EEWeb Pulse - Volume 109

-

Upload

eeweb-magazines -

Category

Documents

-

view

227 -

download

3

description

Transcript of EEWeb Pulse - Volume 109

Steve Grodt Marketing Manager at Chroma Systems

Solutions

Electrical Engineering Community

Test Equipment that

Tests Limits

concepts to reality Bringing your

is as easy as...

Copyright ©2013 Aspen Labs LLC.

Visit: digikey.com/schemeit • partsim.com • pcbweb.com

1.

Create schematics, technical diagrams, and flowcharts using your browser.

• 600+ Symbol Library• Share Schematics Online• Export High Quality Images

digikey.com/schemeit

2.

Free and easy-to-use circuit simulator that runs in your browser.

• SPICE Simulator• AC/DC/Transient Sims• Waveform Viewer

partsim.com

3.

Full featured online CAD application for designing and manufacturing electronics hardware.

• Schematic Capture• PCB Layout• BOM Integration

pcbweb.com

Alex ToombsElectrical Engineer

ntel was formed in 1968 by many influential and pioneering individuals in the semiconductor industry at the time, including Robert Noyce and Gordon Moore. Since then, the company has enjoyed exponential increases in productivity as

processes improved and die sizes shrank, following a 1965 prediction that Gordon Moore made—a prediction now known as Moore’s law. Moore predicted that the number of transistors on an integrated circuit would double roughly every eighteen to twenty-four months—something to which the industry as a whole has well adhered. The capabilities of other digital devices have even been closely linked with Moore’s law, such as the exponential growth in the size of hard drives—at least in the cost per megabyte/gigabyte.

I

3Visit: eeweb.com

CONTENTS

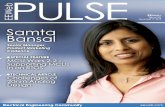

4Steve GrodtMARKETING MANAGER AT CHROMA

How Chroma’s power testing products are pushing the limits of programmable power.

1016NASA’s SpaceShop:

Expressway for IdeasNASA’s new SpaceShop allows their engineers

to prototype their most ambitious ideas.

18The End of Moore’s Law?A look at whether or not Moore’s Law can be

sustained in the years to come.

24VHDL101 - Part 5:Tick Tock, Processing Clocks

How to interface clock signals, the beating heart of modern digital electronics.

24

184

PULSE

Featured ProductsThis week’s latest products from EEWeb.

RTZReturn to Zero Comic 28

4 Visit: eeweb.com

PULSE

Systems Solutions is a leading provider of power electronics testing instruments. Their reliable products have become the go-to choice for a wide array of

industries-from aerospace, to solar, to medical. The success in these industries has allowed the company to place more emphasis on innovation to ensure its leading status. We spoke with Steve Grodt, the Marketing Manager at Chroma, about the company’s new line of test equipment, some new emerging markets, and the company’s recent involvement with an independent film.

Chroma

SteveMarketing Manager

Grodt

5Visit: eeweb.com

INTERVIEW

Systems Solutions is a leading provider of power electronics testing instruments. Their reliable products have become the go-to choice for a wide array of

industries-from aerospace, to solar, to medical. The success in these industries has allowed the company to place more emphasis on innovation to ensure its leading status. We spoke with Steve Grodt, the Marketing Manager at Chroma, about the company’s new line of test equipment, some new emerging markets, and the company’s recent involvement with an independent film.

Chroma

SteveMarketing Manager

Grodt

6 Visit: eeweb.com

PULSE

What types of programmable power products does Chroma provide?

Chroma is a global provider of a wide variety of turnkey test solutions from video pattern generators to laser diode testers to manufacturing execution systems. Chroma Systems Solutions provides test instrumentation and systems for power electronics, electrical safety, passive component and thermoelectric test and control. Products include programmable AC Power Sources and DC Power Supplies, AC and DC Electronic Loads, Digital Power Meters, MultiMeters, Hipot Testers, LCR Meters, TEC Controllers and Thermal Data Loggers.

At our facility in Foothill Ranch California, we design and build custom automated test systems for power conversion test and characterization with architecture and platforms built to fit diverse R&D and design verification specifications. Applications include testing of chargers, DC-DC converters, power supplies, batteries, fuel cells, solar inverters and arrays, LED drivers and point-of-load voltage regulators.

Our instruments can be controlled either by the front panel or remotely via GPIB, USB, CAN bus, RS-232, or Ethernet. Our DC Sources have an LXI option as well.

Could you talk a little about the new Sync Hipot Tester?

