Simulation of the Delft Jet-in-Hot-Coflow burner using transported ...

Effect of the Coflow Stream on a Plane Wall Jet

-

Upload

pratik-joshi -

Category

Documents

-

view

5 -

download

0

description

Transcript of Effect of the Coflow Stream on a Plane Wall Jet

ORIGINAL

Effect of the coflow stream on a plane wall jet

Syrine Ben Haj Ayech • Sabra Habli •

Nejla Mahjoub Saıd • Herve Bournot •

George Le Palec

Received: 24 May 2013 / Accepted: 3 May 2014

� Springer-Verlag Berlin Heidelberg 2014

Abstract We propose in this work to study an isothermal

and a non-isothermal laminar plane wall jet emerging in a

coflow steam. The numerical solution of the governing

equations was performed by a finite difference method. In

this work, we are interested in the study of the influence of

Grashof numbers on the wall jet emerging in a medium at

rest. Further, we will examine the effect of the coflow stream

on the behavior of the dynamic and thermal properties of the

wall jet subjected to a constant temperature. A comparison

with a simple wall jet is carried out. The results show that for

a buoyant wall jet, two parameters can influence the flow: the

inertial and buoyancy forces. The velocity effect indicates

that the potential core length increases with the velocity ratio.

We are also showed that when using a momentum length

scale, the normalized longitudinal maximum velocity can

reach an asymptotic curve at different velocity ratios.

List of symbols

b Ejection nozzle thickness (m)

Cp Specific heat at constant pressure of the

fluid (J kg-1 k-1)

Gr Grashof number [Gr = gbb3(Tp - T?)/v2]

h Local convection coefficient (w m-2 k-1)

J Momentum discharged from the nozzle

exit (J = u02b) (m3 s-2)

Nu Local Nusselt number (Nu = hx/k)

Pr Prandtl number (Pr = lCp/k)

r Coflow velocity ratio (r = uco/u0)

Re Reynolds number (Re = u0b/v)

Rex Local Reynolds number (Rex = umx/v)

u, v Longitudinal and transverse components

of the velocity, respectively (m s-1)

uex = u - uco Longitudinal excess velocity (m s-1)

x, y Longitudinal and transversal coordinate

(m)

y0.5 Dynamic jet half-width, value of the

lateral distance at which longitudinal

velocity is half of the maximum

value (m)

Greek symbols

q Fluid density (kg m-3)

l Dynamic viscosity of the fluid (kg m-1 s-1)

k Thermal conductivity of the fluid (w m-1 k)

spWall shear stress sp ¼ l ou

oy

� �y¼0

� �, Pa

t Fluid kinematic viscosity (l/q) (m2 s-1)

a Thermal diffusivity of the fluid (m/Pr) (m2 s-1)

Subscripts

p Wall value

0 Value at the jet exit

S. B. H. Ayech

LGM, Ecole Nationale d’Ingenieurs de Monastir, Universite de

Monastir, Monastir, Tunisia

e-mail: [email protected]

S. Habli � N. M. Saıd (&)

LGM, ENIM, Institut Preparatoire aux Etudes d’Ingenieurs de

Monastir, Universite de Monastir, Monastir, Tunisia

e-mail: [email protected]; [email protected]

S. Habli

e-mail: [email protected]

H. Bournot � G. Le Palec

Aix-Marseille Universite, CNRS, IUSTI UMR 7343,

13013 Marseille, France

e-mail: [email protected]

G. Le Palec

e-mail: [email protected]

123

Heat Mass Transfer

DOI 10.1007/s00231-014-1372-7

? Ambient conditions value

m Maximum value

co Coflow stream

ex Excess

1 Introduction

A wall jet flow is obtained by ejecting a fluid tangentially

to a solid surface. This type of flow is widely used in

industrial processes such as thermal insulation, spray

cooling air film, welding, smoothing solid etc.

In such flow, there are an inner wall boundary and an

outer one that behaves as a free jet [1, 2]. A wall jet in a

stagnant environment has been the subject of several

studies that combine both dynamic and thermal measure-

ments in order to predict the flow behavior. Quintana et al.

[3] conducted an experimental study in a flow at rest of

wall jet evolving tangentially to a wall subjected to a

constant temperature. Three cases were analyzed: an iso-

thermal plate (Tp = T?), a heated plate (Tp/T? = 1.03)

and a cold plate (Tp/T? = 0.98). Abdulnour et al. [4]

developed an experimental study of a turbulent wall jet, in

a region adjacent to the nozzle exit (1.5 B x/b B 13). They

studied the influence of the wall thermal conditions (sub-

jected to a constant temperature or to a constant heat flux)

and the evolution of the heat transfer coefficient.

