Fibreglass Pipelines

Transcript of Fibreglass Pipelines

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 1 of 48

Fibreglass Pipeline Materials for AS 2885

This paper addresses the need for an appropriate inclusion of Glass Reinforced Plastic (GRP)materials in AS 2885 and suggests how this might be achieved.

2 : 1 line0 0

259.35 129.675

Short Term Envelope (based on lcl values) Long Term Envelope Factored with fscale (Qualified Envelope)σsa(2:1) σqs

Hoop Axial Definition Hoop Axial Definition222.3 0 Ssh 2:1 142.2 0222.3 111.15 Ssa 2:1 142.2 71.10222.3 111.15 Ssa 2:1 142.2 71.10

0 75.2 Ssa 0:1 0.0 48.10

Longt Term Envelope Factored with A0, A1,A2,A3 Long Term Envelope Factored with f2σqf σdes, max

Hoop Axial Definition Hoop Axial Definition129.0 0 86.4 0129.0 64.5 86.4 43.2129.0 64.5 86.4 43.20.0 43.6 0.0 29.2

With Design Pressure Known Short Term Mean Axial Stress Short Term Mean Hoop Stress Long Term Mean Hoop Stressσdes STAS STHS LTHSHoop Axial Hoop Axial Hoop Axial Hoop Axial

50.19 25.09 0 78.5 247.0 0 148.9 050.19 0 247.0 123.5 148.9 74.4550.19 37.35

Design Allowablesσh, sum max allowable hoop stress 86.41 MPaσdex, max max allowable axial stress (pressure only) 43.21 MPaσhp design hoop stress due to pressure 50.19 MPaσap design axial stress due to pressure 25.09 MPaσdes(0:1) max allowable axial stress (unpressurised) 29.23 MPaσa, allow design allowable axial stress 37.35 MPaσab axial stress from sources other that pressure 12.25 MPa

2:1

σsa(2:1)

σsh(2:1)

σsa(0:1)σal(2:1)

σal(0:1)

σqs

σaf(2:1)

σfs

σaf(0:1)

σa,des (0:1)

σh,des

σa,des (2:1)

σab

σap

σh,sum STHSLTHS

STAS

Hoop Tensile Stress (MPa)

Axi

alTe

nsile

Stre

ss(M

Pa)

fscale

A0,A1,A2,A3

f2

f3

1a

2

3

4

5 σa, sum

KEY1 schematic representation of the short-term failure envelope2 idealized short-term failure envelope3 qualified long-term failure envelope at standard conditions4 factored qualified long-term failure envelope at project conditions5 long term design envelope

a For design Purposes, the shape should be based on actual measured data points

Note:i) σsa(2:1) is the 97.5% lower confidence level result obtained in accordance with ASTM D1599 testingii) σsa(0:1) is the 97.5% lower confidence level result obtained in accordance with ASTM D2105 testingiii) σal(2:1) is the 97.5% lower confidence level result obtained in accordance with ASTM D2992 testing

1b

f1

f1

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 2 of 48

TABLE OF CONTENTS:

1 Introduction ...................................................................................................................................... 3

2 Background ...................................................................................................................................... 32.1 GRP for Australian Pipelines ................................................................................................... 4

2.1.1 Difficult Services ........................................................................................................ 42.1.2 Whole of Life Solutions .............................................................................................. 42.1.3 Applications................................................................................................................ 4

2.2 GRP Material and Availability .................................................................................................. 52.2.1 History........................................................................................................................ 52.2.2 Engineering Material .................................................................................................. 52.2.3 Availability .................................................................................................................. 6

2.3 GRP Inclusion in AS 2885 ....................................................................................................... 62.3.1 AS 2885-1 - 1997 Current Issue ................................................................................ 62.3.2 AS 2885 DRAFT ........................................................................................................ 72.3.3 AS 2885 Future.......................................................................................................... 7

3 Technical Considerations ............................................................................................................... 93.1 GRP Pipe Manufacture ............................................................................................................ 9

3.1.1 ISO 14692 Part 2....................................................................................................... 93.1.2 API 15 HR Specification for High Pressure Fiberglass Line Pipe – 2001 ................. 93.1.3 API 15LR - Specification for Low Pressure Fiberglass Line Pipe – 1990 ............... 103.1.4 ASTM D 2992, D 1599, D 2105 and D 3567 ........................................................... 103.1.5 Manufacturing Issues............................................................................................... 10

3.2 GRP Design Standards.......................................................................................................... 113.2.1 Why AS 2885 ........................................................................................................... 113.2.2 Why API 15 HR........................................................................................................ 123.2.3 Why ISO 14692 Part 3............................................................................................. 14

3.3 GRP Design Methodology ..................................................................................................... 183.3.1 Outstanding Issues .................................................................................................. 213.3.2 GRP Design Outcomes ........................................................................................... 21

3.4 GRP Installation ..................................................................................................................... 223.4.1 ISO 14692 Part 4 ..................................................................................................... 223.4.2 Field Fit vs Installation Tolerance ............................................................................ 233.4.3 Non Standard Components vs Standard Pipeline Crews........................................ 233.4.4 Handling and Assembly Methods ............................................................................ 243.4.5 Repairs, Modifications and Tie-Ins .......................................................................... 24

4 Proposed AS 2885 Revisions........................................................................................................ 25

5 Proposed ISO 14692 Revisions .................................................................................................... 285.1 Part 1: Vocabulary, Symbols, Applications and Materials ..................................................... 285.2 Part 2: Qualification and Manufacture ................................................................................... 305.3 Part 3: System Design ........................................................................................................... 335.4 Part 4: Fabrication, Installation and Operation ...................................................................... 38

6 Suggested Further Works ............................................................................................................. 39

7 Reference Material ......................................................................................................................... 41

APPENDIX A: – GRE DESIGN OUTCOMES............................................................................................ 43

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 3 of 48

1 INTRODUCTIONComposite Glass Reinforced Plastic (GRP) has properties of significant benefit for high pressurepipelines in corrosive services where it can have significantly lower operating costs (OPEX) than steelpipe. Recent changes are seeing GRP pipe also compete with steel pipe on installed cost (CAPEX). As aresult its use in Australian pipelines is expected to increase in both corrosive and non-corrosive services.

AS 2885 currently allows GRP as an “alternative material” but otherwise provides little guidance for itsapplication. This paper addresses the need for an appropriate inclusion of GRP materials in AS 2885 andsuggests how this might be achieved.

The paper identifies a number of outstanding issues which will need to be addressed for GRP to bewidely accepted by regulators, designers, constructors and owners as an AS 2885 pipeline material.Pipeline industry and peer input to the subject are essential to manage the risks inherent with theintroduction of this “new” material and the benefits it can bring to the industry.

2 BACKGROUNDGlass Reinforced Epoxy (GRE) pipe is finding increasing use in Australian high pressure pipelines yet thismaterial is not well addressed by the applicable Standards. As a consequence the regulatory frameworkand technical requirements for its use are not clear. The current AS 2885.1 Draft includes limitedreferences to GRP and applicable Standards for pipe manufacture and design. Further detail is necessaryto address the inclusion of GRP material as a real alternative for Australian pipelines and to provideguidance to manage the risks associated with its use on pipelines.

Petroleum pipelines in Australia rely heavily on AS 2885 which aims to be the “single and sufficient”Standard for high pressure pipeline design, construction and operation. For GRP to be an acceptedcomponent of this industry it is necessary to establish appropriate technical requirements for this material.Such requirements should demonstrably “meet the intent of AS 2885” which currently includes wellestablished and detailed criteria for steel pipelines.

