EEWeb Pulse - Issue 77

description

Transcript of EEWeb Pulse - Issue 77

1Visit www.eeweb.com

EEWeb PULSE INTERVIEW

EEWebIssue 77

December 18, 2012

Electrical Engineering Community eeweb.com

Power Interfacingthe Internet of ThingsPart 1

TECHNICAL ARTICLE

Magneto-InductiveTechnologyOverview

TECHNICAL ARTICLE

CEO, PNI Sensors

Becky Oh

EEWeb PULSE TABLE OF CONTENTS

3Visit www.eeweb.com

Becky Oh PNI SeNSor CorPoratIoN

Interview with Becky Oh - CEO

Two experts in RTOS sit down to discuss the initial challenges of getting an RTOS running and where you can find additional information once you are up and running.

RTZ - Return to Zero Comic

Featured Products

4

13

20

26

MCU Wars 2.3: Running an RTOS for the

Power Interfacing the Fundamental Component

32

By roderICk BaCoN with intersil

How the Internet of Things is a new burgeoning field by combining sensing, embedded computing and communication technologies.

An overview of how magneto-inductive (MI) sensing works as well as some inherent advan-tages of MI Sensing

14Magneto-Inductive Sensor Technology

By aNdrew LeuzINger and aNdrew tayLor with Pni sensor

First Time

of the Internet of Things - Part 1

Overview

4

EEWeb PULSE INTERVIEW

EEWeb | Electrical Engineering Community

BeckyOh

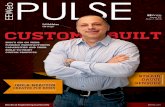

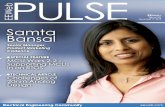

PNI SensorPNI Sensor Corporation is at the forefront of innova-tion in the design, development and application of sensor technology. we spoke with Becky oh, the Ceo of the company, about her extensive resume in chip design, PNI’s patented Magneto-Inductive technology and the company’s unique and innova-tive work culture.

5Visit www.eeweb.com

EEWeb PULSE INTERVIEW

BeckyOh

PNI Sensor

6

EEWeb PULSE INTERVIEW

EEWeb | Electrical Engineering Community

why don’t you give me a bit of background about yourself? How did you get into engineering? and maybe tell us a bit of your academic background, such as going to school?

I got into engineering because of my high school teacher, specifically my Physics teacher. My high school was a very liberal arts-oriented preparatory boarding school. I thought I was going to become an artist – that’s what I was thinking! But I did well in Physics and Math, and my Physics teacher really wanted me to try engineering.

Because I was at a boarding school, during the summer time I had to decide who was going to water my plants. So my Physics teacher said, “Well, why don’t we just build this ‘gizmo’ that will actually do it for you the whole summer?” It was my junior year, going into my senior year – the summer – and he and I went out and built this gadget – with a control board on it – that would hook up to a faucet and then have a drip system into my plants.

So that was my first experience and my Physics teacher said, “Well this is engineering,” and I thought, “that’s pretty cool!” So then he said, “Well why don’t you try to apply to MIT,” and I thought, “My interest is in the field of fine arts but MIT will take me into the field of engineering. I do like creating and building things so perhaps I will give engineering a try. Besides, I do like the challenge.” But when I went to MIT, I realized that the other students had been building entire computers, and were so much ahead of me, and so at first I really struggled. I ended up calling my Mom every week, saying “Oh my gosh, I’m probably going to flunk out, I need to leave this school.”

But I stuck it through, and I’ve been very happy that I did. I got my EECS degree from MIT, and then pursued a Master’s of engineering degree from Cornell. I decided to get my Master’s degree because as a college graduate, I still didn’t quite know what I wanted to do in Engineering. Unlike my fellow classmates who all seemed to have a vision – “okay I want to be a computer scientist, and I want to build computers,” while I was thinking, “Well, I don’t even know what that really means.”

I think I needed a year to take a little breather and evaluate all the material I had learned and then decide what it was I really wanted to do in the field of Engineering. Grad school really helped me identify my area of interest; Integrated Circuit (IC) Design.” And that’s how it all came about.

So you studied chip design at Cornell? Is that the direction you headed in the first part of your career?

