Elec Specs

Transcript of Elec Specs

-

8/10/2019 Elec Specs

1/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 1 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

This is a Controlled Document that complies with

Wesfarmers Chemicals, Energy & Fertilisers formatting and Quality Control standards.

Please check that this is the latest available version before use.

Title: MATERIALS AND WORKMANSHIP FOR ELECTRICALINSTALLATIONS

Number: ES-14-902-01

Version Number: 10.0

Date Revised: 03 January 2013

Owner: Simon Orton

Authoriser: Manoj Thakur

Reasons for Creating

or Amending

Document

New Authoriser

Full Review of Document

Actual Change Details: New Authoriser was Phil Talbot

Control Block updated

No changes to content

TABLE OF CONTENTS

1. SCOPE ....................................................................................................................................... 3

2. STANDARDS ............................................................................................................................ 3

2.1 GENERAL ............................................................................................................................ 32.2 AUSTRALIAN STANDARDS - GENERAL ....................................................................... 32.3 AUSTRALIAN STANDARDS - HAZARDOUS AREAS ................................................... 42.4 CSBP ENGINEERING STANDARDS ................................................................................ 42.5 CSBP STANDARD DRAWINGS ........................................................................................ 5

3. DETAIL DESIGN BY CONTRACTOR ................................................................................. 5

3.1 GENERAL ............................................................................................................................ 53.2 AS BUILT DRAWINGS ................................................................................................... 53.3 CONTRACTOR SUPPLIED DOCUMENTS ....................................................................... 5

4. MATERIALS AND EQUIPMENT ......................................................................................... 6

4.1 MATERIALS OF CONSTRUCTION .................................................................................. 64.2 GENERAL ............................................................................................................................ 64.3 PREFERRED EQUIPMENT ................................................................................................ 64.4 PRINCIPAL SUPPLIED EQUIPMENT ............................................................................... 7

-

8/10/2019 Elec Specs

2/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 2 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

5. INSTALLATION - GENERAL REQUIREMENTS.............................................................. 7

5.1 LAYOUT ARRANGEMENT AND LOCATION OF EQUIPMENT .................................. 75.2 PROTECTIVE SURFACE COATINGS ............................................................................... 85.3 FIXINGS AND FASTENINGS ............................................................................................ 85.4

SUPPORTS AND BRACKET WORK ................................................................................. 9

5.5 CUTTING, CHASING, WELDING & DRILLING.............................................................. 95.6 EXCAVATION, TRENCHING AND CABLE PITS ......................................................... 10 5.7 LABELLING ....................................................................................................................... 10

6. INSTALLATION OF FIELD EQUIPMENT ....................................................................... 10

6.1 GENERAL .......................................................................................................................... 106.2 CABLE LADDERS AND TRAYS ..................................................................................... 116.3 CONDUITS ......................................................................................................................... 126.4 SEALING OF OPENINGS ................................................................................................. 136.5 CABLES & PROTECTION ................................................................................................ 136.6 CABLE GLANDING AND TERMINATIONS ............. ............ .............. ............. ............ .. 186.7 CABLE MARKING AND FERRULING ........................................................................... 226.8 FIELD EQUIPMENT .......................................................................................................... 26

7. EARTHING ............................................................................................................................. 267.1 SUBSTATION POWER EARTH TERMINAL BAR ........................................................ 277.2 POWER EARTH MAT ....................................................................................................... 277.3 LIGHTNING EARTHING .................................................................................................. 28

8. SWITCHBOARDS & CUBICLES ........................................................................................ 28

9. LIGHTING & SMALL POWER .............. ............. ............ .............. ............. ............ ............. 28

9.1 GENERAL .......................................................................................................................... 289.2 LIGHTING .......................................................................................................................... 289.3 SMALL POWER................................................................................................................. 289.4 DISTRIBUTION BOARD .................................................................................................. 299.5 LABELLING ....................................................................................................................... 29

10. HAZARDOUS AREAS ........................................................................................................... 3010.1 INSTALLATION ................................................................................................................ 3010.2 CERTIFICATION & REGULATIONS .............................................................................. 30

11. CHECKING, TESTING AND COMMISSIONING ............................................................ 30

APPENDIX 1 - MATERIALS OF CONSTRUCTION ................................................................... 31

APPENDIX 2 - STANDARD DRAWINGS .......... .............. ............. ............ .............. ............. .......... 32

TABLES

Table 1 - Underground Cables - Marker Post Labelling and Colour Coding .................................. 17

Table 2 - Underground Cables Marker Slab ................................................................................. 17

-

8/10/2019 Elec Specs

3/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 3 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

1. SCOPE

This Standard details the requirements for the supply and installation of the Electrical works as

covered in the relevant contract Scope of Works or plant modification.

2. STANDARDS

2.1

GENERAL

All materials, equipment and work covered by this Standard shall conform to the requirements of

all Statutory Authorities having jurisdiction over the work site.

In addition, all materials, equipment and works shall comply with:

this Standard;

the latest revision of Standard Drawings listed in Appendix 2; Office of Energy and Western Power electrical requirements;

other CSBP Standards;

the latest relevant Standards and Codes of Practice of the Standards Association of Australia

(SAA).

Note: Where SAA standards do not exist, International Electro technical Commission (IEC) orBritish Standards Institution (BSI) shall apply.

Where any conflict occurs with the detail of these requirements the order of precedence shall be:

1. Office of Energy and the Local Power Authority electrical requirements.

2. Standards and Codes of Practice of the Standards Association of Australia.

3. The Contract Scope of Work.

4. The requirements of this Standard.

5.

The latest Revision of the Standard Drawings listed in Appendix 2.

Should there be a conflict between the above standard requirements the Contractor shall notify the

Superintendent in writing. The Superintendent will make a determination within five (5) workingdays.

2.2

AUSTRALIAN STANDARDS - GENERAL

AS1429.1 Electric Cables - Polymeric Insulated for Working Voltages 1.9/3.3kV up to and

including 19/33kVAS1755 Conveyors- Design, Construction, Installation and Operation -Safety Requirements

AS1768 Lightning Protection

AS1931 High-Voltage Test Techniques

AS2053 Conduit and Fittings for Electrical Installations

-

8/10/2019 Elec Specs

4/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 4 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

AS2067 Switchgear Assemblies & Ancillary Equipment for Alternating Voltages Above

1kV

AS2279 Disturbances in Mains Supply Networks

AS2373 Electric Cables for Control and Protection Circuits

AS3000 Electrical Installations (Australian/New Zealand Wiring Rules)

AS3008 Electrical Installations - Selection of Cables

AS3080 Telecommunications Installations Integrated Communications Cabling Systems for

Commercial Premises

AS3147 Approved and Test Specifications - Electric Cables - Thermoplastic Insulated - forWorking Voltages up to and Including 0.6/1kV

AS3191 Approval and Test Specification - Electric Flexible Cords

AS3500.1 National Plumbing and Drainage - Water Supply

AS3500.2.2 National Plumbing and Drainage - Sanitary Plumbing and Drainage AcceptableSolutions

AS3947 Low Voltage Switchgear and Controlgear

Austel TS008 Requirements for Authorised Cabling Products

Austel TS009 Installation Requirements for Customer Cabling (Wiring Rules)

2.3 AUSTRALIAN STANDARDS - HAZARDOUS AREAS

Any installation in an area, which has been classified as hazardous in accordance with AS2430.1

Classification of Hazardous Areas - Explosive Gas Atmospheres shall conform to all of therequirements of the applicable Hazardous Area Installation Standards. In particular the

requirements of the following standards shall be strictly adhered to:

AS1076 Code of Practice for Selection Installation and Maintenance of ElectricalApparatus and Associated Equipment for Use in Explosive Atmospheres (other

than mining applications)

Note: Some parts of AS1076 have been made obsolete by AS2381

AS1828 Electrical Equipment for Explosive Atmospheres - Cable Glands

AS2380 Electrical Equipment for Explosive Atmospheres Explosion Protection Techniques

AS2381 Electrical Equipment for Explosive Atmospheres - Selection, Installation andMaintenance

2.4 CSBP ENGINEERING STANDARDS

ES-14-101-02 Drawing Management

ES-14-101-03 Drawing Preparation

ES-14-101-06 Equipment Numbering System

ES-14-102-09 Labels and Signs: Plant and Equipment

ES-14-102-12 Protective Coatings

ES-14-701-01 Electrical/Instrument Preferred Equipment

ES-14-702-01 Materials and Workmanship for Instrument Installations

ES-14-902-02 Testing and Commissioning of Electrical and Instrumentation Installations

-

8/10/2019 Elec Specs

5/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 5 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

ES-14-903-01 Electrical Enclosures

ES-14-903-07 3 Phase Isolators (Field Mounted) for 415/440V Induction Motors

ES-14-903-12 Electric Motors

ES-14-903-19 Lighting

2.5

CSBP STANDARD DRAWINGS

Where relevant to the work being performed, the Standard Drawings listed in Appendix 2 shall beused as a guide to the method and detail of the work. The Contractor shall ensure that the current

revision of the drawing is used. No deviations shall be permitted unless the Superintendent givesapproval in writing.

3. DETAIL DESIGN BY CONTRACTOR

3.1

GENERAL

The Contractors shall be responsible for carrying out all necessary additional final design work notincluded in the design documentation. Such work may include, but is not limited to:

a. Site determination of field equipment locations and methods of attachment;

b.

Site determination of field cable and conduit routes;

c. Final design of lighting and small power circuits;

d. Detail design of cable ladder brackets;

e. Cable spacing calculations;

f. Proposed cable numbering for lighting and small power circuits;

g. Power losses for fibre optic cable lengths, connectors and splices.

Drawings, sketches and calculations (as applicable), supporting design work shall be submitted to

the Superintendent for his/her written approval at least ten (10) working days in advance of thescheduled construction commencement date.

Note: The Contractor may be required by the Superintendent to remove, rebuild or relocate at

no charge any items installed without the written approval of the Superintendent.

3.2

AS BUILT DRAWINGS

The Contractor shall be responsible for legibly marking copies of the Principals drawings to theAs Built condition within seven (7) days of Practical Completion. Drawings shall be marked upin red colour.

3.3

CONTRACTOR SUPPLIED DOCUMENTS

The Contractor shall supply four (4) complete sets of Installation and Operation Manuals,

Technical Data Sheets, Spare Parts Listings, Hazardous Area Certificates and any other documentsnecessary for the normal operation and maintenance of all equipment supplied by the Contractor.

This shall include all instrumentation on any Vendor Packaged equipment supplied by theContractor.

-

8/10/2019 Elec Specs

6/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 6 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

4.

MATERIALS AND EQUIPMENT

4.1

MATERIALS OF CONSTRUCTION

Appendix 1 details the materials of construction that are to be used within particular plants at thevarious Wesfarmers CSBP sites.

4.2

GENERAL

All materials provided by the Contractor shall be new and of the best quality and of the class mostsuitable for working under the conditions prevailing at site without:

distortion;

deterioration or the setting up of undue stresses in any part;

affecting the strength and suitability of various parts for the intended application.

These conditions shall include, but not be limited to:

Minimum and maximum ambient temperatures;

Maximum relative humidity;

Vibration;

Explosion or fire hazards;

Vermin;

Salt laden air;

Corrosive dusts or gases;

Chemical fumes;

Ultraviolet radiation;

Direct sunlight; Electrical fault level.

Equipment selection and design shall be such that twenty-year operational life and maximumreliability will be ensured.

Defective equipment shall be completely replaced with a new unit unless sanction to repair such

equipment is received in writing from the Superintendent.

4.3

PREFERRED EQUIPMENT

All equipment supplied by the Contractor shall be selected from CSBP Engineering StandardElectrical/Instrument Preferred Equipment (ES-14-701-01). If the Contractor proposes to supply

equipment, which is not included in ES-14-701-01 then approval must be obtained in writing fromthe Superintendent prior to purchase of such equipment. When such approval is not obtained, theSuperintendent may instruct that the equipment is replaced by another type and all costs of the

replacement, including equipment, labour, design and drawing work shall be at the Contractors

expense.

-

8/10/2019 Elec Specs

7/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 7 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

4.4

PRINCIPAL SUPPLIED EQUIPMENT

The Contractor shall be responsible for the storage and handling of all materials and equipmentrelating to the contract regardless of its place of origin.

A Material Transfer Form shall be completed for all Principal Supplied equipment or materialsused by the Contractor.

All materials and equipment shall be inspected upon receipt and defects reported immediately tothe Superintendent. It shall be considered that the materials and equipment were free from defects

at the time of receipt by the Contractor unless a defect notice is submitted to the Superintendentwithin forty eight (48) hours of receipt of the materials or equipment.

The Contractor shall provide the necessary labour and equipment to accept delivery of the materials

and shall be entirely responsible for all items.

Upon completion of the works and without delay when directed to do so by the Superintendent, the

Contractor shall return all unused Principal supplied materials and equipment to the Principalsstore.

5. INSTALLATION - GENERAL REQUIREMENTS

5.1

LAYOUT ARRANGEMENT AND LOCATION OF EQUIPMENT

In consultation with the Superintendent or his authorised representative, the Contractor shallascertain on site:

a. The exact location of equipment including switchboards, control panels, junction boxes,

any field devices, light fittings, outlets and the routing of cables;

b. Ascertain that adequate clearance from other services exists,

c.

Obtain approval from the Superintendent prior to proceeding with any installation work.

Unless directed by the Superintendent, all field equipment shall be arranged so that cabling isbottom entry. The Contractor shall inform the Superintendent accordingly and modify at his own

expense, any top or side entry equipment.

Unless otherwise specified, equipment such as light switches and power outlets shall be mounted

1.2 metres above the operating platform level or grade as applicable. Equipment and/or accessoriesshall not be mounted on building cladding, machinery or unapproved locations unless the

Superintendent gives specific written approval.

Mounting of equipment to handrails is not permitted. Cables, cable-ladders, brackets poles andfittings shall be kept clear of and supported independently from stair and platform handrails and

ladders. Light stanchions shall not be braced to top handrails and shall be spaced off so as to leavethe handrails clear of obstruction.

Any equipment that must be mounted near to handrails or on handrail vertical supports shall not be

within 100mm of the handrail. Typical installations are detailed in Standard Drawings as listed in

Appendix 2.

-

8/10/2019 Elec Specs

8/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 8 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

Where equipment is mounted along or in access ways, it shall be positioned, modified or protected

such that it does not present a hazard to vehicular or pedestrian traffic using the access way, nor be

subject to accidental operation or possible damage.

5.2

PROTECTIVE SURFACE COATINGS

All cleaning and surface treatment shall conform to CSBP Engineering Standard Protective

Coatings (ES-14-102-12).

Remedial work to any damaged paintwork of any material either transported, handled or assembled

by the Contractor, or incurred during such transport, handling or assembly, shall be in accordancewith ES-14-102-12.

5.3

FIXINGS AND FASTENINGS

Flat washers shall be fitted under bolt heads and nuts where, in the opinion of the Superintendent,

these are required to prevent damage to the surface in contact with the bolt head or nut, e.g.

galvanised or painted surfaces, thin plates or rough surfaces. Flat washers shall be provided underall nuts secured by split pins or similar securing devices and under bolt heads and nuts of all

electrical connections.