Several specifications for GRP have been considered for this purpose including ASME B31.3 Section VII,API 15LR, API 15HR, UKOOA Specifications and Recommended Practices, Shell DEP 31.38.70.24 andISO 14692 (developed from the UKOOA specifications and the Shell DEP). ISO 14692 and other relatedStandards have been proposed and are now included in the AS 2885.1 Draft to form the basis of asuitable technical framework.

The pipe material considered by this paper for pipeline use is a continuous glass filament roving, spiralwound onto a mandrel and impregnated with suitably catalysed epoxy resin filler. The pipe typically hasmale–female threaded ends in accordance with API RP 5B which are assembled with a lubricant/sealant.This does not exclude the use of other GRP pipe materials from use on pipelines.

With GRP application to hydrocarbon pipelines possible from production well flowlines right through todistribution networks the regulatory path which enables the use of GRP in each application needs to beestablished and clear. The regulatory framework for petroleum pipelines in Australia is enabled viavarious State Acts and Regulations and within the individual Licenses issued by the RegulatoryAuthorities. In many cases the regulatory path to AS 2885 is incomplete. For example, productionflowlines, distribution system pipelines and consumer pipelines are excluded from the WA PetroleumPipelines Act and AS 2885 is not listed in the WA Petroleum Pipelines Regulations. AS 2885 may in factbe the most suitable standard for these pipelines but the Regulator must include AS 2885 in the Licenseconditions to complete the regulatory path.

The application of GRP to high pressure pipelines already extends to services other than petroleum andhighlights an issue that also affects a growing number of steel pipelines. AS 2885 currently can only beapplied to “petroleum” product pipelines yet is has already been identified as a Standard of choice forother services. Changes to AS 2885 to allow for its use in non petroleum services would help inauthenticating its application to these pipelines. Inclusion of AS 2885 in the License conditions wouldagain be required.

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 4 of 48

2.1 GRP for Australian Pipelines

2.1.1 Difficult ServicesGRP is particularly suited to corrosive services such as well production fluids, waterflood, water disposaland wet or sour gas where it’s almost complete resistance to corrosion has great benefit. It is one of veryfew materials able to provide this benefit in high pressure services.

GRP material is also resistant to external corrosion so does not require high quality coating systems,impressed current or anodic corrosion prevention systems or regular DCVG surveys. This also makesGRP suited to locations with difficult CP conditions such as adjacent to other pipelines or structures, or inhighly inductive locations such as beneath HV power transmission lines.

GRE can be used, with due care, at temperatures down to -40°C and up to 95°C.

The ability for GRP to provide a leak and emission free for life installation in sensitive areas with toughenvironmental restrictions is a distinct advantage over aging carbon steel systems which may have ahistory of leaks. The lightweight GRP material can also provide for a low installation footprint as fewer andlighter weight machines are required. In particularly sensitive areas the pipes may be hand carried andassembled.

2.1.2 Whole of Life SolutionsWith careful design and despite the difficult services GRP can provide a leak free, system for in excess of20 years. In many applications this constitutes a near maintenance free whole of life solution. For othermaterials special coatings, tight quality assurance measures, continuous corrosion protection, regularinspections, pigging surveys, high maintenance and eventually replacement may be necessary for thepipeline to last this long.

Achieving such a whole of life outcome does, however, require a level of excellence in materials,manufacture, shipping, design, installation, inspection, testing and maintenance at a level comparablewith that required by AS 2885 for steel pipelines. Without sufficient care at each step GRP pipelines canand do experience failures.

GRP pipelines have long been seen as requiring high initial CAPEX expenditure but low levels of ongoingOPEX. This has often lead to GRP showing a better whole of life cost in some services. Recent changesin pricing of steel, the high demand and low availability of pipe steels and a tight market for skilledtradespeople are making even the installed cost for GRP pipelines competitive with steel.

2.1.3 ApplicationsCurrent GRP pipeline applications in Australia include hydrocarbon production flowlines, field gatheringsystems, produced water handling/disposal and waterflood systems. This covers a large part of oilfieldinfield pipelines of all production fluids with the exception of gas. While there is limited evidence of GRPpipelines carrying high pressure dry sweet gas there are several installations that have been in service forseveral years carrying wet or sour gas at high pressure. In some markets regulatory limitations have beenapplied to the use of GRP for high pressure gas transportation.

Well Fluids, Wet Gas, Sour Gas, Waterflood, Produced Water and Corrosive Fluids are obvious servicesfor GRP when these need to be carried over distances at high pressures. In many cases GRE hasbecome the material of choice when transporting liquids within the oilfield.

In Australia these pipelines are typically non-registered pipelines as they remain within the oilfieldproduction licence area. Many have used AS 2885 as the governing standard either by direction of theRegulator or by choice. With many of these pipelines unregistered and so lightly regulated GRP has hada low relatively profile with Government Regulators.

Tightening environmental requirements, risk management processes and changing material prices areexpected to lead to increased utilisation of GRP materials. The growth can be expected in the currentservice areas and through expansion into new areas. This will inevitably lead to increased application ofGRP on registered pipelines and the possibility of service on;

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 5 of 48

Coal Seam Methane (CSM) and Coal Mine Methane (CMM) where GRP offers the prospect ofhigh pressure gas gathering pipelines from widely spaced infield production manifolds tocentralised gas treatment facilities.

Gas pipeline laterals where the deletion of corrosion protection, low labour skill levels and quickinstallation provides significant benefit.

Consumer gas pipelines within lease areas where the pipeline maintenance skills do not existand cannot be justified.

Gas distribution network headers where pressures higher than the 1050 kPa limit for HDPE andPVC are required and effective CP can be difficult to implement.

Fuel and other hydrocarbon product pipelines from refineries and tank farms where highenvironmental requirements and difficult CP conditions may exist.

Gas transmission pipeline use is unlikely for now because the fluid is typically dry and sweet.GRP may, however, find use in short difficult sections such as beneath HV power transmissionlines where it might enable the pipeline to share the power corridor.

2.2 GRP Material and Availability

2.2.1 HistoryGRP pipe has been around for 30 plus years with higher pressure continuous filament wound pipe nowreadily available for use at up to 10 MPa in the DN200 size.

GRE pipelines have been in use in the oil and gas industry for many years and particularly for infieldpipelines handling untreated oil/water/gas well fluids where the performance has proven to be veryeffective for these often corrosive applications.

High pressure GRE Pipelines have been used in Australia for around 20 years with around 1,200 kmexpected to be in service by the end of this year.

2.2.2 Engineering MaterialGRE pipe for high pressure pipeline service typically uses a multi layer, dual direction, spiral wound,continuous glass filament roving in an epoxy laminate which is manufactured on a tapered steel mandrel.The joints for high pressure pipe are typically threaded male-female with or without o-rings and either castintegral with the pipe, machined onto the pipe end or moulded on to the pipe shell.

GRE pipeline materials have the glass strands wound at around a 60° included angle to intentionallyexhibit anisotropic elastic properties. The resulting hoop strength is much higher than the axial strengthwhich suits an unrestrained pipe under internal pressure where the hoop stress is naturally double theaxial stress. The pipe wall strength is in this way optimised to match the applied loads. Steel pipes beingclose to isotropic can accommodate higher axial loads but in most conditions this axial strength isunderutilised.

The male-female (M-F) threaded pipe joints are available in typically 9 m lengths and the female-female(F-F) pipe fittings are available in a range of elbow angles, tees and adaptors, including GRE flanges tomate with ASME B16.5 steel flanges. The fittings tend to be quite bulky and require male-male (M-M)nipples to make up with a pipe run. Threads are made up with a lubricating/jointing compound using turnof thread or torque to control the final tightness. Torque can be applied using hand tools for small sizes orwith a hydraulic tool for larger sizes. Thread sealing is achieved within the thread so o-rings are normallyrequired only to keep the threads clean.

