FCU-6000 system manual

Transcript of FCU-6000 system manual

-

8/10/2019 FCU-6000 system manual

1/68

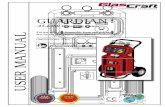

Fire Alarm Control Panel

N 6000

Manual

REV B

DATE 2007-08-08

-

8/10/2019 FCU-6000 system manual

2/68

-

8/10/2019 FCU-6000 system manual

3/68

against telephone line failure, backup radio transmission

systems are recommended.

The most common causeof fire alarm malfunction is

inadequate maintenance. To keep the entire fire alarm

system in excellent working order, ongoing maintenance

is required per the manufacturer's recommendations.

Environments with large amounts of dust, dirt or high air

velocity require more frequent maintenance. A

maintenance agreement should be arranged through the

local manufacturer's representative. Maintenance should

be scheduled or as required by National and/or local fire

codes and should be performed by authorized professional

fire alarm installers only. Adequate written records of all

inspections should be kept.

-

8/10/2019 FCU-6000 system manual

4/68

Installation Precautions

Adherence to the following will aid in problem-free installation with long-term reliability:

Several different sources of power can be

connected to the fire alarm control panel. Disconnectall

sources of power before servicing. Control unit and

associated equipment may be damaged by removing

and/or inserting cards, modules, or interconnecting cables

while the unit is energized. Do not attempt to install, service,

or operate this unit until this manual is read and

understood.

System Reacceptin g Test after Software

Changes. To ensure proper system operation, thisproduct

must be tested after any programming operation or change

in site-specific software.

All components, circuits, system operations, or software

functions known to be affected by a change must be 100%

tested. In addition, to ensure that other operations are not

inadvertently affected, at least 10% of initiating devices that

are not directly affected by the change, up to a maximum of

50 devices, must also be tested and proper system

operation verified.

Verify that w ire sizes are adequate for all initiating and

indicating device loops. Most devices cannot tolerate more

than a 10% I.R. drop from the specified device voltage.

Like all solid state electronic devices, this system may

operate erratically or can be damaged when subjected to

lightning-induced transients. Although no system is

completely immune from lightning transients and

interferences, proper grounding will reduce susceptibility.

Overhead or outside aerial wiring is not recommended,

due to an increased susceptibility to nearby lightning strikes.

Consult with the Technical Services Department if any

problems are anticipated or encountered.

Disconnect AC power and batteries prior to removing

or inserting circuit boards. Failure to do so can damage

circuits.

Remove all electronic assemblies prior to any drilling,

filing, reaming, or punching of the enclosure. When

possible,

make all cable entries from the sides or rear. Before making

modifications, verify that they will not interfere with battery,

transformer, and printed circuit board location.

-

8/10/2019 FCU-6000 system manual

5/68

Table of ContentSection 1:About This Manual ................................................................................................................. 6

1.1Notes, Cautions & Warnings......................................................................................................... 6

1.2Font Definition .............................................................................................................................. 6Section 2:System Overview.................................................................................................................... 7

2.1Introduction ................................................................................................................................... 7

2.2Characteristics of the Product........................................................................................................ 7

Section 3:System Configuration & Installation ...................................................................................... 9

3.1Features Main Performances ......................................................................................................... 9

3.2Electrical Specifications................................................................................................................ 9

3.3System Configuration.................................................................................................................... 9

3.4System Block Diagram................................................................................................................ 10

3.5Installation & Connection ........................................................................................................... 11

3.5.1Enclosures............................................................................................................................ 11

3.5.2Connection Requirements.................................................................................................... 12

3.5.3Connection of Circuit Board Terminals............................................................................... 12

3.5.3.1CPU Diagram............................................................................................................... 12

3.5.3.2Power Supply Connection............................................................................................ 15

3.5.3.3NIC-EC......................................................................................................................... 17

3.5.3.4Loop Control Module Connection................................................................................ 19

3.5.3.5MCU-16B Annunciator Control Module Connection.................................................. 21

3.6Equipment Debugging ............................................................................................................ 23

3.6.1Connection Inspection..................................................................................................... 23

3.6.2Power-on Inspection........................................................................................................ 24

3.6.3External Connection........................................................................................................ 24

3.6.4Important Points .............................................................................................................. 24

3.6.5Inspection Methods for Addressable Device Connections.............................................. 25

Section 4:Operation .............................................................................................................................. 26

4.1LED Indicators and Keys ............................................................................................................ 26

4.1.1Control Panel Display LED Indicators and Keys ................................................................ 26

4.1.2Annunciator Control Module LED Indicators and Keys ..................................................... 29

4.2Power-on ..................................................................................................................................... 304.3System Self-test........................................................................................................................... 30

4.4Event Display .............................................................................................................................. 32

4.4.1Trouble Screen..................................................................................................................... 32

4.4.2Fire Alarm Screen................................................................................................................ 33

4.4.3Supervisory Screen .............................................................................................................. 34

4.4.4Point Disabled Screen.......................................................................................................... 35

4.4.5CBE Screen.......................................................................................................................... 36

4.4.6Pre-alarm Screen.................................................................................................................. 36

4.4.7Horn / strobe Screen ............................................................................................................ 37

4.4.8Feedback Screen .................................................................................................................. 37

-

8/10/2019 FCU-6000 system manual

6/68

Section 5:Programming ........................................................................................................................ 38

5.1Menu....................................................................................................................................... 38

5.2System Management............................................................................................................... 40

5.2.1System setting ................................................................................................................. 41

5.2.2Password modification .................................................................................................... 425.2.3Main Reset....................................................................................................................... 43

5.3Device Configuration.............................................................................................................. 44

5.3.1Loop card......................................................................................................................... 45

5.3.1.1Parameter setting .......................................................................................................... 45

5.3.1.2Auto Programming....................................................................................................... 47

5.3.1.3Point Programming....................................................................................................... 49

5.3.2Annunciator Control Module .......................................................................................... 50

5.3.2.1Parameter setting .......................................................................................................... 51

5.3.2.2Point Programming....................................................................................................... 51

5.3.3Remote Display ............................................................................................................... 52

5.3.3.1Parameter setting .......................................................................................................... 53

5.3.3.2Label Download ........................................................................................................... 53

5.3.3.3Point Programming....................................................................................................... 54

5.3.4CBE Programming............................................................................................................... 54

5.3.4.1General Zone ................................................................................................................ 55

5.3.4.2Logic Zone ................................................................................................................... 55

5.3.5Device Control..................................................................................................................... 56

5.3.5.1Manual Output.............................................................................................................. 57

5.3.5.2Status Tracking............................................................................................................. 58

5.3.5.3Walk Test ..................................................................................................................... 58

5.3.5.4Loop Drill ..................................................................................................................... 60

5.3.5.5Power Supply Management.......................................................................................... 60

5.3.6History Events .......................................................................................................................... 61

Section 6:Miscellaneous ....................................................................................................................... 62

6.1Safety Protection Device............................................................................................................. 62

6.2Usage and Maintenance............................................................................................................... 62

6.3Common Troubles....................................................................................................................... 62

6.4Transportation & Storage ............................................................................................................ 636.5Out-of-box Audit......................................................................................................................... 63

Appendix A........................................................................................................................................... 64

-

8/10/2019 FCU-6000 system manual

7/68

Section 1:About This Manual

1.1Notes, Cautions & Warnings

The following graphics appear in this manual to indicate a note, a caution, or

warning:

Note:Information that highlights an important part of the preceding orsubsequent text or illustration.

Cautions:Information about procedures that could cause programming

errors, runtime errors, or equipment damage.

