECTIONS IN ACCORDANCE WITH THE NEW YORK CITY BUILDING CODE. SECURE ALL REQUIRED PERMITS AND

APPROVALS AND TRANSMIT SAME TO THE OWNER. CONTRACTOR SHALL BE RESPONSIBLE FOR ALL FEES

2.

seal & signature

dwg title

twig

cadd

checked by

issue date

AS NOTED

drawn by

02/11/2011

project no.

dwg. no.

scale

cad file

t10-12-0230

375 Beach 92nd StreetQueens, NY 11693

SUBMISSIONS

DATE rev no issue

project

project

375 Beach 92nd StreetQueens, NY 11693

architect

231 West 29th Street - Suite 606, New York, NY 10001

Tel: 212 . 967 . TWIG / Fax: 212 . 967 . 8945

[email protected] www.twigcon.com

A Division of The Wall Consulting Group, Inc. All Rights Reserved. 2007- 2010©

375 Beach 92nd Street M-201.00.dwg

NYC dob#

sheetTHESE PLANS ARE APPROVED ONLY FOR THE WORK ON THE

BEING APPROVED OR IN ACCORDANCE WITH APPLICABLE CODES.

APPLICATION SPECIFICATION SHEET. ALL OTHER MATTERS SHOWN

ARE NOT TO BE RELIED UPON OR TO BE CONSIDERED AS EITHER

All Drawings And Written Material Herein Constitute The Original And Unpublished Work Of The Wall Consulting Group, Inc. and/or TWIG Consulting Engineers, P.C., And The Same May Not Be Duplicated, Used, Or Disclosed Without The Written Consent Of The Wall Consulting Group, Inc. and/or TWIG Consulting Engineers, P.C. © 2011.

NYCECC NOTES:

TO THE BEST OF MY KNOWLEDGE, BELIEF AND

PROFESSIONAL JUDGMENT, THESE PLANS AND

SPECIFICATIONS ARE IN COMPLIANCE WITH THE

NEW YORK CITY ENERGY CONSERVATION CODE.

02.14.11 1 FILING & PRICING

GROUND FLOORMECHANICALSPECIFICATIONSSHEET I

3 of 8

F. KITCHEN EXHAUST FAN: (KX-1)

1. FURNISH AND INSTALL BACKWARD INCLINED CENTRIFUGAL UTILITY FAN TYPE-SWB, AS SCHEDULED ON THE

DRAWINGS AND DESCRIBED HEREIN. THE EXHAUST FAN SHALL BE MANUFACTURER BY "GREENHECK" OR

APPROVED EQUAL.

2. PROVIDED BACKWARD INCLINED CENTRIFUGAL UTILITY FAN TYPE-SWB SHALL BE OF THE CENTRIFUGAL

TYPE. THE FAN(S) SHALL BE PROVIDED WITH ACOUSTICALLY LINED CABINET, DUCTED INLET AND

DISCHARGE CONFIGURATION, STARTER AND DISCONNECT AT THE UNIT. THE UNIT SHALL BE AMCA RATED

FOR SOUND AND AIR PERFORMANCE UL OR C.S.A. LISTED AND OF THE CAPACITIES AND QUANTITIES

INDICATED ON THE DRAWINGS.

3. THIS CONTROL CONTRACTOR SHALL FURNISH A VARIABLE SPEED SWITCH TO BE LOCATED AT THE FAN IN

THE HUNG CEILING FOR PRESET SPEED CONTROL.

4. BACKWARD INCLINED CENTRIFUGAL UTILITY FAN TYPE-SWB EXHAUST FANS SHALL BE PROVIDED WITH

CONTROL INTERLOCKS TO THE KITCHEN HOOD EXHAUST SYSTEM.

2.07 AUTOMATIC TEMPERATURE CONTROLS

A. GENERAL:

1. FURNISH AND INSTALL AS HEREIN SPECIFIED, A COMPLETE AUTOMATIC TEMPERATURE CONTROL SYSTEM OF

THE ELECTRIC AS REQUIRED MANUFACTURED BY HONEYWELL OR APPROVED EQUAL BY THE ENGINEER.

MANUFACTURER SHALL BE APPROVED BY ENGINEER BEFORE COMMENCING WORK.

2. ALL TEMPERATURE CONTROL SYSTEMS AND COMPONENTS UNDER THIS SUBCONTRACT ARE TO BE FULLY

MODULATING TYPE, EXCEPT WHERE NOTED OTHERWISE. THE SYSTEM SHALL BE COMPLETE IN ALL RESPECTS

INCLUDING ALL ASSOCIATED CONTROL EQUIPMENT, THERMOSTATS, CONTROL VALVES, VALVE ACTUATORS,

DAMPER OPERATORS, RELAYS, PILOT POSITIONERS, CONTROL WIRING, CONTROL AIR PIPING, SWITCHES,

INTERLOCK WIRING, ELECTRICAL OR PNEUMATIC CONTROL COMPONENTS AND ASSOCIATED PIPING OR

WIRING, APPURTENANCES, ETC., TO PROVIDE THE FUNCTIONS DESCRIBED IN THESE SPECIFICATIONS AND

PLANS, REGARDLESS OF WHETHER OR NOT SAID DEVICE RELAY, ETC., IS SPECIFICALLY MENTIONED

HEREAFTER.

3. THE SYSTEM SHALL BE SUPERVISED AND CHECKED OUT COMPLETELY IN ALL RESPECTS BY COMPETENT

MECHANICS, REGULARLY EMPLOYED BY THE MANUFACTURER.

4. CONNECTION TO EXISTING SYSTEM

a. IF NEW WORK IS TO CONNECT TO AN EXISTING SYSTEM, THE PROPOSED NEW SYSTEM TO BE

INSTALLED SHALL BE FULLY COMPATIBLE WITH THE EXISTING SYSTEM. THE MANUFACTURER OF

THE PROPOSED NEW SYSTEM SHALL PROVIDE ALL REQUIRED INTERFACES OR "GATEWAYS" TO ENSURE

THAT THEIR SYSTEM IS FULLY COMPATIBLE.

5. THE CONTROL SYSTEMS SHALL BE IN ACCORDANCE WITH THE FOLLOWING DESCRIPTION OF SYSTEM

OPERATIONS AND/OR DETAIL INFORMATION SHOWN ON THE PLANS AND AS DESCRIBED HEREIN.

6. THE MANUFACTURER OF THE AUTOMATIC CONTROL EQUIPMENT SHALL SUBMIT THE FOLLOWING FOR APPROVAL:

A SCHEMATIC DIAGRAM OF EACH CONTROL SYSTEM WHICH SHALL INDICATE THE PROPER SEQUENCE OF

OPERATION AND RANGE OF THE CONTROLS FOR ALL CYCLES. A COMPLETE DESCRIPTION OF THE AUTOMATIC

OPERATION OF EACH SYSTEM. THE DESCRIPTION SHOULD INCLUDE THE DUTY OF EACH THERMOSTAT,

VALVE, SWITCH, ETC., INCORPORATED IN THE CONTROL SYSTEM WITH A SCHEDULE AND ILLUSTRATION OF

ALL CONTROL INSTRUMENTS AND EQUIPMENT INCLUDING CONTROL PANELS AND DEVICES FOR EACH SYSTEM.

B. ELECTRIC WIRING:

1. ALL ELECTRICAL WORK (EXCEPT FOR MOTOR FEEDERS, WIRING BETWEEN MOTORS, MOTOR CONTROLLERS,

FEEDER PANELS, FUSES, CIRCUIT BREAKERS AND BUS BARS) REQUIRED FOR THE AUTOMATIC TEMPERATURE

CONTROL SYSTEM SHALL BE PROVIDED BY THIS CONTRACTOR. WORK SHALL INCLUDE BUT NOT BE LIMITED

TO TIME SWITCHES, DAMPER MOTORS, DAMPER SWITCHES, ELECTRIC THERMOSTATS, ELECTRIC RELAYS, E/P

SWITCHES, INTERLOCKING WIRING, WIRE, CONDUIT, ETC.