In areas susceptible to vibration bolts are to be secured with Nyloc nuts. The Nyloc nuts shall

only be used once.

Self-threading screws shall not be used.

All nuts, bolts and other fastenings shall be 316 stainless steel, except in the case of hot dippedgalvanised cable ladders where galvanised nuts, bolts and fastenings may be used.

Bolted connections are permitted only on cable ladder joins, holding down cable ladders or wherespecific written approval is obtained from the Superintendent. All other connections are to be

drilled and tapped and the threads coated with anti seize compound.

Threads shall project beyond the outside face of nuts or panels and by no more than two threadpitches.

In equipment rooms and control rooms, rawlplugs are acceptable for the securing of GPO mounting

blocks and conduit saddles, where these items are to be directly fixed to the walls.

Where equipment or supports are fixed to solid brickwork or concrete, standard Loxin orDynabolt type bolts or chemical anchors shall be used. For hollow brickwork Rawlnuts shall

be used. Rawlplugs, coach screws or wrought spikes shall not be used.

Explosive fasteners or similar tools shall not be used.

All fixings and fastenings shall be secured by appropriately sized, adequately designed lock nuts,

lock washers or the like.

-

8/10/2019 Elec Specs

9/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 9 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

5.4

SUPPORTS AND BRACKET WORK

All supports, brackets, poles and hangers shall be designed and installed with due regard forlocation, strength, size, suitability, loading, vulnerability to damage and adequacy for the

application intended, to the approval of the Superintendent. All equipment shall be installed suchthat all possible mechanical loads on the item, including bearing the weight of a tradesman can be

withstood and with adequate rigidity to prevent undue vibration of the equipment.

Supports for cable ladder shall be galvanised channel for galvanised ladder and a minimum of

75x50 angle for stainless steel ladder.

Supports for tray and conduits shall be:

a. Stainless steel, when supporting aluminium or stainless steel ladder or tray.

b. Stainless steel, when supporting only ABS conduit if stainless steel is designated for use inthat area.

c.

Hot-dipped galvanised for all other applications.

Typical support and bracket details are shown in the Standard Drawings as listed in Appendix 2.

The Contractor, as detailed in Section 3.1 of this Standard, shall produce sketches of typicalproposed support structures where they are not explicitly shown in the design drawings.

5.5 CUTTING, CHASING, WELDING & DRILLING

The Contractor shall carryout all required cutting and chasing of walls, floors, etc, which may be

necessary in the execution of the Contract works. Upon completion, the altered surface shall berestored to its original finish.

All brackets and the structure to which they are to be welded shall have their mating surfacestreated to prevent corrosion and where welding is performed the mating joints shall be fully sealwelded.

Adequate clearance shall also be provided to ensure that corrosion protective coatings may bereadily applied.

Brackets may be bolted to structural members provided the boltholes are drilled and are no larger

than 13mm diameter. No other drilling of structural members shall be performed without writtenprior approval of the Superintendent.

No cutting, welding or drilling shall be performed on any pipe, chute, vessel, tank or other plantitem of equipment without prior written approval of the Superintendent.

Competent persons who are appropriately qualified and experienced shall carry out all welding.

-

8/10/2019 Elec Specs

10/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 10 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

5.6 EXCAVATION, TRENCHING AND CABLE PITS

The excavation of cable trenches shall be performed in a manner, which opens the trench withparallel sides and flat bottom free from projections.

Cables in the trench shall be packed with imported fine graded yellow sand with a sieve aperture of

less than 75 microns and free from stones, sharp objects or chemically active material so as toprovide a finished packing thickness of 100mm around all cables. After installation of cables the

imported yellow sand shall be used for the remainder of the backfilling of the trench. Backfill shall

be compacted in 300mm thick layers. Sand shall be imported by the Contractor at the Contractorsexpense and the trench shall be made good to the original surface condition.

Any surplus excavated material is to be disposed of at the Superintendents discretion.

Cables, cable slab and marking tape shall be laid in accordance with the Standard InstallationDetail Drawing as listed in Appendix 2 of this Standard.

Cable pits are to be installed such that the top of the pit is at the finished ground level. Conduitentries to draw pits for fibre optic services shall be as detailed in the Standard Drawings, listed inAppendix 2. All fibre optic draw pits shall be Austel approved with lids marked Fibre Optic

Cables. All non-trafficable pits shall have bollards at each end of the pit as detailed in the

Standard Drawings as listed in Appendix 2.

Trafficable pits are to be provided at roadways and hardstand areas.

Cable pits are to be provided with a 100mm hole in the bottom for drainage. Black plastic is to be

provided under the lids for sealing.

5.7

LABELLING

All equipment labelling shall be in accordance with CSBP Engineering StandardLabels and Signs:Plant and Equipment (ES-14-102-09).

6. INSTALLATION OF FIELD EQUIPMENT

6.1

GENERAL

Brackets, supports, hangers, footings, poles and instrument interfaces shall be designed andinstalled by the Contractor to the approval of the Superintendent.

All equipment shall be securely mounted and the associated cables adequately supported andprotected against mechanical damage. All fixings shall be screwed, bolted or welded in accordance

with Section 6 of this Standard.

Spring fixings and girder clips shall not be used for cable installation.

Local Control Stations for motor control shall be located within one metre of the motor unless

written approval is obtained from the Superintendent.

-

8/10/2019 Elec Specs

11/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 11 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

Other than Ex d certified equipment, any electrical termination box or junction box in plant areas,

whether exposed to the weather or not, shall be additionally protected against ingress of moisture or

chemicals by use of Denso tape around enclosure sealed openings and glands. Lanyard fittings arealso to be protected with Denso tape.

6.2

CABLE LADDERS AND TRAYS

All cable ladders regardless of material type, shall be a minimum of Heavy Duty NEMA 20 Brated, with a minimum wall thickness of 2mm and shall be installed using only manufacturers

proprietary fittings. Heavy-duty cable tray may be used provided only manufacturers proprietaryfittings are used and are installed in a vertical plane with field installations having a maximum

width of 100mm. Selection of material shall be in accordance with Appendix 1 (Materials of

Construction) of this Standard. All fixings and fastenings for cable ladder or tray shall be inaccordance with Section 5.3 of this Standard.

Where the Superintendent stipulates that cable ladder covers are to be fitted, they are to be the

peaked cable ladder cover type for horizontal runs and flat type for vertical runs. Hot dip

galvanised covers shall be minimum 1.6 mm.

All high voltage cables are to be run in dedicated high voltage cable ladders, which are to be fitted

with peaked cable ladder covers.

Cable ladders shall be of the width indicated, installed in the orientation shown and at the plan

location and level as shown on the drawings. In addition to those shown on the drawings or asinstructed by the Superintendent, the Contractor shall provide short spur ladders where more than

three (3) cables run in parallel. All cable ladders shall accommodate the cables required and have a25% allowance for future cabling.

Electrical and mechanical continuity of each cable ladder shall be maintained throughout by theinstallation of appropriate bends, tees, crosses, reducers and splice plates by bonding with 35mm5

copper PVC insulated earthing cable. Every fourth cable ladder joint shall be bonded to structural

steel.

All earth bond connections shall be painted with an epoxy-based paint.

Cable ladder supports shall be open to one side to allow the placing of cables without threading.

Supports shall firmly retain the cable ladder under all wind and other loading conditions. Thesupports shall be provided so as to maintain deflection within the manufacturers tolerances. The

installation shall allow for expansion and contraction of cable ladders. Cable ladders shall not bewelded to supports.