Warnings: Indicates information about procedures that could causeirreversible damage to the control panel, irreversible loss of programming data or

personal injury.

1.2Font Definition

Special font styles used in this manual are listed in Table 1-1, Specifications of

Manual Characters:

Font Meaning Example

Bold

Key on the control panel Press the key Signals

Silenced

Script Name of document N-6000 User Manual

Table 1-1 Specifications of Manual Characters

-

8/10/2019 FCU-6000 system manual

8/68

Section 2:System Overview

2.1Introduction

The N-6000 is a new generation intelligent fire alarm control panel recently

released by Notifier. This panel satisfies all related requirements defined in

GB4717-2005.

This control panel combines both alarm and CBE control functions. The N-6000

can also be programmed off-line when using a PC with Notifier Verifire Tools

(NVT).

The N-6000 fire alarm control panel has many intelligent characteristics; these

include but are not limited to drift compensation, sensitivity adjustment andself-optimizing alarm.

The N-6000 control panel with CBE (control by event) control can manage both

alarm paging and gas extinguishing systems. The N-6000 connected with a CRT

display terminal forms a comprehensive and reliable fire alarm control system,

perfect for medium to large-scale facilities.

2.2Characteristics of the Product

Large LCD Display

This system uses a large 320x240 pixel LCD display. To ensure accurate and

timely detection the LCD displays a full Chinese interface (up to 320 Chinese

characters), equipment type, location, alarm level, loop number and address

number upon alarming.

User Friendly Interface

The Menu contains all programming options. Software supports both English and

Chinese input, full suggest and user friendly dialogue prompts. A user can

conveniently toggle between the alarm information and CBE information screens.

Convenient Programming Options

Multilevel pre-alarm and alarm sensitivity enable localizing detector sensitivity for

different applications. Have the function of trouble disenable also can choose to

disenable any addressing unit in loop bus. Auto programming allows the N-6000

to learn what devices are physically connected and automatically load them in

the program with default values for all parameters. The functions mentioned above

significantly ease system operation while reducing daily maintenance.

Real-time Analogue Display Curve

Real-time threshold value variation monitoring is possible for both intelligent

analogue detectors and/or compound detectors.

Powerful CBE Equations

-

8/10/2019 FCU-6000 system manual

9/68

Accurate and Detailed Event Records

The system automatically and categorically stores and records the latest fire alarm,

trouble or system event. It can display and store up to 8000 historical events.

Automatic Compensation Functions

Drift compensation allows the detector to retain its original ability to detect actualsmoke, and resist false alarms, even as dirt or dust accumulates. It reduces

maintenance requirements by allowing the system to automatically perform

periodic sensitivity measurements. Smoothing filters are also provided by software

to remove transient noise signals, usually caused by electrical interference.

Printing Settings

The system can be networked and prompted to print the latest alarm event using a

Chinese printer.

Equipped With 8 Bus Control Modules.

Built-in Degraded Mode option. In the event of a CPU failure, the system iscapable of general alarm if a fire condition is present.

Off-line Programming and CRT display terminal

Connected with PC through the RS-232 interface, Screen of the control panel to

realize programming setting on circuit configuration, CBE control relation of the

control panel. Also can be connected with NCS through this Screen to carry out

centralized management.

-

8/10/2019 FCU-6000 system manual

10/68

Section 3:System Configuration &Installation

3.1Features Main Performances

Supports 1 to 30 Signaling Line Circuits (SLCs). Up to 199 detectors and 99modules (N.O. manual stations, two-wire smoke, notification or relay) per

SLC

Loop connection ports available, expandable up to 15 loop circuit cards

Supports up to 64 remote LCD displays

Supports up to 32 MCU control card

Micro printer port

N-CRT port provided - seamless connection to a third party system

Fire alarm output and trouble output relays

Real-time clock

3.2Electrical Specifications

Voltage range

Input voltage: 220 VAC

Output voltage:

Two 24 VDC non-resetable outputs

One 24 VDC resetable output

Two 5 VDC outputs

Several dry contacts - power supply trouble relay output

Maximum output current: 14.6A

3.3System Configuration

Intelligent control panel: N-6000

Remote display: LCD-100B, LDM-64B

Intelligent detectors:

Intelligent photoelectric smoke detector: ND-751P

Intelligent heat detector: ND-751T

Intelligent laser smoke detector: FSL-751

-

8/10/2019 FCU-6000 system manual

11/68

Intelligent smoke detector: FSB-200S

Intelligent base:

B601

B501

Intelligent modules:

Intelligent monitor module: MMX-7

Intelligent monitor/control module: CMX-7

Intelligent control module: CMX-7C

Monitor module for two-wire 24 VDC conventional detectors:MMX-7P

Isolator: ISO-7

Intelligent manual call point: M500K

Intelligent manual call point: M700K

Micro printer: uPRT-380S

Chinese graphic and text management software: N-NCS, N-VFT

3.4System Block Diagram

Fig. 3-1 System Block Diagram

If there are many addressable units in the loop bus, user should install the

shortcut isolator in front of the loop bus. The addressable units are less than 25

units between adjacent two isolators.

-

8/10/2019 FCU-6000 system manual

12/68

3.5Installation & Connection

3.5.1Enclosures

Wall-mount designs use a standard NOTIFIER C-type cabinet. This cabinet is

shown in Fig. 3-2 Cabinet Appearance:

Fig. 3-2 Cabinet Appearance

Detailed cabinet dimensions are shown in Fig. 3-3:

Fig. 3-3 C-type Cabinet Dimension Diagram

All NOTIFIER cabinets are fabricated from 16-gauge steel. The cabinet assemblyconsists of two basic parts: a backbox and a locking door. The backbox has been

-

8/10/2019 FCU-6000 system manual

13/68

engineered to provide ease-of-entry for the installer. Knockouts are positioned at

numerous points to aid the installer in bringing a conduit into the enclosure.

3.5.2Connection Requirements

All incoming/outgoing external conduits should use the control panel cabinetsbottom knockout or opening for terminal connections.

Loop transmission line adopts twisted pair cable, the type and specification are:

RVSP21.5mm2

Loop resistance (refers to loop resistance between the machine and two leads ofthe farthest addressing unit) should be less than 50 .

Power wiring should use two-color multiple plastic cable, red for male terminal,

black for female terminal. The type and specification are: RV-22.5mm2

3.5.3Connection of Circuit Board

Terminals

3.5.3.1CPU Diagram

Control panel includes in a circuit board, it has CPU and extend device interface.