2. ALL 115 VOLT POWER REQUIRED FOR CONTROL PURPOSES SHALL BE PROVIDED BY THE CONTROL CONTRACTOR

FROM A SOURCE ESTABLISHED BY THE ELECTRICAL CONTRACTOR.

3. THE CONTROL MANUFACTURER SHALL INCLUDE WIRING DIAGRAMS IN HIS SHOP DRAWINGS SUBMITTALS FULLY

COORDINATED WITH THE ELECTRICAL CONTRACTORS WORK. IT SHALL BE THE AUTOMATIC TEMPERATURE

CONTROL CONTRACTOR'S RESPONSIBILITY TO PROVIDE ALL WIRING AND CONDUIT AS REQUIRED TO ACHIEVE

THE FUNCTION CALLED FOR IN THESE SPECIFICATIONS, CONFORMING WITH LOCAL CODES FOR MATERIAL

AND INSTALLATION. THE ELECTRICAL SPECIFICATION FOR THE PROJECT ELECTRICAL WORK IS TO BE

FOLLOWED.

4. FURNISH A CERTIFICATE INDICATING METHOD OF WIRING COMPLIANCE WITH LOCAL CODES AS PART OF

FIRST SHOP DRAWING SUBMITTAL.

C. ROOM THERMOSTAT AND SWITCH LOCATIONS:

1. ALL ROOM THERMOSTATS AND SWITCH LOCATIONS (WHETHER SHOWN ON PLANS OR NOT) SHALL BE SELECTED

AND SUBMITTED BY THE TEMPERATURE CONTROL MANUFACTURER FOR APPROVAL BY THE ARCHITECT AND

ENGINEER PRIOR TO ACTUAL INSTALLATION.

D. CONTROL VALVES:

1. ALL AUTOMATIC CONTROL VALVES SHALL BE OF THE ELECTRONIC TYPE, FULLY PROPORTIONING, UNLESS

OTHERWISE SPECIFIED, QUIET IN OPERATION, AND SHALL BE ARRANGED TO FAIL SAFE, IN EITHER A

NORMALLY OPEN OR NORMALLY CLOSED POSITION, IN THE EVENT OF POWER FAILURE. THE OPEN OR

CLOSED POSITION SHALL BE AS SPECIFIED OR AS REQUIRED TO SUIT JOB CONDITIONS. PROVISIONS

SHALL BE MADE FOR VALVES OPERATING IN SEQUENCE, WITH OTHER VALVES OR DAMPER OPERATORS TO

HAVE ADJUSTABLE OPERATING RANGES AND STARTING POINTS TO PROVIDE FLEXIBILITY OF ADJUSTMENT

IN SEQUENCING AND THROTTLING RANGE. MODULATING VALVES SHALL BE PROVIDED WITH PILOT

POSITIONERS. VALVES SHALL BE SIZED BY THE TEMPERATURE CONTROL MANUFACTURER AND GUARANTEED

TO MEET THE HEATING OR COOLING REQUIREMENTS AS SPECIFIED. ALL VALVE BODIES SHALL HAVE THE

SAME PRESSURE CHARACTERISTICS AS THE PIPE IN WHICH IT IS INSTALLED.

2. VALVES 2 INCHES AND SMALLER UNLESS OTHERWISE SPECIFIED SHALL HAVE BRONZE BODIES WITH SCREWED

CONNECTIONS. VALVES SHALL BE FISHER TYPE ED, WARREN TYPE 20/70, K&M SERIES GCG, OR AS

APPROVED.

B. ALL DUCT INSULATIONS SHALL BE IN STRICT ACCORDANCE TO MANUFACTURER'S RECOMMENDATIONS AND MEA

LISTING, IN ORDER TO MAINTAIN VAPOR BARRIERS AND FIRE PROTECTION.

C. TYPE D-3: TWO (2) LAYERS OF LIGHTWEIGHT DUCTWRAP, NON-ASBESTOS, HIGH TEMPERATURE, INORGANIC,

CERAMIC FIBER BLANKET TOTALLY ENCAPSULATED IN FOIL/SCRIM HAVINGH A SERVICE TEMPERATURE RANGE

UP TO 2300 DEG.F.

D. PROVIDE AS AN ALTERNATE PANTRY EXHAUST DUCT INSULATION AS MANUFACTURED BY FIREMASTER DUCTWRAP:

3M COMPANY OR AS APPROVED.

2.03 ELECTRICAL WORK

A. GENERAL:

1. ELECTRICAL POWER WIRING SHALL BE PROVIDED BY THE ELECTRICAL CONTRACT; CONTROL WIRING SHALL

BE BY THE HVAC CONTRACT. CONTROL WIRING SHALL BE DEFINED AS ANY 12V, 24V, OR 120V WIRING

INSTALLED FOR PURPOSES OTHER THAN PROVIDING PRIMARY ELECTRICAL POWER TO EQUIPMENT.

2. DUCT MOUNTED SMOKE DETECTORS, WHERE REQUIRED, SHALL BE PROVIDED BY AND WIRED BY THE

ELECTRICAL CONTRACTOR, AND MOUNTED BY THE HVAC CONTRACTOR.

3. ALL ELECTRICAL CONTROL WIRING SHALL COMPLY WITH LOCAL ELECTRICAL CODE, ALL AUTHORITIES

HAVING JURISDICTION AND THE PROJECT ELECTRICAL SPECIFICATIONS.

4. MECHANICAL CONTRACTOR TO OBTAIN QUANTITY OF CONTROLLERS REQUIRED AND COORDINATE WITH

ELECTRICAL CONTRACTOR FOR ALL OPERATING REQUIREMENTS, INTERLOCKS AND CONNECTIONS FOR

STARTERS.

5. THE MECHANICAL CONTRACTOR SHALL PREPARE AND SUBMIT FOR APPROVAL POINT TO POINT, COMPLETELY

COORDINATED WIRING DIAGRAMS AND INDICATE ALL SOURCE POWER REQUIREMENTS AND ALL FIELD WIRING

TO BE PERFORMED BY THE ELECTRICAL CONTRACTOR.

6. WHERE EXISTING STARTERS ARE TO BE REUSED, THIS CONTRACTOR SHALL MAINTAIN ALL EXISTING

CONTROL CONNECTIONS. WHERE NEW STARTERS ARE TO BE PROVIDED TO REPLACE EXISTING, THIS

CONTRACTOR SHALL SURVEY THE EXISTING CONTROL CONNECTIONS AND PREPARE AN EXISTING CONTROL

WIRING DIAGRAM PRIOR TO DEMOLITION FOR SUBMITTAL TO THE ENGINEER. THE NEW STARTERS SHALL

BE PROVIDED WITH THE NECESSARY CONTACTS AND RELAYS REQUIRED TO RECONNECT THE EXISTING

CONTROLS. PROVIDE ALL REQUIRED CONTACTS FOR UNIT START/STOP AND FIRE ALARM.

B. MOTORS:

1. MOTORS SHALL HAVE THE ELECTRICAL CHARACTERISTICS AS LISTED ON THE DRAWINGS. COORDINATE ALL

REQUIREMENTS WITH ELECTRICAL CONTRACTOR. ALL MOTORS SHALL COMPLY WITH NEMA MG-1 STANDARD AND

SHALL BE OF THE HIGH EFFICIENCY TYPE AND MEET THE 1992 EPA ENERGY EFFICIENCY ACT AND

UTILITY COMPANY REBATE REQUIREMENTS.

2. IF CONTRACTOR ELECTS TO SUBSTITUTE OR INCREASE MOTOR HORSEPOWER OVER THAT SPECIFIED, THE

COST OF MOTOR AND ELECTRICAL CHANGES SHALL BE BORNE BY THIS CONTRACTOR.