Numerically, Yu et al. [5] proposed a numerical method

to treat heated laminar free and wall jet. Mhiri et al. [6]

have been interested in studying the influence of emission

conditions at the nozzle exit of an isothermal or non-iso-

thermal laminar flow of a free jet or wall jet developed

tangentially to an adiabatic wall. A numerical study was

made by Mokni et al. [7] in a laminar jet flow ejected

tangentially to a wall subjected to a constant heat flux.

These authors were interested in the influence of emission

conditions at the nozzle exit (uniform and parabolic

velocity profiles) on the dynamic and thermal characteris-

tics of the flow in forced and mixed convections. Bhatta-

charjee and Loth [8] simulated laminar and transitional

cold wall jets. They investigated the significance of three

different inlet profiles: parabolic, uniform and ramp. They

presented the detailed results of time-averaged wall jet

thickness and temperature distribution with RANS

approach for higher Reynolds number and DNS approach

for three dimensional wall jets. Vynnycky et al. [9] have

presented an analytical solution of two-dimensional con-

jugate heat transfer problem of laminar boundary layer

over a flat plate for both high and low Prandtl numbers.

Schwarz and Caswell [10] have investigated the heat

transfer characteristics of a two-dimensional laminar

incompressible wall jet. They found exact solutions for

both constant wall temperature and constant heat flux

cases. Furthermore, a heat transfer expression is obtained

for variable starting length of the heated section if the

temperature of the wall is constant. Angirasa [11] has

studied laminar buoyant wall jet and reported the effect of

velocity and the width of the jet during convective heat

transfer from the vertical surface. A numerical investiga-

tion of two-dimensional transient buoyancy-assisted lami-

nar plane wall jet flow has been conducted by Raja et al.

[12]. The main purpose of this work is to study the transient

behavior of the flow and thermal field for Prandtl numbers

ranging from 0.01 to 15 and for different Grashof numbers

ranging from 104 to 107.

In the presence of an outer flow which moves at a

velocity in the same direction as the jet (coflow stream),

coherent structures of the jet flow can evolve in shear

layers formed between mixed layer (outer layer) and a

coflow stream. These structures play an important role in

the transport of mass, momentum and heat. Thus, several

researchers are interested in the study of jets discharged

into a coflow stream. A detailed numerical study on the

variation of dynamic and thermal characteristics of a

laminar wall jet in forced convection was made by Pan-

tokratoras [13] for three different cases (movable plate,

coflow stream or combination of a movable plate with a

coflow stream). In the literature, the most of works related

to the flow jet in co-flow stream were experimentally

performed on either plane, round or axisymmetric free jet.

Given the complexity of the problem due to the presence of

the wall, this type of flow has been less studied

numerically.

The effect of the coflow stream can be estimated by

calculating the momentum length scale (lc). The study of

Reichardt [14] shows that the influence of coflow becomes

more remarkable for (x/lc [ 1). Considering this relation-

ship, Antoine et al. [15] showed that the effect of coflow

stream starts from (lc = 40 mm).

A coflowing jet is found to have two asymptotic regions;

a strong jet region near the jet exit and a downstream weak

jet region where the magnitudes of the local velocities in

the jet become comparable to the ambient flow velocity

(Antonia and Bilger [16]; Davidson and Wang [17],

Nickels and Perry [18], Habli et al. [19]). Xia et al. [20]

conducted an experimental study on velocity and concen-

tration fields in submerged round jets in a stagnant envi-

ronment and in coflow. These authors noticed that the

dynamic zone length of established flow increases as the

Reynolds number decreases and becomes longer for lami-

nar jets. The concentration zone lengths are shorter than

those for the velocity by one to two jet exit diameter. Both

lengths are shortened further in the presence of a coflow.

The mostly studied moving ambient cases include the

coflow, cross-flow and counter-flow situations. While there

have been many studies aiming the measurement or

Heat Mass Transfer

123

prediction of jet behavior in those moving environments

and in stagnant ambient (Fischer et al. [21]; Wood et al.

