Governing,ignition system,fire order

-

Upload

prof-jignesh-sohaliya -

Category

Documents

-

view

227 -

download

0

Transcript of Governing,ignition system,fire order

-

8/12/2019 Governing,ignition system,fire order

1/33

GOVER

PROF. JIGNE

-

8/12/2019 Governing,ignition system,fire order

2/33

GOVERNING OF I.C ENGINES

1. Qualitative governing

2. Quantitative governing

3. Hit & miss governing

QUALITATIVE GOVERNING

The amount of air taken inside is constant., but the fuel supply varies according to

Quality of air-fuel mixture changes as per the amount of the fuel supply.

So method is known as quality method.

C.I engine works on qualitative governing.

QUANTITY GOVERNING METHOD

Another name is throttle governing.

Used in petrol & gas engine.

This method varies the fuel & air mixture supplied to cylinder.

Quality of mixture remains same.

-

8/12/2019 Governing,ignition system,fire order

3/33

HIT & MISS GOVERNING

In this type of governingthe fuel supply is stopped

for one or more cycle when the engine speed

increases.

By stopping the fuel supply CRANKSHAFT SPEED

BECOME NORMAL. LEVER CARRIES STRIKER which STRIKES THE STEEL

DIEat the normal speed due to rotation of cam. So

the steel die strikes the plunger of fuel pump or gas

valve. This cycle is known as HITTING.

During This Cycle Fuel Is Supplied To The Engine By

Fuel Pump Or By The Gas Valve In Case Of GasEngines.

When Engine Speed Increases, The Lever With Drop

Rod Moves In Upward Direction Due To The Upward

Movement Of The Sleeve.

So The Striker Will Not Strike The Plunger Through

The Steel Die & No Fuel Will Be Supplied During This

Cycle. This cycle is known as MISSING CYCLE.

-

8/12/2019 Governing,ignition system,fire order

4/33

-

8/12/2019 Governing,ignition system,fire order

5/33

BATTERY IGNITION

Battery

It is charged by generator or alternator when engine

is in running.

Required electrical energy for functioning the

system is provided by battery of 6 to 12 volts.

lead acid battery & alkaline batteries are suitable for

i.c. engine.

Ignition switch

To turn on off the power supply from battery to

ignition system.Ignition coil

Primary winding 100 to 200 turns.

Secondary winding 10,000 turns.

Ballast resistor is connected in series with primary

winding to regulate the primary current.

-

8/12/2019 Governing,ignition system,fire order

6/33

Cam & contact breaker

Through the cam shaft on which the cam is used to

brake & make contact between contact point.

Breaker point are closed electric current flows.

Condenser (capacitor) Condenser remains in parallel with contact breaker.

If condenser is not provided, the current would be

re-established which would results into heavy arc

across the contact breaker points & energy of

ignition coil will be consumed by the arc which may

be burn the contact breaker point.

Distributor

Arm is mounted on a cam shaft & it is rotated at the

half speed of the crank shaft in case of 4 ST engine.

Function is to distribute the current which comes

from ignition coil to individual spark plug according

to firing order.

-

8/12/2019 Governing,ignition system,fire order

7/33

Ignition switch is on & primary circuit is closed by contact

breaker & magnetise the core of the coil & E.M.F. is

produced in secondary circuit.

Condenser is connected across contact breaker in primary

circuit which helps to collapse the field very rapidly byabsorbing part of energy.

Which is thrown back to primary winding & producing

very high voltage (10000v to 20000v ) in secondary .

When contact breaker is open & closed & every time high

voltage generated which is distributed by distributor.

-

8/12/2019 Governing,ignition system,fire order

8/33

MAGNETO IGNITION SYSTEM

Magnetos Were Used On The Small Engine's

Ancestor, The Stationary "Hit And Miss"

Engine Which Was Used In The Early

Twentieth Century. Motor Cycle, Scooter.

Magneto Ignition System Has Its Own CurrentGenerating Device, Therefore Battery Is Not

Required.

Magneto Rotates Voltage Is Generated In The

Primary Circuit.

As The Cam Shaft Rotates, The Cam Opens The

Contact Breaker & Interrupts The Flow Of

Current In A Primary.

This Cause The Decay In The Magnetic Field

Lines & Cut The Lines Of Magnetic Field In The

Secondary, & High Voltage Is Generated In The

Secondary.

L C ONIC IGNI ION SYS

-

8/12/2019 Governing,ignition system,fire order

9/33

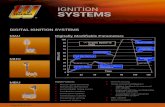

ELECTRONIC IGNITION SYSTEM

Now a days mechanical operated system are changing to electronically operated system

maintenance is low.