Hipot testing is a primary part of electrical safety testing. Most if not all electrical components or products with human safety concerns are bound to standards including transformers, capacitors, power supplies, chargers, home

63600 Series Modular DC Electronic Load

Guardian 19020 Multi-Channel Hipot Tester

7Visit: eeweb.com

INTERVIEWappliances, and medical devices especially. Hipot testing can be a bottleneck to production if performed one DUT at a time.

To answer this, the Guardian 19020 multi-channel hipot tester was created with a brand new architecture. It can measure the hipot leakage current of all channels at the same time and conduct tests on up to 100 DUTs simultaneously. It begins with the world’s first sync hipot test function. A single unit can perform 10 channels sync output and measurements simultaneously. Up to 10 units in master / slave mode can control 100 channels in total.

This enables facilities to save space and money on the production line since there is no need for multiple testers. The one time test increases efficiency and improves productivity. The tester also includes Flashover detection and Open/Short Check and holds several international patents. It’s proving to be a great solution for our customers.

What are Chroma’s target markets?

Back in 2001, Chroma introduced its products into North America by targeting UPS, ATX, and other AC power supply manufacturers and remains a substantial market for us. Over time, our product line grew considerably opening several markets to us and we’ve made great strides developing solutions for new emerging markets where test instrumentation specific to an application are needed. Battery, medical device, solar, EV and EVSE equipment, LED inverter; these are all markets we are focusing on and have developed new products for. Last year we launched a family of DC power sources with built-in solar array simulation and this year we introduced several new battery testers – you get the idea.

What are some of the trends in these new emerging markets? How is Chroma adapting to these trends?

LED is a great example here. The market is growing and finding its efficiencies. With that, we developed the industry’s first LED simulator for LED driver testing. This electronic load is specifically designed for simulating the unique load conditions of an LED & LED Array. Not only can it test in stable conditions, it can also test turn on, PWM dimming characteristics of the LED driver and the Rd value can be adjusted

according to the LED V-I curve. A pretty efficient tester. We also developed a comprehensive 47 page LED Driver Test Guide to assist manufacturers with LED driver development and quality.

Do Chroma’s sense line products come with remote sense functionality?

Absolutely. All Chroma power instruments come equipped with remote sense line capabilities. These provide accurate, reliable, and repetitive settings and read back measurements. All cables are included in the box as well.

What kind of support does Chroma provide its customers?

We focus on providing customers complete support starting with the first quote through the life of the products we deliver. We understand customer service is an important part of business and our employees put in the effort to make sure the service provided exceeds expectations.

Chroma is a company with service and support facilities worldwide. This provides piece of mind for customers who may relocate our products to a different part of the world than where it was originally purchased. On a local level, our customers have access to warranty repair, service, and calibration as well as highly trained engineers that support the operation and applications of our products. For example, in the U.S., Chroma Systems Solutions has facilities in the West Coast and East Coast to serve and support our customers.

“We understand customer service is an important part of business and our employees

put in the effort to make sure the service provided

exceeds expectations.”

8 Visit: eeweb.com

PULSE

We also offer an Extended Warranty Support Package on our automated systems that provides an increased level of support and customer care beyond the standard factory warranty period. With package, customers can take advantage of extended factory warrantees, priority call and RMA handling and free annual on-site calibrations.

In what ways does Chroma approach innovation?

We do this by investing more into research and development than any other manufacturer in the industry. Chroma employs over 450 R&D engineers which is about 37% of the entire workforce. In 2012, Chroma invested 15% of its revenue back into R&D. We put our money where our mouth is when it comes to finding innovative solutions and place high expectations on our future results.

How does Chroma differentiate itself fromits competitors?

In addition to our investment in R&D, we offer a product line that is designed for both bench top and automated test solutions. This allows complete flexibility for the user and makes our instruments a more valuable asset in the lab or production floor. We design and build our own automated test systems controlled with an open software architecture suited for a wide range of applications and devices. We are constantly working on innovative solutions for our customers.

Chroma Systems Solutions was recently involved in an independent film. What was the company’s contribution and how did this opportunity come about?

The historical preservation of the men and women who gave their lives during wartime as well as recognizing the efforts of technological development during those times is a passion to a lot of us here. The short film, Dog it Down, is based on the true story of 3 US Naval Sailors trapped in an airtight compartment aboard the USS West Virginia during the bombing of Pearl Harbor. The project was brought to my attention by an old friend from my days working in the film industry. Later, I met with the writers and director, thought it was a meaningful tribute, and made the decision to help. The short film was entered into several film festivals and did very well including winning “Best Short Film” at the Hollywood Reel Independent Film festival.