The threaded joints make for quick assembly and high axial load capacity.

When changing direction at an elbow or tee it is not always convenient to do so at the end of a 10 mspool so heavy wall nipple stock and couplings are available which can be field threaded to accuratelylocate the fitting.

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 6 of 48

GRE pipe behaviour is entirely predictable making it a reliable engineering material. When loaded thematerial exhibits elastic stress/deformation behaviour up to an initial delamination failure followed muchlater by an eventual rupture in much the same way that steels exhibit yield then rupture. GRE materialstrength is significantly affected by the wall temperature and by the length of time exposed to stress.Under extreme pressure the pipe typically experiences weeping through the wall rather than catastrophicfailure. Pipe rupture is not, however, unknown under combined extremes of pressure, axial load andbending. It is therefore essential that these loads are limited by proper design and pipe restraint.

Physical properties of GRE pipe include;

Anisotropic – the elastic modulus and Poisson’s ratio in the hoop, axial and radial directions varysignificantly and must be properly accounted for in the design.

Elastic behaviour is linear and reversible within the allowable design range.

Strength and elastic properties vary with – glass type, resin type, catalyst type and winding angleallowing the pipe to be tailored for typical pipeline service.

The stress time dependant nature is easily predictable with regression curves available for eachpipe material enabling it to be designed for a required service life.

Temperature dependence of the material at elevated temperatures is established from testingand available for design purposes.

Cyclic loading affects the material strength with established design criteria available.

The affect of a wide range of chemical products on the strength of GRE has been establishedand is accounted for within the design.

2.2.3 AvailabilityGRE high pressure pipeline material is typically available in the following pressure-size ranges;

5 MPa DN40 through DN250 10 MPa DN40 through DN200 12 MPa DN40 through DN150 18 MPa DN40 through DN100

2.3 GRP Inclusion in AS 2885

2.3.1 AS 2885-1 - 1997 Current IssueWhile AS 2885 is specifically written for “steel” pipelines (Clause 1.1) alternative materials are notprohibited. Clause 1.4 - Departures From This Standard, allows the use of other materials and designsthat “…give equivalent or better results…”.

The Australian Standards ME 38 Committee, which is responsible for AS 2885, responded to question’sput to them at a 2003 Perth conference with the following advice:

GRE materials are currently being considered and are expected to be included in a later editionof AS 2885.

GRE materials may be used on current pipelines so long as appropriate Standards are used andthe design satisfies the fundamental principals of AS 2885.

Some apparent requirements of AS 2885 (e.g. Clause 4.3.8.7 Road and railway reserves) maynot be suitable for all applications. In these cases appropriate engineering by competent personsshould be used.

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 7 of 48

2.3.2 AS 2885 DRAFTA number of changes have already been incorporated in the current AS 2885 Draft in order to support theuse of GRP pipe material in Australian pipelines.

PREFACEo 5) Section 3 (Materials) The use of fibreglass and corrosion resistant alloy pipe

materials for pipelines constructed to this Standard is permitted and limited, in thisSection.

SECTION 1 SCOPE AND GENERAL1.1 SCOPE

o Where approved, this Standard may also be used for design and construction ofpipelines made with corrosion resistant alloy steels or fibreglass. Where this Standard isused for pipelines fabricated from these materials appropriate requirements shall beestablished to replace the provisions of this standard in relation to nominated standardsfor Materials (Section 3), Fracture Control (Section 4.8), Stress and Strain (Section 5.7)and Corrosion (Section 8) and the provisions of AS 2885.2 in relation to Welding and NonDestructive Examination. For fibreglass appropriate requirements shall be established toreplace the hydrostatic strength test endpoint provisions of AS2885.5.

SECTION 3 MATERIALS AND COMPONENTS3.2 QUALIFICATION OF MATERIALS AND COMPONENTS

o 3.2.2 Materials and components complying with nominated Standards

o (c) Fibreglass pipe .API 15LR, API 15HR or ISO 14692 Parts 1 and 2

o Note: Where this standard is used for pipelines constructed with Corrosion ResistantAlloy or fibreglass pipe, attention is drawn to the requirements of Clause 3.1.

SECTION 5 PIPELINE DESIGN5.1 BASIS OF SECTION

o NOTE: Where a pipeline is constructed from fibreglass material, ISO 14692 Part 3provides guidance on design procedures for this material.

o 5.5 EXTERNAL INTERFERENCE PROTECTION

o 5.5.5 Physical protection measures

o (b) Resistance to penetration - Resistance to penetration is a physical measure forprotection if the resistance to penetration is sufficient to make penetration improbable.NOTE: For fibreglass pipe resistance to penetration is not considered to be an effectivecontrol for most pipe that would be considered cost effective as an alternative to steel.

A2 REFERENCED DOCUMENTSo ISO 14692 Petroleum and Natural Gas Industries. Glass Reinforced Plastic Piping

o ISO 14692.1 Part 1: Petroleum and Natural Gas Industries

o ISO 14692.4 Part 4: Glass reinforced plastics (GRP)

2.3.3 AS 2885 FutureA further change has been proposed which would allow non petroleum pipelines to utilise AS 2885. Thiswould reflect the fact that it is already being adopted for services other than petroleum.

Additional references or corrections to standards applicable to GRP are suggested as follows;

o AS 2566 Buried Flexible Pipelines [has already been proposed for inclusion]

o ISO 14692 Part 1: Vocabulary, Symbols, Applications and Materials

Part 2: Qualification and Manufacture

Part 3: System Design

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 8 of 48

Part 4: Fabrication, Installation and Operation

o API 15HR High Pressure Fiberglass Line Pipe

o API 15LR Low Pressure Fiberglass Line Pipe

o ASTM D3567 Standard Practice for Determining Dimensions of Fiberglass Pipe andFittings

o ASTM D2992 Standard Practice for Obtaining Hydrostatic Design Basis for FiberglassPipe and Fittings

o ASTM D2105 Standard Test Method for Longitudinal Tensile Properties of FiberglassPipe and Tube

o ASTM D1599 Standard Test Method for Resistance to Short-Term Hydraulic Pressureof Plastic Pipe, Tubing and Fittings

A GRP Appendix may be required to adequately address issues that need to be considered outside of thereferenced standards.

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 9 of 48

3 TECHNICAL CONSIDERATIONS

3.1 GRP Pipe Manufacture

3.1.1 ISO 14692 Part 2ISO 14692 Part 2 is suitable as a manufacturing specification for line pipe materials to be used inAustralian pipelines.

Due to changed and more complex testing and qualification requirements (from the API15HR and LRrequirements) and the time required to carry out some tests this pipe is not currently as widely availableas the API 15HR and LR pipe. It is expected that ISO 14692 qualified pipe will be of a higher quality, dueto tougher quality requirements (than the API pipe) but is also likely to be more expensive.

A number of variations to the current ISO 14692 Part 2 Specification have been proposed by the author ofthis paper and are currently under review by the ISO TC 67/SC 6/WG 5 Committee. The proposedchanges are discussed later in this paper. The variations proposed to the current ISO 14692 Specificationinclude attempts to simplify, clarify and correct errors that exist in the current document.

It is recommended that the Optional Short Term Burst Tests of Clause 6.8.3 be called for and treated as abatch acceptance test per Clause 8.3.4 and as per the proposed variations.

3.1.2 API 15 HR Specification for High Pressure Fiberglass Line Pipe – 2001Cover pipes rated for 500 psi (3.45 MPa) to 5,000 psi (34.5 MPa) with mechanical connections.