C. STARTERS:

1. EACH MOTOR EXCEPT AS NOTED, SHALL BE PROVIDED WITH A COMBINATION FUSED DISCONNECT AND

ACROSS-THE-LINE MAGNETIC STARTER WITH PUSH BUTTON STATIONS MOUNTED ON COVER. COORDINATE

REQUIREMENTS WITH ELECTRICAL CONTRACTOR. FOR AUTOMATICALLY OR REMOTELY CONTROLLED MOTORS,

FURNISH HAND OFF AUTO (HOA) SELECTOR SWITCHES IN PLACE OF THE PUSH BUTTONS.

2. FURNISH MANUALLY OPERATED MOTOR STARTERS OF THE PROPER SIZE FOR ALL MOTORS LESS THAN 1/2 HP

WHICH ARE NOT AUTOMATICALLY CONTROLLED. STARTERS FOR MOTORS 175 WATTS OR LESS SHALL CONSIST

OF A SNAP SWITCH WITH THERMAL OVERLOAD PROTECTION WHERE SUCH PROTECTION IS NOT AN INTEGRAL

PART OF THE MOTOR.

3. COMBINATION MAGNETIC STARTERS FOR ALL MOTORS SHALL HAVE THERMAL OVERLOAD, PILOT LIGHT, LOW

VOLTAGE PROTECTION IN ALL THREE PHASES. INCLUDE A CONTROL TRANSFORMER FOR EACH MAGNETIC

STARTER TO PROVIDE 120 VOLT CONTROL POWER WITH 3 SETS OF SPARE NORMALLY CLOSED OR NORMALLY

OPEN CONTACTS.

4. ALL STARTERS SHALL BE ASSEMBLED AND INTERNALLY WIRED WITH ALL DEVICES IN CONFORMANCE WITH

NEMA STANDARDS.

5. STARTERS FOR MOTORS 75 HP AND ABOVE SHALL BE SOLID STATE ELECTRONIC SOFT START TYPE

STARTERS.

6. DISCONNECT SWITCHES ARE PROVIDED BY THE ELECTRICAL CONTRACTOR IF NOT INTEGRAL WITH

EQUIPMENT.

D. ENCLOSURES:

1. PROVIDE ENCLOSURES FOR STARTERS SUITABLE FOR OPERATING ENVIRONMENT. ENCLOSURE'S SHALL BE

NEMA 1 VENTILATED SHEETMETAL FOR INDOOR APPLICATION, NEMA 3R WITH ADDITIONAL GASKETING

WEATHERPROOF RAINTIGHT ENCLOSURE FOR EXPOSED OUTDOOR SERVICE OR INDOOR SERVICE EXPOSED TO

MOISTURE. PROVIDE DISCONNECT SWITCH ON ENCLOSURE AS REQUIRED FOR SERVICE.

2.04 VIBRATION ISOLATION PRODUCTS

A. FURNISH AND INSTALL ALL NECESSARY VIBRATION ISOLATORS, VIBRATION HANGERS, MOUNTING PADS, RAILS,

ETC., TO ISOLATE VIBRATION AND SOUND FROM BEING TRANSMITTED TO THE BUILDING CONSTRUCTION. ALL

VIBRATION ISOLATION PRODUCTS SHALL BE SPECIFICALLY DESIGNED FOR THEIR INTENDED USE.

B. MANUFACTURER OF VIBRATION ISOLATION EQUIPMENT SHALL HAVE THE FOLLOWING RESPONSIBILITIES:

1. DETERMINE VIBRATION ISOLATOR SIZES AND LOCATIONS.

2. PROVIDE SUITABLE PIPING AND EQUIPMENT VIBRATION ISOLATION SYSTEMS.

3. GUARANTEE SPECIFIED ISOLATION SYSTEM ATTENUATION AND DEFLECTION.

4. PROVIDE INSTALLATION INSTRUCTIONS, DRAWINGS AND FIELD SUPERVISION TO ASSURE PROPER

INSTALLATION AND PERFORMANCE. STARTERS SHALL BE SELECTED TO SUIT MOTOR RUNNING AND STARTING

CHARACTERISTICS.

C. ISOLATION SYSTEMS SHALL BE MANUFACTURED BY MASON INDUSTRIES OR APPROVED EQUAL BY THE ENGINEER.

D. MOUNTING TYPES:

1. STATIC DEFLECTION OF ISOLATORS SHALL BE A MINIMUM OF 90% EFFICIENT. PROVIDE CORROSION

PROTECTION FOR EQUIPMENT MOUNTED OUTDOORS.

2. FLOOR MOUNTING OF CENTRIFUGAL FANS (3 HP AND LESS) SPRING ISOLATORS (TYPE SLF).

3. FLOOR AND ROOF MOUNTING OF FACTORY ASSEMBLED AIR HANDLING UNITS, AIR CONDITIONING UNITS,

HEAT EXCHANGERS AND CONDENSING UNITS, - SPRING ISOLATORS (ROOF MOUNTED EQUIPMENT TYPE

SLR), OR (INDOOR EQUIPMENT TYPE SLF).

4. FLOOR MOUNTING OF CENTRIFUGAL FANS (5 HP AND ABOVE) - SPRING ISOLATOR WITH INERTIA BASE -

(TYPE KSL).

5. MOUNTING OF CEILING-SUPPORTED FANS, IN-LINE PUMPS, HEAT EXCHANGERS, AND AIR HANDLING UNITS -

SPRING ISOLATORS - (TYPE DNHS).

6. SUPPORT OF PIPING IN EQUIPMENT ROOMS AND WHERE EXPOSED ON ROOF

a. ALL WATER PIPING OUTSIDE OF SHAFTS WITHIN 50 FEET OF CONNECTED ROTATING EQUIPMENT TO

BE SUPPLIED WITH ISOLATORS.

b. HANGER ROD ISOLATORS (TYPE 30N) MOUNTINGS.

c. FLOOR SUPPORTED PIPING ISOLATORS (TYPE SLR).

d. VERTICAL RISER PIPING ANCHOR AND GUIDES (TYPE ADA).

7. PROVIDE FLEXIBLE CONNECTIONS BETWEEN ALL FANS AND DUCTWORK (REFER TO DUCTWORK SECTION FOR

SPECIFICATIONS.

2.05 TESTING AND BALANCING

A. GENERAL

1. TESTING AND BALANCING WORK SHALL BE PERFORMED BY AN INDEPENDENT COMPANY (NOT ASSOCIATED WITH

THE HVAC CONTRACTOR), AABC CERTIFIED OR AS APPROVED BY THE ENGINEER BEFORE COMMENCEMENT OF

WORK. APPROVED COMPANIES INCLUDE MERENDINO ASSOCIATES, R.H. MCDERMOTT, INTERNATIONAL

TESTING AND BALANCING OR AS APPROVED BY THE ENGINEER AND BUILDING MANAGEMENT.

2. AFTER ALL PROJECT HVAC WORK IS COMPLETE, TESTED AND IN FULL WORKING ORDER, THE AGENCY SHALL

PERFORM THE BALANCING AND TESTING OF THE PROJECT HEATING, VENTILATING AND AIR CONDITIONING

SYSTEMS.

3. UPON THE COMPLETION OF THE AIR CONDITIONING SYSTEM, THE BALANCING AGENCY SHALL PERFORM

TESTING AND BALANCING AND COMPILE ALL TEST DATA IN A CERTIFIED REPORT AND SUBMIT FOUR (4)

COPIES FOR REVIEW AND APPROVAL TO THE ENGINEER.

4. THE REPORT SHALL INCLUDE DESIGN AND ACTUAL READINGS FOR ALL EQUIPMENT AND LOCATION PLAN

INDICATING WHERE ALL WORK HAS BEEN PERFORMED, AND METHODS OF BALANCING AND DETAILS OF

INSTRUMENTS USED.

