Experimental study on the shear strength of …...Original Research Article Experimental study on...

Transcript of Experimental study on the shear strength of …...Original Research Article Experimental study on...

Original Research Article

Experimental study on the shear strength ofreinforced concrete beams cast with Lavalightweight aggregates

W. Nawaz a, J.A. Abdalla a,b, R.A. Hawileh a,b,*, H.S. Alajmani a,I.H. Abuzayed a, H. Ataya a, H.A. Mohamed a

aAmerican University of Sharjah, Department of Civil Engineering, P.O. Box 26666, Sharjah, United Arab EmiratesbAmerican University of Sharjah, Material Science and Engineering Research Institute (MSERI), P.O. Box 26666,Sharjah, United Arab Emirates

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6

a r t i c l e i n f o

Article history:

Received 9 February 2019

Accepted 11 May 2019

Available online 31 May 2019

Keywords:

Lightweight

Aggregates

Shear strength

Reinforced concrete

Beams

a b s t r a c t

This paper investigates experimentally the shear strength behavior of reinforced concrete

(RC) beams cast with Lava lightweight aggregates as a replacement of normal coarse

aggregates. A total of 24 shear deficient RC beams were fabricated and cast with normal

(NWC) and lightweight (LWC) concrete and tested under three-point bending after 28 and 56

days. The variables of the experimental program include type of aggregate, concrete

compressive strength, and beam size. The experimental results include load–deflection

response curves along with failure mode for each beam specimen. The experimental result

showed that all beams failed in a similar fashion, due to diagonal tension shear crack.

However, a larger number of cracks with less spacing occurred in the LWC beams as

compared to NWC specimens. Based on the experimental results, it can be also concluded

that LWC specimens tested after 56 days achieved comparable shear strength results to that

of NWC beams. In addition, the strength reduction factor (l) for LWC specimens was in the

range of 0.69–0.98. The concrete shear strength (Vc) was also predicted using different shear

design provisions and the results has shown that Eurocode 2 provisions yielded the lowest C.

O.V. of 2.3 and 10.2% for NWC and LWC specimens, respectively.

© 2019 Politechnika Wroclawska. Published by Elsevier B.V. All rights reserved.

Available online at www.sciencedirect.com

ScienceDirect

journal homepage: http://www.elsevier.com/locate/acme

1. Introduction

The rapid development of enormous infrastructure worldwideover the last few decades made the concrete as one of mostwidely used material in the construction industry. Estimateshows that the world has consumed approximately up to 31

* Corresponding author at: American University of Sharjah, DepartmentE-mail address: [email protected] (R.A. Hawileh).

https://doi.org/10.1016/j.acme.2019.05.0031644-9665/© 2019 Politechnika Wroclawska. Published by Elsevier B.V

million tons of concrete, and it also indicates that concrete isone the largest consumer of natural resources [1,2]. The mainnatural sources of aggregates include rock quarries and gravelpits. However, the extraction of coarse aggregates fromdifferent natural resources has created irreversible andenormous impact on the environment [3,4]. Many studiesreported that UK and other developed countries used 208

of Civil Engineering, P.O. Box 26666, Sharjah, United Arab Emirates.

. All rights reserved.

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6982

million tons of crushed aggregates taken from the ground [5].As a result, there is a scarcity of natural aggregates in mostlydeveloped and underdeveloped countries around the world [6].In reply to the shortage of natural aggregates, researchers andengineers developed lightweight aggregate (LWA) from vari-ous technologies and construction waste, as a partial or fullreplacement to natural aggregates in the concrete mixture.The LWA is produced from different materials such as clay,shale, and palm oil, which makes the concrete more porousand lighter [7–11]. Aggregates constitute about 75% of the totalvolume of concrete, which makes it a vital component indetermining the properties of the concrete [12].

The lightweight aggregate is artificial that is obtained fromdifferent sources and it is a prominent solution that alleviatesthe effects of utilizing normal coarse aggregates [13–16].Lightweight concrete (LWC) can be used as a suitablealternative to conventional normal weight concrete (NWC)in the construction industry, due to its low density, freeze-thaw resistance, thermal conductivity, smaller seismicdemand, fire resistance, cost, smaller cross-section, and highstrength-to-weight ratio [17–20]. Accordingly, the use of LWChas increased considerably due to such advantages andstructural members (i.e. beams, slabs, columns, walls, etc.)performance over conventional NWC. However, the proper-ties and structural performance of the LWC depends on thetype of lightweight coarse aggregates used in the concretemixture.

Several researches have been conducted in the past on themechanical properties, durability and bond strength of LWC[14–17]. A research conducted by Shafigh et al. [1] on themechanical properties of LWA showed significant reductionsin the mechanical properties of concrete. A similar researchwas conducted by Yasar et al. [9], where they used basalticvolcanic pumice lightweight aggregate as a normal weightaggregate replacement, along with 20% fly ash as cementitiousreplacement material. Based on the experimental results, theauthors concluded that the use of volcanic pumice aggregate ismechanically feasible to be used in structural applications.Another research was conducted by Korol and Sivakumaran[11] to investigate the energy consumption of LWC slabsduring extreme loading events. The results showed that LWCslabs can absorb a considerable amount of energy incomparison with NWC during collapse. A similar experimentalprogram was conducted on volcanic pumice aggregates byOnoue et al. [12] and reported that lightweight aggregateconcrete had significantly improved the shock-absorbingcapacity, which was in the range of 28–41% compared toconventional concrete. On the other hand, Zhang and Gjorv[13] showed that the tensile strength-to-weight ratio of LWCwas lower than that of NWC.

The use of LWA in the concrete also affects the bondstrength between the reinforcing bars and surroundingconcrete. Many researches conducted over the last few yearstests on the bond strength of different type of LWA concrete.All reported studies showed contradicting results, where thebond strength of LWA concrete varied from one research toanother, depending on the type of LWA. For instance, Bogaset al. [14] reported that LWC made with expanded clayaggregates has higher bond strength as compared to conven-tional NWC. Similar results were reported by other researchers

[15,16], that also showed that LWC has comparable bondstrength to that with NWC [16].

