Evolution of APMC supply chain

Transcript of Evolution of APMC supply chain

Evolution of APMC Supply chain

VJTI Project Management, Mumbai

Presented By:

Sanket Muley (152200018)

09096315732

Nikhil Kasat (152200005)

09028737394

Yash Jain (152200025)

09403607792

Under the Guidance of Prof. Balaji Ramadurai

Nikhil Gudulkar (152200008)

09702794908

Bhushan Kumavat (152200023)

07709925341

Sneha Deshmukh (152201009)

08625926078

APMC – The concept

• Objectives :

1. Ensuring that farmers are not exploited by intermediaries (and money lenders) whocompel farmers to sell their produce at the farm gate for an extremely low price.

2. Providing a fair mechanism where all food produce should first be brought to a marketyard and then sold through auction.

• Mechanism & its Features :

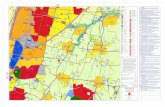

1. Each state which operates APMC markets geographically divide the state and markets(mandis) are established at different places within the state. Farmers are required to selltheir produce via auction only at the mandi in their region.

2. Traders require a license to operate within a mandi. Wholesale and retail traders (e.g.shopping mall owners or mom-pop retailers etc) and food processing companiescannot buy produce directly from a farmer

An agricultural produce market committee (APMC) is a marketing board established by a stategovernment in India. There are 294 APMCs in the State and function as per the Maharashtra AgricultureProduce Marketing (Development and Regulation) Act 1963 and Maharashtra Agriculture ProduceMarketing (Development and Regulation) Rule 1967.

Shortcomingsin current

APMC system

Monopoly& restrictive

InherentConflict ofInterest

Objectives

OtherManipulations

Cartelization

Highcommission,

taxes andlevies

• Farmers are forced to pay commission,marketingfee, APMC cess etc which pushes up costs.

• Besides this many states also impose Value AddedTax.

• Monopoly of any trade (barring fewexceptions) is bad, whether it is by someMNC corporation by government and hereby APMC.

• It creates an artificial barrier & deprivesfarmers from having better customers, andconsumers from original suppliers.

• APMC play dual role of regulator and theMarket, Consequently, its role as regulatoris undermined by vested interest in alucrative trade.

• In addition, member and chairman arenominated/ elected out of the agentoperating in that market. Politics plays alarge role and despite inefficiency they won’tlet go any control.

• Agents have tendency to block a part of paymentfor unexplained or fictitious reasons to farmers. Inseveral instances , Farmer are refused payment slip(acknowledging sale & therefore payment).

• Farmers require these payment slips to get loanfrom Banks. Hence they are forced to go to privatemoney lenders, who work in unison with theagents or political bosses. Ultimately farmers resortto extreme methods like suicides to avoid recoveryagents

• License fee in these markets are highly prohibitive andin many markets farmers are restricted fromoperating. In addition, license fee, rent/value for shopsare kept quite high to keep away competition.

• At most places only a group of village/urban eliteoperates in APMC.

• Cartelization seems to be the order of the daywhere agents get and deliberately restrain fromhigher bidding.

• Produce is procured at manipulatively lower priceand sold at higher price to the market. Spoils thenshared by participants, leaving farmers in lurch.

Shortcomings in current APMC System at a glance

EntryBarriers

Objectives/Suggested improvements to avoid shortcomings in currentAPMC system

1. Provide remunerative price to farmers

2. Reduce uncertainties in production & consumption of farming products

3. Ensuring that end consumers are charged fair price even while producers get fair compensation

4. Strengthening efficiency of supply chain network from producer to consumer via APMC

5. Strategically change the middle man centric present system to farmer & consumer centric system

6. Use of efficient information system with a robust IT backbone to achieve Supply chain improvements usingeffective distribution and stabilizing demand by using efficient cold storage facilities

7. MSP (minimum support price) effective usage for normalizing and balancing demand-supply

8. Include ‘facilitating organization of farmers markets’ under the permitted list of corporate social responsibility(CSR) activities under Companies Act 2013, to encourage companies engaged in agri-allied activities, foodprocessing etc. to take up this activity under CSR and also help in setting up supply chain infrastructure. Thiswould be similar to the e-Choupal initiative of ITC Ltd., but under CSR.