Yes, I did. My first job was with Apple Computer. I was part of the chip design team that worked on the PowerPC processors. That was when Apple had decided to build their own processor. They had been using the Motorola 6800 family of processors for a long time. But Apple decided they needed a more powerful processor and would build their own. In the end the PowerPC was a joint development between Apple, Motorola and IBM.

what brought you to PNI? were there other companies along the way?

I was at Apple for about four and a half years, and Apple at that time provided a 6 week paid Sabbatical after five years of employment. I

could have stayed another 6 months and enjoyed my sabbatical but it was more important for me to continue to work on projects that were fulfilling.

One of the reasons I left Apple was that I wanted to see the bigger picture. In chip design you do a really small portion of the whole system. In fact, we had probably 10 or 20 engineers working on this one little chip. Well, it was a big chip – but you know, I still wanted to feel like I had more influence than just a little portion – it was difficult for me to work without the visibility of how my portion of the design was influencing everything else.

I thought I was going to do more in Engineering than just a little sliver. So what ended up happening was – we were using a Synopsys EDA tool for chip design – so I thought, “you know what, maybe I can hedge my bets a little bit and become a field engineer, which will give me a little sense of sales and marketing, but still utilize my skills as an engineer.

So I worked for Synopsys as a field application engineer for about two years. That experience really opened my eyes to what all the other engineers were

“If you come to the office, you’ll find a lot of equipment that measures magnetic fields. It’s a bit esoteric because you can’t see magnetic fields,

but it is all around us. If we were to draw magnetic field lines around us, we would be covered in field lines. You don’t see it, but it has an influence on a lot of different things, and it’s hard to grasp.”

7Visit www.eeweb.com

EEWeb PULSE INTERVIEW

working on. I learned about many different designs, and the different capabilities of engineers in Silicon Valley. I never considered myself to be a good engineer, but after my role as field application engineering, I realized, “Wow, I can support all of these engineers, I’m not too bad – I’m actually a pretty good engineer!”

That experience gave me a lot of confidence, but I still wanted to do a little more than just support other engineers. And at that time I had a couple friends, three guys, who had started PNI in 1987. I went to grad school with one of the founders and got to know the other two later on. So I said to them, “Hey guys, I don’t really like what I’m doing... and is there anything I can help you with?” And they said, “Well, yeah sure, come in and help, but we may actually be going into bankruptcy because we’ve made all these products and we can’t sell them.” And so I said, “Well bankruptcy doesn’t worry me too much, let me give it a try”

This was before I was thirty so I thought it didn’t matter and though they really couldn’t pay me much I decided I would work for them. I

asked them what I should do to help, and they said, “Well, figure it out.” I said, “Okay, there’s this thing called ‘operations,’ do you think I can just do that?” They responded, “Yeah, sure, go ahead, try it.” So that’s what led me into PNI. I started from there and I realized ‘Operations,’ meant that I had to answer the phones if nobody else was answering it, and be the customer service agent. Then they said, “Here’s a bill of materials, we have to make these things.” And

I responded, “Well, what is that?” in chip design everything’s on a computer and you’re using the tools to create the design. So I had never dealt with a bill of materials before. I was given a list of parts I had to purchase and have built somehow. I didn’t know what to do or know where to source these parts, but I had to figure it out because nobody else was going to do it.

So that’s how I learned all the

“If you come to the office, you’ll find a lot of equipment that measures magnetic fields. It’s a bit esoteric because you can’t see magnetic fields,

but it is all around us. If we were to draw magnetic field lines around us, we would be covered in field lines. You don’t see it, but it has an influence on a lot of different things, and it’s hard to grasp.”

8

EEWeb PULSE INTERVIEW

EEWeb | Electrical Engineering Community

different aspects of the business. I grew into the role of Business Development because of my field-application engineering experience and familiarity of the company’s technology. And then was promoted to president of the company. I’ve been here for about 13 years now.

why don’t you tell us a little about the company? what would you say if you wanted to sum up the products and services offered by PNI?