Research studies conducted in the past focused on themechanical properties, flexural performance and bondstrength of LWA concrete [1–3]. However, there is a lack ofknowledge in the literature on the shear behavior andstrength of reinforced concrete (RC) beams cast with LWA.Shear failures are catastrophic and brittle, and the type ofLWA affects the aggregate interlock, which is one of mainfactors contributing to the concrete shear strength [17–19].Many experimental studies on the shear behavior of LWAshowed that the type of LWA such as oil palm and palm kernelshell aggregates affects the aggregate interlock action [4].Thus, the concrete shear strength (Vc) and performance ofshear deficient RC beams cast with LWA should be examined,before implementing such LWA types in casting RC beamsand slabs. The shear strength of RC beams depends on severalfactors such as the concrete compressive strength, shearspan-to-depth ratio (a/d), shear reinforcement (stirrups),maximum aggregate size, and bond strength in the transitionzone. Jumaat et al. [20] tested RC beam specimens cast with oilpalm LWA, with a density and compressive strength of1650 kg/m3 and 20 MPa, respectively. The experimentalresults showed that the beam's shear capacity was 10%higher than that cast with NWC. A similar research study wasconducted by Johnson et al. [4], on the shear behavior andstrength of RC beams made with palm kernel shell aggregates.Four-point bending tests were conducted on eight beamspecimens. The results showed that the shear strength of RCbeams cast with LWA was 24% higher than that with NWA.The achieved shear strength in those studies [4,20] of LWCspecimens was higher than that with NWC by 10–24%, wasdue to its shorter and narrower developed cracks with roughsurfaces, that improves and increased the shear strength ofLWC beam specimens. It was also noted that LWC beamsexhibited a better performance in terms of crack spacing andaggregate interlock as compared to normal weight concrete. Itcan be also be concluded that type and source of LWA largelyaffects the shear behavior of RC beams. Chao et al. [3]conducted another investigation on the shear strength andbehavior of sedimentary lightweight aggregates. Twenty-fourbeam specimens with different compressive strengths weretested under four-point bending. Experimental resultsshowed that beams made with LWC had comparable crackingand ultimate shear stress to that with NWC. The lightweightmodification factor (l) recommended by the AmericanConcrete Institute (ACI 318-08) shear design provisions wascomputed and ranged from 1.21 to 2.71 for all beam speci-mens. Another investigation was conducted by Kim and Jang[21] to investigate and predict the shear strength and behaviorof sand lightweight RC beams as a NWA replacement based onthe ACI 318-14 [22] and CSA-2004 [23] shear design provisions.An equation was proposed by the authors for Vc, which takesin consideration the elastic modulus of steel reinforcement,shear span to the depth ratio (a/d), and flexural reinforcementratio (r). It was concluded that the proposed design equationand Canadian Standard Association (CSA-2004) shear designmodel accurately predict the concrete shear strength (Vc),whereas the ACI318-14 shear strength model is very conser-vative.

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6 983

It can be concluded from the above literature review anddiscussions that shear strength of RC beams cast with LWCmainly depends upon the type of LWA used in the concretemixture. The aim of this paper is to experimentally investigatethe shear strength and performance of shear deficient beamscast with Lava lightweight aggregates. Lava LWA are extractedfrom volcanic mountains and composed of natural materials.Lava LWA has superior properties such as low thermalconductivity, freeze-thaw resistance, low density, high poros-ity and a lower absorption rate as compared to NWA. Thephysical properties of this type of LWA will be discussed indetails in subsequent sections. A total of 24 shear deficient RCbeam specimens with different targeted concrete compressivestrengths was cast and tested after 28 and 56 days,respectively. The main objective of this experimental programis to evaluate the shear strength and performance of RC beamscast with Lava LWA as a full replacement to coarse NWA. Atotal of eight mixes split equally between lightweight andnormal weight concrete, were designed with different concretestrengths and by incorporating a variety of cementitiousmaterials such as fly ash, micro silica and Portland cement.Three-point bending tests were conducted on all beamspecimens and the cracking behavior was observed till beamfailure. In addition, the concrete shear strength (Vc) waspredicted using the shear provisions of different design codesof practice and other proposed models available in theliterature.

2. Experimental program

2.1. Test matrix

Twenty-four RC beam specimens were constructed anddivided equally into two groups, based on the size of their

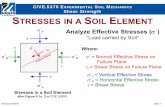

Fig. 1 – Detailing of beam spec

cross-section. The beams were reinforced with flexural steelbars and designed to fail in shear. The variables in each groupof specimens were the aggregate type (NWA and LWA) andconcrete compressive strength (20, 30, 40, and 50 MPa). TheNWC specimens were tested after 28 days, while the LWCbeams were tested after 28 and 56 days, respectively. The RCbeams in Group 1 had a nominal width and height of 150 mmand 300 mm, 2000 mm long, and tested with a shear span-to-depth (a/d) ratio of 3.26. Whereas, beams in Group 2 had anominal width and height of 200 and 300 mm, respectively.The RC beam specimens in both groups were cast withoutstirrups in one shear span as shown in Fig. 1 to ensure shearfailure in that side, and the beams were tested under three-point bending till failure.

Fig. 1 shows the detailing of a typical beam in Groups 1and 2. The beams were reinforced in flexure with 2K16 mmdiameter rebars placed at the beam's tension side at adepth of 260 mm from the top concrete surface, and2K12 mm diameter rebars placed in the beam's compressionside. The reinforcement ratios for Group 1 and Group 2specimens were 1.03 and 0.77%, respectively. The beamspecimens were reinforced in shear on one side of thebeam's shear span with K12 mm diameter stirrups that wereat intervals of 100 mm. It should be noted that all beamspecimens in Groups 1 and 2 had the same reinforcementdetailing. The sample designation and detailing for eachbeam specimen is provided in Table 1. For example, G1-L50-28 beam specimen belongs to Group 1, cast with lightweightconcrete aggregated with a targeted compressive strength of50 MPa, and tested after 28 days. Whereas, G1-N50 specimenbelongs to Group 1, cast with normal weight concrete with atargeted compressive strength of 50 MPa, and tested after 28days. The concrete compressive strength at the day oftesting ( fc) for each beam specimen is also reported inTable 1.

imens in Groups 1 and 2.

Table 1 – Test matrix and compressive strength of specimens.

Group Specimendesignation

Type ofaggregate

Measuredwidth, b (mm)

Targeted concretecompressive

strength (MPa)

fc at day oftesting (MPa)

1 G1-N20 Normal 148 20 19.8G1-L20-28 Light 155 20 20.1G1-L20-56 Light 152 20 23.4G1-N30 Normal 145 30 30.3G1-L30-28 Light 151 30 29.7G1-L30-56 Light 162 30 33.2G1-N40 Normal 144 40 40.2G1-L40-28 Light 155 40 36.5G1-L40-56 Light 163 40 38.4G1-N50 Normal 143 50 49.8G1-L50-28 Light 155 50 45.6G1-L50-56 Light 162 50 48.7

2 G2-N20 Normal 211 20 20.6G2-L20-28 Light 190 20 20.3G2-L20-56 Light 202 20 23.1G2-N30 Normal 210 30 31.9G2-L30-28 Light 190 30 29.6G2-L30-56 Light 203 30 33.1G2-N40 Normal 212 40 41.2G2-L40-28 Light 205 40 36.3G2-L40-56 Light 208 40 38.7G2-N50 Normal 200 50 50.3G2-L50-28 Light 201 50 45.1G2-L50-56 Light 200 50 48.4

Table 2 – Physical properties of aggregates.