[22]; Jirka [23]), most of them investigated the ‘‘far field’’

of the jet, or the zone of established flow (ZEF). In the

ZEF, self similarity behavior is observed on the spreading

of the jet as measured by various mean flow properties

including the growth of jet width, the decay of jet center-

line properties with axial distance, and the radial profiles of

velocity and concentration. Lam et al. [24] presented an

experimental study of a round jet in a stagnant fluid and in

a moving environment of the coflow, counter-flow or cross-

flow situation in the region near the jet exit. The aim of this

work is to determine: the evolution of the axis velocity in

the potential core and in the established flow areas, the

effect of the external flow on the jet fictitious origin and the

length of the potential core. While results show that the

decay constant is increased by a coflow but reduced by a

counter-flow or a cross-flow; the virtual origin was found to

be affected as well. Furthermore, increasing the external

velocity (for a coflow, counter-flow or cross-flow), causes a

slight decrease in the potential core length.

The main objective of this work is to study the effect of the

velocity ratio on the dynamic and thermal behavior of the wall

jet discharged into a coflowing air stream. A comparison with

a wall jet in a medium at rest was carried out. Further, we will

examine the influence of Grashof numbers on the wall jet

emerging in coflow and in a in a medium at rest.

2 Numerical modeling

We consider an incompressible laminar jet issuing from a

rectangular nozzle tangentially to an infinite flat plate

ejected in a coflow stream (Fig. 1). The flow is steady and

satisfies the Boussinesq approximation. Experience has

shown that the static pressure varies very slightly and is

considered constant in the jet. The problem is valid for a

two-dimensional boundary layer flow.

The following dimensionless variables are used:

X ¼ x

b; Y ¼ y

b; U ¼ u

u0

; V ¼ v

u0

and h ¼ T � T1Tp � T1

ð1Þ

Then, the dimensionless equations governing the flow

can be written as follows:

oU

oXþ oV

oY¼ 0 ð2Þ

UoU

oXþ V

oU

oY¼ 1

Re

o2U

o2Yþ Gr

Re2h ð3Þ

UohoXþ V

ohoY¼ 1

Re Pr

o2h

o2Yð4Þ

The boundary conditions for the wall jet written in

dimensionless form are:

For X ¼ 00\Y\1 : U ¼ 1; V ¼ 0; h ¼ 0

Y� 1 : U ¼ r; V ¼ 0; h ¼ 0

(

For X� 0Y ¼ 0 : U ¼ 0; V ¼ 0; h ¼ 1

Y!1 : U ¼ r; h ¼ 0

( ð5Þ

3 Numerical resolution method

Boundary layer equations, associated with the boundary

conditions were solved by a finite difference method using

an implicit scheme. A staggered grid superimposed on the

field of the flow is used. The continuity equation is dise-

cretized at node (i ? 1/2, j ? 1/2) whereas momentum and

energy equations are discretized at node (i ? 1/2, j). This

method, which was successfully used in former works [25–

27], was adopted for numerical stability reasons, compared

to methods using a non-staggered grid discretization. The

method used is associated with the elimination method

Gauss–Seidel. The convergence of the solution is consid-

ered reached when the relative change in the velocity at

two successive iterations is \10-4 for each node of the

field.

A non uniform grid is used in the axial direction of the

flow. Indeed, the calculation step is very small in the

vicinity of the nozzle. Then, it increases as one move away

in the jet in order to be able to go farther in the flow. In the

transverse direction, the calculation step is uniform.

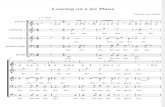

Fig. 1 Geometric configuration of the flow

Heat Mass Transfer

123

To study the effect of the mesh sensibility on the results,

we tested different calculation steps in the longitudinal and

in the transverse directions. Figure 2 shows the transverse

evolution of the vertical velocity normalized by the max-

imum velocity for different calculation steps for an iso-

thermal jet discharged into a flow at rest and for different

heights of the jet (X = 12, X = 16 and X = 20).

The examination of the Fig. 2a–c, shows that there is a

perfect agreement between the velocity profiles in the

boundary layer region between the wall and the reduced

iso-velocity UUm¼ 1

� �for the three test cases (mesh 1,

mesh 2 and mesh 3). However, the difference is more

pronounced between results obtained with meshes 2 and 3

and those obtained using mesh 3 in the outer boundary

layer region.

In the transverse direction, we tested also the sensitivity

of the mesh on the longitudinal evolution of the maximum

velocity for three steps. Figure 3 shows that taking

DY = 10-2 is sufficient obtain accurate results.

4 Results and discussion

4.1 Validation of numerical results

To test the validity of numerical data, we have compared

the numerical results with experimental ones cited in the

literature; i.e., the boundary conditions adopted in this

study correspond closely to those of Quintana et al. [3].