We also helped out the Mighty Eighth Air Force Museum’s “City of Savannah” B-17 Restoration Project by contributing our modular DC power supplies to give the aircraft its DC power. The museum plans to restore the B-17 to its full combat configuration, including operational systems and components, with the goal of making it the finest static display B-17 in the world. It’s an impressive project that had some special power requirements. Our 62000B DC Power Supplies were the perfect power source for a continuous power application like this. If you’re ever in Savannah, you have to see it.

“ We design and build our own automated test systems controlled with an open software architecture suited for a wide range of applications and devices.”

www.partsim.com

Online CircuitSimulator

PartSim includes a full SPICE simulation engine, web-based schematic capture tool, and a graphical waveform viewer.

Some Features include:• Simulate in a standard Web Browser

• AC/DC and Transient Simulations

• Schematic Editor• Schematic Editor

• WaveForm Viewer

• Easily Share Simulations

Try-it Now!

10 Visit: eeweb.com

10-Bit Bidirectional TranslatorThe Gunning Transceiver Logic – Transceiver Voltage Clamps (GTL-TVC) provide high-speed voltage translation with low ON-state resistance and minimal propagation de-lay. The GTL2010 provides 10 NMOS pass transistors (Sn and Dn) with a common gate (GREF) and a reference transistor (SREF and DREF). The device allows bidirectional voltage translations between 1.0 V and 5.0 V without use of a direction pin. When the Sn or Dn port is LOW, the clamp is in the ON-state and a low resistance connection exists between the Sn and Dn ports...Read More

Power-Efficient LED Driver ICThe new R2A50106FT device is a driver IC that powers the white LEDs used in back-light systems. The driver IC makes use of voltage step-up circuit technology, refined over many years for the company’s power supply IC products, in an exclusive DC-DC converter control circuit that is incorporated into the driver IC and provides backlight systems with improved power efficiency. Eight constant-current driver channels ca-pable of driving high-luminosity LEDs are integrated in a single device, reducing the need for external components and making it easier to design a high-luminosity LED backlight system...Read More

Automotive Gate Driver OptocouplerAvago’s 2.5 Amp R2Coupler,Automotive Gate Drive Optocoupler, with Integrated Desaturation (VCE) Detection and Fault Status Feedback makes automotive IGBT VCE fault protection compact, affordable, and easy-to-implement while satisfying automotive AEC-Q100 Grade 1 semiconductor requirement. Avago R2Coupler, Au-tomotive Gate Drive Optocoupler, isolation products provide the reinforced insula-tion and reliability needed for critical in automotive and high temperature industrial applications...Read More

PULSE

ULQT Step-Down ControllerThe TPS51285A and TPS51285B are cost-effective, dual synchronous buck controllers with 5-V and 3.3-V LDOs, targeted for notebook system-power supply solutions. The device achieves low power consumption by the use of auto-skip and ULQ™ modes, which is beneficial for long battery life in system stand-by mode. The 256-kHz VCLK output is provided to drive an external charge pump, generating gate drive voltage for the load switches with minimum power consumption in the main converter. The TPS51285A and TPS51285B are available in a 20-pin 3 × 3 (mm) QFN package and is specified from –40°C to 85°C...Read More

Automotive TFT-LCD Power SupplyThe MAX16928 is a highly integrated power supply for automotive TFT-LCD applica-tions. The device integrates one boost converter, one 1.8V/3.3V regulator control-ler, and two gate voltage regulators. The device comes in several versions to satisfy common automotive TFT-LCD power-supply requirement. The boost converter uses spread-spectrum modulation to reduce peak interference and to optimize EMI per-formance...Read More

11Visit: eeweb.com

FEATURED PRODUCTS

90nm SoC Graphics ControllerThe Fujitsu MB86R02 “Jade-D” is a highly integrated device for embedded automo-tive graphics applications. Incorporating an ARM926EJ-S CPU core, an enhanced version of the successful MB86296 “Coral PA” graphics processor and a number of external interfaces, this 90nm device is highly optimized for applications that require superior CPU performance and sophisticated 2D/3D graphics features in a compact SoC. Target applications include on-board and mobile navigation systems, graphi-cal dashboard systems/clusters, HUD units, rear-seat entertainment systems, point-of-sales terminals and industrial control panels...Read More

Low Inductance Laser Diode DriverThe HPL-2400 is a water-cooled, very low inductive high power load, capable of dis-sipating up to 2400 Watts. Fault detection is possible using a six pin connector, with normally open and normally closed feedback. The use of this fault feedback is rec-ommended but not required. Using the load is simple utilizing either the d-sub con-nector or ring terminals. The d-sub connector allows the load to be used in pulsed applications with less than 100 nanosecond rise and fall times...Read More

Extended Power Range SwitcherTOPSwitch-HX incorporates a 700 V power MOSFET, high voltage switched current source, PWM control, oscillator, thermal shutdown circuit, fault protection and other control circuitry onto a mono-lithic device. TOPSwitch-HX is an integrated switched mode power supply chip that converts a current at the control input to a duty cycle at the open drain output of a high voltage power MOSFET.