When a cable ladder is run horizontally on its side, support brackets shall be installed under theside of the ladder and through bolted to prevent the ladder sliding off the support. Due to the

reduced resistance to bending, a cable ladder installed on its side will require much closer spacingbetween supports to maintain manufacturers tolerances for deflection, as compared with a cable

ladder installed on its bottom.

Cable ladder rung pitch shall not exceed 300mm. Splices shall provide for thermal expansion and

be capable of location at mid span without strength loss. Fixings that may damage cables shall notprotrude into the cable zone.

-

8/10/2019 Elec Specs

12/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 12 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

Horizontal and sloping runs of cable ladder shall, unless otherwise approved, be installed to receive

cables on the uppermost face.

Cable ladders shall be installed such that the retention of liquids in any channel or other partthereof, or the flow of fluid from one area into another (such as a switchroom) is not possible.

6.3

CONDUITS

6.3.1 Conduit systems for cable support and/or mechanical protection shall be installed by the

open ended method unless specified by the Superintendent. The length of exposed cable

shall be kept to a minimum. The bending radius between conduits shall be 60mm or theminimum bending radius of the cable, whichever is the larger.

Conduits for fibre optic cables shall be continuous and shall utilise long radius bends witha minimum-bending radius of 300mm.

All fittings and accessories shall be of the same material as the conduit system in use.

Conduits shall be installed in a manner that prevents the accumulation of water at any pointin the conduit. Conduits finishing in junction boxes shall be fitted with a locknut on eachside of the box.

Steel conduits shall be fitted with PVC bushes and shall not be direct welded.

All open ends of conduits shall be deburred internally and externally such that a smoothsurface is presented. Deburring shall be carried out using a tool specifically designed for

the purpose intended.

Surface run conduits shall be affixed by means of 316 stainless steel saddles or 316stainless steel U bolts, fastened at regular intervals of no greater than 850 mm, in

accordance with Section 5.3 of this Standard.

In instances where Unistrut is used for conduit support stainless steel conduit clamps are tobe used.

6.3.2 Either Class 15 ABS conduit or stainless steel tubing (with equivalent wall thickness as

stainless steel conduit) shall be used in all above ground installations, unless theSuperintendent specifies other conduit systems.

6.3.3 The use of PVC conduit shall be limited to underground applications except where

otherwise approved by the Superintendent. PVC conduit shall be heavy-duty electricalorange conduit, in accordance with AS2053 except where exposed to ultraviolet

radiation from direct sunlight.

6.3.4 Steel conduit shall be heavy-duty galvanised steel as defined in AS2053. Its use shall besubject to the approval by the Superintendent.

In non-corrosive environments it may be unprotected.

-

8/10/2019 Elec Specs

13/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 13 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

In corrosive environments where heavy duty galvanised steel conduit is used it shall have

the ends sealed and be treated with System D paint specification as per CSBP

Engineering Standard Protective Coatings (ES-14-102-12).

Flexible, watertight PVC coated steel conduit with stainless steel flexible conduit fittings

may be used with the written approval of the Superintendent.

6.3.5 Class 12 white PVC conduit shall be used for all fibre optic installations.

6.4

SEALING OF OPENINGS

The Contractor shall provide collars and/or weather hoods where cables pass through walls, floors,roofs or other barriers. During construction all openings shall be temporarily sealed

Following testing and commissioning, all electrical openings into buildings and switchrooms, cable

pits trenches and underground open conduits shall be effectively sealed off against fire, water, airand dust passage, to the satisfaction of the Superintendent.

All floor and wall penetrations shall be formed on both sides prior to sealant being applied. The

finish shall be smooth and excess neatly trimmed off. A removable rigid cover shall be supplied ontop of the floor level.

Sealing materials shall be soft cement for larger diameter underground ducts or conduits and non-ignitable foam, faced with rigid non-combustible material for substation walls and floors.

Materials used shall be to the approval of the Superintendent.

6.5 CABLES & PROTECTION

6.5.1 Cable Type and Quality

6.5.1.1 Plant Area Cables (Non Hazardous Areas)

HV Power Cables: As specified

MV Power Cables: 0.6/1.0kV, V75 Cu PVC/PVC minimum size 2.5mm2coloured red, white,

blue, black, green-yellow.

Screened cable, e.g. PVC/PVC/SWA/PVC for variable speed drives

between motor and drive.

Aluminium Conductors and/or XLPE insulation may be used for cables95mm

2or larger per phase.

Cable sizing for single phase and 3 phase outlets shall be discussed andagreed with the Principal prior to installation.

Control Cables: For 240V AC control circuits.0.6/1.0kV, V75 Cu PVC/PVC minimum size1.5mm

2white numbered cores.

For 24V or 48V DC control circuits. Overall screened V90 Cu PVC/PVCminimum 0.5mm

2.

-

8/10/2019 Elec Specs

14/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 14 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

Instrumentation Cables:Overall screen, PVC/PVC insulated and sheathed

Analog Multipairs to be 0.5mm2

Digital Input Multipairs to be 0.5mm2

Digital Output Multipairs to be 1.5mm2

Fibre Optic Cables: Loose tube or slotted core, multi mode cablePolyethylene sheathed

Nylon jacketedCore diameter 62.5 nanometres

IEEE 802.3 10 Base F

6.5.1.2 Plant Area Cables (Hazardous Areas)

All cabling in Class 1 Zone 2 areas shall be PVC/PVC except where there are specific requirements

for shielding such as for variable speed drives.

All cabling in Class 1 Zone 1 areas shall be PVC/PVC/SWA/PVC. This shall include cables

passing through as well as terminating in Class 1 Zone 1 areas.

6.5.1.3 Underground HV Cables

All high voltage direct buried underground cable shall have a nylon jacket with expendable PVC

overall sheath.

6.5.2

Installation

6.5.2.1 Mechanical Protection and Enclosures

Cables shall be completely protected or enclosed by one of the following means:

a.

Installed in and firmly tied to cable ladder. Where there is a risk of mechanical damage,kickplates and/or cable ladder covers shall be provided to the satisfaction of theSuperintendent.

b. Enclosed in conduit or ducting.

c. Integral steel wire armouring.

The only exception to the above shall be:

1. Short spans of rigid cable in a recognised electrical only enclosure such as betweencable ladder or duct and an MCC or transformer.

2. The point within the confines of a cable ladder at which cabling exits from the ladder.

3. The short length where cabling glands into field equipment.

6.5.2.2

Cable Ties

Multicore cables that run on ladder or tray shall be tied using polypropylene cable ties on

horizontal runs. Cables laid in trefoil shall be secured with stainless steel cable ties.

For vertical cable runs and horizontal cable runs with the ladder on edge, the cable tie system must

have a long life and must not risk cutting through the cable sheath. In these cases, stainless steel

-

8/10/2019 Elec Specs

15/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 15 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

cable ties shall be used and the ties shall either be inserted through a suitably thick sleeve prior to

installation over the cable, or a suitably thick sacrificial sheath shall be installed over the cable

prior to fastening with the cable tie. A sample of the proposed fixing system shall be submitted forthe Superintendents approval prior to use on site.

Maximum spacing between ties shall be as follows:

Horizontal runs, ladder on flat 900mm

Horizontal runs, ladder on edge 300mm

Vertical runs, ladder on end 600mm

Plastic coated steel or brass straps or nylon cable ties shall not be used for securing cables.

Where single core cables are used for multi phases, the cable shall be supported in trefoil formation

along the length of the cable and gland plates shall be made of non-ferrous metals, e.g. aluminium,

to avoid overheating due to eddy current losses.