In Fig. 4a, b, we represent lateral profiles of the longi-

tudinal velocity normalized by the maximum longitudinal

velocity, the transversal coordinate is normalized by the

dynamic half-width for different stations of the jet

(X = 12, X = 16 and X = 20). These figures show the

experimental results suggested by Quintana et al. [3],

respectively, for the cases: heated wall (Fig. 4a) and cold

wall (Fig. 4b).

We noticed a good agreement between the numerical

results and the experimental data at different downstream

Fig. 2 Effect of the mesh on the transverse evolution of the vertical velocity normalized by the maximum velocity for DY = 10-2

Fig. 3 Effect of the mesh on the longitudinal evolution of the

maximum velocity for mesh 2 (DX = 10-2 for X B 10 and

DX = 10-1 for X [ 10)

Heat Mass Transfer

123

stations. Further, it is well known that when cooling is

applied, the velocity gradient in the inner region of the

boundary layer increases and the maximum velocity is

moved closer to the wall. Otherwise, reverse effect is

observed for a heated wall. However, in this study, the

difference between results for the three cases is negligible

because the temperature difference between the wall and

the exterior is relatively low for heated and cold walls and

flow tends to an isothermal flow.

4.2 Isothermal flow

For jets discharged into a coflow stream and further

downstream of the origin, the mean behavior of the jet is

self-similar, independent of initial conditions and depends

only on the initial excess momentum of the jet at the exit

Me. For a plane jet, it is defined as: Me = (u0 - uco)u0b.

The effect of the coflow velocity on the jet development

can be estimated by calculating the excess momentum

length scale lm; defined by: lm ¼ Me

u2co

[20].

Dimensional analysis indicates that near the jet exit, the

effect of coflow stream is small and the jet behaves like a

pure jet. Further, downstream the jet exit, the jet is gen-

erally influenced by the coflow stream as a weak flow

region. The transition between the pure jet and the weak

flow occurs when x/lm � 1.

Figure 5 shows the profiles of the excess velocity nor-

malized by the coflow velocity ratio against (x/lm) for

various coflow velocity ratios at (Re = 1,000). We noticed

that close to the nozzle exit, and more precisely when

(x/lm \ 1), the normalized excess velocity profiles remain

constant. Further, the potential core length increases with

the velocity ratio. Whereas, in the region of established

flow, the normalized excess velocity profiles coincide with

that of a simple jet (for r = 0) for various velocity ratios.

The profiles of the longitudinal excess velocity

(uex = u - uco) normalized by the maximum longitudinal

excess velocity (uexm = um - uco) against yy0:5

are plotted in

Fig. 6 to examine the effect of the velocity ratio on the

establishment of the similarity region. Figure 6a shows the

lateral evolution of uex

uexm

� �for a jet in a medium at rest

Fig. 4 Lateral evolution of the longitudinal velocity

Fig. 5 Longitudinal evolution of the normalized excess longitudinal

velocity for different coflow velocity ratios : Re = 1,000

Heat Mass Transfer

123

(r = 0). Results show that the normalized longitudinal

excess velocity profiles coincide for X C 70. For r = 0.08,

Fig. 6b shows that the self similarity is reached for

X C 100. However, for r = 0.2, Fig. 6c shows that the

normalized excess velocity profiles do not coincide even

at high values of X. This confirms the total absence of

self-similarity in the presence of significant coflow stream

[18]. Furthermore, in Table 1, we show that the increases

in the coflow velocity can slow the development of the jet

to a similarity state.

In Fig. 7, we examine the effect of coflow velocity ratio

on the position of the fictitious origin X1 modeling the

external zone of the boundary layer [7]. It have been seen

that, an increase in the coflow velocity ratio causes a slight

decrease in the fictitious origin (X1). Thus, we conclude

that the position of the fictitious origin of isothermal wall

jet becomes increasingly towards the upstream of the

nozzle when the coflow velocity stream increases [28].

The effect of the coflow velocity ratio on the longitu-

dinal distribution of the dynamic half-width is plotted in

Fig. 8 for Re = 1,000. y0.5 is found as the lateral location

Fig. 6 Lateral evolution of the normalized excess longitudinal velocity for different stations of the wall jet: Re = 1,000

Table 1 Coflow velocity ratios effect on the zone of established flow

for an isothermal wall jet: Re = 1,000

Coflow velocity ratio r = 0 r = 0.05 r = 0.2

Zone of established flow X & 70 X & 100 –

Fig. 7 Effect of coflow velocity ratio on the virtual origin:

Re = 1,000

Fig. 8 Longitudinal evolution of the dynamic half-width for different

coflow velocity ratios: Re = 1,000

Heat Mass Transfer

123

where uum¼ 1

2. The width of the jet is 2y0.5. Near the jet exit,

half-width profiles remain constant and similar for various

coflow velocity ratios. This means that the secondary flow

velocity variation has no effect on the dynamic half-width

in the potential core area. Downstream of the jet exit, a

difference between results appears. This difference

becomes significant in the ZEF. Further, an increase in the

coflow velocity ratio leads to an increase in the dynamic

half-width.