You can order the board supports for 8, 16, 30 loops. The connections terminals,

jumper and status lights are showed below:

-

8/10/2019 FCU-6000 system manual

14/68

Fig. 3-4 CPU Diagram

Connections terminal illuminate table:

Terminal Illumination

TB1 System Event Relay1programmableDefault is fire alarm trigger

TB2 System Event Relay12programmableDefault is trouble trigger

TB3 System Event Relay13programmableDefault is reset trigger

TB4 24VDCPower

TB5 RS-232 Micro printer port

TB6 RS-232 NIC port

TB7 N-CRT PortVFTthird party system

TB8 RPT port

TB9 Loop communication port

TB10 Extended device portMCU/POM-8C/MPS

J10 Loudspeaker see J15

J13 Power, loop and extended device channel aggregate terminal

-

8/10/2019 FCU-6000 system manual

15/68

J15 Buzzer; user can select J10 or J15 to be system sound component

Table 3-1 CPU-6000 Board Terminal Illuminate

Jumper illuminate table:

Terminal Illumination

JP2 System Event Relay 1output selection 24Vor trunk node

JP3 System Event Relay 2output selection 24Vor trunk node

JP5 System Event Relay 3output selection 24Vor trunk node

JP9 ISP program write down jumper, user should cover jumper cap whenISP upgrade program

JP18 Loop RS485 communication match terminal resistance selection

jumper

JP19 Loop RS485 communication match terminal capacitance selection

jumper

JP21 Extended device RS485 communication match terminal resistanceselection jumper

JP22 Extended device RS485 communication match terminal capacitance

selection jumper

JP23 RPT RS485 communication match terminal resistance selectionjumper

JP24 RPT RS485 communication match terminal capacitance selectionjumper

Table 3-2 CPU-6000 Board Jumper Illuminate

LED status illuminate table:

Terminal Illumination

LED1 System status normalGreen

LED2 System fire alarm and CBE eventRed

LED3 System trouble eventYellow

LED4 System supervise eventBlue

LED5 Relay1relay close is green

LED6Relay2

relay close is green

LED7 Relay3relay close is green

LED8 24VDCGreen

LED9 5VDCGreen

LED10 Micro printer channel signal send; signal on is green

LED11 N-CRT protocol channel signal send; signal on is green

LED12 Micro printer channel signal receive; signal on is green

LED13 N-CRT protocol channel signal receive; signal on is green

LED15 RPT channel signal receive; signal on is green

-

8/10/2019 FCU-6000 system manual

16/68

LED17 RPT channel signal send; signal on is green

LED18 Extended device channel signal receive; signal on is green

LED19 Loop channel signal receive; signal on is green

LED20 Extended device channel signal send; signal on is green

LED21 Loop channel signal send; signal on is green

Table 3-3 CPU-6000 Status Light Illumination

3.5.3.2Power Supply Connection

The N-6000 fire alarm control panel is powered by the MPS-350W power supply

module. This power module provides multi-path 24 VDC and 5 VDC outputs.

During a power loss the MPS-350W battery will automatically engage and provide

power. LED displays indicate the status of multiple functions, including: main

power trouble, reserve power trouble, grounding trouble, storage battery chargingtrouble and power supply relay output trouble.

Refer to the MPS-350W user manual for additional information regarding function,

connection and/or application of the MPS-350W power supply.

Fig. 3-5 Power Supply Connection Diagram

Connections terminal illuminate table:

Terminal Illumination

-

8/10/2019 FCU-6000 system manual

17/68

TB1 Non-resetable 24VDC terminal

TB2 Non-resetable 24VDC terminal

TB3 Resetable 24VDC terminal

TB4 Non-resetable 24VDC terminal

TB5 Non-resetable 24VDC terminal

TB12 Trouble relay trunk node terminal

TB13 RS-485 serial communication port terminal

TB14 Extended system supervise signal terminal

Table 3-4 MPS-350 Terminal Illumination

Jumper illuminate table:

Terminal Illumination

JP1 Program jumper, user can not change

JP2 RS-485 bus terminal match capacitance

JP3 RS-485bus terminal match resistance

JP4/ JP5 Earth trouble function enable, disable

Table 3-5 MPS-350 Jumper Illumination

LED status illuminate table:

LED Illumination

LED1 Non-resetable 24VDC fuse melt indication

LED2 Non-resetable 24VDC fuse melt indication

LED3 Resetable 24VDC fuse melt indication

LED13 Non-resetable 5VDC fuse melt indication

LED19 Non-resetable 5VDC fuse melt indication

LED23 Battery cut protect indication

LED24 Battery fuse melt indication

LED25 Power normal indication

LED26 Power trouble indication

LED27 Battery normal indication

LED28 Battery trouble indication

LED29 System running indication

LED30 Earth trouble indication

Table 3-6 MPS-350 Status Light Illumination

-

8/10/2019 FCU-6000 system manual

18/68

3.5.3.3NIC-EC

When N-6000 connect into N-NET fire alarm network, each control panel must

install a NIC-EC card. Connection terminal, jumper and indicative show as below:

Fig. 3-6 NIC-EC Connection Diagram

Connections terminal illuminate table:

Terminal Illumination

TB1 Network port A

TB2 24VDC power port

TB3 NIC-EC and CPU-6000 communication portRS232

TB5 Network port A

Table 3-7 NIC-EC Terminal Illumination

Jumper illuminate table:

Terminal Illumination

JP6 RS232 modeleave factory set, not to change

JP7 Open leave factory set, not to change

JP8 Open leave factory set, not to change

JP9 RS232 modeleave factory set, not to change

Table 3-8 NIC-EC Jumper Illumination

LED status illuminate table:

-

8/10/2019 FCU-6000 system manual

19/68

LED1 Green Port B signal outputBlink when signal output

otherwise off

LED2 Green Port B signal inputBlink when signal input

otherwise off

LED23 Green Port B informationstatus

Status overturn after send or

receive a frame informationcorrectly

LED24 Yellow Port B troubleLED on when send or receive aframe information wrongly or

check out communication error

LED25 Red Port B circuit trouble LED on when any trouble occur

LED3 Green Port A signal outputBlink when signal output

otherwise off

LED4 Green Port A signal inputBlink when signal input

otherwise off

LED20 GreenPort A information

status

Status overturn after send or

receive a frame informationcorrectly

LED21 Yellow Port A trouble

LED on when send or receive a

frame information wrongly orcheck out communication error

LED22 Red Port A circuit trouble LED on when any trouble occur

LED5 GreenSystem running

indicationBlink when running normally

LED6 YellowControl panel type

indicationLED on when connect to

CPU-6000

LED7 RedControl panel type

indicationLED on when connect to N-NCS

LED8 Green+24V power status

lightLED on when +24V power

supply normally

LED9 Green+5V power status

lightLED on when +5V power supply

normally

LED10 GreenTB3 port signal

inputBlink when signal input

otherwise off

LED11 Green J9 signal inputindication

Blink when signal inputotherwise off

LED12 GreenTB3 port signal

outputBlink when signal output

otherwise off

LED13 GreenJ9 signal output

indication

Blink when signal output

otherwise off

LED14 Green Function reserve

LED15 Green Function reserve

LED16 Red Function reserve

LED17 Green TB3 portinformation

Status overturn after send or

receive a frame information

-

8/10/2019 FCU-6000 system manual

20/68

correctly

LED18 Yellow TB3 port troubleLED on when receive

information error

LED19 RedTB3 port circuit

troubleLED on when receive

information error

LED26 Blue Function reserve

Table 3-9 NIC-EC Indicative Light Illumination

DIP switch network address setting table:

SW2 status Function

ON1

OFF

ON2

OFFON

3OFF

ON4

OFF

ON5

OFF

ON6

OFF

1~6bits switch

ON for 1OFF for 0

Composing a 6 bits binary number,

this number infer network cardaddress. Network card address

range is the number between 0~63.

Network card address must be same

as the connect devices address.

ON Relay mode7

OFF Bus mode

ON N-NCS8

OFF CPU-6000

Table 3-10 NIC-EC Address Setting

3.5.3.4Loop Control Module Connection

N-6000 support 15 LCM-2 cards, and 30 loops. LCM-2 support style 4 or T-type

wiring. TB2 in LCM-2 board connect to CUP-6000 interface, the rest connect each

other. LCM-2 can connect with twisted shielded pair cable: signal connect to TB2,

power connect to TB3; also can connect each other through J2 and J4.