6.5.2.3

Overlaying and Layering in Ladders

Overlaying and cross over of cables is prohibited unless approved in writing by the Superintendent.No more than seven control cables shall be encompassed as a bundle by one cable tie.

Power cables shall be installed as a single layer and shall be spaced not less than 10mm apart to

allow free air circulation, unless specified otherwise.

In the case of under utilised cables, grouping and layering may be permitted up to a maximum of

two layers only. The Contractor shall produce calculations substantiating any such layering of

power cables for consideration and approval by the Superintendent prior to installationcommencing.

6.5.2.4

Segregation of Cables

Cable ladder installation shall maintain a minimum of 350mm separation between ELV cables andother cables. Where LV and ELV cables are installed in separate cable ladders then the minimum

distance between any part of either cable ladder shall be 350 mm.

Where LV and ELV cables are installed in a common ladder the 350-mm separation distance mustbe maintained and also segregation barriers installed in accordance with AS3000.

HV cables are only to be installed in dedicated HV cable ladders.

Where a segregated cable ladder or separate cable ladders are not considered suitable or the 350-mm minimum spacing cannot be practically achieved then ELV cables may be installed in a

separate metallic conduit in accordance with Section 6.3.4. The steel conduit may be affixed to theside of the LV cable ladder.

A separate metallic conduit, in accordance with Section 6.3.4, shall be installed for all ultra low

voltage signals such as communication, load cell, flame scanner, thermocouple and frequency etc.

Above and below ground cables shall be segregated from water services in accordance withAS3500.1.

-

8/10/2019 Elec Specs

16/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 16 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

6.5.2.5 Underground Cables

Underground cable installation shall be in accordance with the Standard Installation Drawings as

listed in Appendix 2.

Cables shall be installed in unbroken lengths between end terminations, unless prior specific

written approval for intermediate joints is obtained from the Superintendent. Such joints shall be

made using only approved jointing materials and techniques as recommended by the cablemanufacturers and to the approval of the Superintendent.

Power cables shall be spaced sufficiently apart so that the cables do not overheat. The Contractor

shall submit detailed calculations of cable spacing proposed, as per Section 3.1 of this Standard, forapproval of the Superintendent prior to excavation commencing.

In addition to the foregoing, it shall be possible to readily identify the route of underground cables

as follows:-

a. Where there are not any above ground items of electrical or control equipment such as lightpoles, underground residential distribution boxes, telecom distribution frames etc. OR these

items are greater than 50 metres apart, then all power, control, instrumentation and

communication cables shall have markers to identify the cable route. The route markersshall be above ground posts where there is traffic free open ground or slabs buried flush

with the finished ground level where the cable route is below vehicle or pedestrian accessareas. The route markers shall be installed in the centre line of the trench at every change

of direction, cable joints, on each side of a road or rail or pedestrian crossing and at amaximum of 50 metres apart on the straight runs. Where the cable trench is wider than 1.2

metres, multiple markers shall be installed at each designated point on the cable route suchthat there is not more than 600mm from a cable marker to the outside edge of the trench

and no more than 1.2 metres between markers. The marker posts may be hammered in

place provided the trench is new and there are no direct buried cables within 850mm of the

finished ground level. Where marker posts are used to mark existing cable trenches, thecable shall be located first and the hole for the posts shall be hand dug to the 600mm depth

required. The route markers shall be in accordance with the standard drawings listed inAppendix 2 and Tables 1 and 2.

b. Where above ground items of electrical or control equipment exist and the distances

between each item is less than 50 metres then some combination of the following shall beimplemented such that the underground cable route is clearly marked. In all cases the

solution implemented shall be as determined by the Superintendent following consultation

with the installation Contractor.

1. "In ground" cable markers as per above installed at the mid points of each straight

underground run from one item of equipment to another.

OR

2. A stainless steel label 300 mm above ground shall be screwed to the above ground

equipment. Separate labels shall be installed on each side of the equipment where

the under ground cables approach or leave the equipment. The label wording shallbe "UNDERGROUND (POWER / TELEPHONE / COMMUNICATION / etc.)

CABLE THIS SIDE".

-

8/10/2019 Elec Specs

17/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 17 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

Above Ground Marker Posts

Above ground posts shall be labelled and coloured in accordance with Table 1.

DUTY MARKER POST COLOUR LABEL WORDING

High voltage cables Orange DANGER

HIGH VOLTAGE

CABLES IN THIS VICINITY

Low voltage cables,

Control cables,Instrument cables

Orange CAUTION

LOW VOLTAGE

CABLES IN THIS VICINITY

Telephone cables,Communication cables,

Data cables

White CAUTION

COMMUNICATION CABLES

IN THIS VICINITY

Fibre optic cables White CAUTION

FIBRE OPTIC CABLES

IN THIS VICINITY

Cable Joint (see Note) CABLE JOINT BELOW

Table 1 - Underground Cables - Marker Post Labelling and Colour Coding

Note: Where there is a cable joint, an additional label shall be fitted to the route marker post

with the words CABLE JOINT BELOW.

Note: Where high voltage and other electrical cables share the same trench, a high-voltage cableand a low-voltage cable route marker label shall be installed on the same post.

Note:

Where fibre optic and other communication cables share the same trench, a fibre opticcable and a communications cable route marker label shall be installed on the same post.

Above Ground Marker Slabs

Cable marker slabs shall have embossed wording in accordance with Table 2.

DUTY WORDING

High voltage cables H/V CABLES

Low voltages cables,

Control cables, Instrument cablesELECTRIC CABLES

Telephone cables, Communication cables,Data cables

COMMUNICATION CABLES

Fibre optic cables FIBRE OPTIC CABLES

Cable Joint (see Note) CABLE JOINT

Table 2 - Underground Cables Marker Slab

-

8/10/2019 Elec Specs

18/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 18 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

Note: Where there is a cable joint, an additional marker slab shall be installed with the wordsCABLE JOINT.

Note: Where high voltage and other electrical cables share the same trench, only the high

voltage cable route marker slabs need be installed.

Note: Where fibre optic and other communication cables share the same trench, only the fibre

optic cable route marker slabs need be installed.

6.5.2.6 Damaged Cable

The Contractor shall ensure that the insulation, sheathing or covering of any wire or cable is notdamaged. Any rectification to damaged cabling shall be at the Contractors expense to the

approval of the Superintendent.

6.5.2.7 Fibre Optic Cables

Fibre optic cables shall have a minimum bending radius of 300mm. Personnel shall be located atall changes of direction to feed the cable by hand. The maximum pulling strain on the cable is not

to exceed 60kg. All installation shall be by hand, mechanical means of cable pulling is notpermitted.

Proprietary brand lubricants shall be used when pulling cables through conduits to reduce friction.

6.5.2.8 Concrete Slabs

Cables shall not be installed in suspended concrete slabs but instead shall pass vertically through

the slab, and then run either on the underside or topside of the slab.

In the case of ground floor slabs, the cable shall be run in the soil at a depth in accordance with

Section 6.5.2.5

prior to pouring the concrete. Where the ground floor slab has already been laid,the cable may be installed in a channel cut out of the concrete and then grouted over, and in

accordance with AS3000.

6.6

CABLE GLANDING AND TERMINATIONS

All cables shall be glanded directly to the equipment, with weatherproof glands unless specifiedotherwise.

6.6.1

Miniature Equipment

Cables shall be terminated at rail mounted terminals in a conveniently located multi-way junctionbox that has a minimum ingress protection rating of IP65 where:

cables are to be connected to equipment that is too small to accommodate the connections orglands;

permanent wiring tails are provided with the equipment.