In Fig. 9, we examine the longitudinal distribution of the

normalized wall shear stress in the form ofspm2

qJ2

� �for dif-

ferent coflow velocity ratios. The analysis of this figure

shows that the normalized wall shear stress remains constant

in the potential core region, then decreases with height x.

We also notice that the profiles of the shear stress coincide

with that of a simple wall jet, for various coflow velocities

up to large distances xJm2

� �where the coflow stream effect

occurs. Far away from the jet exit, results show that the

effect of velocity ratio is negligible for (r \ 0.1) and the jet

behaves like a simple wall jet (wall jet flow at rest).

Otherwise, for (r C 0.1), the introduction of such pertur-

bation leads to a remarkable increase in the wall shear stress.

4.3 Non-isothermal flow

4.3.1 Buoyant wall jet in a flow at rest

In Fig. 10, we represent the axial evolution of the maximum

longitudinal velocity for different Grashof numbers at

Re = 1,500. For small values of X, the maximum velocity

remains unchanged and equal to the velocity at the nozzle

exit. Far away from the nozzle exit, for a wall jet in forced

convection (Gr = 0), the maximum longitudinal velocity

decreases as a function of X. Furthermore, under the effect of

buoyancy forces, when the Grashof number increases the

maximum velocity of the buoyant wall jet increases with X.

Indeed, in a buoyant wall jet, three regions exist. The first,

which occurs near the jet exit, is a pure jet similar to an

isothermal flow, where buoyancy effects are negligible

compared to the inertial forces. In this region, the maximum

velocity remains constant and approximately equal to its

value at the nozzle exit for different Grashof numbers. This

region is followed by the transition zone where the buoyancy

and inertia play equally important roles. In this region, the

maximum velocity may go above or below the value at the

output of the jet depending on the size of the buoyancy forces

and inertia. The third region, where the flow is away from the

source, which is a plume, inertia effects are negligible and

the buoyancy becomes the only important parameter. In this

region, the maximum velocity increases with the distance X.

Further, an increase in Grashof number leads to a shortening

of the length of the pure jet region, and therefore the maxi-

mum velocity reaches faster the region of established flow.

We present in Fig. 11, the evolution of the longitudinal

velocity normalized by the maximum longitudinal velocity

against yy0:5

at various stations of the jet for Gr = 100 and

Gr = 105.

For Gr = 100 (Fig. 11a), the longitudinal velocity pro-

files become similar from a distance X = 200. Otherwise,

for Gr = 105 the similarity starts farthest for X = 750

(Fig. 11b). The comparison of these results, in Table 2,

shows that the decrease in the Grashof number accelerates

the development of the jet to a similarity state.

Fig. 9 Longitudinal evolution of the normalized wall shear stress for

different coflow velocity ratios: Re = 1,000

Fig. 10 Longitudinal evolution of the maximum longitudinal veloc-

ity for different Grashof numbers : Re = 1,500 and r = 0

Heat Mass Transfer

123

The longitudinal distribution of the dynamic half-width

is plotted in Fig. 12 for different Grashof numbers at

Re = 1,500. Close to the nozzle exit, the inertial forces are

dominant to buoyancy forces so that the heating of the wall

does not affect the dynamic half-width. Indeed, the

dynamic half-width profiles remain constant and behave as

a jet in a forced convection. However, away from the jet

exit in the transition zone, the influence of the heated wall

starts to be noticed and dynamic half-width profiles are

different for various Grashof numbers depending on

buoyancy and inertia forces. For high value of X, in the

plume region, the dynamic half-width increases with the

height as a result of buoyant forces.

Figure 13 shows the evolution of the longitudinal wall

shear stress (sp) for different Grashof numbers at

Re = 1,500. Profiles of the shear stress are similar in the jet

region for different Grashof numbers. In the intermediate

region, a reduction in this parameter has been observed. Far

downstream the jet exit, the wall shear stress increases with

height X. Further, the increase of the Grashof number

causes an increase in the wall shear stress related in the

increase of the velocity gradient oUoY

which is more impor-

tant for a heated wall jet. However, the wall shear stress for

a flow in forced convection (Gr = 0), decreases even at

higher distances of the jet. This is expected, since only the

inertial forces govern the flow in forced convection.