9. We have included a comparative study of APMC model followed by the neighboring Karnataka state as of theone prevalent in Maharashtra in Vashi. Major improvements are drawn from such a comparison.

10. In the next phase of our study, the systems followed by other state governments in Tamilnadu in terms ofestablishing Cold storage facilities, also. This will help us understand the salient features in normalizingavailability of agri-commodities, through out the year.

Case Study- Mumbai Vashi APMC

1. The APMC (Agricultural Produce Market Committee) Vashi market, one of the largest markets in India is in andaround Sector 19 of Vashi.

2. There are a staggering 3700 godowns, 1500 commercial blocks, 4 large auction halls, 2 giant warehouses, and 5large wholesale market yards. Apart from this, there are big processing centers - a vapour heat treatment plant,ripening facilities, cold storage facilities, an export facilitation center and so on

3. Every day, nearly 1,800 tonnes of vegetables — enough to provide 90 grams to each of the 2.02 crore residents ofMumbai, Thane and Navi Mumbai — roll into the yard from vegetable producing areas like Nashik, Pune, Satara,Sangli and other parts of Maharashtra as well as from outside the state

4. The produce is sold by auction and the prices are noted and managed by the APMC. It is the committee'sresponsibility to ensure that sales do not take place below the minimum price fixed by the government. They arealso responsible for ensuring fair measurement and weighing, and fair charges for labor.

5. As per rules, the farmer has to pay APMC a sum ranging from 0.2 % to 2 % as fee for facilitating the sale of hisproduce. After separation, the stock is then sold with the help of commission agents, who charge anywherebetween eight to 15 per cent from the farmer for helping him sell his produce, as against the allowed two to eightper cent.

6. The wholesalers who buy the produce then ferry the produce to the retailer who then sells it to consumers. Alongthe chain, the farmer seems to come off as the worst affected. By the time the produce reaches the consumer, theprice is inflated by almost 60 per cent and the middle men at various stages take the cut.

Introduction:

Supermarketor hotels

APMC market with Warehousing,packing ,Grading facility for fruits &

Vegetables

Farmers

Distributers at localmandi’s

Consumers

Purchaser or kaccha vyapari(Retailer)

Current Model of distribution network for APMC - Vashi

Producer flowCustomer flow

End Purchaser or pakka vyapari(wholesaler)

Retailers

Wholesaler/Middle man

Supermarketor hotels

APMC market having IT support withcomputerized auction system & Ware-housing facility for fruits & Vegetables

Farmers

Distributers at localmandi’s authorized

by APMC

Consumers

Distribution centre (taluka ordistrict level) authorized by

APMC which does informationPackaging & inventory

management

Proposed Model of distribution network for APMC - Vashi

Producer flowInformation FlowCustomer flow

Panchayat/villagelevel information

center

Karnataka APMC Model Salient Features Karnataka government had taken a major issue in the agricultural marketing sector by establishing Rashtriya e-

Market Services Limited (ReMS), a joint venture of Karnataka Government and NCDEX Spot Exchange Limitedand has emphasized the importance of Leveraging technology in agriculture marketing system.

The ReMS claims to offer complete technology and management solution for modernizing markets in state &operating the markets at par with international practices.

The iAgriMarC™ APMC Management Software Suite is aimed at automating the entire Gate-to-Gate operations aswell as Check-post management and outside-mandi purchases of APMC Mandi's. The base product is modeled asper the Agriculture Produce Markets Law, 1961 passed by the Central Government of India.

The unified market has integrated some 51 markets so far and aims at covering all the 155 main market yards aswell as 354 sub-yards of Karnataka state.

From the day of launch (February 22, 2014), 7.5 lakh lots of trading has been done on the platform with 45 laks bidsbeing made with total transaction on platform of worth Rs. 15000 crore

It has accommodated lakhs of farmers, 31473 traders & 17149 commission agents for all the 92 regulatedcommodities