This API specification has previously been used to select GRE line pipe and fittings materials for use inAustralian pipelines and to demonstrate compliance of the pipeline applications engineering. It is not,however, suitable for this second purpose.

1 Scope

1.1 Purpose

o 1.1.1 “…. to provide for the availability of ….. fibreglass line pipe.”

o 1.1.2 “….. provides requirements for performance, design, materials, tests andinspections, marking, handling, storage and shipping.”

This confirms that the purpose of the code is to set out requirements for design, manufacture and deliveryof the line pipe as an engineered product and not for the application design of pipelines.

API 15HR is suitable as a manufacturing specification for line pipe materials to be used in Australianpipelines. It does not provide guidance for the installation design of pipelines and therefore is not asuitable standard for pipeline design under AS 2885 in Australia.

Equation 1: Pr = Sf x Ss x (Ro^2 – Ri^2) / (Ro^2 + Ri^2) – thick wall method

Or Equation 2: [corrected to read] Pr = Sf x Ss x 2 x t / D – thin wall method

Where Sf = 0.67

are used to calculate the API 15HR Standard Pressure Rating Pr for a given pipe @ 20 yrs @ 150°F forsalt water which represents a maximum allowable pressure for straight buried pipelines under theseconditions only but subject to no other external loads.

API 15HR Pr with a Sf of 0.67 should not be used for the selection of the pipeline wall thickness as it doesnot take into account installation loads and stresses that can adversely affect the pipe and lead topremature failure. Appendix G already suggests some of the factors that are better dealt with by

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 10 of 48

ISO 14692. A pipeline design pressure may need to be well below the Pr pressure depending on theservice and installation conditions.

With a suitably modified design factor (determined by the installation designer) API 15HR appears to besuitable for the design and manufacture of the line pipe and fittings as a product.

ISO 14692 more closely meets the intent of AS2885 for both material design, manufacture andapplications design.

It is recommended that the API 15HR pipe design pressure or wall thickness and allowable stresses bedetermined in accordance with ISO 14692 and not API 15HR.

API 15 HR allows for the manufacture of line pipe either with or without the API logo applied. If the APIlogo is applied then all requirements of the Specification must be met. If the logo is not applied then it iscritical that all variations to the Specification are understood and accepted by the purchaser and thedesigner. Pipes with the API logo applied are likely to be more expensive than non certified pipe.

It is recommended that the Short Term Failure Pressure testing required by Clause 7.4.3 and used as abatch acceptance test as required by Clause 7.4.5 be retained. It is further recommended that these testsbe carried out to failure rather than terminated once the acceptance pressure is achieved. This ensuresthat the eventual failure mechanism is identified and is consistent for all pipes.

Additional testing requirements may be appropriate depending on the pipeline service (e.g. pneumaticleak testing of each product type and of samples from each batch may be appropriate for gas service).

3.1.3 API 15LR - Specification for Low Pressure Fiberglass Line Pipe – 1990Covers pipe from 150 psi (1.0 MPa) to 300 psi (2.1 MPa) and higher in sizes up to 16” (400 NPS).

API 15LR also appears to be suitable as a manufacturing specification for line pipe materials to be usedin Australian pipelines.

It should be noted that the API 15LR pipe pressure rating and allowable stresses should be determined inaccordance with ISO 14692 and not API 15LR.

3.1.4 ASTM D 2992, D 1599, D 2105 and D 3567These four ASTM Standards are common to the API and ISO Specifications and an inherent part of thepipe qualification and design processes. Unfortunately between the API, ISO and ASTM documentsminor variations in product measurements and formulas exist which result in significant confusion ininterpreting and applying test results to the pipes. The problems relate to the way the reinforced wallthickness and pipe diameter are determined and used in calculations which convert pressure to stressand back to pressure again. One result is that different manufacturers could arrive at different pressureratings for a similar pipe. The variations proposed to the current ISO 14692 Specification include anattempt to simplify and clarify how ASTM test pressure results should be converted to pipe wall stressesand these then converted back to design pressures. This should provide for a level playing field for allpipe manufacturers. It is therefore recommended that the methods outlined in this paper, as variations toISO 14692, be applied where appropriate, in place of those in the ASTM Standards.

3.1.5 Manufacturing IssuesThe tools and processes used to manufacture the pipe lengths have been developed over many yearsand vary between manufacturers. The methods used rely heavily on the manual skil ls of the workforcewith a slowly growing level of automation. Supervision, quality tracking and testing are used to identifyand minimise manufacturing issues. Some issues remain which can lead to substandard batches orindividual pipe lengths, a small number of which are considered below.

Wetting of the glass fibres can be incomplete and lead to gas escape or weeping failure. Visualexamination will usually identify this but it is much harder to determine at what level dry areasmight become a problem. Operator training and machine maintenance are the usual methods tomanage this problem. It may also be necessary to reconsider the facilities used for glass storagein order to reduce the moisture level on the fibres. Once the glass roving packages have been

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 11 of 48

opened moisture can condense on the surface of the glass strands and prevent complete wetting.Storage in a dry or heated environment may reduce the wetting problem. Pneumatic testing ofassembled production spools for a pipe order should help ensure this problem does not reach thefield.

Voids are often present within the epoxy filler due to laminating technique or as a result of thecuring process. If these are large, elongated or too many in number they can lead to gas escapeor weeping failure in the machined area behind the male thread. Regular microscopicexamination of production piping will identify such a fault and may require retraining or changes incatalyst type or level. Pneumatic testing of assembled production spools for a pipe order shouldhelp ensure this problem does not reach the field.

The integrity of the screwed joints is often not adequately tested by shop hydrotesting of eachpipe length. It is therefore important that hydraulic burst tests are carried out on each batch andthat acceptance of the batch be conditional on a satisfactory test result. It is considered that thejoints should not be a dominant failure point for these tests.

The detailed installation design of a pipeline must consider pipe, joint and fittings and ISO 14692provides means to complete this design. The detail required to accommodate joints and fittingscan be tedious and too slow to allow up front ordering of materials. It is considered that if thecomponent design and testing is sufficient to demonstrate that each component is at least asstrong as the pipe then it should be satisfactory to design for the pipe only. This would be a verydesirable outcome as it would also allow manufacturers to schedule component manufacturearound pipe orders and maintain a stock of such components. At this time insufficient evidencemay be available to show that the components meet this target and it may be necessary to havespecific component tests conducted.

3.2 GRP Design Standards

3.2.1 Why AS 2885AS 2885 is not the only standard suited to design of pipelines but it is certainly one of the most advanced.Key elements of the AS 2885 design methodology include;

Risk based approach

Performance based design - known failure conditions plus design margin

Highly theoretical approach to design analysis

Considers all stress inducing loads and load combinations

Staged contribution to safety from various protective measures

Maintained for life of pipeline with regular condition review

Addresses all stages from pipe procurement through to abandonment

GRP is already an alternative material

However; since departures from AS 2885 require approval by the Operating Authority some GRP relevantdepartures are listed below.

The design factor, effective yield stress and MAOP calculation used for GRP design are not inaccordance with Sections 3.4, 4.2.3, 4.3.4.1 but would use the appropriate equivalentrequirements of ISO 14692, ASTM D2992, ASTM D1599 and ASTM D2105 for this purpose.

A fracture control plan as required by Sections 2.3.4, 3.5, 4.3.7 is not appropriate for GRP pipematerial. A review of GRP failure modes, including consideration of known failures and impacttesting concluded that the selected material is not normally subject to catastrophic failure modes.Running fracture would, in any case, be arrested by the screwed joints.