Product Highlights

• Multi-mode operation maximizes efficiency at all loads.• New eSIP-7C and eSIP-7F packages build on PI’s experience with

high power and high reliability packages.• No heatsink required up to 35 W (up to 48 W at 230 VAC) using P,

G or M packages.

Read More

Multiphase PWM RegulatorThe ISL6277A is a fully compliant multiphase PWM regulator with AMD Fusion SVI 2.0 that provides complete solution for microprocessor and graphics processor core power. The ISL6277A controller supports two Voltage Regulators (VRs) with three integrated gate drivers and two optional external drivers for maximum flexibility. The Core VR can be configured for 3-, 2-, or 1-phase operation while the Northbridge VR supports 2- or 1-phase configurations. The two VRs share a serial control bus to com-municate with the AMD CPU and achieve lower cost and smaller board area com-pared with two-chip solutions...Read More

12 Visit: eeweb.com

Quad-Frequency Programmable XOThe IDT 8N3Q001 is a Quad-Frequency Programmable Clock Oscillator with very flexible frequency programming capabilities. The device uses IDT’s fourth generation FemtoClock NG technology for an optimum of high clock frequency and low phase noise performance. The device accepts 2.5V or 3.3V supply and is packaged in a small, lead-free (RoHS 6) 10-lead Ceramic 5mm x 7mm x 1.55mm package. The extended temperature range supports wireless infrastructure, telecommunication and networking end equipment requirements...Read More

Low-Power Bluetooth Radio ModuleThe RN41XV and RN42XV are small form factor, lowpower Bluetooth radio modules offering plug-in compatibility for the widely used 2 × 10 (2-mm) socket typically used by 802.15.4 radio modules. Based on the popular 2 × 10 (2-mm) socket footprint often found in embedded applications, the Roving Networks’ RN41XV and RN42XV modules provide Bluetooth connectivity in legacy and existing designs that may have been based upon the 802.15.4 standard. The RN41XV Class 1 Bluetooth module is based on the RN41, and the RN42XV Class 2 Bluetooth module is based on the RN42...Read More

PULSE

Lowest Power PCIe Clock GeneratorsMouser Electronics, Inc. is now stocking the lowest power PCI Express (PCIe) clock generators in the industry. Silicon Labs’ new ultra-low-power Si52111 and Si52112 PCIe clocks help designers address green design needs while also offering the smallest footprint on the market for space-constrained ap-plications. These new Silicon Labs PCIe clock generators do not require the use of termination resistors, allowing designers to reduce the complexity of board design and save board space...Read More

EEPROM-Configurable Pressure SensorThe MLX91802 is a system in package solution for tire pressure monitoring sys-tem (TPMS) implementations that combines an analog pressure sensor and a low power sensor interface with an MLX16 16-bit RISC-based microcontroller. It is housed in a compact, pressure ported, plastic SO16 package and has an operational temperature range of -40 °C to 125 °C. The Uni-ROM concept makes available Melexis’ ready-to-use firmware: any TPMS incorporated this device can be fully developed without the need for custom software engi-neering...Read More

FEATURED PRODUCTS

White Body LED ProtectorsLittelfuse, Inc. has introduced an addition to the company’s PLED Open LED protec-tion devices line. The PLEDxSW Series LED Protector, unlike earlier PLED devices from Littelfuse that had black molded bodies, is molded from a white material, which makes it less noticeable in LED fixtures, particularly for indoor applications. It also reflects more light to improve overall light engine efficiency. This device provides an electronic shunt path when an LED in an LED string fails as an open circuit. PLED devices are connected in parallel with each LED in a series string...Read More

Smallest Infrared Sensor ElementIR1011 is the world smallest mid-infrared quantum photo diode, made of InSb. Considering dimensions as small as 2.65mm×1.9mm×0.4mm, the device is a surface mount type sensor that can be operated at room temperature. AKM’s IR1011 Infra-red Sensor does not require any bias current to establish proper operating condi-tion. The device is highly sensitive and has very fast response. IR1011 is applicable to human body detection, non-contacting temperature measurement, and NDIR gas sensor...Read More