-

8/10/2019 FCU-6000 system manual

21/68

Fig. 3-7 Loop Control Module Connection Diagram

Connection terminal illuminate table:

Terminal Illumination

TB2 Connect to CPU-6000RS485also can connect to LCM card

TB3 24VDC power port

TB4 Loop 1 portthe loop number is SW1s value

TB5 Loop 2 portthe loop number is SW1s value1

J2 Interlink port

J4 Interlink port

Table 3-11 LCM-2 Card Terminal Illumination

Jumper illuminate table:

Terminal Illumination

JP1 Communication to CPU-6000 port terminal resistance (normal open)

JP2 Communication to CPU-6000 port terminal capacitance (normalopen)

JP4 Switch to RS232 modeleave factory set, not to change

JP5 Switch to RS232 modeleave factory set, not to change

Table 3-12 LCM-2 Card Jumper Illumination

LED Status Illuminate table:

Terminal Illumination

LED1 3.3V system power supply indication

LED2 24 V system power supply indication

-

8/10/2019 FCU-6000 system manual

22/68

LED3 5 V system power supply indication

LED4 CPU-6000 communication/LCM card local mode indecation

LED5 Loop 1 running indication

LED6 Loop 1 trouble indication

LED7 Loop 1 fire alarm indication

LED8 Loop 2 running indication

LED9 Loop 2 trouble indication

LED10 Loop 2 fire alarm indication

LED11 Communication to CPU-6000send indication

LED12 Communication to CPU-6000send indication

Table 3-13 LCM-2 Card Status Light Illumination

DIP Switch Loop Number Setting table:

SW1~8 1~8bits switch

ON for 1OFF for 0

Composing a 8 bits binary number, infer LCM card

address. SW1 setting range is the odd number between1~29

Table 3-14 LCM-2 Loop Number Setting

3.5.3.5MCU-16B Annunciator Control Module

ConnectionN-6000 can connect MCU-16B. Support the manual control to output point of

control module, and use LED to show the status of controlled points.

MCU-16B includes 16 output indicative light, 16 feedback statuses light, 16 button

to manual control, a complex function button, a enable/disable button and a

manual/auto status light.

Each manual control module can be programmed to any control module. Each

feedback statuses light can be programmed to control an input device.

Enable/disable button use to enable or disable 16 manual control buttons.

MCU-16B connects to N-6000 by RS-485 port, this port can support 32MCU-16B.

-

8/10/2019 FCU-6000 system manual

23/68

Fig. 3-8 Annunciator Control Module Connection Diagram

Connection terminal illuminate table:

Terminal Illumination

TB1 24VDC power port

TB2 Connect to CPU-6000RS485

J1 Interlink port

J3 Interlink port

Table 3-15 MCU-16B Terminal Illumination

Jumper illuminate table:

Terminal Illumination

JP1Open

leave factory set, not to change

JP2 Communication to CPU-6000 port terminal resistance (normalopen)

JP3 Communication to CPU-6000 port terminal capacitance (normal

open)

JP4 Switch to RS232 modeleave factory set, not to change

JP5 Switch to RS232 modeleave factory set, not to change

JP6 Buzzer switchdefault shortcut, enable

Table 3-16 MCU-16B Jumper Illumination

LED Status Illuminate table:

-

8/10/2019 FCU-6000 system manual

24/68

Terminal Illumination

LED1 24 V system power supply indication

LED2 5 V system power supply indication

LED3 3.3 V system power supply indication

LED4 System running indication

LED39 Communication to CPU-6000send indication

LED40 Communication to CPU-6000send indication

Table 3-17 MCU-16B Status Light Illumination

DIP Switch Loop Number Setting table:

SW2 status function

ON1

OFF

ON2

OFF

ON3

OFF

ON4

OFF

ON5

OFF

1~8bits switch

ON for 1OFF for 0

Composing a 5 bits binary number, thisnumber +1 infer MCUs address.

MCUs address range is the numberbetween 1~29

ON6

OFFNONE

ON7

OFFNONE

8 ON NONE

Table 3-18 MCU-16B Network address setting

3.6Equipment Debugging

3.6.1Connection Inspection

Visually inspect the control panel condition

Visually inspect the external connection ports

Open the control panel and visually inspect all connections. Confirm connectionsare correct, that there are no loose connections, no short circuits, unplugged or

-

8/10/2019 FCU-6000 system manual

25/68

disconnected connectors as well as confirm the power supply does not have

any short circuit trouble.

Visually inspect the jumpers in the circuit to confirm there are no duplicatenumbers.

3.6.2Power-on Inspection

After you have finished the visual inspection, power-on the battery power supply.

With the battery started a buzzer should be heard and the LCD should temporarily

function normally. Once the control panel enters normal operation status, a buzzer

and LED horn/strobe will indicate a troubled status because main power is not

connected. Power-down and disconnect the battery power supply then connect and

power on the main power supply. Once the control panel enters normal operation

status, a buzzer and LED horn/strobe will indicate a troubled status because the

battery power supply is not connected. At this time, connect the battery power

supply. Soon after the control panel will return to normal operating status.

During normal operation, if both the main and battery power supplies are

connected the power supply status lamp (on the main panel of the control panel)

will maintain normal illumination.

When the main power supply fails because of loss of power, poor power

connection, an over-voltage or under-voltage of 5V and 24V, or a short circuit with

rack earth and communication trouble with the mainframe, the power supply status

lamp (on main panel of the control panel) illumination will stop. Then both a

buzzer and LED horn/strobe will indicate a troubled status while additional

information will be shown on the control panel LCD.

3.6.3External Connection

Look for any short-circuits or disconnections to and from the control panel. Once

everything has been inspected, connect the control panel.

Batch installation -- connecting 10-20 detectors or modules on the loop per time --

is highly recommended. After installing the detectors or modules restart the control

panel to ensure the newly installed devices are recognized and installed correctly.

If the control panel gives a trouble signal recheck the circuit and addressable

devices are installed properly. Once the trouble signal has been solved, continuebatch installation and power testing. After all the devices have been installed, the

simulated trouble, fire alarm and CBE event functions maybe tested. Confirm that

the control panel alarms normally, properly links field equipment and accurately

prints corresponding alarm information. Continue testing and adjusting until panel

maintains normal operating status.

3.6.4Important Points

Avoid touching the circuit board IC chip during installation

Pay attention to polarity during connection and installation

-

8/10/2019 FCU-6000 system manual

26/68

Before starting the system, check for short circuits, disconnection or reversepolarity

Connectors among leads shall be wielded and inter-line insulation shall beguaranteed.

3.6.5Inspection Methods for Addressable Device

Connections

To test the function of the multi-meter, connect the loop in reverse polarity (the

positive pole connects with the loop negative and the negative pole connects with

the loop positive). The multi-meter should indicate a bias value for the diode.

Then connect the multi-meter normally (positive pole connects with the loop

positive and negative pole connects with the loop negative). The multi-meter

should indicate a low resistance value that increases with the charging of the loop

capacitor. If after proper polarity connection the multi-meter still indicates a biasvalue for the diode, there is one or more addressable device(s) connected in reverse

polarity.

-

8/10/2019 FCU-6000 system manual

27/68

Section 4:Operation

4.1LED Indicators and Keys

4.1.1Control Panel Display LED

Indicators and Keys

The N-6000 is an intelligent addressable Fire Alarm Control Panel (FACP) with

advanced features ideal for a variety of applications. The CPU-6000 includes a

front display/keypad enabling localized control panel viewing and programming.The display/keypad provides an easy-to-use keypad and large LCD (liquid crystal

display) that simplifies the programming process.

The display is 53 characters wide by 20 lines long and displays all programming

screens. These include the events, history, devices as well as other additional

information.