The junction box type is to be of a material that matches the conduit system being installed. Where

four (4) or more connections are to be made in a junction box, Klippon rail mounted feed through

-

8/10/2019 Elec Specs

19/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 19 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

terminals are to be fitted and the junction box sized to ensure clean termination and glanding.

Where no mounting plate is provided the terminal rail is to be affixed to the junction box with a

suitable adhesive for the type of junction box.

All penetrations in the box required for mounting purposes shall be sealed and caps used where

provided.

Cables entering the box shall be glanded. Where flying leads consisting of two or more individualcores are to be terminated in the junction box the cores shall be covered with self-sealing

heatshrink and glanded into the junction box.

6.6.2

Looping Circuits

Where circuits feed several devices as in the case of light fittings and general-purpose outlets, the

cables shall loop via a 3 way junction box conveniently located adjacent to the fitting. For lighting

circuits the 3 way junction box shall incorporate a socket outlet for plug in light fittings which shall

have a minimum IP65 rating.

Refer CSBP Engineering Standard Electrical/Instrument Preferred Equipment (ES-14-701-01)for

details. Terminations in these junction boxes are to be completed as described in Section 6.6.1

6.6.3

Glands - Non-Hazardous Areas

All glands terminating to equipment outside explosive hazardous areas to be one of the following:

a. PVC/PVC cables: 32mm or less - Phenolic glands

Larger than 32mm - Plastic coated brass cable glands

a.

PVC/PVC/SWA/PVC Cables

All gland sizes - Plastic coated brass cable glands

6.6.4

Glands - PVC/PVC Cables in Class 1 Zone 2 Areas

All glands terminating PVC/PVC cables to either electrical or instrument explosion proofequipment (including Exd and Exn) located within Class 1 Zone 2 areas to be explosion proof

gland certified to Australian Standards.

Where there is sufficient lead-time then these glands shall be either 316 stainless steel or plastic

coated brass.

Where there is insufficient lead-time and there is written agreement from the Superintendent, theglands shall be nickel coated brass with self sealing heat shrink to provide an effective seal against

corrosive dusts and moisture. In this case the gland must be inspected and the installation acceptedby the Superintendent prior to fitting of the heat shrink cover.

6.6.5

Glands PVC/SWA/PVC/PVC Cables in Class 1 Zone 2 Areas

All glands terminating PVC/PVC/SWA/PVC cables to either electrical or instrument explosion

proof equipment (including Exd and Exn) located within Class 1 Zone 2 areas to beflameproof in accordance with AS1828 Electrical Equipment for Explosive Atmospheres - CableGlands.

-

8/10/2019 Elec Specs

20/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 20 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

Where there is sufficient lead-time then these glands shall be either 316 stainless steel or plastic

coated brass.

Where there is insufficient lead-time and then only by written agreement from the Superintendentthe glands shall be nickel coated brass with self sealing heat shrink to provide an effective seal

against corrosive dusts and moisture. In this case the gland must be inspected and the installation

accepted by the Superintendent prior to fitting of the heat shrink cover.

Earth rings shall be fitted for all Steel Wire Armoured Cable Gland installations.

6.6.6

Terminations

Power cables shall be terminated using crimp lugs and the correct size aluminium or copper die forcables 10mm5 or larger. Aluminium cables shall be terminated using suitable metallic Al/Cu lugs

and the lugs shall be fitted in accordance with the manufacturers recommendations.

All cores of control and instrument cables shall be terminated, including spares. Clear ferrule

sleeving shall be installed on spare cores such that ferrules may be installed at a later date withouthaving to remove crimp pins or lugs.

Where screened instrument cables are used, wherever possible white shall be positive and black

shall be negative.

Control and instrument cables shall be terminated using insulated crimp pins or lugs, which shall be

crimped with the proprietary-crimping tool.

The correct size pins are to be used for each core size, e.g.:

Red 0.5mm2to 1.5mm

2

Blue 1.2mm2to 2.5mm

2

Yellow 2.5mm2 to 6.0mm2

All of the above shall be Supergrip connectors (Utiliux or Burndy)

Miniature crimp pins, in accordance with CSBP Engineering Standard Electrical/InstrumentPreferred Equipment (ES-14-701-01), are permissible with the approval of the Superintendent only

on high-density applications such as PLC cards, etc. Wiring from PLC cards to cabinet terminalstrips shall be 0.5mm^2.

Where screened cables are glanded into cabinets, junction boxes, field devices or the like, black

heatshrink shall be used over the sleeve, cores and screens of the cable. The cable sheath shall

extend beyond the cable gland for a minimum of 50mm.

Each core or pair of any cable glanded into a junction box shall reach to any terminals within that

junction box. Similarly within cabinets or marshalling panels each core or pair shall reach to anypoint within the zone in which it is to be terminated.

All screens are to be sheathed with clear sleeving which shall be ferruled in accordance with

Section 6.7.3.

-

8/10/2019 Elec Specs

21/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 21 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

6.6.7

Fibre Optic Termination & Splicing

The methods employed for termination and splicing the fibre optic cables shall conform to the

following:

6.6.7.1

Terminations

All terminations at the termination panels shall be via factory assembled pig tail assemblies.

The connectors shall be ceramic ST style connectors as manufactured by Dorran Phototronics

(distributed by 3M Fibre Optic Products) or approved equivalent.

Jointing of the pigtail to the fibre optic cable shall be by the fusion method.

Sufficient cable length must be left at the termination panel to enable easy withdrawal for fusion

splicing to the pigtails.

6.6.7.2 Splicing

All fibre optic cable runs shall, where possible, be designed so there are no splice joints. However,if cable production or installation methods require a splice joint, then the following methods shouldbe employed:

a. All fibre shall be fusion jointed.

b. All splices shall be located where easy access is available to provide a clean environment

required for fusion splicing. This will usually require a location at ground level withvehicular access or an open floor level within a building.

c. Sufficient cable length must be left at the splice joint location to enable the cable ends to be

extended to the location of the fusion jointing equipment.

d. All splices shall be contained within a 3M-fibre optic splice case.

Note: A suitably qualified technician shall perform all fusion jointing and splicing.

6.6.7.3 Termination Panels

The termination panels provided shall conform to the following:

a. Each termination panel shall be as supplied by Dorran Phototronics (distributed by 3M

Fibre Optic Products), or approved equivalent.

b. The termination panel shall be complete with all accessories recommended by the

Manufacturer for a completion installation.

c.

Each panel shall have a connector module complete with couplings including sufficient

ports to accommodate all fibres of the incoming cable.

d. A splice module shall be provided complete with splice tray suitable for fusion splicing.

e. All doors shall be fitted with locks and the splice module shall have a removable front door.

-

8/10/2019 Elec Specs

22/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 22 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

6.6.7.4 Cable Management

All fibre patch leads, UTP patch leads and power cables shall have proper cable management.

All fibre patch leads shall be rolled 200mm diameter and placed inside the fibre management tray.

6.7

CABLE MARKING AND FERRULING

6.7.1

Numbering Scheme

Cable numbers shall be allocated using a code that identifies the source and the destination.

Field devices for electrical motor controls shall be identified by field equipment codes. Where the

field equipment is a type of instrument then the ISA naming system shall be used. In all othercases, electrical field equipment codes shall be used as follows.

Note: Field equipment for electric motor controls do not have unique Equipment Numbers as

per CSBP Engineering StandardEquipment Numbering System (ES1410106).