Resistive Touch Panel Controller ICsAlthough capacitive touch panels capable of multi-point de-tection are increasing in popularity, there is still much demand for lower cost resistive touch technology in digital cameras, car navigation systems, and other applications. The resistive touch method typically provides 1-point detection opera-tion using a stylus/pen or for simple button selection. How-ever, ROHM has successfully developed and mass-produced 2-point detection controller ICs that are market-proven and have been widely adopted in automotive applications such as displays for audio and car navigation systems...Read More

Automotive-Grade LED Driver ICAllegro MicroSystems, Inc. adds a new DC-DC converter controller to their existing line of automotive LED lighting drivers. This new LED driver IC provides a program-mable constant current output for driving high power LEDs in series. Allegro’s A6268 is targeted at both the automotive and industrial markets with end applications to include LED Headlights, Daytime Running Lights (DRL), Fog Lights and other high power LED applications. The A6268 operates from a wide input voltage range, mak-ing it ideal for start/stop designs as well as handling double-battery and load-dump conditions...Read More

eeweb.com/register

Portability & Power All In One...Debug digital designs on an iPad, iPhone, iPod.

Can a logic analyzer be sexy? Watch the video and weigh in...

Logiscope transforms an iPhone, iPad or iPod into a 100MHz, 16 channel logic analyzer.

Not only is it the most intuitive logic analyzer available, the triggering is so powerful you’ll be able to count the hair on your bug.

See why our innovation keeps getting recognized.

16 Visit: eeweb.com

PULSE

17Visit: eeweb.com

FEATURED ARTICLE

All over the country, “TechShops” and “Makerspaces” have been popping up. These are places where anyone

interested can pay a monthly fee and have access to sophisticated tools, such as lathes, laser-etching machines, and 3D printers. The success and popularity of these spaces has been fueled by the burgeoning “maker” movement, and were an inspiration for a similar space set up by NASA’s AMES Laboratory. Jumping on the maker trend, Ames opened SpaceShop, a lab modeled after other TechShops and designed to allow NASA engineers and designers (and even interns) to work through their designs and prototype their wildest ideas.

According to Chad Frost, Chief of the Mission Design Division at NASA, the SpaceShop has, “big, traditional machine shops and manufacturing capabilities with experts who have decades of experience making stuff.” However, the role of SpaceShop is to provide a very fast and easy way for designers and engineers to prototype their ideas, and to discover (sometimes within an hour) whether an idea is worth pursuing.

Additive engineering, also known as 3D printing, has been a key technological innovation behind the success of TechShops and SpaceShop itself. It is a technology that allows actual prototypes to be built quickly and to size, and NASA hopes that soon entire complex systems, such as satellites, will be able to be printed with additive manufacturing.

In fact, NASA is exploring using 3D-printing for everything from feeding astronauts in space, to building space stations entirely using additive manufacturing. Right now, spacecraft with 3D-printed parts have already been launched, but in the near future, NASA hopes to not only print the structure of such systems, but to print the electronics of the systems as well.

NASA seems confident that technologies like additive engineering and new spaces like SpaceShop will significantly speed up innovation. According to Chad Frost, SpaceShop lowers the barriers of entry into the design process at AMES, and so, could be “potentially transformative” to the space program.

This article is part of the Littelfuse Speed2Design Program. This year, events will be hosted at NASA Ames Research Center, CA and Johnson Space Center, TX. To learn more about innovations at NASA and how you can win a trip to one of this year’s Speed2Design events at NASA, please visit www.speed2design.com.

The role of SpaceShop is to provide a very fast and easy way for designers and engineers to prototype their ideas, and to discover whether an idea is worth pursuing.

Figure 1: The ORDbot Quantum 3D-Printer. Image Courtesy of the Buildlog.net.

18 Visit: eeweb.com

PULSE

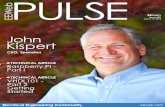

Alex ToombsElectrical Engineer

ntel was formed in 1968 by many influential and pioneering individuals in the semiconductor industry at the time, including Robert Noyce and Gordon Moore. Since then, the company has enjoyed exponential increases in productivity as

processes improved and die sizes shrank, following a 1965 prediction that Gordon Moore made—a prediction now known as Moore’s law. Moore predicted that the number of transistors on an integrated circuit would double roughly every eighteen to twenty-four months—something to which the industry as a whole has well adhered. The capabilities of other digital devices have even been closely linked with Moore’s law, such as the exponential growth in the size of hard drives—at least in the cost per megabyte/gigabyte.