Fields may be entered or changed and commands may be issued using the display

keypad.

Fig. 4-1 Display/Keypad Diagram

-

8/10/2019 FCU-6000 system manual

28/68

LED Lamp Status

LED Indicator Color Functions

Fire alarm Red Illuminates when at least one fire alarm event exists. It will

flash if any of these events are unacknowledged.

Pre-alarm Red Illuminates when at least one pre-alarm event exists. It will

flash if any of these events are unacknowledged.

Trouble Yellow Illuminates when at least one trouble event exists. It will flash

if any of these events are unacknowledged.

Power Green Indicates current status of the power supply. During normal

communication with the power supply, the lamp will flash.

Self-test Yellow Indicates the system is in self-test status. The LED will

remain lit during the self-test.

CBE Red I/O module is functioning properly or there is a feedback

signal.

Delay Red If the control panel has a delayed control output the LED will

remain illuminated throughout the delay period. It will turn

off upon termination of the delay period.

Signal Silenced Yellow Illuminates if NFS-3030 Notification Appliances have been

silenced. It flashes if some but not all of the N-6000 NACs

have been silenced.

Point Disabled Yellow Illuminates when at least one device has been disabled. It will

flash until all disabled points have been acknowledged.

Supervisory Red Illuminates when at least one supervisory event exists. It will

flash if any of these events are unacknowledged.

CPU Failure Yellow Illuminates if there is an abnormal hardware or software

condition. Contact technical support. The panel is out of

service when this LED is illuminated or flashing.

Table 4-1 LED Indicator Description

Operation Keys:

A-a: Caps lock key

Space: During programming, change the status of the check boxto and change back to when finished

Backspace: Backspace key

Menu: Press to enter the menu

Help: Help key

PREV/NEXT: Press to skip to the previous/next control screen

-

8/10/2019 FCU-6000 system manual

29/68

ESC: Escape key

Enter: Key to acknowledge input

TAB: Switch key, same as the NEXTkey

: Previous page/next page/ : Previous event/next event

Fixed Function Keys:

Acknowledge: Acknowledge event operation

Signals Silenced:

1. Press for less than 1 second: carries out silencing operation onperipheral equipment

2. Press for longer than 1 second: system exercise (please refer to

relevant topics under loop card setting)

Fire alarm/Pre-alarm:

1. Press for less than 1 second: query fire alarm event

2. Press for longer than 1 second: query pre-alarm event

Trouble/ Horn / Strobe: Carry out query operation during troubleevent

1. Press for less than 1 second: query trouble event

2. Press for longer than 1 second: query horn/strobe event

Supervision/Feedback: Carry out query operation on supervisionevent

1. Press for less than 1 second: query supervision event

2. Press for longer than 1 second: query feedback event

CBE/Delay:

1. Press for less than 1 second: query CBE event information

2. Press for longer than 1 second: query the logic zone in delay status

with a logic value of TRUE

Manual/Automatic: Control manual/automatic execution link

Lamp inspection/Self-test: System lamp inspection/self-test

Reset: Reset system operation

-

8/10/2019 FCU-6000 system manual

30/68

4.1.2Annunciator Control Module LED

Indicators and Keys

Fig. 4-2 Bus Control Module Schematic Diagram

The annunciator control module has a total of 32 indicating lamps, 16 keys and 16

feedback signals.

One composite button: Time function key has 3 functions

1Press for about 1 second: LED lamp below the key will illuminate locking thecontrol key module

2Press for more than 1 second: LED lamp on the right side of the key willilluminate with manual/automatic allowed

3Press for more than 4 seconds: horn/strobe self-test

No. 1-16 Start Keys:

-Press a key and the corresponding feedback signal a (Lamp 1-16) flash, whichmeans corresponding key has been pressed.

-

8/10/2019 FCU-6000 system manual

31/68

-When a feedback indicating lamp (Lamp 1-16) flashes, it indicates that anoperational signal from CBE equipment has been received and the

corresponding CBE equipment will be started.

4.2Power-onConnect 220V AC power, and then turn on the main power supply using the switch

inside the cabinet. Power-on Screen is shown in Fig. 4-4:

Fig.4-3 Power-on Screen

4.3System Self-test

Fig. 4-4 System Self-test Screen

After the N-6000 has been turned on, it will self-test both the hardware and

software of the system. During the self-test all LED indicating lamps on the left

side of the mainframe panel will flash. Once the self-test has finished a buzzer willsound and LEDs will temporarily illuminate after which the panel will return to a

-

8/10/2019 FCU-6000 system manual

32/68

normal operation status. Additionally, the system will show the display screen

while the power supply indicating lamp continues to flash.

After a self-test, the system will show the following screen:

Fig. 4-5 Normal System Screen

The normal system screen is divided into three bars; these include the event

statistics bar, the alarm screen bar and the status bar. The event statistics bar shows

fire alarms, trouble alarms, supervision, CBE and point disabled locations. The

status bar shows the node number, manual/automatic status, transmission

equipment status, main or reserved power supply status, the current date/delay

status of the latest logic zone as well as the current time.

Manual/Automatic Status

System in manual status

System in automatic status

Transmission Equipment Status

Both delivery and feedback

Transmission equipment in delivery status

Transmission equipment in feedback status

Transmission equipment in normal status without delivery or feedback

Transmission equipment in Point disabled status

Transmission equipment in trouble status

Operation Status of the Main or Reserved Power Supply

Main power normal

Low voltage in main power

Trouble in main power

Battery normal

-

8/10/2019 FCU-6000 system manual

33/68

Low voltage in battery

Battery disconnected

Current date/delay status of the latest logic zone, this item can show the current

date. When CBE appears, it will also show delay status information of the latest

logic zone. For example: , where ZL0099 means logic zonenumber 99 and 00001 means that CBE will output after a 1 second delay.

4.4Event Display

Event Order:

First: Fire alarm, CBE, feedback

Second: Supervision

Third: Trouble

Fourth: Point Disabled - disabled

4.4.1Trouble Screen

Fig. 4-6 Trouble Screen

When the control panel detects a failing power supply or other trouble, it will

execute a series of operations:

A trouble relay will be activated and the control panel will alarm

A system trouble indicating lamp on the control panel display will flash and theLCD will show a trouble screen

Detailed trouble type will show the exact geographic location and occurrencetime on the LCD

-

8/10/2019 FCU-6000 system manual

34/68

A trouble event will be saved to the native Flash ROM and the printer will print arecord of the trouble event

Press the key or the key on the main panel to review the previous or

next trouble event and press thekey to page up or down. Press

ACKkey on the main panel to acknowledge, and all trouble events will beshown one by one. Once the alarm has silenced and all trouble events have beenacknowledged, the system trouble indicating lamp on the main panel will return to

its normal illumination.

The most common trouble events include but are not limited to: equipment off-line,

grounding the equipments positive terminal, grounding the equipments negative

terminal, the equipments positive terminal is disconnected, the equipments

negative terminal is disconnected, power supply shows low voltage, power supply

shows high voltage, unmatched load types, low threshold values, database errors.

4.4.2Fire Alarm Screen

Fig. 4-7 Fire Alarm Screen

When a detector or monitoring module is activated (fire alarm detected), the

control panel will execute a series of operations:

A system alarm relay will be activated and the control panel will alarm

A fire alarm indicating lamp on control panel display will flash and the LCD willshow a fire alarm screen.

Detailed fire alarm name will show the exact geographic location and occurrencetime on the LCD.

Alarm information will be saved to the native Flash and the printer will print arecord of the alarm event.