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 12 of 48

Gauging of the pipelines, as required by Section 6.17, may be unnecessary and impractical forGRP pipelines which include short radius elbows.

Pigging facilities may not be appropriate on a pipeline that is not subject to corrosion. The abilityto retrofit pigging capability may, however, be worth retaining.

The field hydrotest requirements will need to be reconsidered. ISO 14692 requires a fieldhydrotest at 1.5 x Design Pressure or a maximum of 0.89 times the Qualified Pressure of thepipe.

A detailed review will no doubt identify many more departures that will need to be documentedand approved.

3.2.2 Why API 15 HRAPI 15HR is suggested as being a suitable specification for manufacture of pipeline materials but must beused with care.

1.2.2 Service Conditions

o “The standard service conditions … are ….:

Service Life 20 years.

Service Temperature 150oF.

The fluid environment is salt water.”

o “Axial loads shall include end loads due to pressure and bending, where the curvature ofthe pipe divided by the outside radius of the pipe shall be greater than or equal to 1200.”

o “Cyclic pressure variation shall include 3,000 cycles from 0 to 120% of the Specification15HR Standard Pressure Rating. Cyclic pressure variation shall include 109 cycles withan R value of 0.9. (R = minimum pressure divided by maximum pressure).

The second paragraph states that the standard service conditions include axial loads generated byinternal pressure and axial loads generated by pipe curvature up to 1200 x Ro. I assume that the axialload from pressure refers to the unrestrained pipe condition which generates the highest axial loads. Thecurvature limit will result in a pipe wall strain of 1/1200 = 0.00083. .Since the elastic modulus of mostpipeline GRE composites does not vary much then the resulting wall stress will be nearly constant(14,000 MPa x 0.00083 = 11.6 MPa) regardless of the pipe size. I believe that it is intended that thiscurvature limit should be the all inclusive result of several installation conditions such as;

Installation curvature at direction changes

Support Span, self weight bending

Wind Load bending

Thermal expansion bending

Clause 1.2.2 also suggests that the installation curvature radius may be acceptable in addition to theinternal pressure Pr. Appendix G suggests that this may not be appropriate. The stress generated bycurvature is not insignificant and should be properly accounted for in the wall thickness determination andpipeline installation design [as it is in ISO 14692].

1.2.2 “Service conditions other than the standard .... conditions are discussed in 5.1.1 andAppendix G.”

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 13 of 48

5.1.1 “The published … 15HR Standard Pressure Rating shall be calculated by thefollowing equations …..

Pr = Ss x Sf x (Ro2 - Ri2)/(Ro2 + Ri2) Eqn 1

o [Standard thick walled vessel formula]

Pr = Ss x Sf x 2 x t / D. Eqn 2”

o [Standard thin walled vessel formula]

o [Note: Eqn 2 has been printed with Sf missing from the formula]

where “Ss = 95% LCL …. @ 20 years …. @ 150oF …. .

and Sf = 0.67 service (design) factor (See Appendix G)……”

Ss is defined at 150oF or higher – I believe this means that the testing temperature must be at or above150oF. It is not clear whether Ss should be adjusted for the application service temperature.

Appendix G suggests a more comprehensive determination of the default Sf = 0.67.

App G Service (Design) Factors.

“Consideration is being given to adopting a more comprehensive method of determiningthe pipe and prime connection pressure performance. The overall service (design) factor,Sf in Equation 1, will be the product of the individual service factors thus permittingadjustment of the Specification 15HR Standard Pressure Rating for specific applicationshaving other than the defined Standard Conditions.

Sf = Sfc x Sfe x Sfl x Sft x Sfa

Where

c – cyclic loading factor

e – environment factor

l – design life factor

t – temperature factor

a – additional axial load factor

Sfa = (sAP – sAA)/sAP

sAP = axial stress due to 15HR pressure rating

sAA = axial stress due to additional axial loads, for example bending a pipe to a certainradius of curvature, where sAA would be calculated as shown,

sAA = Ea.Ro/Rc”

The method stated, however, does not include a design margin or safety factor it simply adjusts forvarious service conditions. I believe that what was intended is to calculate a suitable adjustment to the15HR standard pressure rating (as is stated in the App G introduction above). App G should thenpropose;

Sf (service) = 0.67 x Sfc x Sfe x Sfl x Sft x Sfa

which can be used to adjust Pr to a design pressure for project conditions and is closely equivalent to theISO 14692 method.

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 14 of 48

Sfa, which accounts for axial loads other than from internal pressure, should include for ALL othersources of axial load on the pipeline not just installation curvature.

Note that if the wall thickness is determined based on the Ss, hoop stress, only with a designfactor of 0.67 then the added curve stress of 11.6 MPa will reduce the safety margin.

Experience from recent GRE pipeline design shows that for above ground installations in a harshenvironment Sfa needs to be around 0.6 (i.e. 60% of the strength, or wall thickness, is used forpressure containment and 40% is available for other axial loads.) The design factor Sf for use inEqn 1 or 2 would then be 0.4 rather than the 0.67 used in API 15HR Eqn 1 and 2.

For buried pipelines where installation curvature Rc can be restricted it is likely that Sfa willtypically be around 0.7 (Rc ~ 1500 x Ro) with a maximum of 0.85 (Rc ~ 3000 x Ro). The designfactor Sf for use in Eqn 1 or 2 would then be between 0.45 and 0.57 rather than the 0.67 used inAPI 15HR Eqn 1 and 2.

It is noted that Appendix G does not include any adjustment for sustained vs thermal vs occasional loadsyet the material is known to be very susceptible to such load duration changes. The basis for determiningSs appears to be for sustained type loads so such a correction would seem to be appropriate. Noalternatives to the 0.67 design factor are offered as is done in ISO 14692.

Unfortunately no method is proposed for determining the magnitude of several of the service factors so,while the method has merit, it does not provide a solution to the pipeline designer.

Ss represents the limiting failure hoop stress after 20 years of continuous exposure to the standardpressure and temperature. The required shop hydrotest (Sect 7.4.1) is 1.5 x Pr. Note that 1/1.5 ~ 0.67 sothe shop hydrotest is done at the 95% LCL long term failure stress. The manufacturers typicallyrecommended field hydrotest of 1.25 x Pr is therefore conducted at 83% of the limiting long term failurecondition. Installation curvature, static head and thermal expansion loads will also be present adding tothe pressure induced stresses. This could lead to field hydrotest pipe wall stress greater than thatachieved during the shop hydrotest which would not be desirable. ISO 14692 requires a field hydrotest at1.5 x Design Pressure with a maximum of 0.89 times the Qualified Pressure of the pipe and this upperlimit should ensure that the field stress is lower than that from the shop hydrotest.

Pipe wall thickness calculations utilise a test result from ASTM D2992, Procedure B, which involves astatic pressure test. There is no explanation or testing required to confirm that the material is indeedsuitable for the cyclic stress loading noted in the Cl 1.2.2 Service Conditions. ASTM D2992, Procedure A,involves a cyclic pressure test but is not referenced in API 15HR and is not comparable.

1.3 “Availability of Test Results.”

“The manufacturer shall prepare a report as outlined below:”

A list of materials tests and design calculations is provided which would provide acomprehensive Design Book record of the pipe and its properties.

Manufacturing and quality records are called up elsewhere though these would not provide full materialtraceability that would be expected for steel pipelines built in Australia. Depending on the risk levelsassociated with the particular pipeline additional traceability records may be considered appropriate butmay not be readily available.

3.2.3 Why ISO 14692 Part 3ISO 14692 is proposed as the basis for engineering design of GRP pipelines and exhibits several keyelements of the design methodology used by AS 2885.