The influence of the wall heating on the longitudinal

distribution of the friction coefficient Cf ¼ 2sp

qu2m

� �is plotted

in Fig. 14 for Re = 1,500 and for different Grashof num-

bers. Examination of this figure shows that near the nozzle

exit (in the pure jet region) and far from the nozzle exit (in

the plume region) Grashof number does not affect the

friction coefficient and profiles are similar. Between these

Fig. 11 Lateral evolution of the vertical velocity for different stations of the jet: Re = 1,500 and r = 0

Table 2 Zone of established flow for different Grashof numbers for a

wall jet at rest: Re = 1,500

Gr Gr = 0 Gr = 100 Gr = 105

Zone of established flow X & 70 X & 200 X & 750

Fig. 12 Longitudinal evolution of the dynamic half-width for

different Grashof numbers: Re = 1,500 and r = 0

Heat Mass Transfer

123

two regions (in the transition zone) where buoyancy forces

are of the same order of inertial forces, an increase in the

Grashof number leads to an increase in the friction coef-

ficient in this region.

To analyze the effect of heating on the heat transfer, we

have plotted, in Fig. 15, the longitudinal distribution of the

local Nusselt number Nu ¼ hxk

� �for different Grashof

numbers at Re = 1,500. It was found that the local Nusselt

number increases with height for different Grashof num-

bers in all sections of the jet. However, the local Nusselt

number profiles are similar in the vicinity of the ejection

nozzle. Beyond this region, Profiles are different and an

increase in the Grashof number causes an increase in heat

transfer. However, the influence of the heating wall on the

heat transfer begins at distances varying according to the

importance of buoyancy and inertia forces. In fact, for large

Grashof number the effect of buoyancy forces, which

become predominant over inertia forces, appear for low

values of X.

4.3.2 Influence of the coflow velocity ratio on the buoyant

wall jet

The longitudinal distributions of the velocity in the absence

and presence of a coflow stream by maintaining the

Grashof number equal to Gr = 100 are given in Fig. 16a.

This figure shows that the increase in the coflow velocity

does not change the flow in the vicinity of the jet exit and

profiles remain constant and similar to that of a simple wall

jet. As one moves away from this region, a difference

between the maximum velocity profiles begins to appear

and becomes more important in the plume region. Further,

an increase in the coflow velocity causes an increase in the

maximum longitudinal velocity. It is also noticed that the

increase in the coflow velocity ratio for (r \ 0.1) influences

slightly the flow. Otherwise, for (r C 0.1), an increase of

the coflow velocity ratio strongly influences the flow.

The effect of coflow velocity ratio on the maximum

longitudinal velocity for Gr = 105, is also shown in

Fig. 16b. It is clearly observed that profiles are similar to

that of a simple wall jet in the vicinity of the nozzle exit.

Going far downstream, the maximum longitudinal velocity

increases with X. We also noticed that the maximum lon-

gitudinal velocity profiles are perfectly similar for different

coflow velocity ratios. This means that coflow velocity has

no effect on the flow for high grashof numbers.

Fig. 13 Longitudinal evolution of the wall shear stress for different

Grashof numbers: Re = 1,500 and r = 0

Fig. 14 Longitudinal evolution of the friction coefficient for different

Grashof numbers: Re = 1,500 and r = 0

Fig. 15 Longitudinal evolution of the local Nusselt number for

different Grashof numbers: Re = 1,500 and r = 0

Heat Mass Transfer

123

The effect of coflow velocity ratio on lateral evolution

of the longitudinal excess velocity (uex = u - uco) nor-

malized by the maximum longitudinal excess velocity

(uexm = um - uco) with height X is represented in Fig. 17

for Gr = 100 and Re = 1,500. The results, summarized in

Table 3, show that similarity is slower for higher coflow

velocity. However, for a stronger coflow velocity, the

absence of a complete similarity is observed [24].

The longitudinal distribution of the dynamic half-width

is shown, in Fig. 18a, for Gr = 100 and Re = 1,500. In the

vicinity of the nozzle exit, dynamic half-width profiles

coincide with that of a simple wall jet and coflow has no

influence on this parameter in this region. However, away

from this region, an increase in the velocity ratio leads to an

increase in this parameter. It is also noticed that for r \ 0.1,

the dynamic half-width is slightly influenced by the varia-

tion of the coflow velocity and this type of jet behaves as a

simple flow at rest. Though, for r C 0.1, the influence of the

coflow velocity becomes more pronounced.