Typical field equipment codes for electric motor controls are as follows:

BDS Belt drift switch

FIS Field isolator switch

LCS Local control station

LSH Level switch high (ISA name)

LSHH Level switch extra high (ISA name)

LSL Level switch low (ISA name)

LSLL Level switch extra low (ISA name)

PWS Pull wire switch i.e. lanyard switch

ZS Position switch (ISA name)USS Under speed switch

Field devices for security systems shall be identified by field equipment codes related to associated

security system numbers.

Note: Field equipment for security systems do not have unique Equipment Numbers as per

CSBP Engineering StandardEquipment Numbering System (ES1410106).

Typical field equipment codes for security systems are as follows:

BG Break Glass

BS Beam Set, Long Range, Infra-Red

C CameraCP Control Panel

CPU Central Processing Unit

CR Card Reader

DP Duress Call Point

EL Door Electric Lock

-

8/10/2019 Elec Specs

23/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 23 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

ES Door Electric Strike

G Gate, Boom Gate

I Intercom

IM Master Intercom

IS Slave IntercomJB Junction Box

KP Keypad

LM Lock Monitor

M Monitor for CCTV

MP Mimic Panel/Console

MW Microwave Detection

P Remote Panel

PE Photo Electric Cell

PIRA Passive Infra-Red Sensor - General

PIRC Passive Infra-Red Sensor - Curtain

PIRD Passive Infra-Red Sensor - Dual TechPIRL Passive Infra-Red Sensor - Long Range

PIRW Passive Infra-Red Sensor - Wide Angle

PS Power Supply (

-

8/10/2019 Elec Specs

24/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 24 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

Local Control Station to Pull Wire Switch No. 2

Cable No. X830LCS/PWS2

Cables in Security Systems shall reference the Security System Number.

Examples: Security System No. SS0001Main Control Panel to Reed Switch No 3

Cable No. SS1CP/RS3

Cable installed between the Main Control Panels of 2 separate nominated security

systems, in the same area.Cable No. SS1CP/SS2CP

Should the cabling run between plants with differing plant area codes or from a switchroom orequipment room which services more than one plant area, it is necessary to indicate the plant area

codes prefix on the cable.

Example: Area 25 (Granulating Plant) Area 26 (Prilling Plant)25 SB-0601 to 26 JB-0167 2nd cable

Cable No. 25SB601/26JB167-2

6.7.2

Cable Markers

All cables shall be assigned cable numbers including earth cables. Where it is necessary for the

Contractor to assign cable numbers these numbers are to be approved by the Superintendent priorto installation as detailed in Section 3.1.

Cable markers and carrier strips shall be as per CSBP Engineering Standard Electrical/Instrument

Preferred Equipment (ES-14-701-01).

All cable markers shall be installed in the same orientation. Markers shall read from bottom to topand from left to right. Refer to Standard Drawings listed in Appendix 2 for typical installationdetails.

6.7.3

Ferruling of Cores

All cable cores shall be ferruled using the ferruling system specified in CSBP Engineering Standard

Electrical/Instrument Preferred Equipment (ES-14-701-01) other than high density PLC

terminations which shall utilise screen printed heat shrink labels treated with protective coating toprotect lettering.

All ferruling including distribution board circuit identification shall be in accordance with thedrawings. Refer to Standard Drawings as listed in Appendix 2 for details.

Ferruling of instrument cable cores shall be according to the instrument tag number and its polarity.

The full tag number including leading zeroes shall be used.

For Example:

FIT 0234 Positive shall be ferruled FIT 0234+

FIT 0234 Negative shall be ferruled FIT 0234-

-

8/10/2019 Elec Specs

25/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 25 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

6.7.4

Wiring

Panel wiring shall be carried out in accordance with CSBP Engineering Standard Electrical

Enclosures (ES-14-903-01).

Where panel wiring is performed it shall meet all of the conditions of CSBP Engineering Standard

Electrical Enclosures (ES-14-903-01)and in particular shall follow the colour-coding standard of:

Grey 240VAC Control wiring

Red 240VAC Active

Black 240VAC Neutral

White 110VAC Active

Brown 110VAC Neutral

White/Red Stripe 110VDC Positive

Black/White Stripe 110VDC Negative

Pink 48VDC Positive

Purple 48VDC Negative (0 Volts)

Orange 24VDC Positive

Blue 24VDC Negative (0 Volts)

Green/Yellow Earth

Current Transformer Secondaries shall follow phase colours.

-

8/10/2019 Elec Specs

26/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 26 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

6.8

FIELD EQUIPMENT

6.8.1

Lanyards

Installation of lanyards shall comply with the requirements of AS1755. Lanyard switches shall be

slack wire tripping type with a maximum rope length of no more than 30 metres to the fixingpoint.

A stainless steel spring arrangement is to be provided at the fixed end of the lanyard rope to allow

the switch to operate when pulled in either direction longitudinally to the rope.

All lanyards are to run parallel with the conveyor. Lanyard ropes shall not change direction.

It is not acceptable to support lanyard guides from handrails. Lanyard guide eyes shall be a

maximum of four (4) metres apart. Guides shall be supported as detailed in the Standard Drawings

listed in Appendix 2 of this Standard.

All lanyard fittings shall be 316 stainless steel. Lanyard rope shall be plastic coated.

6.8.2 Local Control Stations

Local control stations shall be the combination LCS and junction box type and shall be installed in

accordance with Standard Drawings as listed in Appendix 2.

Spillage/dust covers shall be fitted to local control stations in all dust environments and areas

susceptible to spillage.

6.8.3

Emergency Trip Pushbuttons

All field mounted emergency trip pushbuttons that will result in a plant trip if operated, shall be

protected against accidental operation. This shall include emergency trip pushbuttons that mayresult in a consequential trip of the plant by, for example, shutting down a critical drive etc. Suchprotection shall be effective against personnel leaning on the button or equipment falling over on to

the button or due to carried equipment such as ladders or scaffolding striking the button. Allproposals for protection of emergency trip pushbuttons shall be submitted to the Responsible

Officer for approval prior to proceeding with purchasing.

7.

EARTHINGAll equipment shall be earthed in accordance with the relevant Australian Standards. Refer toStandard Drawings as listed in Appendix 2 for details.

-

8/10/2019 Elec Specs

27/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 27 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

7.1

SUBSTATION POWER EARTH TERMINAL BAR

Each Substation shall be provided with a main earth bar of minimum dimensions 500 x 40 x 6.3mmhard-drawn copper mounted 750mm above floor level at an accessible position. The earth

conductor(s) for the following equipment shall be connected to this bar:a. Power earth mat connection No.1

b. Power earth mat connection No.2

c.

Transformer star point

d. Transformer frame

e. Cable tray/ladder

f.

HV switchboard connection No.1

g. HV switchboard connection No.2

h. LV switchboard (for MEN connection)

i. Grading Earth connection No 1

j.

Grading Earth connection No 2

The earth cables attached to this bar shall be identified at each end in accordance with Section 7.7.

These cables shall be PVC insulated and mechanically protected throughout their length.

Underground cables shall have cable slabs laid above them and cable marker tape.

Cable cross sectional area shall be capable of handling the maximum fault current for one second.

All items of switchgear and associated metal work shall be connected to the general mass of earth

to the Superintendents satisfaction.

7.2

POWER EARTH MAT

The earth mat system shall comprise 20mm diameter extendable steel copper-clad earthing

electrodes, driven to an approved pattern and interconnected with a PVC insulated earth conductorarranged in a continuous loop. Cable slabs shall be used to provide mechanical protection of the

interconnecting cables. When additionally required by the Standards, a direct buried base gradingearth conductor shall be installed to minimise lethal touch potential. Transfer compounds shall

have each steel fence post bonded to the grading grid. Horizontal posts shall be earth-bonded to

vertical fence posts. Gates shall be bonded to the supporting fence posts with flexible tinnedcopper braid and earthing connectors. The grading earth conductor shall be connected to the

substation earth bar. The interconnecting cable/electrode connection shall be bolted clamp type to

allow for removal of the cable for testing or inspection of the electrode.