Performance based design - known failure condition plus design margin

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 15 of 48

Highly theoretical approach to design analysis

Considers all stress inducing loads and load combinations

Maintained for life of pipeline with regular condition inspections

Addresses all stages from pipe manufacture through to abandonment

ISO 14692 requires consideration of an extensive range of design issues apart from just an analysis ofthe hoop stress in the pipe. These include;

Joint Selection

Fire and Blast Resistance

Jet Fires

Electrostatic Discharge

Galvanic Corrosion (when carbon fibre is present)

Erosion

Water Hammer

Vacuum

Cyclic Conditions

Dynamic Loads

Thermal Expansion

Low Temperature Service

UV Protection

Weathering Resistance

Pipe Support Contact Stress

Lightning Strike

Flexibility Analysis

Limited Third Party Damage Risks

In many instances significant guidance is included to assist the designer. In some, such as third partyprotection, further work is clearly required to ensure an AS 2885 equivalent design.

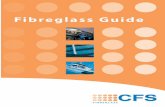

The main methodology of the ISO 14692 design is a comprehensive assessment of the pipes ability tosafely withstand stress. This is achieved by;

1. Identifying, through destructive testing, key points on a simplified short term failure stressenvelope on a plot of hoop and axial pipe wall stress as the two primary axes.

2. Long term destructive testing is then used to develop a scaled version of the failure envelopesuitable for a sustained 20 year, salt water, steady pressure load at 65°C.

3. This envelope is then further scaled using established factors which correct the test resultsfor the project conditions, such as;

a. Design Life other than 20 years

b. A temperature other than 65°C [factor A1]

c. A fluid other than salt water [factor A2]

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 16 of 48

d. Cyclic Loading Conditions and Fatigue [factor A3]

4. Finally, a suitable design safety factor [f2] is applied to again scale the failure envelopedepending on the load duration being either sustained or occasional. The design factorsused are as follows;

Load Type Duration Factor f2 Example

Occasional Short Term 0.89 Hydrotest, Transient Pressure, Wind

Sustained plus Thermal Long Term 0.83 Self Weight + Thermal Growth

Sustained Long Term 0.67 Self Weight, Operating Pressure

Note: An additional factor of 1.0 has subsequently been proposed for hydrotest.

The result will be one or more allowable stress design envelopes which are used to determine if thedesign loads are acceptable or not.

A further factor [f3] is used to ensure that the pipe has adequate strength to withstand both internalpressure and axial stress resulting from other loading conditions. While no recommended values areprovided for f3 it is likely that this will be in the range from 0.4 to 0.85 with maximum of 0.9.

Design loads are to be determined using a comprehensive analysis of all relevant combinations of loadswhich may generate stress in the pipe wall. Conventional stress analysis and flexibility calculationmethods are used to calculate the wall stresses so existing tools and design knowledge can be applied.

Pipe hoop stress is determined using thin wall theory as the method is limited to pipe with D/t > 10.

Hoop stress from internal pressure is calculated as Shp = P x D / (2 x tr) [Eqn 27]

where D is the mean reinforced pipe wall diameter D = ID + tr

and tr is the average reinforced wall thickness of the pipe

[Note: It has been proposed that tr should be the minimum reinforced wall thickness]

Axial stress from internal pressure in an unrestrained pipe Sap = P x D / (4 x tr) [Eqn 29]

Axial stress due to installation curvature is determined using normal beam theory.

Axial stress and deflection due to support spans uses conventional beam bending formula depending onthe degree of end restraints.

Shell and column buckling loads are considered with suitable design margins applied.

Combinations of the identified loads are applied as appropriate to the conditions and the load duration.

So long as each design case considered results in combinations of hoop and axial stress which fall withinthe allowable stress envelope the design is considered to be satisfactory.

The method used has significant parallels to those currently used for design of steel pipe material inAS 2885 and so goes a long way towards the ME 38 requirement as stated in 2003 “to satisfy thefundamental principals used in AS 2885”.

An example of the development from failure envelope to allowable stress envelopes is provided below;

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 17 of 48

2 : 1 line0 0

259.35 129.675

Short Term Envelope (based on lcl values) Long Term Envelope Factored with fscale (Qualified Envelope)σsa(2:1) σqs

Hoop Axial Definition Hoop Axial Definition222.3 0 Ssh 2:1 142.2 0222.3 111.15 Ssa 2:1 142.2 71.10222.3 111.15 Ssa 2:1 142.2 71.10

0 75.2 Ssa 0:1 0.0 48.10

Longt Term Envelope Factored with A0, A1,A2,A3 Long Term Envelope Factored with f2σqf σdes, max

Hoop Axial Definition Hoop Axial Definition129.0 0 86.4 0129.0 64.5 86.4 43.2129.0 64.5 86.4 43.20.0 43.6 0.0 29.2

With Design Pressure Known Short Term Mean Axial Stress Short Term Mean Hoop Stress Long Term Mean Hoop Stressσdes STAS STHS LTHSHoop Axial Hoop Axial Hoop Axial Hoop Axial

50.19 25.09 0 78.5 247.0 0 148.9 050.19 0 247.0 123.5 148.9 74.4550.19 37.35

Design Allowablesσh, sum max allowable hoop stress 86.41 MPaσdex, max max allowable axial stress (pressure only) 43.21 MPaσhp design hoop stress due to pressure 50.19 MPaσap design axial stress due to pressure 25.09 MPaσdes(0:1) max allowable axial stress (unpressurised) 29.23 MPaσa, allow design allowable axial stress 37.35 MPaσab axial stress from sources other that pressure 12.25 MPa

2:1

σsa(2:1)

σsh(2:1)

σsa(0:1)σal(2:1)

σal(0:1)

σqs

σaf(2:1)

σfs

σaf(0:1)

σa,des (0:1)

σh,des

σa,des (2:1)

σab

σap

σh,sum STHSLTHS

STAS

Hoop Tensile Stress (MPa)

Axi

alTe

nsile

Str

ess

(MP

a)

fscale

A0,A1,A2,A3

f2

f3

1a

2

3

4

5σa, sum

KEY1 schematic representation of the short-term failure envelope2 idealized short-term failure envelope3 qualified long-term failure envelope at standard conditions4 factored qualified long-term failure envelope at project conditions5 long term design envelope

a For design Purposes, the shape should be based on actual measured data points

Note:i) σsa(2:1) is the 97.5% lower confidence level result obtained in accordance with ASTM D1599 testingii) σsa(0:1) is the 97.5% lower confidence level result obtained in accordance with ASTM D2105 testingiii) σal(2:1) is the 97.5% lower confidence level result obtained in accordance with ASTM D2992 testing

1b

f1

f1

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 18 of 48

3.3 GRP Design MethodologyAdequate design of GRP pipelines does require special consideration of some aspects in order toaddress differences between this material and steel pipelines.

GRE, due to the arrangement of the glass fibres within the Epoxy matrix, exhibits strongly anisotropicmechanical properties. Along the primary axes of axial, hoop and radial the properties can typically be;

Axis ElasticModulus

Poisson Ratio Short TermFailure Stress

Long TermFailure Stress

SustainedDesign Stress

Axial 13,800 MPa 0.64 h/a75.2 MPa 48.1 MPa 31.1 MPa

Hoop 22,800 MPa 0.39 a/h222.3 MPa 142.2 MPa 92.0 MPa

Radial N/A N/A N/A N/A N/A

Note: Radial properties are generally not available.Note: The bold red values are derived from ASTM D2105, D1599 and D2992 tests.