5. IF DISCREPANCIES EXIST IN THE REPORT THAT REQUIRE FIELD VERIFICATION, THE TESTING AND

BALANCING COMPANY IN THE PRESENCE OF THE ENGINEER SHALL VISIT THE JOBSITE FOR FIELD

VERIFICATION OF THE REPORT.

6. AFTER SUBMISSION OF THE FIELD VERIFIED BALANCING REPORT, THE AIR BALANCING COMPANY SHALL

RETURN TO THE JOB SITE TO PERFORM TWO (2) OCCUPANT COMFORT BALANCES AS DIRECTED BY THE OWNER

OR ENGINEER.

7. THE FINAL REPORT AFTER THE COMFORT BALANCE IS TO BE INCLUDED IN PROJECT OPERATING AND

MAINTENANCE MANUAL.

8. THE TESTING AND BALANCING AGENCY SHALL INCLUDE AS PART OF THEIR WORK AN EXTENDED WARRANTY

OF 90 DAYS AFTER COMPLETION OF TEST AND BALANCE WORK. THE ENGINEER AT HIS DISCRETION DURING

THE WARRANTY PERIOD MAY REQUEST A RECHECK, OR RESETTING OF ANY EQUIPMENT. THE MECHANICAL

CONTRACTOR AND THE BALANCING CONTRACTOR SHALL PROVIDE THE NECESSARY TECHNICIANS TO

FACILITATE THIS WORK.

9. BALANCING AGENCY SHALL PERMANENTLY MARK ALL ADJUSTMENT DEVICES (VALVES, DAMPERS, ETC.,) TO

ENABLE THE SETTING TO BE RESTORED.

B. AIR BALANCING

1. HVAC CONTRACTOR SHALL ENSURE THAT A FIRST SET OF AIR FILTERS ARE IN PLACE, WHENEVER FANS ARE

RUNNING AND REPLACED WITH A NEW CLEAN SET OF FILTERS BEFORE TESTING IS COMMENCED.

2. TEST, ADJUST, REPLACE SHEAVES, AND BALANCE ALL EQUIPMENT AND AIR DISTRIBUTION SYSTEMS TO

PROVIDE AIR QUANTITIES INDICATED ON PLANS WITHIN PLUS OR MINUS 5 PERCENT.

3. TEST REPORT SHALL INCLUDE, BUT NOT BE LIMITED TO THE FOLLOWING:

a. FLOW, LEAKAGE CLASS, TEMPERATURE, STATIC PRESSURE OF AIR AT ALL TRUNK DUCTS SERVING

AREAS OF WORK.

b. TEMPERATURE OF AIR LEAVING OUTLETS AT TWO (2) TYPICAL AIR OUTLETS.

c. QUANTITY OF AIR AT EACH AIR INLET AND OUTLET AFTER BALANCING.

d. PROVIDE FOR ALL FANS, FAN MOTOR HP, AMPS, VOLTS, FAN RPM, CFM, INLET AND DISCHARGE

STATIC PRESSURE, SHEAVE POSITION.

e. PROVIDE FOR ALL AIR CONDITIONING UNITS, SUPPLY CFM, OUTSIDE AIR CFM, RETURN AIR CFM,

MIXED AIR CFM. PROVIDE OUTSIDE AIR, MIXED AIR AND SUPPLY AIR TEMPERATURES (DRY BULB -

COOLING AND HEATING, WET-BULB-COOLING.) INDICATE UNIT OPERATING MODE DURING TEST.

f. CALIBRATE ALL NEW AND EXISTING TO BE REUSED TERMINAL BOXES (VAV, FAN POWERED OR DUAL

DUCT) AS REQUIRED TO MEET SPECIFIED MINIMUM/MAXIMUM CFM.

g. LISTING OF DESIGN AND ACTUAL READINGS AS WELL AS ALL MANUFACTURER'S DATA FOR

EQUIPMENT.

2.06 EQUIPMENT

A. PROVIDE ALL EQUIPMENT AND ACCESSORIES OF THE SIZES AND CAPACITIES AS SCHEDULED AND AS INDICATED ON

THE DRAWINGS.

B. INSTALL EQUIPMENT IN ACCORDANCE WITH APPROVED SHOP DRAWINGS, MANUFACTURERS RECOMMENDATIONS,

INSTRUCTIONS, AND ALL AUTHORITIES HAVING JURISDICTION.

C. PROVIDE EQUIPMENT SUPPORTS AND/OR MOUNTINGS AS INDICATED ON THE DRAWING, IN VIBRATION SPECIFICATION

AND AS FOLLOWS:

1. FLOOR MOUNTED EQUIPMENT - PROVIDE DIMENSIONS FOR A 4" CONCRETE HOUSEKEEPING PAD WITH ALL

REQUIRED WATERPROOFING TO THE CONSTRUCTION MANAGER.

2. EQUIPMENT ON FLOOR STANDS - PROVIDE FLOOR STAND OF STRUCTURAL STEEL OR STEEL PIPES AND

FITTINGS AND BOLT TO FLOOR.

3. ROOF MOUNTED EQUIPMENT - PROVIDE PREFABRICATED ISOLATED ROOF CURB WITH INTEGRAL VIBRATION

ISOLATORS.

4. CEILING MOUNTED EQUIPMENT - PROVIDE SUPPORTS WITH APPROVED SUITABLE ANCHORS SUSPENDED

DIRECTLY FORM BUILDING STEEL STRUCTURE.

5. PROVIDE SUPPLEMENTAL STEEL AS REQUIRED TO ADEQUATELY SUPPORT THE EQUIPMENT LOAD.

D. EQUIPMENT SHALL BE INSTALLED WITH VIBRATION ISOLATION, REFER TO VIBRATION ISOLATION SECTION.

E. DIFFUSERS, GRILLES AND REGISTERS:

1. GENERAL

a. GRILLES, REGISTERS AND DIFFUSERS SHALL BE TESTED IN ACCORDANCE WITH ASHRAE STANDARD

70-1991 OR LATEST EDITION. THE MANUFACTURER SHALL PROVIDE PUBLISHED PERFORMANCE DATA

FOR ALL AIR INLETS AND OUTLETS TO BE USED ON PROJECT AS PART OF SUBMISSION.

b. MECHANICAL CONTRACTOR TO COORDINATE THE LOCATION OF DIFFUSERS, GRILLES AND REGISTERS

WITH OTHER TRADES AND WITH CEILING AND WALL CONSTRUCTION. THE MECHANICAL CONTRACTOR

TO VERIFY THAT ALL DIFFUSERS, GRILLES AND REGISTERS ARE COMPATIBLE WITH CEILING

CONSTRUCTION TO WHICH THEY ARE TO BE INSTALLED.

c. COORDINATE ALL WORK WITH GENERAL CONTRACTOR AND REFER TO ARCHITECTURAL DRAWINGS FOR

EXACT LOCATION, LENGTHS AND FOR FRAMING AND MITERING ARRANGEMENTS THAT MAY DIFFER

FROM THOSE SHOWN ON HVAC DRAWINGS. PROVIDE ALL REQUIRED GENERAL CONSTRUCTION,

FRAMING, BLOCKING, PLASTERING AND SUPPORTS TO MATCH CEILING, SOFFIT OR WALL

CONSTRUCTION AS PART OF PROJECT.

d. INLETS AND OUTLETS SHALL HANDLE AIR QUANTITIES INDICATED AT OPERATING VELOCITIES WITH

SOUND PRESSURE LEVEL NOT TO EXCEED NC-30, UNLESS NOTED OTHERWISE.

e. DIFFUSERS, GRILLES AND REGISTERS SHALL BE INSTALLED WITH FACES SET LEVEL AND PLUMB

AND MOUNTED TIGHTLY AGAINST MOUNTING SERVICE.

f. ALL AIR INLETS AND OUTLETS TO BE STEEL OR ALUMINUM IF EXPOSED TO MOISTURE UNLESS

OTHERWISE INDICATED. FINISHES TO BE SELECTED BY ARCHITECT.

g. DIFFUSERS, GRILLES AND REGISTERS SHALL BE MANUFACTURED BY TITUS OR ANEMOSTAT.

h. SUBMIT FOR APPROVAL A COMPLETE SCHEDULE OF ALL AIR INLETS AND OUTLETS TO BE USED ON

PROJECT INCLUDING MANUFACTURERS MODELS, SIZES, PERFORMANCE, ACCESSORIES, ACOUSTIC

INFORMATION, FINISHES, ETC., BEFORE RELEASE FOR FABRICATION. NOTE ANY DEVIATIONS

FROM SPECIFICATIONS AND SCHEDULES SHALL BE INDICATED ON SUBMITTAL.