Aggregate type Bulk specificgravity (OD)

(g/cm3)

Bulk specificgravity (SSD)

(g/cm3)

Apparent specificgravity (g/cm3)

Waterabsorption (%)

Lava lightweight aggregate 1.558 1.727 1.875 10.9Normal weight aggregate 2.85 2.93 2.98 40

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6984

2.2. Material properties

2.2.1. AggregatesTable 2 summarizes the properties of Lava LWA and NWA interms of oven dried (OD) bulk specific gravity, saturatedsurface dry (SSD) bulk specific gravity, apparent specificgravity, and water absorption, respectively. Aggregates of size9–20 mm are used as coarse aggregates, whereas dune sandand crushed sand were used as fine aggregates (<4.75 mm).Fig. 2 shows the gradation of NWA, LWA, and fine aggregates. Itis clear from Table 2 that Lava LWA have a 24 h absorption of10.9%, whereas, NWA have a 24 h absorption of 40%. Table 2also shows that the Lava LWA has a saturated surface dry (SSD)bulk specific gravity and apparent specific gravity of 1.727 and1.875, respectively which are lower than NWA by 41.2% and37.1%.

2.2.2. Concrete mix design and specimen constructionEight different batches of ready mixed concrete weredesigned and used to cast normal weight concrete (NWC)and lightweight concrete (LWC) beam specimens along with

cylinders with different targeted concrete compressivestrengths. All the beam specimens, cube and cylinders werecured for 7 days by spraying water and covering it with nylonsheets and burlap. All the specimens were cured and storedin the lab until the day of testing. Tables 3 and 4 show the mixproportion of LWC and NWC in each group. Type I cementwith a specific gravity of 3.15 was used for all the mixes ofLWC and NWC. The utilized admixture was commerciallyavailable and used to alter workability levels during the mix.LWC had different water to binder ratio for different targetedcompressive strength as shown in Table 3. The materialsused were Lava LWA as a coarse aggregate, dune sand,crushed sand, cement, superplasticizer, and fly ash as partialcementitious replacement. The chemical composition of theutilized cement, fly ash, and micro silica in the concrete mixis provided in Table 5. Concrete specimens and cylinderswere also cast for each batch mix. In-addition, concretespecimens were cured and stored along with the cylindersuntil the testing date in the lab. The obtained averagecylindrical compressive strength of 3 samples tested at thesame day of testing the beam specimens is provided inTable 1.

Fig. 2 – Sieve analysis of Lava LWA, NWA, and fine aggregates.

Table 3 – Design mix for light weight concrete (LWC)mixes.

Component LW-20 LW-30 LW-40 LW-50

Cement (kg) 311 420 380 548Fly ash (kg) 0 0 130 0Micro silica (kg) 0 46.7 50 61Water (L) 170 265 323 247W/B ratio 0.55 0.57 0.58 0.41Lightweight coarseaggregate (kg)

1060 958.5 891 1060

Fine aggregate(crushed sand) (kg)

435 322 200 198

Fine aggregate(dune sand) (kg)

435 400 200 400

Superplasticizer (L/m3) 6.43 9.64 9.64 20

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6 985

2.2.3. Steel reinforcementASTM A615 steel bar of diameter 16 mm were used as aninternal reinforcement in the beam specimens. To evaluatethe mechanical properties of the steel bars, three couponsamples 16 mm specimen diameter were subjected to tensiletest using a Universal Testing Machine (UTM). The UTM has aload capacity of 1000 kN and all bars were tested at a rate of10 mm/min. The total length of the coupon specimens was300 mm with gauge length of 100 mm. The obtained averageyield stress, elastic modulus, ultimate tensile strength, and

Table 4 – Design mix for normal weight concrete (NWC) mixes

Component NW-20

Cement (kg) 400

Micro silica (kg) 43.4

Water (L) 154

W/B ratio 0.38

Coarse aggregate (kg) 1020

Fine aggregate (crushed sand) (kg) 240

Fine aggregate (dune sand) (kg) 275

Superplasticizer (L/m3) 5.2

percentage elongation for the steel bars was 530 MPa, 200 GPa,610 MPa, and 12.2%, respectively.

2.3. Experimental setup

Fig. 3 depicts the experimental set-up of the tested beamspecimens, respectively. It is clearly indicated in Fig. 3 that allbeam specimens were tested under three point bending usinga UTM that has the capacity of 2000 kN. The specimens weretested under a displacement rate of 2 mm/min and the loadwas transferred to the beam specimens through a roller at themid-span of the beam specimen. A linear variable differentialtransducer (LVDT) was used to monitor the mid-spandeformation throughout the test. The load and mid-spandisplacement were recorded for all the tested beam specimensin data acquisition system till failure of specimen. The crackswere also marked and traced during loading and the mode offailure was recorded for each beam specimen.

3. Experimental results and observations

3.1. Observation of cracking and failure modes

The development of cracks in all the tested beam specimenswere observed and recorded till the failure of the specimens.

.

NW-30 NW-40 NW-50

380 360 54848.7 55.4 64.5170 175 1850.35 0.32 0.33935 920 1085260 271 278255 262 2697.3 8.4 9.3

Table 5 – Chemical compositions of cement, fly ash and micro silica.

Binder SiO2 Al2O3 Fe2O3 CaO MgO SO3 Na2O Cl� LOI

Cement 21.29 4.89 3.42 64.16 1.41 2.53 0.38 0.01 3.17Fly ash 35.00 – – – 5.00 2.75 1.50 – 6.00Micro silica 83.00 1.15 1.38 0.48 0.52 – 0.87 – 4.70

Fig. 3 – Test-setup.

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6986

All specimens failed in shear as expected, due to a typicaldiagonal major crack developed between the loading supportsof the right shear span (side without stirrups) as shown inFig. 3. During the early stages of the loading, flexural crackswere initiated and detected at the beam's mid-span, where thebending moment was the highest. Fig. 4 shows the crackingpattern and failure modes of the selected NWC and LWCspecimens. These cracks developed at a load level of about 15–20% of the ultimate attained load in NWC (normal weightconcrete) beams. However, in the case of LWC (lightweightconcrete) beam, flexural cracks were developed at early stagesof loading, which may be due to the lower modulus of ruptureof lightweight concrete. As the load further increased, flexuralcracks became more evident and changed to flexural shearcracks as the cracks propagated into the shear span. Thesecracks were inclined at an angle in the range of 348–458 andpropagated toward the loading point. It can be indicated fromFig. 4 that some horizontal cracks were also developed near thebottom longitudinal reinforcement, which reduced the shearstress and the dowel action between the concrete and steelreinforcement. More cracks were developed in LWC beams andthe average spacing between the cracks was about 90 mm ascompared to NWC in which the average crack spacing was180 mm. Therefore, it can be concluded that smaller crack

width with larger number of cracks occurred in LWC beams. Itshould also be noted that the cracks were much more evidentin LWC beams tested at 56 days as compared to those at 28days. Thus, on average LWC specimens tested at 56 days hasachieved comparable shear strength to that of NWC.