I

19Visit: eeweb.com

TECH ARTICLE

Alex ToombsElectrical Engineer

ntel was formed in 1968 by many influential and pioneering individuals in the semiconductor industry at the time, including Robert Noyce and Gordon Moore. Since then, the company has enjoyed exponential increases in productivity as

processes improved and die sizes shrank, following a 1965 prediction that Gordon Moore made—a prediction now known as Moore’s law. Moore predicted that the number of transistors on an integrated circuit would double roughly every eighteen to twenty-four months—something to which the industry as a whole has well adhered. The capabilities of other digital devices have even been closely linked with Moore’s law, such as the exponential growth in the size of hard drives—at least in the cost per megabyte/gigabyte.

I

20 Visit: eeweb.com

PULSE

Changes in processing and materials with each generation have made it easier to shrink the size of individual devices while improving yield.

Something noteworthy in the consumer processor industry is that, compared to the past several decades, processing speed of chips has stayed roughly the same while the number of cores has increased. Performance has begun to stagnate, worrying some at Intel that the era of Moore’s Law is over. This article will talk a little about what Moore’s Law has been able to predict, what is holding conventional processors back from growing at the same rate, and what can be done to try and keep the home personal computer business growing at the same rate as before.

Moore’s Law and Intel’s Business

In 1968 Moore and Noyce, along with the rest of the founders of Intel, saw the potential of the fledgling integrated circuit field. For many years, Intel was able to market the next generation of devices as being substantially faster than its predecessors, and there was a demand for faster computers that they could fill. Offices, manufacturing plants, universities, and even home users benefited from the increased processor performance, while Intel made a huge amount of money for several decades. More transistors per die meant that more operations could be performed, enabling computers to take over more complex calculations, and making organizations ever more dependent upon the technologies Intel offered. Figure 1 below shows the effect of Moore’s law, with Intel’s product line marked off as they came out along the line.

It wasn’t until 2005 that Intel started exploring dual core architectures on its consumer processor line, starting largely with the Pentium D. Multi-core processors offer

two or more central processing units on the same chip, and they can offer great gains in speed when software is written specifically to take advantage of their benefits. As clock speed of individual cores has stagnated due to power dissipation concerns, Intel has turned to releasing largely multi-core processors over the last seven or eight years.

Problems with the Moore’s Law Trend

The amazing accuracy with which Intel’s processors have followed Moore’s law, as shown in Figure 1, are predicted to soon come to an end. In a 2005 interview, Gordon Moore himself agreed as much, stating that transistor gate length likely couldn’t shrink much more. This is one of the limiting factors facing transistors. Part of Moore’s law is that the size of individual transistors would shrink year over year, leading to more transistors residing on the same die. As of April 2013, Intel is producing chips with a gate length of just 22 nanometers — a remarkable feat, considering that gate lengths in 2005 were in the neighborhood of 90 nm. But as Moore stated in his interview, there is a fundamental limit as to how small you can make these things, and that limit is approaching. The size of your average atom used in fabrication is around 0.2 nanometers, and a certain number of transistors are required for a transistor to function. Also, as gate lengths grow ever shorter, leakage current— or current from electrons that probabilistically tunnel across the dielectric layer of the FET and cause errors— becomes a major problem for power and error reasons.

Heat has also become a huge problem over the last decade, eventually forcing the switch to multi-core processors for Intel. In order to cope with the problem of heat dissipated by processors in the past,

CAN MOORE’S LAW

BE SUSTAINED?

21Visit: eeweb.com

TECH ARTICLE

“ More transistors per die meant that more operations could be performed, enabling computers to take over more complex calculations, and making organizations ever more dependent upon the technologies Intel offered.”

Figure 1: CPU Transistor Counts(courtesy of Wikimedia user Wgsimon)

22 Visit: eeweb.com

PULSE

chip manufacturers simply lowered the voltage bias applied to the devices. However, this has hit another fundamental limit, as devices require voltages of around 0.8 V to 1.3 V in order to remain in the correct bias. With the amount of voltage applied stagnating, and as the number of processors continues to grow, the amount of cooling required for a regular microprocessors in five years or so will likely be greater than that required for a one gigawatt nuclear power plant. These extra transistors being thrown at chips don’t even necessarily linearly increase the processing power in a multi-core system, especially in cases where software isn’t optimized to take advantage of multiple cores. Dropping more CPUs onto a die leads to another set of problems — including wire delay and resistance — when each processor is communicating with one another. Those interconnects can have a significant impact upon speed and power efficiency.

Potential Solutions to the Semiconductor Industry’s Woes

There are several avenues down which companies could go to keep Moore’s law alive and keep Intel profitable, though most would require major retooling of fabrication labs as we see them now. Ray Kurzweil, a popular futurist known for his theories about the technological singularity, has speculated that research will lead to devices using optical, quantum, or biological technologies. His prediction is that such technologies will allow Moore’s law to remain alive and well long past the end of the decade.