2. AIR INLET AND OUTLET DEVICES

a. PROVIDE DIFFUSERS, GRILLES AND REGISTERS FOR SUPPLY, RETURN AND EXHAUST INLETS AND

OUTLETS, OF THE SIZE, TYPE, AND DESIGN INDICATED ON DRAWINGS.

b. ALL SUPPLY RETURN AND EXHAUST AIR INLETS AND OUTLETS SHALL BE PROVIDED WITH AN

OPPOSED BLADE DAMPER AND GRID (ADJUSTABLE THROUGH THE FACE) FOR TRIM BALANCING.

c. SUPPLY REGISTERS SHALL HAVE TWO SETS OF DIRECTIONAL CONTROL BLADES.

d. ONLY 4 WAY DIFFUSERS SHALL BE USED, PROVIDE BLANK OFF SHEET METAL BAFFLE FOR ALL 1-

WAY, 2-WAY AND 3-WAY DIFFUSERS.

e. ALL LINEAR DIFFUSERS SHALL BE PROVIDED WITH CABLE OPERATED OPPOSED BLADE DAMPER

ADJUSTABLE THROUGH THE FACE OF THE DIFFUSER. DAMPERS AND PLENUM TAPS SHALL BE SPACED

AT A MAXIMUM OF 4 FEET ON CENTER. PROVIDE DIFFUSERS WITH ADJUSTABLE AIR PATTERN

CONTROL VANES.

6"UP TO 30 HP

MOTOR HP

INERTIA BASE THICKNESS

REQUIRED MINIMUM CONCRETE MINIMUM ISOLATION

DEFLECTION

3/4"

2. PROVIDE AS AN ALTERNATE FOR KITCHEN EXHAUST DUCT INSULATION

A. KITCHEN EXHAUST DUCTWORK INSULATION SHALL BE IN DIRECT CONTACT WITH THE DUCT IT ENCLOSES. PROTECT

EVERY PORTION OF THE DUCT WITH NO LESS THAN TWO (2) LAYERS FOR GREASE DUCT APPLICATIONS AND TWO

(2) LAYERS FOR TWO (2) HOUR AIR DUCT ENCLOSURES. OVERLAP BOTH PERIMETER AND LONGITUDINAL JOINTS

WITH AMINIMUM OF 3" PER LAYER OF MATERIAL. ALL KITECHN EXHAUST DUCT HANGERS SHALL BE WRAPPED

WITH FIREMASTER DUCT WRAP TO MAINTAIN A 3-HOUR RATED SUPPORT AND THE MEA LISTING.

MECHANICAL SPECIFICATIONS - II

seal & signature

dwg title

twig

cadd

checked by

issue date

AS NOTED

drawn by

02/11/2011

project no.

dwg. no.

scale

cad file

t10-12-0230

375 Beach 92nd StreetQueens, NY 11693

SUBMISSIONS

DATE rev no issue

project

project

375 Beach 92nd StreetQueens, NY 11693

architect

231 West 29th Street - Suite 606, New York, NY 10001

Tel: 212 . 967 . TWIG / Fax: 212 . 967 . 8945

[email protected] www.twigcon.com

A Division of The Wall Consulting Group, Inc. All Rights Reserved. 2007- 2010©

375 Beach 92nd Street M-202.00.dwg

NYC dob#

sheetTHESE PLANS ARE APPROVED ONLY FOR THE WORK ON THE

BEING APPROVED OR IN ACCORDANCE WITH APPLICABLE CODES.

APPLICATION SPECIFICATION SHEET. ALL OTHER MATTERS SHOWN

ARE NOT TO BE RELIED UPON OR TO BE CONSIDERED AS EITHER

All Drawings And Written Material Herein Constitute The Original And Unpublished Work Of The Wall Consulting Group, Inc. and/or TWIG Consulting Engineers, P.C., And The Same May Not Be Duplicated, Used, Or Disclosed Without The Written Consent Of The Wall Consulting Group, Inc. and/or TWIG Consulting Engineers, P.C. © 2011.

NYCECC NOTES:

TO THE BEST OF MY KNOWLEDGE, BELIEF AND

PROFESSIONAL JUDGMENT, THESE PLANS AND

SPECIFICATIONS ARE IN COMPLIANCE WITH THE

NEW YORK CITY ENERGY CONSERVATION CODE.

02.14.11 1 FILING & PRICING

GROUND FLOORMECHANICALSPECIFICATIONSSHEET II

4 of 8

3. VALVES BETWEEN 2 «" AND 4 INCH UNLESS OTHERWISE SPECIFIED, SHALL HAVE CAST IRON OR CARBON

STEEL BODIES WITH FLANGED CONNECTIONS IN ACCORDANCE WITH THE PIPING SPECIFICATIONS. VALVES

SHALL BE FISHER STYLE ED, WARREN TYPE 20/70 OR 1800 SERIES GCG, K & M SERIES GCG OR AS

APPROVED.

4. CONTROL VALVES 4" AND LARGER UNLESS OTHERWISE SPECIFIED SHALL BE FISHER V100, K & M C-

PORTBALL, WARREN 3800 SERIES, OR AS APPROVED.

5. ALL BUTTERFLY CONTROL VALVES, WHERE SHOWN ON THE DRAWINGS OR SPECIFIED SHALL CONFORM WITH

THE PIPING SPECIFICATION.

6. AUTOMATIC CONTROL VALVES EXPOSED TO THE ELEMENTS SHALL HAVE ELECTRIC ACTUATORS WITH ALL

REQUIRED ACCESSORIES.

E. AUTOMATIC DAMPERS:

1. PROVIDE CONTROLS FOR ALL THE AUTOMATIC DAMPERS, AS SPECIFIED IN THE DUCTWORK SECTION, AND

SHOWN ON THE DRAWINGS.

2. CONTROL MOTORS OR ACTUATORS SHALL BE OF THE ELECTRONIC OR PNEUMATIC TYPE, UNLESS OTHERWISE

NOTED, OF APPROPRIATE SIZE AND QUANTITIES TO PROVIDE TWO-POSITION OR PROPORTIONING CONTROL

ACTION AS SPECIFIED. PROPORTIONING TYPE SHALL BE EQUIPPED WITH PILOT TYPE POSITIONERS. PILOT

POSITIONERS SHALL BE SELECTED FOR VARIED SPRING RANGES AND ADJUSTABLE WITHOUT DISMANTLING

POSITIONER AND CONTROL MOTOR.

3. AUTOMATIC DAMPERS EXPOSED TO THE ELEMENTS SHALL HAVE ELECTRIC ACTUATORS WITH ALL REQUIRED

ACCESSORIES.

F. CONTROL PANELS:

1. FURNISH AND INSTALL IN THE MECHANICAL ROOM, AS HEREIN SPECIFIED, CONTROL PANELS OF STEEL,

WITH WELDED ANGLE IRON BRACKETS, FOR WALL OR FLOOR MOUNTING.