3.2. Results and discussions

The load–deflection response curve and obtained experimen-tal results of all the tested specimens in term of ultimateattained load (Pexp), flexural cracking load (Pcr), ratio of Pcr/Pexp,ultimate deflection, beam shear strength (Vexp), normalizedshear strength, and light weight reduction factor (l) for beamsof Groups 1 and 2 are presented in Table 6 and Figs. 5 and 6. Thenormalized shear strength is expressed as

Normalized shear strength ¼ Vexp

bdffiffiffiffif 0c

q (1)

where f 0c is the concrete compressive strength in MPa, b is thewidth of the beam's section in mm, and d is the depth of thesection in mm. It should be noted that all the tested specimensin Groups 1 and 2 did not have same concrete compressivestrengths. Therefore, in order to compare the performance, the

Fig. 4 – Failure mode of the selected NWC and LWCspecimens.

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6 987

ultimate shear strength is normalized to minimize the differ-ence in concrete compressive strength and it is provided inTable 6 and Figs. 7 and 8. The shear strength of NWC beams areused as a benchmark to compare the performance of LWCbeams tested at 28 and 56 days. It is observed from Fig. 5 thatall the LWC specimens tested at 56 days in Group 1 attainedhigher shear strength as compared to NWC specimens exceptthe specimen G1-L20-56. The percentage increase in shear

strength for G1-L30-56, G1-L30-56, and G1-L50-56 was 14, 10and 11% respectively over the NWC specimens. However, allLWC beam specimens tested at 28 days exhibited lower shearstrength as compared to NWC beams. In Group 1 specimens,the LWC beams tested at 56 days showed better performanceas compared to NWC specimens. Fig. 7 shows the normalizedshear strength of Group 1 specimens that clearly indicates thatno significant difference is observed between the NWC andLWC tested at 56 days. It can be concluded from Fig. 7 andTable 6 that LWC specimens has comparable normalized shearstrength to NWC, respectively. It is also observed from Table 6that the normalized shear strength for NWC and LWC speci-mens in Group 1 is in the range of 0.15–0.19 and 0.14–0.16,respectively. It can be also noticed from Fig. 5 that the stiffnessof the LWC beam specimens tested at 56 days is higher thanthe NWC and LWC specimens tested at 28 days, except forbeam specimen G1-L20-56. It can be also observed from Fig. 5that the slope of LWC beams tested at 56 days is much steeperthan the NWC beams. It could be concluded that better aggre-gate interlock increased the tension stiffness of the concretebetween the cracks, which as a result increase the dowelaction between the longitudinal reinforcement and the sur-rounding concrete. Therefore, all the tested beams at 56 dayshave comparable normalized shear strength as compared toNWC beams. It is also observed from Table 6 that the lightweight strength reduction factor (l) for LWC specimens at 28days and 56 days in Group 1 is in the range of 0.84–0.94 and0.78–1.00, respectively. It can also be concluded from Table 6that the light weight reduction factor for LWC beam specimenswith higher compressive strength (40 MPa and 50 MPa) is veryclose to 1 which is same for NWC beam specimens.

Table 6 summarizes the results of the experimentallymeasured shear strength and Fig. 6 depicts the load versusmid-span deflection response curves for Group 2 specimens.It is clear from Fig. 6 and Table 6 that all the LWC specimenstested at 28 days and 56 days had comparable less shearstrength as compared to NWC beams. The reduction in theshear strength for LWC beams at 56 days is in the range of 5–18%, whereas in case of LWC beams at 28 days the reduction isin the range of 8–29% as compared to NWC specimens. Itshould also be noted that more reduction in shear strength isobserved for specimens with low compressive strength(20 MPa and 30 MPa) instead of high compressive strength.Table 6 and Fig. 8 show the normalized shear strength ofGroup 2 specimens and it can be clearly seen that nosignificant difference is observed between the NWC andLWC tested at 56 days. It can be concluded from Fig. 8 andTable 6 that LWC specimens has comparable normalizedshear strength, respectively. Whereas, NWC specimensperformed better and has high normalized shear strengthas compared to LWC specimens with low compressivestrengths like G2-N30 and G2-N40. It is also observed fromTable 6 that the normalized shear strength for NWC and LWCspecimens in Group 2 is in the range of 0.16–0.19 and 0.14–0.16,respectively. In the initial stages of the loading, the stiffness ofLWC specimens tested at 28 days was higher than the NWCand LWC beams tested at 56 days except for the specimen G2-L20-28. As shown in Fig. 6 that the slope of the LWC tested at 28days beam specimens was much more stepper as compared toNWC and LWC beams tested at 56 days. All the LWC

Table 6 – Experimental results.

Specimendesignation

f 0c at day oftesting (MPa)

Ultimateload,

Pexp (kN)

Flexuralcracking

load, Pcr (kN)

PcrPexp

Ultimatedeflection

(mm)

Shear strengthVexp = Pexp/2 (kN)

NormalizedVexp

bdffiffiffiffif 0c

p :

Light weightreductionfactor, l

G1-N20 19.81 65.96 11.85 0.18 8.43 32.98 0.19 -G1-L20-28 20.10 59.08 7.11 0.12 5.75 29.54 0.16 0.84G1-L20-56 23.42 57.12 8.21 0.14 12.1 28.56 0.15 0.78G1-N30 30.31 70.04 14.02 0.20 5.82 35.02 0.17 –

G1-L30-28 29.72 66.16 8.15 0.12 6.5 33.08 0.15 0.88G1-L30-56 33.22 80.08 10.41 0.13 4.98 40.04 0.16 0.94G1-N40 40.21 72.76 15.02 0.21 6.52 36.38 0.15 –

G1-L40-28 36.54 68.48 8.90 0.13 7.25 34.24 0.14 0.93G1-L40-56 38.44 80.56 11.25 0.14 5.6 40.28 0.15 1.00G1-N50 49.81 82.24 16.85 0.20 5.6 41.12 0.16 –

G1-L50-28 45.62 83.6 11.71 0.14 5.94 41.8 0.15 0.94G1-L50-56 48.71 91.12 13.25 0.15 5.16 45.56 0.15 0.94G2-N20 20.65 97.02 15.52 0.16 5.62 48.51 0.19 –