PNI is very highly specialized – you’re probably not going to find anyone else in the world who knows magnetic fields better than us. We’ve been working with magnetic fields since 1987 – the first product was a sensor that would measure

magnetic fields, specifically, Earth’s magnetic field, in order to be able to make a digital compass. That’s how we got started, we’ve been making our sensors, and writing software, and creating products based around our magnetic sensor, since 1987.

If you come to the office, you’ll find a lot of equipment that measures magnetic fields. It’s a bit esoteric because you can’t see magnetic fields, but it is all around us. If we were to draw magnetic field lines around us, we would be covered in field lines. You don’t see it, but it has an influence on a lot of different things, and it’s hard to grasp.

The way we started is interesting because the reason the founders made this sensor was because at

Stanford they attended an electrical engineering class where the professor (who was a really avid sailor) said, “Okay guys, now that you’ve been in my class, if you guys could build me a sensor that could be used in a digital compass for my sailboat, that would be great, because there’s no sensor in the market that’s low power enough to be battery operated. After that class, they were just kicking the idea around, and then decided, “Okay, well, let’s go build this sensor.”

The magnetic sensor was actually created to make a digital compass, so it can measure earth’s magnetic field precisely to enable high accuracy digital compassing – probably the best one out there.

9Visit www.eeweb.com

EEWeb PULSE INTERVIEW

Once the sensor was created, the founders thought, everyone will want a digital compass. But in 1987 few consumer electronic products needed a digital compass. One market that saw the benefit of a digital compass and really liked what PNI had was the military market.

The initial seed money for PNI was raised in the Stanford dorms – they had shareholders putting in anything from two thousand dollars to a couple hundred dollars – and so obviously they needed more money. They got their first contract – an SBIR contract, which is a small business innovative research contract through the Department of Defense – and it was to create a sensor that could be put in all of the military hand-held compasses. This was the first of many products we created for the Military market. What

was good about manufacturing product for the military was the smaller production volumes and slower ramp up; this gave us time to refine the sensor, and we were able to create something that was really robust for that market. But these first contracts were not that big, and the founders still had a vision that everyone wanted a digital compass. First we needed to determine who would truly benefit from a digital compass.

One application that would benefit from the features of an electronic compass would be a car compass. A compass needs to just measure earth’s field. However the magnetic field a car generates is much greater than the earth field. An electronic compass would have the smarts to just separate out the earth’s field and provide accurate compass heading.

We then tried to convince people of its benefit, but people responded, “oh we don’t want it – who needs a compass in a car?” But we still believed if we built it, there would be a demand for it. So our first product was the Wayfinder car compass that mounted onto the windshield of a car. The product was sold through

Sharper Image. The Wayfinder compass made it on the cover of Sharper Image and the Wall Street Journal published an article about it. But the problem was we were young and inexperienced – and one thing we were lacking was the ability to manage our finances properly: We lost money on every one we sold. Sharper Image needed a 60 percent margin, so for them to sell at $99 they needed to buy it for $40, it cost us $50 to make the product. But we figured, “We can drive the manufacturing cost down so let’s continue to make the product.” And that’s about the time I joined the company. That’s why I mentioned that the founders said, “Well we might be going into bankruptcy, but you can help.” It was an interesting time to join, but I figured that I was young and had nothing to lose. If it didn’t work, I could just find something else.

That is the roots of our company. Even now we make magnetic sensors. We make the highest-performing sensor in the market, which gets used in a wide range of applications and markets; military and consumer electronics – it’s the same technology. Because we were initially targeting the consumer

“We make the highest-performing

sensor in the market, which gets used in a wide range of

applications and markets; military

and consumer electronics – it’s the same technology.”

10

EEWeb PULSE INTERVIEW

EEWeb | Electrical Engineering Community

sailboat compass, the magnetic sensor design is suitable for low cost manufacturing yet has the performance it needs to be used in military applications as well. To sum it up, I would say we’re highly specialized in magnetic sensing, and our products are magnetic sensors and magnetic sensor modules that give orientation.

How big is the company? are you based in California?

We’re about 34 people right now. And we manufacture everything in-

house. We’ve automated everything so we need very few operators. We are based in Northern California.

tell me a little about the culture of the company. what’s it like working for PNI?are many of you are technical? a third? Half?