2. THE BASIC BACKGROUND COLOR OF THE PANEL SHALL BE AS APPROVED BY THE ARCHITECT AND ENGINEER.

3. PANELS SHOULD BE FULLY ENCLOSED, WITH HINGED LOCKING FRONT DOOR FOR EACH PANEL. THE PANEL

SHALL CONTAIN ALL CONTROLLERS, RELAYS, SWITCHES, ETC. PROVIDE ENGRAVED NAMEPLATES TO LABEL

THE CONTROLLED EQUIPMENT AND FOR EACH PANEL MOUNTED CONTROL DEVICE. PLASTIC LAMINATED

CONTROL SCHEMATIC DRAWINGS FOR THE SYSTEM SHALL BE HUNG AT EACH LOCAL CONTROL PANEL.

4. DETAILS OF EACH OF THESE PANELS SHALL BE SUBMITTED FOR APPROVAL PRIOR TO FABRICATION.

LOCATIONS OF EACH PANEL ARE TO BE CONVENIENT FOR ADJUSTMENT AND SERVICE AND ALL SUCH

LOCATIONS ARE TO BE APPROVED PRIOR TO INSTALLATION.

PART 3 SEQUENCE OF OPERATIONS:

3.01 KITCHEN EXHAUST FAN (KX-1)

THE KITCHEN EXHAUST SYSTEM SHALL RUN WHENEVER GAS IS FLOWING IN THE KITCHEN OR THE DISHWASHER IS

OPERATING. THE EXHAUST SYSTEM SHALL CONTINUE TO OPERATE FOR 15 MINUTES AFTER THE DISHWASHER HAS

COMPLETED ITS CYCLE AND THE GAS FLOW HAS CEASED. THE KITCHEN EXHAUST SHALL HAVE CONTINUOUS POWER

TO ALLOW THE UNIT TO PERFORM SCHEDULE WASH DOWN DURING THE NIGHT WHEN THE UNIT IS NOT IN OPERATION.

PROVIDE (2) TWO SETS OF POSITIVE CONTACTS FOR THE FOLLOWINGS (1) AS SPARE, AND (1) FOR TIE-IN TO

THE ANSUL FIRE SUPPRESSION SYSTEM, GIVING THE ANSUL THE ABILITY TO START AND STOP THE KITCHEN

EXHAUST UNIT.

PART 4 EXECUTION

4.01 DEMOLITION, REMOVAL AND RELOCATION

A. REMOVAL, TEMPORARY CONNECTIONS AND RELOCATION OF CERTAIN EXISTING WORK WILL BE NECESSARY FOR THE

INSTALLATION OF THE NEW SYSTEMS. ALL EXISTING CONDITIONS ARE NOT TO BE COMPLETELY DETAILED ON THE

DRAWINGS. THE CONTRACTOR SHALL SURVEY THE SITE AND MAKE ALL NECESSARY CHANGES REQUIRED BASED ON

EXISTING CONDITIONS FOR PROPER INSTALLATION OF NEW WORK.

B. DISCONNECT, REMOVE AND/OR RELOCATE EXISTING MATERIAL, EQUIPMENT, AND OTHER WORK AS NOTED OR REQUIRED

FOR PROPER INSTALLATION OF NEW SYSTEM.

C. EQUIPMENT REQUIRED TO BE TEMPORARILY DISCONNECTED AND RELOCATED SHALL BE CAREFULLY REMOVED, STORED,

CLEANED, REINSTALLED, RECONNECTED AND MADE OPERATIONAL.

D. ALL EXISTING WORK NOT INDICATED FOR DEMOLITION SHALL BE PROTECTED FROM DAMAGE. WHERE EXISTING WORK

TO REMAIN IS DAMAGED OR DISTURBED, CONTRACTOR SHALL REPAIR OR REPLACE TO OWNER'S AND BUILDING

MANAGER'S SATISFACTION AT NO COST TO THE OWNER OR BUILDING MANAGEMENT.

E. GENERAL CONTRACTOR TO REMOVE ALL CEILING IN AREAS WHERE NEW DUCTWORK OR PIPING IS TO BE INSTALLED

OR EXISTING IS ALTERED, AS PER ARCHITECT'S INSTRUCTIONS.

F. ALL NECESSARY CUTTING AND PATCHING TO ACCOMMODATE THE NEW HVAC WORK SHALL BE PERFORMED BY THIS

CONTRACTOR AND COORDINATED WITH BUILDING MANAGEMENT SO AS TO MINIMIZE DISRUPTION OF EXISTING TENANTS

AND SERVICES. RESTORE ALL ITEMS TO MATCH EXISTING CONDITIONS.

G. ALL EXISTING MATERIAL AND EQUIPMENT TO BE REMOVED UNDER THIS CONTRACT WILL REMAIN THE PROPERTY OF

THE OWNER OR SHALL BE LEGALLY DISPOSED OF BY THIS CONTRACTOR AS DIRECTED BY THE ARCHITECT OR OWNER.

REFRIGERATION CONTAINED IN EXISTING EQUIPMENT TO BE REMOVED SHALL BE RECLAIMED OR LEGALLY DISPOSED

OF IN ACCORDANCE WITH EPA REQUIREMENTS AND ASHRAE.

H. PROVIDE FOR LEGAL REMOVAL AND DISPOSAL OF ALL RUBBISH AND DEBRIS FROM THE BUILDING AND SITE.

COORDINATE ALL DEMOLITION AND REMOVALS WITH BUILDING MANAGEMENT.

4.02 CONNECTIONS TO EXISTING WORK

A. PLAN INSTALLATION OF NEW WORK AND CONNECTIONS TO EXISTING WORK TO INSURE MINIMUM INTERFERENCE WITH

REGULAR OPERATION OF EXISTING FACILITIES. ALL SYSTEM SHUTDOWNS AFFECTING OTHER AREAS SHALL BE

COORDINATED WITH BUILDING MANAGEMENT. INSTALL ISOLATION VALVES AT POINT OF CONNECTION TO THE

EXISTING PIPING. INSTALL ISOLATION DAMPERS AT CONNECTION TO EXISTING DUCTWORK. PROVIDE TEMPORARY

DUCTWORK AND PIPING CONNECTIONS AS REQUIRED TO MINIMIZE SHUTDOWN TIME.

B. CONNECT NEW WORK TO EXISTING WORK IN NEAT AND APPROVED MANNER. RESTORE EXISTING WORK DISTURBED WHILE

INSTALLING NEW WORK TO ACCEPTABLE CONDITION AS DETERMINED BY ARCHITECT AND BUILDING MANAGER.

C. MAINTAIN CONTINUOUS OPERATION OF EXISTING FACILITATES.

4.03 CHASING, CHOPPING OR CORE DRILLING

A. PRIOR TO ANY CHASING, CHOPPING, OR CORE DRILLING BEING PERFORMED, THIS CONTRACTOR SHALL FIELD

INVESTIGATE EXISTING CONDITIONS AND COORDINATE WITH ALL APPROPRIATE TRADES AND BUILDING MANAGEMENT

TO ENSURE THAT WORK WILL BE IN HARMONY WITH OTHER WORK AND NOT AFFECT ANY EXISTING BUILDING SYSTEMS.

THIS WORK MUST BE APPROVED BY BUILDING MANAGEMENT PRIOR TO PROCEEDING.

4.04 SYSTEM COMMISSIONING

A. PRIOR TO FULL OPERATION, A COMPLETE DEMONSTRATION AND TESTING OF THE SYSTEM OPERATING FUNCTIONS AND

ALARMS SHALL BE PERFORMED BY THIS CONTRACTOR IN THE PRESENCE OF THE OWNER'S REPRESENTATIVE AND

ENGINEER. THIS TESTING SHALL TAKE PLACE AFTER HAVING SATISFACTORILY MET THE REQUIREMENTS OF SHOP

DRAWING ACCEPTANCE. COMMISSIONING OF THE SYSTEMS SHALL BE SCHEDULED BEFORE SPACE IS OCCUPIED

LEAVING ENOUGH TIME TO CORRECT SYSTEM DEFICIENCY'S AND AFTER SHOP DRAWING ACCEPTANCE. UPON

SUCCESSFUL COMPLETION OF SYSTEM OPERATION, THE CONTRACTOR SHALL SUBMIT A STATEMENT STATING THAT THE

FULL OPERATION OF ALL SYSTEMS, FUNCTIONS AND ALARMS HAS BEEN DEMONSTRATED AND ARE OPERATIONAL AS

WELL AS A LISTING OF ALL SYSTEMS, ALARMS AND FUNCTIONS THAT HAVE BEEN COMMISSIONED. ALL ITEMS SHALL

BE SUBMITTED FOR REVIEW AND ACCEPTANCE TO THE OWNER, OWNER'S REPRESENTATIVE AND ENGINEER BEFORE

FINAL ACCEPTANCE CAN TAKE PLACE.