G2-L20-28 20.33 70.78 9.20 0.13 5.81 35.39 0.16 0.84G2-L20-56 23.12 78.8 10.58 0.13 6.6 39.4 0.16 0.84G2-N30 31.93 107.86 18.35 0.17 9.25 53.93 0.17 –

G2-L30-28 29.61 76.2 10.25 0.13 4.88 38.1 0.14 0.82G2-L30-56 33.12 100.72 14.10 0.14 8.35 50.36 0.17 1.00G2-N40 41.22 116.46 22.12 0.19 9.87 58.23 0.16 –

G2-L40-28 36.34 91.28 12.77 0.14 5.21 45.64 0.14 0.87G2-L40-56 38.75 104.46 15.67 0.15 11.02 52.23 0.16 1.00G2-N50 50.34 123.84 24.76 0.20 7.55 61.92 0.17 –

G2-L50-28 45.12 113.14 15.84 0.14 8.35 56.57 0.16 0.94G2-L50-56 48.43 117.5 16.85 0.14 7.42 58.75 0.16 0.94

Fig. 5 – Load-midspan deflection response of Group 1 specimens.

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6988

specimens tested at 56 days has comparable ultimatedeflection as compared to NWC specimens except thespecimen G2-L40-56 and G2-L30-56 as shown in Table 6.

Higher ultimate deflection of G2-L40-56 LWC specimen couldbe due to the lower modulus of elasticity of LWC. It is alsoobserved from Table 6 that the light weight strength reduction

Fig. 6 – Load-midspan deflection response of Group 2 specimens.

Fig. 7 – Normalized shear strength of Group 1 specimens.

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6 989

factor (l) for LWC specimens at 28 days and 56 days for Group 2specimens is in the range of 0.82–0.94 and 0.84–1.00,respectively. Similar results were found in the literature[3,4] and it can also be concluded from Table 6 that the lightweight reduction factor for LWC beam specimens at 56 dayswith higher compressive strength (40 MPa and 50 MPa) is very

close to 1.0 which is the same as that for NWC beamspecimens.

3.2.1. Effect of concrete compressive strengthFigs. 9 and 10 show that effect of the compressive strength onthe shear strength of Group 1 and 2 specimens. It is depicted

Fig. 8 – Normalized shear strength of Group 2 specimens.

Fig. 9 – Shear strength versus compressive strength of Group 1 specimens.

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6990

from Fig. 9 that the beam's shear strength increases with theincrease in concrete compressive strength. However, theincrement is more evident in NWC specimens as comparedto LWC specimens except for specimens G2-N20 and G2-N30shown in Fig. 10. Thus, it can be concluded that for both NWCand LWC specimens, the concrete strength has a significanteffect on the shear strength (Vc) of RC beams.

4. Analytical predictions

In this section, the shear strength (Vc) of the tested specimenswas computed using different design codes and modelsdeveloped such as Frosch equation [24,25] and the University

of Houston (UH) method [26,27] given in the literature. Theshear strength of tested specimens was also predicted usingdesign provisions of the ACI 318-14 [22], BS EN 1992-1-1:2004[28], Model code [29] and CSA-2004 [23] codes. Different designshear provisions will be summarized in the subsequentsections.

4.1. ACI 318-14 method

The ACI 318-14 [22] shear design provisions have two differentempirical equations to compute the concrete shear strengthVc. The first equation is a simplified equation, which is basedon three different design parameters and provided undersection 22.5.5.1 of ACI 318-14 [22] guidelines as:

Fig. 10 – Shear strength versus compressive strength of Group 2 specimens.

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6 991

Vc ¼ 0:17lffiffiffiffif 0c

qbwd (2)

where f 0c is the compressive strength of the concrete in MPa, bwis the width of the concrete section in mm, d is the depth of thesection in mm. The second model is a detailed equation, whichincludes several parameters which is provided under section22.5.5.1 of ACI 318-14 [22] guidelines as

Vc ¼ 0:16lffiffiffiffif 0c

qþ 17rw

VudMu

� �bwd�0:29

ffiffiffiffif 0c

qbwd (3)

where l is a reduction factor to account for lightweight con-crete, rw is the longitudinal flexural reinforcement ratio, Vu isthe ultimate shear force in N and Mu is the ultimate moment inN mm.

4.2. Canadian standard CSA-2004

Shear design provisions given in the Canadian code CSA2004[23] is based on the simplified modified compression fieldtheory (SMCFT). The concrete shear strength in the CSA-2004[23] code depends on the compressive strength, tensile stressfactor b, width, and depth of the section. In the SMCFT, thelongitudinal strain ex is computed based on the interlockingmechanism of the concrete. The computation of Vc accordingto the CSA-2004 design guidelines, provided under section 11of CSA-2004 [23] is expressed as

Vc ¼ lb

ffiffiffiffif 0c

qbwdv (4)

where

b ¼ 0:40ð1 þ 1500exÞ

1300ð1000 þ szeÞ (5)

sze ¼ 35sz15 þ ag

(6)

ex ¼Mf =dv þ Vf

2ðEsAsÞ (7)

u ¼ 29 þ 7000ex (8)

where dv is the shear depth taken as the greater of 0.9 d or0.72 h in mm, h is the total depth of the beam, ex is thelongitudinal strain in the web (mm/mm), sze is the crackspacing parameter in mm, l is a factor for lightweight con-crete, sz is the crack spacing parameter in mm, ag is themaximum aggregate size in mm, Mf is the moment at thesection in N mm, Vf is the ultimate shear force in N, Es isthe modulus of elasticity of steel in MPa, As is the area of steelin mm2, and u is the angle of inclination of diagonal compres-sive stresses.

4.3. Frosch method

Frosch [24,25] proposed an empirical model to compute Vc

based on the uncracked concrete depth above the neutral axis.This model assumes that Vc depends on the depth of theneutral axis and expressed as

Vc ¼ 25

ffiffiffiffif 0c

qbwc (9)

where f 0c is the compressive strength of the concrete in MPa, bwis the width of the concrete section in mm, and c is the depth ofthe neutral axis in mm.

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6992

4.4. UH method

An experimental study was conducted by University ofHouston [26,27] to study the Vc of prestressed concrete beams.However, this equation was later modified for RC beams. Themodel for Vc according to this method depends on severalparameters such as a/d ratio, concrete compressive strengthand effective web area (bwc) which was provided by Tureyenand Frosch [25]. The modified UH method for RC beams isexpressed as

Vc ¼ 1:17ad

� ��0:7 ffiffiffiffif 0c

qbwc�0:83

ffiffiffiffif 0c

qbwc (10)

where f 0c the compressive strength of the concrete in MPa, bw isthe width of the concrete section in mm, c is the depth of theneutral axis in mm, a is the shear span in mm, and d is thedepth of the section in mm.