Press thekey or thekey on main panel to review the previous or next

fire alarm event and press thekey to page up or down. Press

the OKkey on main panel to acknowledge, and all fire alarm events will beshown one by one. Once the alarm has silenced and all fire alarm events have been

-

8/10/2019 FCU-6000 system manual

35/68

acknowledged, the system fire alarm indicating lamp on the main panel will return

to its normal illumination.

4.4.3Supervisory Screen

Fig. 4-8 Supervision Screen

The monitoring modules produce monitoring style codes. Once a monitoring

module has been activated, the control panel will execute a series of operations:

A monitoring relay will be activated and the control panel will alarm

A supervision indicating lamp on the control panel will flash and the display willshow the supervision screen

Monitoring information will be saved to the native Flash and the printer will printa record of the supervision event

Press the key or the key on main panel review the previous or next

fire alarm event and press thekey to page up or down. Press

theOKkey on main panel to acknowledge all supervision information has beenshown. Once the alarm has silenced and all the supervision events have been

acknowledged, the supervision indicating lamp on the main panel will return to its

normal illumination.

-

8/10/2019 FCU-6000 system manual

36/68

4.4.4Point Disabled Screen

Fig. 4-9 Point Disabled Screen

When a point disabled location exists in a loop, each disabled point (detector,

module, and loop) will be shown one by one (see Fig. 4-10). The control panel will

execute a series of operations:

A point disabled indicating lamp on the control panel will flash but the controlpanel will not alarm

A point disabled indicating lamp will be illuminated

The point disabled information will be saved to the native Flash and the printerwill print the current point disabled information

Press thekey or thekey on main panel of the control panel to review

the previous or next point disabled event and press the key

to page up or down. Press OK key on main panel of the control panel toacknowledge all Point disabled information has been shown. Once the alarm has

silenced and all point disabled events have been acknowledged, the point disabled

indicating lamp on the main panel will return to its normal illumination.

-

8/10/2019 FCU-6000 system manual

37/68

4.4.5CBE Screen

Fig. 4-10 CBE Screen

4.4.6Pre-alarm Screen

To enter the pre-alarm screen and also query the pre-alarm screen keep pressing the

Fire alarm/Pre-alarmcomposite key on the main panel. The pre-alarm screen isshown below:

Fig. 4-11 Pre-alarm Screen

-

8/10/2019 FCU-6000 system manual

38/68

4.4.7Horn / strobe Screen

To enter the horn/strobe screen and also query the horn/strobe screen keep pressing

the Trouble/Horn/Strobecomposite key on the main panel. The horn/strobe

screen is shown below:

Fig. 4-12 Horn/Strobe Screen

4.4.8Feedback Screen

To enter the supervision/feedback screen and also query the supervision/feedbackscreen keep pressing theSupervision/Feedbackcomposite key on the main panel.The supervision/feedback screen is shown below:

Fig. 4-13 Feedback Screen

-

8/10/2019 FCU-6000 system manual

39/68

Section 5:Programming

5.1Menu

-

8/10/2019 FCU-6000 system manual

40/68

System Management

Device Configuration

CBE Programming

Device Control

History Event

System Setting

Modify Password

Main Reset

LCM

DCU

MCU

Remote Display

General Zone

Logic Zone

Manual Output

Status Track

Walk Test

Power Management

Setting

Auto Programming

Point Programming

Setting

Point Programming

Setting

Point Programming

Setting

Point Programming

Status Track

Download Labels

Menu

Fig. 5-1 N-6000 Schematic Menu Diagram

-

8/10/2019 FCU-6000 system manual

41/68

When programming the control panel or reviewing history events, press the

Menukey to view thefollowing screen:

Fig. 5-2 User Login Screen

Once a user has entered the correct password, he/she will enter the main menu and

view the following screen. In the main menu screen, he/she can update or change

the system management, device configuration, CBE programming, device control

and history events.

Fig. 5-3 Main Menu Screen

5.2System Management

Under System management the operator has 3 options; (1) System setting, (2)

Modify Password, or (3) Main Reset. The system management screen is shown as

follows:

-

8/10/2019 FCU-6000 system manual

42/68

Fig. 5-4 System Management Screen

5.2.1System setting

Under System Setting the following screen will be shown:

Fig. 5-5 System Setting Screen

Line 1: The node is the control panels address within the network while the label is

a description of the control panel

Line 2: If (YES) is selected for the time server option, then this control panel is

the time master within the network and all other panels will synchronous

accordingly. Click the button time & date to set the time and date of the control

panel

Line 3: Languagedetermines the language of the control panel display. At

present two languages are currently available: Chinese and English

Line 4: Backlightthe duration of time the LED display remains lit. There are fourchoices available: Normal Open, Normal Close, Off in 30 Seconds and No Display.

-

8/10/2019 FCU-6000 system manual

43/68

Line 5 to Line 7: Relaysthere are 3 relays each with 7 operational modes:

Disabledthe relay is disabled

Fire alarm outputthe relay will close upon fire alarm

Trouble outputthe relay will close during trouble status

CBEthe relay will close during CBE

Supervisionthe relay will close during supervision

CBE logic outputthe relay will only be used in CBE output expression.When the value of located expression is true, the relay will close and re-open in

the opposite condition

Reset outputthe relay will close during normal operation or when the systemis being reset.

Line 8& Line 9: COM2 serial ports each with 4 operational modes:

Degradation CBE: (YES)/ (NO). The default status (YES) is

Normal Open. Degradation CBE only works when enabled

Fire Alarm Verification: (YES)/ (NO). The default status is (YES).

This function has a time sensitive fire alarm, ensuring an alarmed status will be

accurate. This setting can greatly reduce false alarms and improve system

efficiency

Failover: (YES)/ (NO). The default status is (NO). Failover is the

trouble display switch for the whole control panel. If (YES) is chosen, all

trouble signals will be disabled without any display or alarm although a history

record is still maintainedMain Power Supply: (YES)/ (NO). The default status is (YES),

which installs the main power supply for the control panel

Reserved Power Supply: (YES)/ (NO). The default status is (YES),

which installs the reserved power supply for the control panel

Reset Verification: (YES)/ (NO). The default status is (NO). If

(YES) is chosen, a password needs to be entered before resetting. If (NO) is

chosen, a password does not need to be entered before resetting

5.2.2Password modificationUnder Password modification, a user can modify his/her password according to

their system status (Admin, Engineer, or Guest). The password modification screen

is shown below:

-

8/10/2019 FCU-6000 system manual

44/68

Fig. 5-6 Password Modification Screen

The N-6000 has 3 different user levels, each level is password protected. The three

levels are (ordered from highest to lowest) Administrator, Engineer and User. Each

level has its own password. The Administrator user can modify any password in

the system (including the Administrator level). The User can only operate on the

4th setting, Device Control and the 5th setting, History event. The Engineer

can operate all five settings in the menu but will be interrupted (exit programming)

when an alarm event occurs. The Administrator can operate all five settings in the

menu and will not be interrupted during an alarm event.

Factory default passwords are as follows: 333333 for Administrator, 222222 for

Engineer and 111111 for User.

After the initial login the user will enter the password modification screen. He/she

can change the password by entering a new password in the Enter new password

dialogue box and then re-entering the new password in the Confirm new

password dialogue box. Once the system has confirmed the two passwords are the

same, the user should pressOKto confirm the password change. After the user

has pressed OK the password will be successfully modified, to cancel the

previous operation press the Cancelbutton.

Note: If an incorrect password is entered, the system will show another dialogue

box requesting the correct password be entered.