Limitations of battery & magneto ignition system

1. Excessive wear at contact breaker

2. If the gap between contact breaker points changes , it will affect the current generation.

3. Interruption of carbon particles between the contact point will affect the engine performa

ELECTRONIC IGNITION SYSTEM

1. Transistorised coil ignition system

2. High voltage capacitive discharge ignition system

-

8/12/2019 Governing,ignition system,fire order

10/33

TRANSISTORISED COIL IGNITION SYSTEM

In almost modern automobile, the conventional battery

system is replaced by Transistorised coil ignition system.

This system provided handling the increasing voltage

required for high performance of the engines, longer

sparkplug life, reduced wear, maintanace of ignitionsystem & high reliable.

Working

Contact points are connected to the base of transistor

which is further connected to primary circuit.

Contact point is reduced to approximate 1/10th

of theoriginal value of conventional system.

Emitter of the transistor is connected to ignition coil

through ballast resistor & collector to battery.

Base circuit current being much smaller as compared to

primary current

-

8/12/2019 Governing,ignition system,fire order

11/33

HIGH VOLTAGE CAPACITIVE DISCHARGE IGNITION SYS

CAPACITOR Discharge Ignition System (CDI)

Dc To Dc Convertor Is Used To Conver 12v Of

Battery To 500v.

Condenser Is Charged To This Output Voltage

Of The Converter Through The Charging

Resistance.

Resistance Is So Designed That It Controls

The Required Current In The Silicon

Controlled Rectifier(SCR).

The Condenser Is Discharged When The SCR

Triggering Device Sends The Pulse &

Producing High Voltage In Secondary Circuit.

SPARK PLUG

-

8/12/2019 Governing,ignition system,fire order

12/33

SPARK PLUG

It Consist Two Electrodes With A Proper Gap About

1mm.

Electrodes Are Subjected To High Corrosion &

Erosion So It Is Made From High Nickel Alloy.

Tip Of The Electrode Are Subjected To Very High

Temperature In Order Of 2000-2400 C.

Depending Upon The Temp. Of Tip The Spark Plug

Are Classified

1. Hot Spark Plug

2. Cold Spark Plug

-

8/12/2019 Governing,ignition system,fire order

13/33

CENTRIFUGAL

SPARK

ADVANCE

MECHANISM

-

8/12/2019 Governing,ignition system,fire order

14/33

CENTRIFUGALSPARKADVANCEMECHANISM

It Consist Of Spring Loaded Weights Mounted

On A Platform & Connected To The Contact

Breaker Cam.

Platform Gets Rotating Motion From Cam Shaft

As It Is Connected With Cam Shaft Of Engine.

Fly Weights Are Connect With Platform Only By

Pivot.

Speed Increases Fly Weight To Move

Outward Which Alters The Ignition Timing As

Per Requirement.

VACUUM ADVANCE MECHANISM

-

8/12/2019 Governing,ignition system,fire order

15/33

VACUUM ADVANCE MECHANISM

Intensity Of Vacuum At Ventury Tube Is Vary

With The Position Of Throttle.

In Idling Position , There Is No Vacuum

Advance.

As Soon As The Throttle Valve Open, It SwingsThe Past Opening Of Vacuum Passage.

This Cause Diaphragm To Move Against

Spring.

Linkages To The Breaker Plate Than Rotate

The Breaker Plate.

This Movement Create A Contact Between

Contact Point. Due To Movement Of Contact Point , Cam Is

Also Displaced .

Supply Spark At The Spark Plug Earlier In The

Compression Stroke.

FIRING ORDER FOR I C ENGINES

-

8/12/2019 Governing,ignition system,fire order

16/33

FIRING ORDER FOR I.C ENGINES.

The Main Factor For Deciding The Order Of Firing, The Engine Cylinder Are Balancing Of

Reduce Vibration, Engine Cooling & The Development Of Back Pressure.

If The Firing Order Is Kept 1-2-3-4 The Exhaust Of The Cylinder 2 Will Overlap With The Exha

It Would Be Need Size Of Exhaust Pipe Bigger In Size Otherwise The Back Pressure On Th

Increase & Reducing Net Output.

Firing Order Is 1-3-4-2 Or 1-2-4-3.

1-3-4-2 Is Common Used.

For Six Cylinder 1-5-3-6-2-4, 1-5-4-6-2-3, 1-2-4-6-5-3, 1-2-3-6-5-4

1-5-3-6-2-4 Is Common Used.

INTAKE & EXHAUST SYSTEM

-

8/12/2019 Governing,ignition system,fire order

17/33

INTAKE & EXHAUST SYSTEM

In S.I engine PETROL + AIR

In C.I engine only AIR

The size, shape & orientation of intake manifold is

designed such that there is a smooth flow of mixture or

air.

It will improve volumetric efficiency & power output.

INTAKE & EXHAUST SYSTEM FOR S.I ENGINE

-

8/12/2019 Governing,ignition system,fire order

18/33

INTAKE & EXHAUST SYSTEM FOR S.I ENGINE

AIR + fuel mixture from carburetor.

Partially evaporated fuel & air with high

velocity passes through the intake manifold

& than reach to suction valve of cylinder.