4.5. Eurocode

The concrete shear design provision in the BS EN 1992-1-1:2004[28] is based on several parameters such as reinforcementratio, concrete compressive strength, axial stress, and depthand width of the section. The computation of concrete shearstrength VRd;c according to BS EN 1992-1-1:2004 code [28] isexpressed as

VRd;c ¼ ½CRd;ckð100r1f ckÞ1=3 þ k1scp�bwd (11)

Table 7 – Measured and predicted shear strength results.

Group Specimendesignation

Shearstrength,Vexp (kN)

ACI 318-14detailed,Vc (kN)

ACI 318-14simplified,Vc (kN)

1 G1-N20 32.98 30.0 29.7

G1-L20-28 29.54 30.0 29.7

G1-L20-56 36.45 31.8 31.6

G1-N30 35.02 36.3 36.3

G1-L30-28 33.08 36.3 36.3

G1-L30-56 40.04 37.8 38.0

G1-N40 36.38 41.6 41.9

G1-L40-28 34.24 39.8 40.1

G1-L40-56 40.28 40.8 41.1

G1-N50 41.12 46.2 46.9

G1-L50-28 41.80 44.2 44.8

G1-L50-56 45.56 45.6 46.3

2 G2-N20 48.51 39.3 39.5

G2-L20-28 35.39 39.3 39.5

G2-L20-56 39.40 41.7 42.1

G2-N30 53.93 47.7 48.4

G2-L30-28 38.1 47.7 48.4

G2-L30-56 50.36 49.7 50.6

G2-N40 58.23 54.7 55.9

G2-L40-28 45.64 52.2 53.3

G2-L40-56 52.23 53.8 55.0

G2-N50 61.92 60.9 62.5

G2-L50-28 56.57 58.0 59.4

G2-L50-56 58.75 41.7 42.1

VRd;c min ¼ ½Vmin þ k1scp�bwd (12)

Vmin ¼ 0:035k3=2 þ f 1=2ck (13)

k ¼ 1 þffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi200d

�2

rð12Þ (14)

where fck is the compressive strength of the concrete in MPa, r1

is the reinforcement ratio, bw is the width of the concretesection in mm, scp is the axial stress, a is the shear span inmm, and d is the depth of the section in mm, k1 coefficient toconsider the effect of axial force and is equal to 0.15.

4.6. Model code

The concrete shear design provision in the Fib Model Code2010 [29] is based on several parameters such as concretecompressive strength, depth and width of the section. Thecomputation of concrete shear strength VRd;c according to FibModel Code 2010 [29] is expressed as

VRd;c ¼ 0:9kv

ffiffiffiffiffiffif ckcc

sbwd (15)

kv ¼ 5201000 þ 0:9kgdd

(16)

CSA 2004,Vc (kN)

Froschmodel,Vc (kN)

UHmethod,Vc (kN)

Eurocode,Vc (kN)

Modelcode,Vc (kN)

30.4 21.7 27.7 29.6 21.730.4 21.7 27.7 30.7 22.931.7 22.7 29.0 31.5 24.334.6 25.0 31.9 32.7 26.334.6 25.0 31.9 33.5 27.235.6 25.8 32.9 36.3 30.837.9 27.6 35.2 35.2 30.136.9 26.7 34.1 36.1 30.937.5 27.2 34.7 38.0 33.340.7 29.7 37.9 37.2 33.340.8 28.8 36.8 38.5 34.540.3 29.5 37.6 40.4 37.3

36.6 26.5 33.8 38.8 31.636.6 26.5 33.8 35.8 28.338.0 27.6 35.3 38.7 32.041.5 30.3 38.7 43.4 39.141.5 30.3 38.7 39.5 34.142.6 31.2 39.9 42.8 38.545.3 33.3 42.5 46.9 44.941.9 32.3 41.2 44.2 40.843.9 33.0 45.3 45.4 42.748.5 35.8 45.7 47.5 46.843.7 34.7 44.2 46.2 44.545.7 35.5 45.3 47.0 45.9

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6 993

where fck the compressive strength of the concrete in MPa, gc isthe factor concrete, bw is the width of the concrete section inmm d is the depth of the section in mm and kgd is the coeffi-cient which is equal to 1.

5. Experimental versus analytical results

Experimentally measured (Vexp) and analytically predicted(Vpred) shear strength of the tested beam specimens are shownin Table 7. In addition, Table 8 and Fig. 11 show theexperimentally measured to predicted shear strength ratios,computed as

Vexp

Vpred(17)

Table 8 – Measured to predicted shear strength ratios of Group

Vexp/Vp

Group Specimendesignation

ACI 318-14detailed

ACI 318-14simplified

CS

1 G1-L20-28 0.98 0.99

G1-L20-56 1.15 1.15

G1-L30-28 0.91 0.91

G1-L30-56 1.06 1.05

G1-L40-28 0.86 0.85

G1-L40-56 0.99 0.98

G1-L50-28 0.95 0.93

G1-L50-56 1.00 0.98

Mean 0.99 0.98

Std. dev. 0.09 0.09

C.O.V. 8.92 9.30

5% fractile 1.12 1.12

G1-N20 1.10 1.11

G1-N30 0.96 0.96

G1-N40 0.87 0.87

G1-N50 0.89 0.88

Mean 0.96 0.96

Std. dev. 0.10 0.11

C.O.V. 10.72 11.77

5% fractile 1.08 1.09

2 G2-L20-28 0.90 0.90

G2-L20-56 0.94 0.94

G2-L30-28 0.80 0.79

G2-L30-56 1.01 1.00

G2-L40-28 0.87 0.86

G2-L40-56 0.97 0.95

G2-L50-28 0.98 0.95

G2-L50-56 1.41 1.40

Mean 0.99 0.97

Std. dev. 0.18 0.18

C.O.V. 18.64 18.89

5% fractile 1.27 1.26

G2-N20 1.23 1.23

G2-N30 1.13 1.11

G2-N40 1.06 1.04

G2-N50 1.02 0.99

Mean 1.11 1.09

Std. dev. 0.09 0.10

C.O.V. 8.29 9.52

5% fractile 1.22 1.21

This ratio has been evaluated based on all the designprovisions discussed in the previous section. Additionally,statistical analysis were conducted for LWC and NWC speci-mens and presented in Table 8. It is observed from Table 8 andFig. 11 that CSA equations provide the closest prediction for Vc

for all the LWC and NWC specimens in Group 1 and 2 ascompared to experimentally measured shear strength. The

average ratio of VexpVpred

for the CSA equation for LWC and NWC

specimens in Group 1 was 1.04 and 1.02, whereas for Group 2 itwas 1.12 and 1.30 respectively. Table 8 also shows that CSAmodel has the least standard deviation among both groups,

except for the LWC specimens in Group 2. The VexpVpred

ratio of LWC

and NWC specimens in Group 1 has standard deviation of�0.09 and �0.05 with a coefficient of variation (C.O.V.) of8.32% and 5.06%. Whereas, LWC and NWC in Group 2 have