The longitudinal evolution of the dynamic half-width for

Gr = 105 (flow in mixed convection) and Re = 1,500 is

given in Fig. 18b. Results show that profiles are similar in

the pure jet area and in the plume region. Between these

Fig. 16 Longitudinal evolution of the maximum longitudinal velocity for different coflow velocity ratios: Gr = 100 and Re = 1,500

Fig. 17 Lateral evolution of the normalized excess longitudinal velocity for different stations of the wall jet: Gr = 100 and Re = 1,500

Table 3 Coflow velocity ratios effect on the zone of established flow

for a buoyant wall jet: Gr = 100 and Re = 1,500

Coflow velocity ratio r = 0 r = 0.05 r = 0.2

Zone of established flow X & 200 X & 200 –

Heat Mass Transfer

123

two regions in (the intermediate zone), a difference

between results was observed.

The longitudinal evolution of the wall shear stress for

various coflow velocity ratios for Gr = 100 and

Re = 1,500 is discussed in (Fig. 19a). It is observed that

the increase in the coflow velocity causes a slight increase

in shear stress only for higher locations of the jet. However,

for a wall jet in mixed convection (Fig. 19b), the increase

in the coflow velocity has no effect on sp in all stations of

the jet.

To analyze the effect of the coflow velocity on the heat

transfer between the jet and the heated wall, we present in

Fig. 20a, the longitudinal evolution of the local Nusselt

number for Gr = 100 and Re = 1,500. From this figure,

we noticed an increase in the heat transfer in all sections of

the jet. Further, near the jet exit, the local Nusselt number

profiles are similar to that of a wall jet at rest and coflow

has no influence in this region. Away from this region, a

difference between profiles is observed. Indeed, it is dis-

covered that the heat exchange is higher for a stronger

coflow and becomes more important from r C 0.1. Other-

wise, for a Grashof number equal to Gr = 105 (Fig. 20b),

local Nusselt number profiles are not influenced by the

coflow and results are similar.

Fig. 18 Longitudinal evolution of the dynamic half-width for different coflow velocity ratios: Re = 1,500

Fig. 19 Longitudinal evolution of the wall shear stress for different coflow velocity ratios: Re = 1,500

Heat Mass Transfer

123

5 Conclusion

This work investigates a numerical study of an isothermal

or non-isothermal laminar wall jet evolving in a coflow

stream. The discussion focuses on the effect of the coflow

velocity on the dynamic and thermal characteristics of the

jet flow in comparison with a wall jet in a medium at rest.

The main results established in this study are as follows:

For a non-isothermal flow, two parameters can influence

the flow: the inertial and buoyancy forces. Indeed, in non-

isothermal wall jet, three regions exist. The first, which

occurs near the jet exit, is called a jet region where buoy-

ancy effects are negligible compared to the inertial forces

since the results are similar for different Grashof numbers.

This region is followed by a transition region where the

buoyancy and inertia forces play equally important roles.

For the third region, where the flow is away from the source,

the inertial forces effects are negligible and the buoyancy

becomes the only important parameter.

Concerning the effect of the coflow velocity ratio on the

wall jet, it has been seen for an isothermal flow that the

potential core length increases with the velocity ratio. It

was also showed, downstream from the jet exit, that lon-

gitudinal distributions of normalized forms of the maxi-

mum longitudinal excess velocity against a length scale

depending on the initial excess momentum of the jet at the

exit reach a single decay for various coflow ratios.

The effect of the coflow velocity is also discussed

considering a buoyant wall jet. We have shown that results

for low Grashof numbers (forced convection) are similar to

the isothermal flow. For mixed convection, we noticed the

absence of the influence of the coflow velocity on most

parameters.