5.2.3Main Reset

In the System Setting screen choose Main Reset to reset the system to all

default factory settings.

-

8/10/2019 FCU-6000 system manual

45/68

Fig. 5-7 Main Reset Screen

After the correct Administrator password has been entered, a dialogue box will

prompt to verify the Main Reset choice. Press OK to confirm the reset and

restore default factory settings. Press Cancel to cancel the operation and exit the

screen.

5.3Device Configuration

Choose the Device Configuration screen to adjust the settings of the loop cards,

multi-line control modules, annunciator control modules and repeaters. Screen

shown below:

-

8/10/2019 FCU-6000 system manual

46/68

Fig. 5-8 Device Configuration Screen

5.3.1Loop card

In the Device Configuration screen, choose the LCM option to enter the screen

shown below in Fig. 4-23:

Fig. 5-9 Loop Card Screen

5.3.1.1Parameter setting

In the LCM screen, to adjust the settings and program options, choose Setting,

Auto Programming, or Point programming. The screen is shown in Fig. 4-24:

-

8/10/2019 FCU-6000 system manual

47/68

Fig. 5-10 Parameter Setting Screen

Line 1: LCM- Loop number.

Line 2: Name- Loop Description

Line 3: Installation status these include: Uninstalled, Normal, and Disabled.

Line 4: Time Rapid Polling - the number of preferential in-process checks, the

default value is 0. This option controls both the point and card level settings. The

card level setting determines the preferential times while the point level setting

determines whether the point needs the preferential in-process check. The loop

card will carry out preferential in-process checks on the load points where

Preferential in-process check has been activated.

Line 5: Style 4 Wiring - (YES)/ (NO). The system default status is

(YES). Using style 4 wiring the circuit status can be monitored through the

ring circuit line voltage. The system will detect differences between the positive

and negative circuits to monitor if a disconnection trouble within the loop occurs. If

the wiring connection does not use style 4 configuration, the mainframe will report

a disconnection trouble.

Line 6: Local Mode - (YES)/ (NO). If (YES) is selected, the local

CBE setting will be effective within the loop.

Line 7: Silenceable - (YES)/ (NO). This option controls both the point and

card level settings. By programming definition the point level setting is the same asthe card level setting. When (YES) is chosen and a horn/strobe alarm or alarm

bell activates, the user can press Signals Silencedon main panel of the controlpanel to silence the alarmed equipment. If (NO) is selected, the user cannot

silence the alarmed equipment using the Signals Silencedbutton.

Line 8: Address Conflict - (YES)/ (NO). If (YES) is selected, during

inspection the system will search for device address duplications within a loop. If

duplication is found, the panel will show a prompt with further instructions. If

(NO) is chosen, the detector will not report duplicate addresses.

Line 9: L+ Ground Fault Detect - (YES)/ (NO). When (YES) is

selected and a positive end of the loop is grounded, the system will report positive

-

8/10/2019 FCU-6000 system manual

48/68

end grounding trouble. If (NO) is chosen, the system will not report positive

end grounding trouble.

There are three function keys, Sync, Save, and Quit in the status bar. The

Sync button allows the operator to download parameter settings (both card level

and point level settings). The Save button saves the changes that have been

selected. The Quit button allows the user to quit without saving the changes.

5.3.1.2Auto Programming

Fig. 5-1 Automatic Login Screen

Each loop has 3 status options: Installed, Uninstalled, and Disabled. During normalinstallation, the programmer may enter the Auto Programming screen. When

he/she selects a loop number for automatic programming and then presses OK,

the system will verify each device on the selected loop.

Caution: When either a CMX-2 control module or a M500K call point are on

a loop using Auto Programming the control panel will misidentify the CMX-2 as

a CMX-7(C) and misidentify the M500K as an MMX-7. When this happens, the

user should enter 4.5.2.1.3 Point Programming screen (device configuration

LCMpoint programming) to modify the device identity by selecting the proper

equipment type.

-

8/10/2019 FCU-6000 system manual

49/68

Fig. 5-12 Automatic Programming

Upon completion of auto-programming, the quantity, type, and status of each

device on the loop will be automatically shown. This is a convenient time for

system operators to inspect, check, and manage the connected field devices. Press

thekey or thekey to review the address and type of each point installedon the loop. The screen is shown in Fig. 5-13:

Fig. 5-13 Auto Programming

-

8/10/2019 FCU-6000 system manual

50/68

-

8/10/2019 FCU-6000 system manual

51/68

Local Mode: (YES)/ (NO). The factory default setting is (NO). Thisoption controls both the point and card level settings. By programming

definition the point level setting is the same as the card level setting. If the loop

card and mainframe have a communication failure all selected modules

(degradation mode) will automatically output a fire alarm signal.

Silenceable: (YES)/ (NO). When (YES) is chosen and a horn/strobe

alarm or alarm bell activates, the user can press Signals Silencedon mainpanel of the control panel to silence the alarmed equipment. If (NO) is

selected, the user cannot silence the alarmed equipment using the Signals

Silencedbutton.

Switch Inhibited: (YES)/ (NO). When (YES) is chosen manualoutput point operation is inhibited.

Resetable: (YES)/ (NO). When (YES) is selected, the equipmentwill automatically reset all output signals when the system is reset.

Drift Compensation: (YES)/ (NO). When (YES) is selected, thesystem will restrain individual sensors from automatically performing drift

compensation.

Rapid Polling: (YES)/ (NO). When (YES) is selected, the systemwill increase the frequency of in-process inspection on the loop thus increasing

the sensitivity of the equipment.

Alarm Verification: (YES)/ (NO). When (YES) is selected, therewill be an adjustable delay in the alarm period after a preliminary alarm has

registered, allowing time for the alarm to be verified before sending a general

alarm. Should an alarm condition still exist after verification, the panel willthen go into alarm. Verification time is adjustable (in seconds intervals) and

can be customized by using the edit feature on the right side of the alarm

verification label.

5.3.2Annunciator Control Module

In the MCU screen, a programmer can access the Setting and Point

programming options for an annunciator control module.

-

8/10/2019 FCU-6000 system manual

52/68

Fig. 5-15 Annunciator Control Module Screen

5.3.2.1Parameter setting

Fig. 5-16 Parameter setting Screen

Line 1: MCUSelect the MCU number.

Line 2: DescriptionDescribe the selected MCU.

Line 3: Set the current MCU status. These include: Uninstalled, Normal and

Disabled.

Press Save to save the current settings. If the user presses Exit without saving,

the following dialogue box will be prompted. At this time the user can also save the

current settings. The user can also exit the current screen to retain previous settings;

the current settings will not be saved.

5.3.2.2Point Programming

Point Programming of MCU can access to set the relative module address of keys

and feedback led.

-

8/10/2019 FCU-6000 system manual

53/68

Fig. 5-17 Point Programming Screen

5.3.3Remote Display

In the Remote Display screen, a programmer can access the Setting,

Download Label and Point Programming option screens. One N-6000 fire

alarm control panel can have up to 64 remote displays.

Fig. 5-18 Remote Display Screen

-

8/10/2019 FCU-6000 system manual

54/68

5.3.3.1Parameter setting

Fig. 5-19 Parameter setting Screen

Line 1: Remote displayDisplays the remote display number.

Line 2: DescriptionDescribes the selected remote display.

Line 3: Set the current remote display status. These include: Normal, Disabled and

Uninstalled.

Press Save to save the current settings. If the user presses Exit without saving,

the following dialogue box will be prompted. At this time the user can also save the

current settings. The user can also exit the current screen to retain previous settings;

the current settings will not be saved.