1 and 2 specimens.

red

A 2004 Froschmodel

UHmethod

Eurocode Modelcode

0.97 1.36 1.07 0.96 1.291.15 1.61 1.26 1.16 1.500.96 1.32 1.04 0.99 1.221.12 1.55 1.22 1.10 1.300.93 1.28 1.00 0.95 1.111.07 1.48 1.16 1.06 1.211.02 1.45 1.14 1.09 1.211.13 1.54 1.21 1.13 1.221.04 1.45 1.14 1.05 1.260.09 0.12 0.09 0.08 0.128.32 8.10 8.12 7.46 9.151.14 1.59 1.24 1.15 1.431.08 1.52 1.19 1.12 1.521.01 1.40 1.10 1.07 1.330.96 1.32 1.03 1.03 1.211.01 1.38 1.08 1.11 1.231.02 1.41 1.10 1.08 1.320.05 0.08 0.07 0.04 0.145.06 5.97 5.94 3.44 10.611.07 1.50 1.18 1.11 1.49

0.97 1.34 1.05 0.99 1.251.04 1.43 1.12 1.02 1.230.92 1.26 0.98 0.96 1.121.18 1.61 1.26 1.18 1.311.09 1.41 1.11 1.03 1.121.19 1.58 1.15 1.15 1.221.29 1.63 1.28 1.22 1.271.29 1.65 1.30 1.25 1.281.12 1.49 1.16 1.10 1.220.14 0.15 0.11 0.11 0.07

12.56 10.11 9.90 10.21 5.791.29 1.65 1.29 1.24 1.301.33 1.83 1.44 1.25 1.541.30 1.78 1.39 1.24 1.381.29 1.75 1.37 1.24 1.301.28 1.73 1.35 1.30 1.321.30 1.77 1.39 1.26 1.390.02 0.04 0.04 0.03 0.111.66 2.45 2.78 2.28 7.851.33 1.82 1.43 1.29 1.52

Fig. 11 – Experimental versus predicted shear strength of Group 1 and 2 specimens.

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6994

standard deviation of �0.14 and �0.02 and a coefficient ofvariation (C.O.V.) of 12.5% and 1.66%. The CSA-2004 codeprovisions provides the closest estimates for Vc since it takesinto account many factors such as reinforcement ratio,aggregate size and crack spacing. It can be also seen fromTable 8 that the model proposed by Frosch is the mostconservative, as compared to other shear design models. The

mean ratio of VexpVpred

by Frosch method was the highest among all

equations and could be used as a lower bound to estimate the

shear strength of LWC and NWC specimens. The VexpVpred

for LWC

specimens in Groups 1 and 2 is in the range of 1.28–1.61 and

1.26–1.65. Moreover, the VexpVpred

ratio for NWC specimens in

Groups 1 and 2 was in the range of 1.32–1.52 and 1.73–1.83,respectively. It is also observed from Table 8 that both ACI 318-14 equations have the highest standard deviation and C.O.V.

among all the other design model equations. It should also benoted that ACI 318-14 equations are overestimating the shearstrength of LWC specimens in Group 1 and 2, whereasunderestimating the shear strength of the NWC specimensin Group 2 as shown in Table 8. It is also observed from Table 8that Eurocode and Model code is underestimating the shearstrength of both LWC and NWC specimens in Group 1 and 2. Inaddition, UH method predicted better results than the Froschmethod, since it is a modified form of Frosch model andincludes both neutral axis depth and shear span to depthration (a/d)�0.7 in predicting Vc. The UH method is under-estimating the Vc of all the tested LWC and NWC specimens inGroups 1 and 2. It should also be note from Table 8 that the ACI318-14 equations has the least 5% fractile in both groups,

which indicates that 95% of the time VexpVpred

is below 1.12 and 1.27

for Groups 1 and 2 LWC beam specimens.

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6 995

6. Summary and conclusions

The scarcity of natural aggregates and depletion of naturalresources around the world had led to the emergence oflightweight aggregate (LWA). The use of LWA in concretemakes the concrete more lighter that can be used as asuitable alternative to conventional normal weight concrete(NWC) due to its superior properties and structural perfor-mance. Therefore, in this study a total of 24 shear deficientRC beams were cast with Lava lightweight aggregate as areplacement of natural coarse aggregates. Beams weredivided equally into two groups based on their geometryand cross-section. In each group, beams were cast with fourdifferent compressive strengths and tested at 28 and 56 days.Three-point bending tests were conducted on all the testedspecimens and load–deflection response curves wererecorded until the failure of the specimens. In addition,concrete shear strength was predicted using different designprovisions. The following conclusion can be drawn from thefinding of this study:

1. All the tested specimens failed in shear due to a diagonaltension crack on one side and more number of cracks wereobserved for LWC beams as compared to NWC specimens.Therefore, it can be concluded that smaller crack width andmore number of cracks in LWC beams showed better bondbehavior in term of aggregate interlock as compared to NWCspecimens.

2. The behavior and trend of the load–deflection responsecurves for LWC beams is quite similar to that of NWCbeams.

3. The stiffness of the LWC beam specimens tested at 56 dayswas higher than that of the NWC specimens due to betteraggregate interlock mechanism.

4. The light weight strength reduction factor (l) for LWCspecimens at 28 days and 56 days in Group 1 and 2 is in therange of 0.78–1.00. Thus, it can concluded that light weightstrength reduction factor (l) is very close to 1.00 for LWCspecimens tested at 56 days with higher compressivestrengths is very similar to that of NWC specimens.

5. No significant difference is observed between the normal-ized shear strength of NWC and LWC tested at 56 days andshowed comparable shear resistance in both groups ofspecimens

6. Concrete shear strength was predicted using differentdesign codes. Frosch equation was the most conservativeamong all the shear design equations along with the Modelcode. Additionally, the experimental to predicted shearstrength for LWC specimens in Group 1 and 2 was in a rangeof 1.32–1.61 and 1.26–1.77.

7. ACI318-14 equations had standard deviation of � 0.09 and� 0.18 and coefficient of variation (C.O.V.) of 9.3% and 18.8%for LWC specimens in Group 1 and 2. ACI 318-14 equationswere overestimating the shear strength of LWC specimensin Group 1 and underestimating the shear strength of theNWC specimens in Group 2.

8. CSA-2004 equations had a small C.O.V. of 6.8% for NWCspecimens and a C.O.V. of 8.3% and 12.5% for LWCspecimens in both groups. However, Eurocode 2 design

provisions yielded the least C.O.V. of 2.3% for NWCspecimens and 7.5 and 10.2% for LWC specimens in Groups1 and 2, respectively.