Comparison of APMC Karnataka model to that of our suggested model at APMC Vashi

Sr.No Parameters APMC-KarnatakaModel

Current APMC-VashiModel

ProposedAPMC –Vashi Model

1 Use of ITsystem

At APMC Level and to some villagelevel

No IT system Starting With APMC level to various villageLevel

2 InfluencingPower ofAgents

Low due to high transparency createdby IT system for Various transaction

Very High as all thetransaction are executedat personnel level with

less & inefficientrecording of it by APMC

Low due to efficient transparency whichconnect Farmers & customers via APMC

effectively with efficient recording of all thetransaction at APMC

3 Inventory Due to Online platform inventorylevel is visible to both farmers &

customers

High inventory with lessvisibility

Due to distribution centers at village leveland also online platform Inventory level at

APMC has lower down with increasedvisibility

4 MSP(minimum

supportprice)

MSP for both perishable & non-perishable goods

MSP only for non-Perishable goods

MSP for both perishable & non-perishablegoods

5 Supplychain

efficiency

High availability of real time data ofincoming and outgoing farming

products from APMC

Low due to less co-ordination betweendemand & supply ofagricultural products

because of unavailabilityreal time supply demand

data

High due to real time data availability ofincoming and outgoing agricultural product

at APMC which also includes village levelforecasted farming production data in

segmented form

Analysis of Proposed supply chain at APMC – VashiLets consider for our analysis Tomato

Introduction:

1. Total area under Tomato Cultivation in Maharashtra is 35000 Ha

2. Tomato Growing Districts in Maharashtra are Nashik, Pune, Nagpur, Ahmednagar.

3. Mainly tomato is Rabbi Crop but in Maharashtra it also comes in Kharif crop category atsome locations.

4. We selected Pimpalgaon village in Nashik District which is roughly 200 km far from APMC-Vashi Market

5. Out of 50 farmers in village 20 farmers decided to do Tomato farming from mid of June toSeptember ending & next three months i.e October, November & December are harvestingperiod.

Farmer No- Acres ofland

Farmer No- Acres ofland

1 0.5 11 4

2 1 12 3.5

3 2 13 0.52

4 1.5 14 2

5 3 15 1

6 1.5 16 1

7 2 17 1.5

8 1 18 0.5

9 3 19 1

10 2 20 1.5

1. Production Capacity of 20 farmers = 28.20 t/ha or 11.5 t/ acreand land under tomato cultivation (20 farmers) = 35 acre

2. Assume that tomatoes are yellowish pink in color whichremains fresh upto 8 days in normal condition

3. Total forecasted production= total land under tomato cultivation× production capacity in Maharashtra (t/acre) = 35 acre × 11.5(t/acre) =402.5 tons or 400 tons (aprox)

4. Assume that 25 % losses due to environmental uncertaintyconsumption of farmer itself or wastage of tomato beforereaching to APMC Vashi, so total production = 300 tons

Detail supply chain of tomatoes of 20 farmers under consideration

Time span

15-20 June

07-15 July

25-30 Sept

Oct, Nov, Dec

Seed Sowingin Nursery

After 3 weeks plants aretransferred to farms

Harvesting Start

7-8 time harvest tomato fromplant during next 3 months

At these point alldata transfer toD1 & APMC

Time Span of cultivation of tomatoes by the 20 farmer considered

Process

Total Acres ofland= 35 acres The Data’s taken here for analysis is

slightly dated and we will validatewith fresh data, when available

Note:

Detail analysis of Revenues of farmers underconsideration using proposed supply chain model

Data Collected from eachfarmer/Warehouse cold

StorageD1

APMC - Vashi

Distributer 1(dealer)

At district ortaluka level

ToFarmers

204 km

40 km

Information flow ofdistributer order

30-50 km

Last update on 25 Sept.

Placed order of 300 kg oftomato on 25 sept.

Distance

1. Lets consider an Order of 300 kg which arrived on 25 Sept.

2. Four farmers ready to harvest 300 kg tomato & collect it in D1 on 27 septmorning

3. Then travelling time from D1 center to Vashi is 12 hours

4. APMC accept tomato & transfers it to license holder wholesaler & unloadtomato by using mathadi kamgar (contract loaders)

5. Distributer collect that order and pay money to APMC (15 Rs/kg)

6. Total Revenue from 300 kg = 4500 Rs

Wholesaler % and Mathadi kamgar charge = 1000

& APMC maintenance charge = 500

Total Revenue earned by farmer =3000 Rs (i.e 10 Rs/kg)

• Production Cost per kg tomato :