5.3.3.2Label Download

Fig. 5-20 Download Label Screen

In the Download Label screen a programmer can view detailed information byselecting the desired floor repeater number and pressing OK. At this time, the

-

8/10/2019 FCU-6000 system manual

55/68

system will download relative content for each point in the selected repeater floor

display. If past events have occurred in the selected equipment points, all

previously downloaded contents will also be shown on the remote display. This

allows field operators to update equipment settings for optimal device function.

5.3.3.3Point Programming

Fig. 5-21 Point Programming Screen

Line 1: Displays the remote display number, point number and installation status.

These include: Uninstalled, Normal, and Disabled.

Line 2: Displays the current remote display point description

Line 3: Point MappingEach remote display can have up to 64 points. Each point

must have a specific zone and loop address. After each point has been mapped,

during an event (fire alarm, trouble, etc) the mapped equipments location and

event will be shown on the relative remote display screen.

Press Save to save the current settings. If the user presses Exit without saving,

the following dialogue box will be prompted. At this time the user can also save the

current settings. The user can also exit the current screen to retain previous settings;

the current settings will not be saved.

5.3.4CBE Programming

In the CBE Programming screen programmers can access both the General

Zone and Logic Zone setting screens.

-

8/10/2019 FCU-6000 system manual

56/68

Fig. 5-22 CBE Programming Screen

5.3.4.1General Zone

Within the General Zone screen a user can select zones 0-499 to review the

relative logic equation of a particular zone. Use the VFT programming software to

modify the logic equations as necessary.

Fig. 5-23 General Zone

5.3.4.2Logic Zone

Within the Logic Zone screen a user can select zones 0-999 to review the relative

equation of a particular zone. Use the VFT programming software equation to

modify the logic equations as necessary.

-

8/10/2019 FCU-6000 system manual

57/68

Fig. 5-24 Logic Zone

5.3.5Device Control

In the Device Control screen a user can access the Point Output, Status

Tracking, Walking Test, Loop Exercise and Power Supply Management

setting screens.

Fig. 5-25 Device Control Screen

-

8/10/2019 FCU-6000 system manual

58/68

5.3.5.1Manual Output

Fig. 5-26 Manual Output Screen

Within the Point Output screen a user can set the loop number, address number,

type of equipment, label and the inspection lamp ON/OFF status. Press the

key or the key to review a points status.

Line 1: Displays the current loop number, address and status. These include:

Uninstalled, Normal and Disabled.

Line 2 & Line 3: Displays the current point description and extended description.

Line 4: Displays the current point alarm type. These include: Fire Alarm,Supervision, Feedback and General Output.

Line 5 & Line 6: Displays the current equipment type and model.

Line 7: Displays the selected output module status. If the user chooses Start and

then presses OK, the point in the current loop will be output by the module; if set

at Close, the point will not be output by the module.

-

8/10/2019 FCU-6000 system manual

59/68

5.3.5.2Status Tracking

Fig. 5-27 Status Tracking Screen

Within the Status Track screen a user can set the loop number, address number,

address type as well as monitor the point.

Line 1: Displays the current loop number, loop address and its status. These include:

Uninstalled, Normal and Disabled.

Line 2 & Line 3: Displays the current point description and extended description.

Line 4: Displays the current point alarm type. These include: Fire Alarm,

Supervision, Feedback and General Output.

Line 5 & Line 6: Display the current equipment type and model.

Line 7: Displays the current point status.

5.3.5.3Walk Test

Fig. 5-28 Walk Test Screen

-

8/10/2019 FCU-6000 system manual

60/68

Within the Walk Test screen a user can set the loop number, address number,

address type as well as run a walking test on a particular loop.

Line 1: Displays the loop number, current address and installation status. These

include: Uninstalled, Normal and Disabled.

Line 2 & Line 3: Displays the current point description and extended description.Line 4: Displays the current point alarm type. These include: Fire Alarm,

Supervision, Feedback and General Output.

Line 5 & Line 6: Displays the current equipment type and model.

After adjusting the systems settings, pressing theLamp inspection/Self-testkeyon main panel will cause the control panel to run a self-test on the current loop.

During this test, both the self-test indicating lamp and the load verification lamp

will be normally illuminated. Press Review the Result to view every address in

the current walk test, the addresses will be displayed on the right hand side of the

walk test interface screen (Fig. 4-50).

Fig. 5-29 Walk Test Address Screen

Press OK to control current point set in the loop.

-

8/10/2019 FCU-6000 system manual

61/68

5.3.5.4Loop Drill

Fig. 5-30 Loop Drill Screen

5.3.5.5Power Supply Management

Fig. 5-31 Power Management Screen

N-6000 fire alarm control panel uses the MPS-350W power supply. Within the

Power Management screen the user can review the current status of each power

supply.

Line 1: Displays the currently connected power supply type. The MPS-350W is the

primary power supply for the N-6000.

Line 2: Displays the current status and voltage of the main power supply.

Line 3: Displays the current status and voltage of the reserved power supply.

Line 4: Press Dischargeto discharge the power supply. Press Stopto stop

discharging. Press Exitto exit the power supply control screen.

-

8/10/2019 FCU-6000 system manual

62/68

5.3.6History Events

Within the History Events screen a user can access the systems history

records/events. This screen is seen below:

Fig. 5-32 History Event Screen

Line 1: Displays the type of history event. History event types include but are not

limited to: fire alarm, trouble, supervision, CBE and Isolation. When All Events

is selected, detailed information will be provided for each event. If All Events is

not selected the user must select a particular event to view the additional and

detailed information.

Line 2: Displays the total number of events that can be reviewed.

Line 3: Displays the status of the current event. The operator may obtain detailed

information about the current event including location, type, time of occurrence,

serial number, as well as additional information from the following text box.

Line 4: Press Exitto exit the history event screen.

Pressing theNEXTkey or thePREVkey on main panel of the control panel,a user can review the detailed description of the next or previous history event.

N-6000 can record and display up to 8000 individual history events.

-

8/10/2019 FCU-6000 system manual

63/68

Section 6:Miscellaneous

6.1Safety Protection Device

The N-6000 has been designed with built-in safety devices to protect both the operator and

control panel in case of improper use and/or installation. These devices include an anti-misplugterminal which can endure extremely high voltage and current ensuring the safety of both

operators as well as the control panel. Additionally the control panel has current limitingprotection for the power supply, protection circuits for communication devices, and special

grounding terminals provided within the cabinet.

6.2Usage and MaintenanceTo ensure consistent and reliable operation the following items should be observed andfollowed:

The control panel must be installed and debugged by qualified technicians

The operator on duty should be familiar with the current building structure as well asunderstand all possible control panel events and operations

An operator should monitor the control panel status to eliminate various trouble signals andprevent alarm signals when possible

If a power failure exceeds 8 hours, the reserve power supply should be disconnected to avoid

damage due to over-dischargeIf additional construction is performed in the protected building, shut down the control panel

to ensure fire detection capabilities are not compromised

During any status other than operation (transportation, storage, etc), the reserve power supplyshould be disconnected from the control panel

6.3Common Troubles

The N-6000 has advanced features such as self-diagnosis and self-protection; however even

with the advanced technology an occasional trouble signal is unavoidable. Table 5-1 has

additional information regarding common troubles.

Trouble Cause analysis Solution

Poor AC220V connectionRe-connect the AC220V

power supplyMain power supply

trouble Fuse blowing out due to external

short circuit or over-currentReplace the fuse

Poor plug connection Check connectorsReserved power