Sometimes Liquid May Be Condenseon thesurface of intake manifold &reduces their

heat transfer.

So for better vaporization of fuel intake

manifold is heated.

it provided byexhaust gases& this purpose

mostly intake & exhaust manifold hascommon wall.

Overheating of the intake manifold will

reduces volumetric efficiency & power

output.

Inner surface of intake manifold kept

smooth so that friction during flow reduces.

-

8/12/2019 Governing,ignition system,fire order

19/33

In Multi Cylinder Engine The Design Of The

-

8/12/2019 Governing,ignition system,fire order

20/33

y g g

Intake Manifold Become Very Important In

Order To Reduce Inertia Effect & To Make

Distribution Of ChargeTo All Cylinder.

Parameters should be consider for designing

1. Inlet surface should be smooth so that

pressure losses are minimum.

2. Air-fuel mixture should be distribute

uniformly.

3. For max. vaporization of fuel, intake

manifold should be heated by exhaust gases.

4. Condensation of fuel should not take place

during the flow.

Exhaust Gases Are Useless.

-

8/12/2019 Governing,ignition system,fire order

21/33

The Passage Or Pipe Through Which Exhaust

Gases Come Out Is Known As Exhaust

Manifold.

Main Components

1. Exhaust Manifold

2. Muffler (Silencer)

3. Tail Pipe Muffler It Reduces The Noise Level Of

Exhaust System.

In Modern Vehicle Gas Converter Is Also

Attached Which ConvertsHarmful Gases To

HarmlessExhaust Gases.

Parameter considered for designing

1. Passage should be smooth & withminimum obstruction to reduce the back

pressure.

2. Proper design of muffler.

3. Gases should quickly discharge.

4. For multi cylinder, more braches to avoid

overlapping.

-

8/12/2019 Governing,ignition system,fire order

22/33

SCAVENGING SYSTEM

-

8/12/2019 Governing,ignition system,fire order

23/33

SCAVENGING SYSTEM

The compressed charge passes through transfer

port into the engine cylinder flushing the

products of combustion. This process is known as

scavenging process.

Based on direction of flow of fresh charge &exhaust gases, scavenging methods

1. Cross scavenging

2. Loop or reverse scavenging

a. Full loop or MAN scavenging

b. Tangential loop

c. Curtis scavenging

3. Uniflow scavenging

CROSS SCAVENGING

-

8/12/2019 Governing,ignition system,fire order

24/33

CROSS SCAVENGING

In cross scavenging the incoming air is directed

upwards, pushing the exhaust gases before it. The exhaust gases then travel down and out of

the exhaust ports. Figure above illustrates the

process.

Used for low capacity 2 stroke engine.

Inlet & exhaust port are replaced opposite to eachother.

Deflector is provided on piston top.

LOOP SCAVENGING

-

8/12/2019 Governing,ignition system,fire order

25/33

LOOP SCAVENGING

In this method flow of fresh charge makes a loop

for better removal of exhaust.

Incoming charge is directed in such a way that

both charge loss & mixing are minimized.

In loop scavenging the incoming air passes over

the piston crown then rises towards the cylinder

head.

The exhaust gases are forced before the air

passing down and out of exhaust ports located

just above the inlet ports.

UNIFLOW SCAVENGING

-

8/12/2019 Governing,ignition system,fire order

26/33

UNIFLOW SCAVENGING

With uniflow scavenging the incoming air enters at

the lower end of the cylinder and leaves at the top.

The outlet at the top of the cylinder may be ports or

a large valve.

-

8/12/2019 Governing,ignition system,fire order

27/33

Each Of The Systems Has Various Advantages And Disadvantages.

Cross Scavenging Requires The Fitting Of A Piston Skirt To Prevent Air Or Exhaust Gas Esca

At The Top Of The Stroke.

Loop Scavenge Arrangements Have Low Temperature Air And High Temperature Exhaus

Adjacent Ports, Causing Temperature Differential Problems For The Liner Material.

Uniflow Is The Most Efficient Scavenging System But Requires Either An Opposed Pisto

Exhaust Valve In The Cylinder Head.

All Three Systems Have The Ports Angled To Swirl The Incoming Air And Direct It In The App

-

8/12/2019 Governing,ignition system,fire order

28/33

CRANK CASE SCAVENGING

-

8/12/2019 Governing,ignition system,fire order

29/33

CRANK CASE SCAVENGING

ROOT BLOWER

-

8/12/2019 Governing,ignition system,fire order

30/33

ROOT BLOWER

CENTRIFUGAL BLOWER

-

8/12/2019 Governing,ignition system,fire order

31/33

CENTRIFUGAL BLOWER

-

8/12/2019 Governing,ignition system,fire order

32/33

PISTON TYPE BLOWER

-

8/12/2019 Governing,ignition system,fire order

33/33

TH NK YOU