Graphene and other carbon nanotube structures are other wonder materials applied to almost every scientific field at this point. IBM has thrown its weight into carbon nanotubes for its future transistors, announcing last October that it has created a processor using ten thousand carbon nanotube transistors. These devices use rolled tubes of carbon molecules that can conduct electricity better than silicon and can be scaled much more indefinitely. A schematic view of a sample carbon nanotube field effect transistor, or CNFET, is shown below as Figure 2.

There are certainly downsides to carbon nanotubes, though they are similar to those downsides faced by the semiconductor industry in the past. Carbon nanotubes must be extremely pure, which is difficult to do at the moment. Additionally, they are very fickle and difficult to work with, requiring incredibly precise alignments to function.

Significance of Moore’s Law for the Industry

In the end, computer processors are here to stay regardless of the physical limitations we currently see. Moore’s law may have just become a self-fulfilling prophetic goal for chip manufacturers to attain over the last few decades rather than a law of nature itself. Gordon Moore and other famous physicists like Michio Kaku have long predicted the end of its dominance, though it’s hard to tell when that will be. Some say it is imminent, others within the next decade, and others still give a longer lifespan of close to half a century. In the meantime, other technologies can be improved. Silicon used to be too impure for use in microprocessors, and industrial grade silicon is now the purest material that mankind can manufacture. Processing techniques can always improve with further research, and it’s certainly true that the computer processor industry will continue to live.

“ Moore’s law may have just become a self-fulfilling prophetic goal for chip manufacturers to attain over the last few decades rather than a law of nature itself.”

Figure 2: Carbon Nanotube Field Effect Transistor(courtesy of Wikimedia user JB Waldner)

to comment on the article.

» CLICK HERE

19MHz Rad Hard 40V Quad Rail-to-Rail Input-Output, Low-Power Operational AmplifiersISL70444SEHThe ISL70444SEH features four low-power amplifiers optimized to provide maximum dynamic range. These op amps feature a unique combination of rail to rail operation on the input and output as well as a slew enhanced front end that provides ultra fast slew rates positively proportional to a given step size; thereby increasing accuracy under transient conditions, whether it’s periodic or momentary. They also offer low power, low offset voltage, and low temperature drift, making it ideal for applications requiring both high DC accuracy and AC performance. With <5µs recovery for Single Event Transients (SET) (LETTH = 86.4MeV•cm2/mg), the number of filtering components needed is drastically reduced. The ISL70444SEH is also immune to Single Event Latch-up as it is fabricated in Intersil’s Proprietary PR40 Silicon On Insulator (SOI) process.

They are designed to operate over a single supply range of 2.7V to 40V or a split supply voltage range of ±1.35V to ±20V. Applications for these amplifiers include precision instrumentation, data acquisition, precision power supply controls, and process controls.

The ISL70444SEH is available in a 14 Ld Hermetic Ceramic Flatpack and die forms that operate over the temperature range of -55°C to +125°C.

Related Literature• ISL70444SEH Evaluation Board User’s Guide AN1824

• ISL70444SEH Single Event Effects Report AN1838

• ISL70444SEH SMD 5962-13214

• ISL70444SEH Radiation Test Report

Features• Electrically screened to DLA SMD# 5962-13214

• Acceptance tested to 50krad(Si) (LDR) wafer-by-wafer

• <5µs recovery from SEE (LETTH = 86.4MeV•cm2/mg)

• Unity gain stable

• Rail-to-rail input and output

• Wide gain·bandwidth product . . . . . . . . . . . . . . . . . . . . 19MHz

• Wide single and dual supply range. . . . . . . . 2.7V to 40V Max• Low input offset voltage . . . . . . . . . . . . . . . . . . . . . . . . . 300µV• Low current consumption (per amplifier) . . . . . . . 1.1mA, Typ• No phase reversal with input overdrive• Slew rate

- Large signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60V/µs• Operating temperature range. . . . . . . . . . . . -55°C to +125°C

• Radiation tolerance- High dose rate (50-300rad(Si)/s). . . . . . . . . . . 300krad(Si)- Low dose rate (0.01rad(Si)/s) . . . . . . . . . . . . 100krad(Si)*- SEL/SEB LETTH . . . . . . . . . . . . . . . . . . . . 86.4MeV•cm2/mg

* Product capability established by initial characterization.