Appropriate design formulas for exact 3D stress strain behaviour of anisotropic materials are not alwaysreadily available, for example, Roark’s Formulas for Stress and Strain do not address anisotropicmaterials. Anisotropic elastic design formulas need to be identified for accurate analysis of someconditions. For most design tasks, though, the differences have a limited impact on the design. Forpressure, curvature and bending analysis conventional design methods are appropriate but analysis ofstress in buried and restrained pipe under pressure requires other methods.

The symbols used to define the Poisson’s Ratio vary between reference texts with uncertain results.

Symbols used include h/a, a/h,a,h, ah, ha, major, minor. The terminology used in ISO 14692 is;

ha – axial strain component resulting from hoop stress

ah – hoop strain component resulting from axial stress

It is recommended that this terminology be used throughout as it aligns with several other standards.

There should be a fixed relationship between the Elastic Modulus and the Poisson’s Ratios as follows;

Ea x h/a = Eh xa/h (also refer ISO 14692 Pt 3, Annex C, Symbols – bottom of list)

Unfortunately vendors data provided for their pipes often does not fit this essential relationship and shouldbe queried.

The inclusion of burst acceptance tests for each batch of pipe is strongly recommended as a keycomponent in ensuring an appropriate margin between operating and failure pressures.

The ISO 14692 failure and design envelopes provide a convenient and highly visible way to demonstratecompliance of all design load cases by plotting all of these onto the relevant envelope. It is recommendedthat these plots be provided in the design and maintained with the pipeline records.

Analysis of pipe joints and fittings can be greatly simplified if it is known that each of the pipe fittings is atleast as strong as the pipe itself under all expected conditions of pressure, bending and axialtension/compression. If this is known to be the case then the design can be carried out based on thestrength of the pipe alone. At this time such evidence does not exist for the available pipe fittings. Thesavings in design costs may be sufficient to justify specific tests of components for a project.

In larger diameter and higher pressure pipes the standard pipe joint thread designs currently used bymanufacturers can result in the joints not being as strong as the pipe itself. This can be identified if thescrewed joints become the dominant failure mode in burst tests. As demand for larger and higherpressure pipes develops it is likely that the current thread design will need to be changed to avoid this

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 19 of 48

event. If the joints are not as strong as the pipes then the pipes may still be suitable for use subject tofurther design analysis.

The requirements of AS 2885 for fracture control of CS pipe are not applicable to GRP pipe. Failureanalysis for GRP must consider the likely modes of failure for the material. Technical informationreviewed from vendors and other publications typically identify a weeping type failure, due todelamination, as the normal mode of failure. Failure loads included internal pressure from hydrotest orthermal expansion of fluid, water hammer, external mechanical loading (e.g. vehicle impact) andsideways movement under compression due to insufficient lateral restraint. A review of identified GREfailure cases indicated that a catastrophic failure of the pipe material could occur in some instances,though a running fracture type failure is not seen as credible. Tests carried out to determine the likelyfailure mode for the selected material under combined pressure and impact resulted in only a partial lossof containment when failure did eventually occur rather than a catastrophic failure mode.

The wall thickness required of the pipe material will normally need to be determined well before a detailedinstallation design can be completed so that the pipe can be ordered, manufactured and delivered. To dothis sufficient hydraulic design of the pipeline must be completed to determine both normal, maximum andhydrotest pressures, including hydraulic head from elevation changes. An initial assessment of installationstresses, including curvature and support span should be carried out to determine resulting axialstresses. Note that if the pipeline is buried then consider imposing curvature limitations greater than thetypical Rc = 1200 x Ro. If above ground sections are associated with a long pipeline then consider usinga different wall thickness for these. A pipe must then be selected suitable to withstand the internalpressures and the axial stress at the same time. Note that most vendors publish Nominal PressureRatings for their product and these will typically be Pnpr = 0.67 x Pq and this value will be suitable onlyfor a sustained internal pressure so long as there is no other loads inducing further stress. This situationwill not occur in any pipeline as installation curvature or pipe spans alone will produce significant furtherstress. The ISO 14692 allowable stress envelope for a particular pipe and load case will quickly identifywhat pressure stress Sh,sum a pipe is able to withstand coincident with the required axial stress Sab.With Sh,sum and Pd known the required minimum reinforced pipe wall can be determined from tr,min =Pd x D / (2 x Sh,sum).

Additional wall thickness may be required for an un-reinforced internal liner (e.g. abrasion) and anexternal protective layer (e.g. UV protection).

The ISO 14692 design factors f2 vary from 0.67 through to 0.89 depending on the load duration, howeverfollowing advice from Dr Simon Frost, who chaired the ISO committee for this standard, a factor of 1.0may be approriate for the hydrotest condition.

AS 2885 relies heavily to the pipeline MAOP to identify and regulate pipeline design and operation. ForGRP pipelines the selection of an MAOP is a little different. MAOP is a maximum continuous operatingpressure and would equate to Pd,max = Sh,sum x 2 x tr,min / D, where Sh,sum was determined from thesustained load, f2 = 0.67, allowable stress envelope. AS 2885 pipelines are normally not allowed tooperate above MAOP (with a maximum short term transient of +10%). GRP pipelines may, however, besuitable to operate at well above this pressure. It is proposed that the MAOP term be retained and appliedto the sustained load case maximum design pressure, where f2 = 0.67, but the allowable transientpressure excursions be in accordance with ISO 14692 requirements. This may require pipeline pressurecontrols and pressure protection to allow excursions above the MAOP for regulated periods.

Cyclic or transient loading and water hammer must be considered in design of a GRP pipeline andsuitable allowances included per ISO 14692.

Installation curvature generates sustained stresses in the pipe wall and must be included for in thedesign. Curvature due to self weight and wind loading must be considered for above ground pipelinesalong with installation curvature. Total curvature, in the form of coincident vertical and horizontal bending,may need to be considered.

Support spans should be calculated to manage both stress and deflection using normal beam theory andappropriate end restraint conditions. Spans may be reduced in areas where other coincident loads occurin order to manage the total pipe stress.

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 20 of 48

GRP materials exhibit relatively high thermal expansion but also have a relatively low elastic modulus.This combination enables the management of thermal growth using anchors and guides and the pipesown flexibility. Some reference texts state that the pipe can consequently be fully restrained withoutcausing damage and this may be true for a long straight buried pipeline. Restraint of above groundpipelines and direction changes should, however, be applied with great care as the forces involved forthick wall, high pressure, pipes can be very significant and very difficult to transfer from pipe to grade. Thebest approach seems to be to anchor the pipe infrequently and guide any thermal (and pressure) growthto flexible expansion points such as expansion loops. Analysis has concluded that simple inline directionchanges can usually be arranged to accommodate thermal growth.

Stress and flexibility analysis can be carried out with conventional tools such as Caesar II or finiteelement software. Coade are currently preparing an update to Caesar II to include the ISO 14692methods and acceptance criteria, though the UKOOA criteria already exist and may be adequate withsuitable care (refer to Coade for guidance). Within the normal design stress range the material stress vsstrain behaviour is fully elastic so conventional mechanical/structural analysis is normally adequate.

Buried straight pipelines will be fully axially restrained away from any above ground transitions andanalysis has concluded that the restrained pipe stresses will be within the ISO allowable limits. Anchorloads from the pipe at bends and above ground transitions and design of the anchors to safely transferloads from the pipe to the soil will need to be developed.

Anchor design for above ground pipes can utilise a flange to transfer the pipe load to the anchor and so tograde. Alternative arrangements shown in reference texts which utilise shear keys or sleeves glued to theoutside of the pipe are unlikely to work for thick wall, high pressure pipes as the loads can be very high. Ifsuch anchor points were to be used then appropriate design calculations and possibly tests should beconsidered.