References

1. Nizou PY, Tida T (1995) Transferts de chaleur et de quantite de

mouvement dans les jets parietaux plans turbulents. Int J Heat

Mass Transf 38(7):1187–1200

2. Nizou PY (1984) Analogie entre transferts de chaleur et de

quantite de mouvement dans un jet parietal plan turbulent. Int J

Heat Mass Transf 27(10):1737–1748

3. Quintana DL, Amitay M, Ortega A, Wygnanski IJ (1997) Heat

Transfer in the Forced laminar wall jet. Int J Heat Transf

119:451–459

4. Abdulnour RS, Willenborg K, McGrath JJ, Foss JF, AbdulNour

BS (2000) Measurements of the convection heat transfer coeffi-

cient for a planar wall jet: uniform temperature and uniform heat

flux boundary. Exp Therm Fluid Sci 22:123–131

5. Yu WS, Lin HT, Shin HS (1992) Rigorous numerical solutions

and correlations for two-dimensional laminar buoyant jets. Int J

Heat Mass Transf 35(5):1131–1141

6. Mhiri H, El Golli S, Le Palec G, Bournot Ph (1998) Influence des

conditions d’emission sur un ecoulement de type jet plan laminaire

isotherme ou chauffe. Revue Generale de Thermique 37:898–910

7. Mokni A, Kechiche J, Mhiri H, Le Palec G, Bournot P (2009)

Inlet conditions effects on vertical wall jets in forced and mixed

convection regimes. Int J Therm Sci 48:1884–1893

8. Bhattacharjee P, Loth E (2004) Simulations of laminar and

transitional cold wall jets. Int J Heat Fluid Flow 25:32–43

9. Vynnycky M, Kimura S, Kanev K, Pop I (1998) Forced con-

vection heat transfer from a flat plate: the conjugate problem. Int

J Heat Mass Transf 41:45–59

10. Schwarz W, Caswell B (1961) Some heat transfer characteristics

of the two-dimensional laminar incompressible wall jet. Chem

Eng Sci 16:338–351

11. Angirasa D (1999) Interaction of low-velocity plane jets with

buoyant convection adjacent to heated vertical surfaces. Numer

Heat Transf Part A 35:67–84

12. Raja KK, Das KM, Rajesh Kanna P (2007) Transient study of

buoyancy-assisted mixed convection in laminar plane wall jet

flow. Int. Commun Heat Mass Transf 34:809–819

13. Pantokratoras A (2011) The non similar laminar wall jet along a

moving wall, in a free stream and in a free stream/moving wall.

Appl Math Modelling 35:471–481

Fig. 20 Longitudinal evolution of the local Nusselt number for different coflow velocity ratios: Re = 1,500

Heat Mass Transfer

123

14. Reichardt H (1964) Turbulence Strahlausbreitung in gleichge-

richteter Grundstromung. Forsch Ingenieurwes 30:133–164

15. Antoine Y, Lemoine F, Lebouche M (2001) Turbulent transport

of a passive scalar in a round jet discharging into a coflowing

stream. Eur J Mech B Fluids 20:275–301

16. Antonia RA, Bilger RW (1973) An experimental investigation of

an axisymmetric jet in a coflowing air stream. J Fluid Mech

61:805–822

17. Davidson MJ, Wang HJ (2002) Strongly advected jet in a coflow.

J Hydraul Eng 128(8):742–752

18. Nickels TB, Perry AE (1996) An experimental and theoreti-

cal study of the turbulent coflowing jet. J Fluid Mech

309:157–182

19. Habli S, Mahjoub Saıd N, Le Palec G, Bournot P (2008) Influ-

ence of a coflowing ambient stream on a turbulent axisymmetric

buoyant jet. J Heat Transf 130(2):22201–22400

20. Xia LP, Lam KM (2009) Velocity and concentration measure-

ments in initial region of submerged round jets in stagnant

environment and in co flow. J Hydro-Environ Res 3:21–34

21. Fischer HB, List EJ, Koh RCY, Imberger J, Brooks NH

(1979) Mixing in Inland and coastal waters. Academic Press,

New York

22. Wood IR, Bell BG, Wilkinson DL (1993) Ocean disposal of

wastewater. Int Adv Ser Ocean Eng 8. World Scientific,

RiverEdge

23. Jirka GH (2004) Integral model for turbulent buoyant jets in

unbounded stratified flows, Part 1: the single round jet. Environ

Fluid Mech 4(1):1–56

24. Or CM, Lam KM, Liu P (2011) Potential core lengths of round

jets in stagnant and moving environments. J Hydro-Environ Res

5:81–91

25. Mhiri H, Habli S, El Golli S, Le Palec G, Bournot Ph (1999)

Etude numerique des conditions d’emission sur un ecoulement de

type jet plan turbulent isotherme ou chauffe. Int J Therm Sci

38:904–915

26. Habli S, Mhiri H, Golli S, Le Palec G, Bournot Ph (2001) Etude

numerique des conditions d’emission sur un ecoulement de type

jet axisymetrique turbulent. Int J Therm Sci 40:497–511

27. Kechiche J (2006) Application des modeles de turbulence a bas

nombre de Reynolds pour l’etude des jets parietaux turbulents.

Ph. D. Thesis, Universite de la Mediterranee, France, Universite

de Monastir, Tunisie

28. Pope SB (1978) An explanation of the round jet/plane jet

anomaly. AIAA J 16:279–281

Heat Mass Transfer

123