MECHANICAL SPECIFICATIONS - III

seal & signature

dwg title

twig

cadd

checked by

issue date

AS NOTED

drawn by

02/11/2011

project no.

dwg. no.

scale

cad file

t10-12-0230

375 Beach 92nd StreetQueens, NY 11693

SUBMISSIONS

DATE rev no issue

project

project

375 Beach 92nd StreetQueens, NY 11693

architect

231 West 29th Street - Suite 606, New York, NY 10001

Tel: 212 . 967 . TWIG / Fax: 212 . 967 . 8945

[email protected] www.twigcon.com

A Division of The Wall Consulting Group, Inc. All Rights Reserved. 2007- 2010©

375 Beach 92nd Street M-203.00.dwg

NYC dob#

sheetTHESE PLANS ARE APPROVED ONLY FOR THE WORK ON THE

BEING APPROVED OR IN ACCORDANCE WITH APPLICABLE CODES.

APPLICATION SPECIFICATION SHEET. ALL OTHER MATTERS SHOWN

ARE NOT TO BE RELIED UPON OR TO BE CONSIDERED AS EITHER

All Drawings And Written Material Herein Constitute The Original And Unpublished Work Of The Wall Consulting Group, Inc. and/or TWIG Consulting Engineers, P.C., And The Same May Not Be Duplicated, Used, Or Disclosed Without The Written Consent Of The Wall Consulting Group, Inc. and/or TWIG Consulting Engineers, P.C. © 2011.

NYCECC NOTES:

TO THE BEST OF MY KNOWLEDGE, BELIEF AND

PROFESSIONAL JUDGMENT, THESE PLANS AND

SPECIFICATIONS ARE IN COMPLIANCE WITH THE

NEW YORK CITY ENERGY CONSERVATION CODE.

02.14.11 1 FILING & PRICING

GROUND FLOORMECHANICALSPECIFICATIONSSHEET III

5 of 8

GROUND FLOOR: MECHANICAL PLAN

SCALE: 3/16" - 1'-0"

ACCESS DOORS, VOLUME DAMPERS, ETC. ARE INDICATED ON THE

CONTRACT DOCUMENT DRAWINGS FOR CLARITY FOR A SPECIFIC

LOCATION REQUIREMENT AND SHALL NOT BE INTERPRETED AS THE

3. ALL DUCTWORK DIMENSIONS, SHOWN ON THE DRAWINGS, ARE

INTERNAL CLEAR DIMENSIONS AND DUCT SIZES SHALL BE INCREASED

4. PROVIDE ACCESS DOORS IN DUCTWORK TO PROVIDE ACCESS

FOR ALL SMOKE DETECTORS, FIRE DAMPERS, SMOKE DAMPERS,

VOLUME DAMPERS, HEATING COILS, AND OTHER ITEMS LOCATED IN

THE DUCTWORK WHICH REQUIRE SERVICE AND/OR INSPECTION.

6. ALL DUCTWORK SHALL BE COORDINATED WITH ALL TRADES

5. DUCT SMOKE DETECTORS SHALL BE FURNISHED AND WIRED BY

THE ELECTRICAL CONTRACTOR. THE MECHANICAL CONTRACTOR

SHALL BE RESPONSIBLE FOR MOUNTING THE SMOKE DETECTOR

IN DUCTWORK AS SHOWN ON THE DRAWINGS AND IN ACCORDANCE

TRANSITIONS AROUND OBSTRUCTIONS, SHALL BE PROVIDED AT NO

INVOLVED. OFFSETS IN DUCTS, INCLUDING DIVIDED DUCTS AND

ADDITIONAL COST TO THE OWNER.

EXTENT OF THE REQUIREMENT FOR THESE ITEMS.

TO COMPENSATE FOR DUCT USING THICKNESS.

WITH MANUFACTURER'S PRINTED INSTRUCTIONS.

1. PROVIDE ALL MATERIALS AND EQUIPMENT AND PERFORM ALL

LABOR REQUIRED TO INSTALL COMPLETE AN OPERABLE HVAC

SYSTEMS AS INDICATED ON THE DRAWINGS, AS SPECIFIED AND

2. CERTAIN ITEMS SUCH AS RISES AND DROPS IN DUCTWORK,

MECHANICAL GENERAL NOTES

AS REQUIRED BY CODE.

7. ALL KITCHEN EXHAUST DUCTWORK SHALL BE 10 GAUGE BLACK-IRON

RATED INSULATION.

WITH WELDED JOINTS AND SEAMS AND INSULATED WITH A TWO-HOUR

8. FINAL CONNECTIONS TO EXHAUST HOOD SHALL FIELD COORDINATED

WITH APPROVED SHOP DRAWINGS. (TYP FOR ALL SUPPLY AND MAKE-

UP AIR CONNECTIONS.

G

8X6 KITCHEN EXHAUST

DUCT (TYP. FOR 4)

6X6 TOILET EXHAUST

DUCT

GRAVITY DAMPER

TX-1

NEW FANTECH CEILING

TOILET EXHAUST (150CFM)

20 X 14

EXISTING TOILET

EXHAUST TO REMAIN

(TYP. FOR 4)

16X16 UPTO KE-1

(2800 CFM)

C.O.

C.O. C.O.

14"Ø MUA FROM FAN

(2000 CFM)

EDH-1

6KW

EXISTING

FLUE

2

6

5

4

3

RELOCATE EXISTING

DUCTS AS REQUIRED

TO ALLOW FOR

KITCHEN EXHAUST

INSTALLATION

8X6 AT 6'-0"

AFF

HW BASE BOARD

EXISTING

FURNACE

20 X 8

seal & signature

dwg title

twig

cadd

checked by

issue date

AS NOTED

drawn by

02/11/2011

project no.

dwg. no.

scale

cad file

t10-12-0230

375 Beach 92nd StreetQueens, NY 11693

SUBMISSIONS

DATE rev no issue

project

project

375 Beach 92nd StreetQueens, NY 11693

architect

231 West 29th Street - Suite 606, New York, NY 10001

Tel: 212 . 967 . TWIG / Fax: 212 . 967 . 8945

[email protected] www.twigcon.com

A Division of The Wall Consulting Group, Inc. All Rights Reserved. 2007- 2010©

375 Beach 92nd Street M-301.00.dwg

NYC dob#

sheetTHESE PLANS ARE APPROVED ONLY FOR THE WORK ON THE

BEING APPROVED OR IN ACCORDANCE WITH APPLICABLE CODES.

APPLICATION SPECIFICATION SHEET. ALL OTHER MATTERS SHOWN

ARE NOT TO BE RELIED UPON OR TO BE CONSIDERED AS EITHER

All Drawings And Written Material Herein Constitute The Original And Unpublished Work Of The Wall Consulting Group, Inc. and/or TWIG Consulting Engineers, P.C., And The Same May Not Be Duplicated, Used, Or Disclosed Without The Written Consent Of The Wall Consulting Group, Inc. and/or TWIG Consulting Engineers, P.C. © 2011.

NYCECC NOTES:

TO THE BEST OF MY KNOWLEDGE, BELIEF AND

PROFESSIONAL JUDGMENT, THESE PLANS AND

SPECIFICATIONS ARE IN COMPLIANCE WITH THE

NEW YORK CITY ENERGY CONSERVATION CODE.