Pipe supports must meet criteria established in ISO 14692 Pt 3, Cl 8.6, Annex E and Pt 4 Cl 5.5.3 withother useful references in UKOOA and the Shell DEP. Supports typically require the pipe to supportcontact area to be an extended saddle which wraps around a 120° arc of the pipe and is fitted with a softelastomer lining. Alternatives such as GRP saddles bonded to the pipe wall may provide an alternative ifa suitable design can be identified. There is however currently insufficient information available tocomplete a design. Analysis and testing have identified that thin walled pipes as small as 200 NPS cansuffer from excessive ovalising above supports. It is likely that ring design formulae or finite elementmodelling will be required to establish the suitability of this detail of a pipe support design.

Stresses in buried pipe trenches and road crossing should be analysed using AS 2566 as theAPI RP 1102 method called for in AS 2885 is suited only to steel pipes. AS 2566 has been proposed forinclusion in the revised AS 2885.

Pipe flotation and buoyancy control for water crossings and saturated trench backfill will need to beconsidered in the pipeline design. Particular attention may be needed to backfill compaction to preventboth flotation from saturated soil and uplift from thermal compression loads in the pipe. This has beenidentified as the likely cause of at least one significant pipeline failure event.

The GRP pipe outer wall is subject to UV damage if exposed to solar radiation and weather. If notprotected the epoxy will powder and expose the glass fibres, some of which may break off. The depth ofthis damage is very small and, if limited release of short glass strands is acceptable then ordering pipewith an extra 0.5 to 1.0 mm of outer wall may be sufficient to ensure this has no structural impact. Wherefurther protection is required a coat of polyurethane paint may prove to be a satisfactory solution.

Since GRP has a relatively low conductivity static charges can build up in dry gas or non-conductive fluidservices. Guidance is provided in ISO 14692 Pt 2 Annex G to determination of the materials electrostaticproperties. Guidance is provided in ISO 14692 Pt 3, Cl 10 for the associated hazard determination andmitigation measures.

In flammable gas service the screwed joints may be considered a potential leak source and so attract ahazardous area rating. It may be possible to avoid this by using a catalysed epoxy paste as the threadlubricant, effectively converting the maintainable screwed joint into a sealed integral joint. Theacceptability of this solution should be established before use.

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 21 of 48

3.3.1 Outstanding IssuesA number of issues remain to be resolved for GRP to be widely accepted as an alternative AS 2885material. This itself should not prevent GRP use on particular pipelines so long as these issues areconsidered within the pipeline design.

Third party protection measures can be expected to differ from those appropriate for steel pipes due tothe expected much lower resistance to penetration of the GRP pipe material. Options to address such ashortfall could include;

An increased design margin,

Increased burial depth,

Concrete slabs at ditches,

Geotextiles installed above the pipe

Testing should be carried out to determine the penetration resistance of GRP pipes of a similar pressurerating to that of steel pipes that have previously been tested. Testing methods and equipment shouldparallel those previously completed to ensure a reasonable comparison of the results.

Gas release rates associated with third party equipment penetration can be determined from the resultsof the suggested penetration resistance tests.

A determination should be obtained of the hazardous area rating associated with the screwed pipe jointsof each manufacturer. This should include the joints in the normally assembled condition and sealed withan alternative compound such as catalysed epoxy.

A review should be done of typical buried pipe locating equipment to determine whether burial of a cablewith the pipeline will be sufficient for existing equipment to reliably locate a buried GRP pipeline.

Further information should be obtained regarding expected abrasion rates of GRP pipe in typical servicesand methods determined to avoid abrasion affecting the structural integrity of the pipe. It may benecessary to provide pre-measured test spools in the pipeline to allow wall loss rates to be determined.

Design and testing should be considered for methods to attach pipe anchors, for both above and belowground service, to the pipe wall and so enable safe and effective transfer of axial stress from the pipe wallto an anchor device.

A finite element modelling analysis of the local stresses generated within the pipe wall at pipe supportlocations may identify a simpler method, such as ring bending analysis, for this modelling. A simplermethod would put this task within reach of most pipeline designers.

The ISO 14692 design stress methodology considers only tensile stresses in the hoop and axialdirections. There are cases where compressive axial stress can develop, which are considered in theshell and column buckling design, but not in the stress envelope. The UKOOA specification included acompressive axial stress component in the stress envelope which may be applicable for use in thedesign.

Pipeline gauging after fabrication may not be appropriate for screwed GRP pipe which includes asignificant diameter expansion and step at each joint.

Pipeline pigging may prove to be unnecessary for cleaning GRP pipelines, though provision of the abilityto post install pig launchers and receivers may still be worthwhile. Intelligent pigging equipment iscurrently not available though simple tasks such as wall thickness survey should be achievable.

3.3.2 GRP Design OutcomesSome examples of what GRP pipe products can be expected to look like both as delivered and duringinstallation have been included in Appendix A to help illustrate the topic.

AS 2885.1 - ISSUE PAPER

Issue No: 4.28 Revision: 0 Rev Date 6 Nov 2006Title: Fibreglass Pipeline Materials for AS 2885Author: D Kirk-Burnnand – PCT Engineers

- compliments of Alinta Asset Management

2841DOC0001.doc Page 22 of 48

3.4 GRP Installation

3.4.1 ISO 14692 Part 4Part 4 of ISO 14692 addresses Fabrication, Installation and Operation of GRP piping aimed to “ensurethat installed piping systems will meet the specified performance requirements throughout theiroperational life”.

The recommendations apply to delivery inspection, handling, storage, personnel qualification, installation,NDT, pressure testing, maintenance, repair and decommissioning. This completes the ISO 14692 coverof GRP piping from manufacture through to the end of facility life in a manner that fits well with therequirements of AS 2885.

Several project histories reviewed include horror stories of damage from inadequate packing, shipmentand delivery of the pipe and fittings. Damage not identified at this time can lead to premature pipe failureduring hydrotest or in service. The delivery inspection is therefore an essential component for projectsuccess and requires a competent, trained inspector to ensure that damaged products are identified,replaced and do not make their way into the pipeline. A listing of defect types, acceptance criteria andcorrective actions is included in Annex A. Training courses and competency assessments may need to beestablished in Australia to achieve this.

Many examples can be found of pipe damage and failures resulting from improper joint assembly andpipe handling. With sufficient training, care and the right equipment these problems can be easilyavoided. Under ISO 14692 qualifications are required for GRP Pipe Fitters, GRP Piping Inspectors andGRP Piping Supervisors with guidelines outlined in Annex D. Training must be carried out by a suitablycompetent organisation, this may be in conjunction with the pipe manufacturer. Qualification must becarried out by a recognised certification body, independent from the trainer, and shall include appropriateexaminations. Training courses and competency assessments may need to be established in Australia toachieve this.

An installation contractor is required to maintain a quality management system to ensure compliance withall requirements of ISO 14692 Pt 4. An inspector experienced in all aspects of GRP piping field fabricationshall be designated as responsible for quality control and records throughout the installation. Eachconnection is required to be individually numbered and recorded. This may be considered unnecessaryfor assembly of the shop manufactured threaded joints on small diameter pipes. The procedure should befollowed for all large diameter pipe joints and for all field manufactured threads, each of which should alsobe hydrotested prior to installation into the work.

Consideration should be given to low pressure pneumatic testing of each day’s production and applicationof leak detection solution to all joints in the test section.

A hydrostatic test is required at 1.5 times the design pressure or 0.89 times the qualified pressure of thepipe, whichever is lower. This test must be held for a minimum of 1 hour. A further test at 1.1 times thedesign pressure should then be carried out for a minimum of 24 hours.