9. The shear capacity of reinforced concrete beams will not beaffected by replacing normal weight aggregate with Lavalight weight aggregate in the concrete mix. Therefore,utilizing Lava light weight aggregate in the concrete mix willnot only the reduce the usage of normal weight aggregatebut it will also have less harmful impact on the environ-ment.

r e f e r e n c e s

[1] P. Shafgh, H.B. Mahmud, M.Z.B. Jumaat, R. Ahmmad, S. Bahri,Structural lightweight aggregate concrete using two types ofwaste from the palm oil industry as aggregate, J. Clean. Prod.80 (2014) 187–196.

[2] M. Limbachiya, M.S. Meddah, Y. Ouchagour, Performance ofportland/silica fume cement concrete produced with recycledconcrete aggregate, ACI Mater. J. 109 (1) (2012) 91–100.

[3] C. Tang, T. Yen, H. Chen, Shear behavior of reinforcedconcrete beams made with sedimentary light weightaggregate without shear reinforcement, J. Mater. Civ. Eng.21 (12) (2009) 730–739.

[4] A.U. Johnson, M.Z. Jumaat, H. Mahmud, M.M. Fayyadh, Shearbehaviour of reinforced palm kernel shell concrete beams,Constr. Build. Mater. 25 (2011) 2918–2927.

[5] R.A. Hawileh, J.A. Abdalla, F. Fakherdine, S.A. Poya,Performance of reinforced concrete beams cast withdifferent percentages of GGBS replacement to cement, Arch.Civ. Mech. Eng. 17 (2017) 511–519.

[6] K.H. Yang, S. Jae, C. Byong, T.L. Eun, Effect of aggregate sizeon shear behavior of lightweight concrete continuous slenderbeams, ACI Mater. J. 108 (5) (2011) 501–509.

[7] K.H. Yang, A.F. Ashour, Modification factor for shear capacityof lightweight concrete beams, ACI Struct. J. 112 (4) (2015)485–492.

[8] J.A. Ramirez, J. Olek, B.J. Malone, Shear strength oflightweight reinforced concrete beams, ACI Spec. Publ. 218(218) (2004) 69–90.

[9] E. Yasar, D.A. Cengiz, K. Alaettin, G. Hasan, Strengthproperties of lightweight concrete made with basalticpumice and fly ash, Mater. Lett. 57 (15) (2003) 2267–2270.

[10] S.M. Bashar, W.L. Foo, K.M.A. Hossain, M. Abdullahi, Shearstrength of palm oil clinker concrete beams, Mater. Des. 46(2013) 270–276.

[11] R.M. Korol, K.S. Sivakumaran, Energy absorption potential oflight weight concrete floors, Can. J. Civ. Eng. 39 (11) (2012)1193–1201.

[12] K. Onoue, T. Hiroki, S. Hendro, Shock-absorbing capability oflightweight concrete utilizing volcanic pumice aggregate,Constr. Build. Mater. 83 (2015) 261–274.

[13] M.H. Zhang, O.E. Gjorv, Microstructure of the interfacial zonebetween lightweight aggregate and cement paste, Cem.Concr. Res. 20 (4) (1990) 610–618.

[14] J.A. Bogas, M.G. Gomes, S. Real, Bonding of steelreinforcement in structural expanded clay lightweightaggregate concrete: the influence of failure mechanismand concrete composition, Constr. Build. Mater. 65 (2014)350–359.

[15] K.H. Mo, U.J. Alengaram, P. Visintin, S.H. Goh, M.Z. Jumaat,Influence of lightweight aggregate on the bond properties ofconcrete with various strength grades, Constr. Build. Mater.84 (2015) 377–386.

a r c h i v e s o f c i v i l a n d m e c h a n i c a l e n g i n e e r i n g 1 9 ( 2 0 1 9 ) 9 8 1 – 9 9 6996

[16] M. Pecce, F. Ceroni, F.A. Bibbo, S. Acierno, Steel-concrete bondbehaviour of lightweight concrete with expandedpolystyrene (EPS), Mater. Struct. 48 (1–2) (2015) 139–152.

[17] B. Xu, D.V. Bompa, A.Y. Elghazouli, A.M. Ruiz-Teran, P.J.Stafford, Behaviour of rubberised concrete members inasymmetric shear tests, Constr. Build. Mater. 159 (2018)361–375.

[18] D.V. Bompa, A.Y. Elghazouli, Ultimate shear behaviour ofhybrid reinforced concrete beam-to-steel columnassemblages, Eng. Struct. 101 (2015) 318–336.

[19] S. Campana, M. Fernández Ruiz, A. Anastasi, A. Muttoni,Analysis of shear transfer actions on one-way RC membersbased on measured cracking pattern and failure kinematics,Mag. Concr. Res. 56 (6) (2013) 386–404.

[20] M.Z. Jumaat, A.U. Johnson, H. Mahmud, Shear behaviour ofoil palm shell reinforced concrete beams, Mater. Des. 30(2009) 2227–2236.

[21] C.H. Kim, S.J. Heui, Concrete shear strength of normal andlightweight concrete beams reinforced with FRP bars, J.Compos. Constr. 18 (2) (2014) 122–131.

[22] ACI Committee 318, Building Code Requirementsfor Structural Concrete (ACI 318-14) and Commentry

(318R-14), American Concrete Institute, Farmington Hills,MI, 2005.

[23] Canadian Standards Association (CSA), Design of ConcreteStructures. CAN/CSA 2004-A23.3-04, Rexdale, Ontario, 2004.

[24] R.J. Frosch, Contribution of concrete to shear resistance, ACIStruct. J. 99 (4) (2002) 427–433.

[25] A.K. Tureyen, R.J. Frosch, Shear tests of FRP-reinforcedconcrete beams without stirrups, ACI Struct. J. 99 (4) (2002)427–433.

[26] A. Laskar, T.C. Hsu, Y.L. Mo, Shear strengths of prestressedconcrete beams part 1: experiments and shear designequations, ACI Struct. J. 107 (3) (2010) 330–339.

[27] T.C. Hsu, A. Laskar, Y.L. Mo, Shear strengths of prestressedconcrete beams part 2: comparisons with ACI and AASHTOprovisions, ACI Struct. J. 107 (3) (2010) 340–345.

[28] EN 1992-1-1 (2004) (English). Eurocode 2: Design of ConcreteStructures – Part 1-1: General Rules and Rules for Buildings[Authority: The European Union Per Regulation 305/2011,Directive 98/34/EC, Directive 2004/18/EC].

[29] Fib, CEB/FIP Model Code 2010 for Concrete Structures, ComitéEuro-International du Béton (CEB), Lausanne, Switzerland,2012.