Applications• Precision instruments

• Active filter blocks

• Data acquisition

• Power supply control

• Process control

FIGURE 1. TYPICAL APPLICATION: SINGLE-SUPPLY, HIGH-SIDE CURRENT SENSE AMPLIFIER

FIGURE 2. VOS SHIFT vs HIGH DOSE RATE RADIATION

-IN

+IN

RF

RREF+

ISL70444

+2.7V

V-

V+

RIN-

10kΩ

RIN+

10kΩ

-

+

100kΩ

VREF

100kΩ

VOUT

LOAD

RSENSE

to 40V

VOUT = 10 (ILOAD * RSENSE)

+

-30

-20

-10

0

10

20

30

0 50 100 150 200 250 300 krad (Si)

V OS

(µV)

Vs = ±18V

GROUNDED

BIASED

June 14, 2013FN8411.1

Get the Datasheet and Order Samples

http://www.intersil.com

Intersil (and design) is a registered trademark of Intersil Americas Inc. Copyright Intersil Americas Inc. 2013All Rights Reserved. All other trademarks mentioned are the property of their respective owners.

24 Visit: eeweb.com

PULSE

25Visit: eeweb.com

TECH ARTICLE

So far we have been looking at the more basic structure of VHDL and using com-binational logic circuits. In this article, however, we will look at how to use and interface clock signals, the beating heart of modern digital electronics.

26 Visit: eeweb.com

PULSE

Clock signals have to be treated with respect. They form the timing element of your circuit. As the frequency rises, their use become more and

more important, though they are often overlooked as something that happens in the background.

In a microcontroller, for example, the clock could be little more than a crystal and some setting that determines how fast code is processed. Still, however, the silicon manufactures have had to spend lots of time considering how the clock is used inside the device.

FPGA manufacturers take this into consideration, which is why they have special clock paths within a device’s fabric. These pathways allow you to distribute the clock signal throughout the device and minimize setup and hold times of your logic. If you are developing more complex designs, it is therefore important that to look deeper into how clocks are used and distributed in FPGA fabric. First, though, let’s look at just the VHDL coding level.

For now, think of the clock signal just as any other signal within the design, but keep in mind that you will be using some part of if to control the rest of the circuits. Often I have seen people say that a circuit operates when the clock signal is high, but that is actually incorrect. The truth is that in a design you need an instantaneous trigger to tell each circuit to operate once — not twice or three times or some other random amount— just once. This is done by responding to the rising edge of the clock only. Therefore we see clock signals processed using the following VHDL term (where ‘clk’ is our clock signal wire):

Let’s look at an example of this in operation. The classic example includes using a D-type flip-flop and counters. The D-type will store and hold a value on its input ‘D’ at the point in time that the clock rises. The internal workings do not need to be described in VHDL, as it will look at our code and know what is needed.

1001011001000011011001011001000011010101100100001101001

The code uses the process structure we first looked at last week and includes the ‘clk’ signal in the sensitivity list, along with our ‘DataIn’ input. You can then see that you can simply use the rising edge of the clock within an IF statement. This assigns the input ‘DataIn’ to our output ‘DataOut’ (seen below.)

100101100100001101100101100100001101010110010000110100101101010110010000101101010110Figure 1: Using the rising edge of the clock within an IF Statement.

27Visit: eeweb.com

TECH ARTICLE

100101100100001101100101100100001101010110010000110100101101010110010000101101010110

Simple ‘dff’ D-type filp-flops are the most basic type you can use in VHDL. The fact is that FPGAs actually contain more complex latches that include resets and clears or complementary outputs and enable inputs.

It is important to think about the D-type flip-flops and latches that you use but often they are only a part of the bigger design. For example we know counters use flip-flops but we don’t write VHDL code to wire up flip-flops as counters. Early on we looked at how the internals of ‘Adders’ work but then found that VHDL can infer these as part of the design.

Here we will use the clock signal to control the counting. The counter has a signal called ‘count’ that stores an internal count value, here it is a four bit number. Each time the clock

rises the value of ‘count’ is increased by one. Notice that this is not the actual output signal. VHDL understands the difference between inputs and outputs. Reading a output back is not allowed so we use a signal to store the count value. These will become values stored in a latch or register inside the counter. The signal is then routed to the output outside the process (seen above).

The importance here is however that the count is only happening once per clock cycle. Had the code checked if clk was high, it is possible the value could be incremented many more times until the clock finally changed to low. That’s why we only look at the rising edge of the clock.

About the Author

Paul Clarke is a digital electronics engineer with strong software skills in assembly and C for embedded systems. At ebm-papst, he is developing embedded electronics for the air movement industry.

To read Part 4 of the VHDL series, click below:

Figure 2: Routed signal to the ouput outside of the process.