1. As assumed that 75% of forecasted production will annually produce.

2. Cultivation cost= 24300 Rs/acre & Production capacity 11.5 t/acre

3. amount require for 300 kg production of tomato =24300 ×400/11500= 845,which is the production cost of 300 kg tomato ,so per kg production cost=845/300= 2.80 Rs/kg

• Lets consider, Harvesting & distribution cost per kg tomato=1 Rs/kg

• Travelling cost (farm to APMC) for 250 km = 0.33125 Rs/kg or

0.5 Rs/kg (aprox)

• Total cost of 1 kg tomato =2.80+ 1+0.5=4.3 Rs/kg

• Percentage total profit earned by farmer = 150 %

• This increase is based on the revised model proposed by us.

• But if the old model is used then farmer as per their production cycle willproduce large output that usually not required and also will sell its tomato atmaximum 5 Rs to kaccha vyapari which would yield him very less profit

Requirements for proposed supply chain

Sr. No. Item

1 Server with Operating system

2 Computer at gate

3 Computer for Kiosks

4 Computer at office

5

Network Items

Router

Firewall

Switches

Wi-Fi system

6 Dot Matrix Printer 132 Col

7 Dot Matrix Printer 80 Col

8 Laser Printer

9 Application software for 20 APMCs. y

10 Sound system- 2 Mikes, 1 Amplifier, 5 speakers & cables

11 Portable Generators

12 Civil work & furniture

The items of expenditure for the proposed computerizedauction system at APMC-Vashi are given below.

The items of expenditure for the proposed at Distribution centerin district nearby villages & nearby consumers are given below.

Sr. No. Item

1 Office & warehouse as per supply at each distribution center

2 Civil work & furniture

3 Sampling and information extraction tools

4 Server with Operating system

5

Computer each distributer center

Router

Firewall

Switches

Wi-Fi system

6 Dot Matrix Printer 132 Col

7 Dot Matrix Printer 80 Col

8 Laser Printer

9 Application software designed for distributions centre.

11 Portable Generators

MSP Concept for matching Supply-Demand

Month TomatoPrice/Kg

(Rs.)(year 2015)

Volumeof Tomato

(ton)arrives atAPMC-Vashi

(year 2015)

ProposedMSP( Rs.)

(for year2016)

January 15 100 18.75

February 20 70 25

March 22 50 27.5

April 33 30 41.25

May 38 30 47.5

June 40 25 50

July 42 30 50.5

August 45 50 56.25

September 20 150 24

October 10 200 12

November 15 300 17.25

December 15 400 16.5

1. MSP (Minimum Support Price) ensures that farmers should get support by giving them asurety of buying their goods irrespective of market price at Minimum Support Price if theywant to sell or they want to store in cold storage for lean periods.

2. This method is used mainly to promote or demote the farmer so as to have continuousconstant supply of tomato all round the year and to have a price predictability to theconsumers.

3. This can be done by keeping flexible MSP according to the production to so as to neutralizeeffect of low and high production and announce the year round MSP according to last yeardata in paper and other medium at start of next year.

4. The MSP in the case given is selected according to production i.e 1)25%( increment to theprice) for 1-100 ton volume 2) 20% for 101-200 ton 3) 15% for 201-3004) 10 % for 301-400 5) 5% for 401-500

5. Being a perishable commodity farmers are forced to dispose of their tomato produceimmediately. Establishment of cold storage facilities by the Government in a central locationin the tomato producing area would help the farmers in preserving the produce during thelean period thereby availing better prices and also providing vegetables at cheaper rate tothe consumers. In Tamilnadu Government has established cold storage facilities for tomatoand is helping farmers tremendously.

Consider case of APMC Vashi of supply of tomato in year 2015 and MSPconsideration for year 2016Where1. Production cost includes: 1)Land development cost 2)Seeds Cost 3)Pesticides

Cost 4)Sowing Expenses 5)Fertilizer Cost 6) Transportation Cost 7) packagingcost 8) Labor

2. Price/Kg includes: 1) Production Cost 2)APMC Processing Cost 3) labor cost

Salient features of MSP concept considering case above (which should be usedalong with supply chain model suggested previously for gaining more security ,profit & stability of Supply- Demand)

Pl. contact us, if you have a feedback and that would help us make the report much better.