02.14.11 1 FILING & PRICING

GROUND FLOORMECHANICALPLAN & NOTES

6 of 8

(FIREMASTER ALTERNATE TO CALCIUM-SILICATE INSULATION)

GREASE DUCT ACCESS DOOR ENCLOSURE INSTALLATION

10

12

NOT TO SCALE

11

8

7

6

10

9

12

11

6

8

9

7

4

5

2

3

1/4" DIAMETER WING NUTS

FIREMASTER DUCT WRAP 1" OVERLAP

ALUMINUM TAPE AT EDGES

SPOOL PIECES FOR THREADED RODS

FIREMASTER DUCT WRAP 1" OVERLAP

FIREMASTER DUCT WRAP

SPEED CLIPS

NOT TO SCALE

FIREMASTER DUCT FLOOR/WALL THROUGH PENETRATION SYSTEM

(FIREMASTER ALTERNATE TO CALCIUM-SILICATE INSULATION)

1

3

2

5

4

INSULATION PINS - WELDED

ACCESS COVER - 16 GAUGE

1/4" DIAMETER ALL THREAD RODS

ACCESS FRAME WELDED TO DUCT

DOOR HOLE

4

5

3

A A1

CONCRETE SLAB

1/4" 3M FIRE BARRIER 2000+ SILICONE

4-1/4" FIREMASTER DUCT WRAP

TWO LAYERS FIREMASTER DUCT WRAP

1 DUCT

3

2

5

4

2

1. 2.

3. 4.

6. 7.

TWO REQUIRED FOR EACH SIDE

TWO REQUIRED FOR EACH SIDE

ROUND DUCT PATTERN

RECTANGULAR DUCT PATTERN

(FIREMASTER ALTERNATE TO CALCIUM-SILICATE INSULATION)

INSTALLATION DETAIL

TERMINATION OF DUCT WRAP AT HOOD LOCATION

NOT TO SCALE

2 1st LAYER FIREMASTER DUCT WRAP

1st LAYER TRANSITION PATTERN FIREMASTER DUCT WRAP

2nd LAYER TRANSITION PATTERN FIREMASTER DUCT WRAP

6 3" MINIMUM OVERLAP

7 BANDING

2nd LAYER FIREMASTER DUCT WRAP

4

5

3

1 HOOD

BAR STOCK 2"-3" WIDE, 1/8" THICK9

ANCHOR FASTENER SYSTEM8

3

DUCT SUPPORT

3

2

2

4

NOT TO SCALE

(FIREMASTER ALTERNATE TO CALCIUM-SILICATE INSULATION)

TYPICAL VERTICAL DUCT SUPPORT INSTALLATION DETAIL

ANGLE BRACKET

MECHANICAL FASTENERS & WASHERS3

DUCT4

TWO LAYER FIREMASTER DUCT WRAP

ONE LAYER FIREMASTER DUCT WRAP

1

2

RATED FLOOR5

KITCHEN ROOF EXHAUST FAN DETAIL

40

" M

IN

IM

UM

SEE SCHEDULES FOR SIZE

OF EXHAUST DUCT

CURB (18"HIGH)

PREFABRICATED ROOF

TO VENTILATED PEDESTAL

ANCHOR FAN SECURELY

HINGED SUB-BASE

SHEETROCK ENCLOSURE

SEE ARCHITECTURAL DRAWINGS

AND KITCHEN EXHAUST HOOD DETAILS

SIDES OF DUCT AND CURB.

3" MINIMUM AIR SPACE BETWEEN

CANT STRIP AS REQUIRED

16 GAUGE WELDED BLACK

RIGID INSULATION

STEEL EXHAUST DUCT

UPBLAST ROOF-MOUNTED

EXHAUST FAN WITH

BIRD SCREEN

NOT TO SCALE

16 GAUGE WELDED BLACK

KITCHEN EXHAUST HOOD DETAIL

6'-6" TO FINISHED FLOOR.

4'-0" MAX.

COOKING SURFACE.

, 2'-0" MIN. TO

CEILING LINE

STAINLESS STEEL ENCLOSURE

PANEL. ALL SIDES.

SPRINKLER CONTRACTOR

IN EXHAUST DUCT ABOVE

COLLAR, BY FIRE

GYPSUM BOARD 2 HR MINIMUM

SEE ARCHITECTURAL

FIRE RATED ENCLOSURE

FIRE SPRINKLER HEAD

DRAWINGS.

STEEL GREASE DUCT

AIR SPACE.

DUCT. (TYP.)

12"x12" MINIMUM ACCESS

PANEL BOTH SIDES OF

FIRE SPRINKLER HEAD

IN EXHAUST DUCT BELOW

ROOF DECK, BY FIRE

SPRINKLER CONTRACTOR

(3" MIN., 12" MAX.)

VENTILATED CURB. SEE DETAIL.

UPBLAST ROOF EXHAUST FAN WITH

COOKING SURFACE

ON ALL OPEN SIDES

OF COOKING SURFACE

6" MINIMUM OVERHANG

SUPPRESSION SYSTEM

BOLT TO METAL STUDS AND TO

EXHAUST HOODS. FULL LENGTH

CHANNEL SEISMIC BRACING

FLASH SOLID (16 GAUGE MIN.)

3" AIR SPACE. ALL SIDES

STAINLESS STEEL PANEL. ALL

SIDES. RUN TO TOP OF TILE

FOR DIMENSIONS

EXHAUST HOOD

SEE SCHEDULES

SHALL BE INSTALLED IN

ACCORDANCE WITH NFPA 96.

3. PROVIDE ACCESS OPENING

OPPOSITE DUCT ACCESS

DOORS, IN RATED ENCLOSURE.

ACCESS DOORS TO MATCH

ENCLOSURE IN FIRE

PROTECTIVE RATING.

AUTOMATIC WET CHEMICAL FIRE

KITCHEN EXHAUST HOOD

SHALL BE I.C.B.O. AND

ENDS FOR SEISMIC BRACING.

BOLT TO ROOF STRUCTURE

AND TO EXHAUST HOOD.

(4 PER HOOD, 1 AT EACH

INTAKE OR PARAPET.

ROOF LINE

10'-0" MINIMUM FROM

ADJACENT BUILDING,

PROPERTY LINE, AIR

1/2" ROD WITH THREADED

MAX.

SIDE

HANGER

HORIZONTAL

SUPPORT ANGLE

MAXIMUM

SPACING

HANGER SIZES FOR RECTANGULAR DUCT

30"

36"

48"

60"

84"

1" X 18" GAGE STRAP

1/4" ROUND ROD

1/4" ROUND ROD

5/16" ROUND ROD

3/8" ROUND ROD

1 1/2" X 1 1/2" X 1/8"

2" X 2" X 1/8"

2" X 2" X 1/8"

2" X 2" X 1/8"

NONE REQUIRED 10'-0"

8'-0"

8'-0"

8'-0"

8'-0"

HANGER STRAPS

NO POP RIVETS ALLOWED

SELF TAPPING CADMIUM PLATED HEX HEAD

SHEET METAL SCREW STRAPS TO BE TIGHT

AGAINST DUCT.

TOP CHORD OF

TRUSS

DUCT STRAP HANGER DETAIL

1"

NOT TO SCALE

5.NOT TO SCALE

seal & signature

dwg title

twig

cadd

checked by

issue date

AS NOTED

drawn by

02/11/2011

project no.

dwg. no.

scale

cad file

t10-12-0230

375 Beach 92nd StreetQueens, NY 11693

SUBMISSIONS

DATE rev no issue

project

project

375 Beach 92nd StreetQueens, NY 11693

architect

231 West 29th Street - Suite 606, New York, NY 10001

Tel: 212 . 967 . TWIG / Fax: 212 . 967 . 8945

[email protected] www.twigcon.com