For the purposes of bonding cables to equipment and other cables, exothermic connectors including

tee, cross, lug, plate thru, surface and crane rail types shall be used.

Each earth electrode shall be installed within an earth pit comprising a protective/locating box orconcrete pipe fitted with a lid and recessed handle and set at finished ground level. The lid shall be

clearly identified and labelled. Interconnecting earth cables shall be at a depth of 450mm.

Note: For earth cables connected to generator neutral points or to resistor banks connected to

generator neutral points, each end of the cable(s) shall have a label affixed Do NotRemove This Earth Connection Unless Generator Is At Standstill & Isolated.

-

8/10/2019 Elec Specs

28/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 28 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

7.3

LIGHTNING EARTHING

All installations shall be provided with earth electrodes, buried earth conductor, interconnectingearth conductors, lightning arresters, equipment bonding conductors all in accordance with AS1768

Lightning Protection. The lightning earthing system shall be interconnected to the power earthingsystem.

8. SWITCHBOARDS & CUBICLES

Switchboards and Control Cubicles shall be supplied, erected modified and assembled strictly inaccordance with CSBP Engineering Standard Electrical Enclosures (ES-14-903-01) and the

manufacturers installation instructions.

9. LIGHTING & SMALL POWER

9.1 GENERAL

Where required, the Contractor shall design and detail the lighting and small power system,

inclusive of distribution boards, light fittings, power outlets, supports, poles, standards, hangers,brackets, wiring and cabling.

The provisional layout and selection of equipment is indicated on the drawings. The Contractor

shall produce calculations, layout and detail drawings, including those for the distribution boards,for the approval of the Superintendent. These shall be submitted in accordance with Section 3.1

prior to construction commencing.

9.2

LIGHTING

Lighting systems to be in accordance with CSBP Engineering Standard,Lighting (ES-14-903-19).

9.3 SMALL POWER

General purpose, single-phase outlets and three phase welding outlet circuits shall be supplied from

distribution boards as indicated on the drawings. Circuit loadings shall be restricted to 60% of thatallowed in AS3000 to provide future additions. All single phase and 3 phase power outlets shall be

provided with non-portable earth leakage protection with trip settings of 30mA for both single andthree-phase with the points of protection as follows:

Individual non-portable RCD at the outlet for Workshops, Laboratories and Field Devices. Non-

portable RCD at Distribution Board protecting a number of GPOs on each circuit for all buildingssuch as Offices, Control Rooms, Crib Rooms and Canteens with the exception of Refrigerators and

Hot Water Services which shall be on dedicated circuits.

Where a non-portable residual current device has been installed at the switchboard, a notice shall

be displayed in a prominent place at or near the switchboard indicating that a non-portable residualcurrent device is installed. The notice shall be as follows:

RESIDUAL CURRENT PROTECTION DEVICES FITTED WITHIN THIS DISTRIBUTION

BOARD

-

8/10/2019 Elec Specs

29/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 29 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

All fixed socket outlets that are protected by non-portable residual current devices, either at the

switchboard or at the socket outlet, shall have a label to identify the socket outlet as being protected

by a residual current device.

All fixed socket outlets shall have a label identifying the switchboard and the circuit, which powers

the socket outlet. For example:

DB1/R3 for distribution board no.1, single phase circuit no.3, on red phase or,

DB2/RWB2 for distribution board no.2, three-phase circuit no.2.

In plant areas, the switchboard identification shall also include the plant area prefix: For example:

25DB2/RWB6 for Granulating Plant (area 25), distribution board no.2, threephase circuit no. 6.

All labels must be attached to a fixed part of the installation to prevent the label being removed

completely or relocated to a different outlet.

Lighting will not be on RCD protected circuits.

Small power outlets shall be located generally as indicated on the drawing and grouped together

with 3 phase welding outlets wherever possible.

Welding outlets shall be 32 Amps 3 phase neutral and earth type, 5 pin.

9.4 DISTRIBUTION BOARD

Distribution Boards shall be located at the positions indicated on the drawings.

30% spare circuit breaker capacity shall be provided.

Refer to Section 6.7.3 for information on how circuits are to be identified and ferruled.

An up to date circuit identification sheet shall be provided in the door of the distribution board.

9.5 LABELLING

All light fittings and power outlets shall have their supply source identified by means of an

appropriate cable marker label affixed to the supply cable as specified in Section 6.7.2. Suchlabelling shall clearly identify the supply source panel designated and circuit number. In addition,GPOs shall be further identified using a coloured numbered plastic stud. Refer to CSBP

Engineering StandardLabels and Signs: Plant and Equipment (ES-14-102-09).

-

8/10/2019 Elec Specs

30/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 30 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

10. HAZARDOUS AREAS

10.1 INSTALLATION

Any installation in an area, which has been classified as hazardous in accordance with AS 2430

Classification of Hazardous Areas - Explosive Gas Atmospheres, shall conform to all of therequirements of the applicable Hazardous Area installation standards. In particular the

requirements of the standards listed in Section 2.3 shall be strictly adhered to.

10.2

CERTIFICATION & REGULATIONS

Any equipment supplied by the Contractor for use in designated hazardous areas shall be

accompanied by the appropriate certification documentation. This documentation is applicable to

all items of electrical construction materials as well as any electrical equipment supplied by theContractor.

All electrical construction materials shall have SAA approvals without exception.

All Contractor supplied electrical equipment shall have approvals in the following ranking order:

1.

SAA Australian Standards

or if SAA Approval is not available:

2. CEN, CENELEC, BASEEFA European Standards

3.

CSA Canadian Standards

4. FM American Standards

11.

CHECKING, TESTING AND COMMISSIONING

Checking, testing and commissioning of plant and equipment shall be in accordance with CSBPEngineering Standard Testing and Commissioning of Electrical and Instrumentation Installations

(ES-14-902-02).

-

8/10/2019 Elec Specs

31/32

Materials and Workmanship for Electrical Installations

ES-14-902-01

Version No. 10.0 Page 31 of 32

Document last modified: 03 January 2013. Date printed: 18 January 2013.

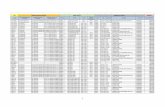

APPENDIX 1 - MATERIALS OF CONSTRUCTION

PLANT EQUIPMENT RATING MATERIAL WET

AREAS

MATERIAL DRY

AREASSwitchrooms Cable Ladder

Cable Tray

Conduit

NEMA 20

B Class 15

Hot Dipped Galvanised

Hot Dipped Galvanised

ABS

Ammonia Cable Ladder

Cable Tray

Conduit

NEMA 20

B Class 15

Hot Dipped Galvanised316 Stainless Steel

ABS

Hot Dipped Galvanised316 Stainless Steel

ABS

Ammonium

NitrateCable Ladder

Cable Tray

Conduit

NEMA 20

B Class 15

Marine Grade Aluminium

316 Stainless Steel

ABS

Marine Grade Aluminium

316 Stainless Steel

ABS

Nitric Acid Cable Ladder

Cable Tray

Conduit

NEMA 20

B Class 15

316 Stainless Steel

316 Stainless Steel

ABS

316 Stainless Steel

316 Stainless Steel

ABSPrilling Cable Ladder

Cable Tray

Conduit

NEMA 20

B Class 15

Marine Grade Aluminium

316 Stainless Steel

ABS

Marine Grade Aluminium

316 Stainless Steel

ABS

Chlor-Alkali Cable Ladder

Cable Tray

Conduit