Oh yeah, more than half. I would say about 70% of us have some type of engineering or technical degree. Not all of us are doing engineering design, per say, but we understand

the technology. Probably half of our employees or more are design or R&D engineers.

The culture is...we’re a very flat organization. We don’t have any middle-management, obviously, as a company of this size. The culture is that we expect everyone we hire to be responsible adults. For instance, we don’t have a set PTO policy; it’s complete flex hours. If you get your work done you can go – you should know if you can take off a week or not, depending on how you’re collaborating with your coworkers. We leave it up to everyone’s judgment; it’s not a 9-5 place at all. When you need to get your stuff done, and when you think you can be the most productive, that’s when you need to do it. You just need to make sure you complete your project on time and collaborate with your team members.

That’s been working out really well for us. Obviously the people who can’t work in this environment don’t stay very long. It’s a little too loose for some people – they want structure, they want someone to tell them exactly what they’re supposed to do. But PNI’s not like that because we don’t have a lot of middle-management telling people what to do. We all agree on a corporate goal; we share all the financials with all the employees, and say this is what we need to do. Everyone has their own personal action plans for what they need to do, and how they go about that is up to them.

what kind of direction do you see the company headed in the future?

In 2011 our revenue was split 50% in the military/scientific market, and 50% in the consumer market. This year, I’m excited to announce that

“The culture is that we expect everyone we hire to be responsible adults. For instance,

we don’t have a set PTO policy; it’s complete flex hours. If you get your work done you can go – you should know if you can take off a week or not, depending on how you’re

collaborating with your coworkers.”

11Visit www.eeweb.com

EEWeb PULSE INTERVIEW we are supplying our geomagnetic sensors to Nintendo’s new Wii U GamePad. Hence sales to the consumer market will become a larger percentage of our total revenues.

are any of the original founders of the company still involved?

Yes. Let’s see, George Hsu – he’s the chairman and CTO. He is the technical visionary.

Could you tell us a little more about what new products PNI is developing?

Yes, perhaps I can quickly touch on PNI’s new products. With the introduction of the iPhone 3, sensors such as magnetic sensors, gyroscopes, and accelerometers, have started to be designed in to mainstream consumer electronic products. I used to work with gyroscopes that were thousands of dollars, and now we have gyroscopes that are about $1.40., and have almost the same functionality. However they are noisier, have more

drift, and they’re not as sensitive. But they’re tiny, and they’re really cheap. Accelerometers: same thing. I remember buying a couple hundred dollar accelerometer; now they’re about $.40, and they’re tiny and consume very little power, but again they have the same issues. Same applies to the magnetic sensors. Sensors manufactured for the consumer electronics market have sacrificed performance for smaller size and lower cost.

Small form factor and low cost are requirements for consumer electronics. But in some ways consumers actually expect more from these sensors than the military. The military customer understands that in order to achieve the performance, they will need to go out of their way to calibrate the sensors. Consumers – they don’t want to do any of that, but they still expect the sensors to be precise.

It’s become inevitable, that the only way you can try to satisfy the consumer requirements is to use software algorithms to integrate the

3 different sensors to achieve higher accuracy than the individual sensor can achieve on its own. You have to make sure that the sum is greater than the individual parts. This is referred to as Sensor Fusion.

Since we understand sensors really well, and have many years of experience integrating gyroscopes and accelerometers, we are able to offer Sensor Fusion algorithms to achieve very accurate motion-tracking with consumer grade gyros, accelerometers and magnetic sensors.

We have been primarily a magnetic sensor company but I’m excited that we have been able to expand our product offerings to include sensor fusion algorithms in our SpacePoint Technology products. I’m very excited about the future of PNI.

For more information on PNI Sensor, visit their website at:

www.pnisensor.com

Optocouplers are the only isolation devices that meet or exceed the IEC 60747-5-5 International Safety Standard for insulation and isolation. Stringent evaluation tests show Avago’s optocouplers deliver outstanding performance on essential safety and deliver exceptional High Voltage protection for your equipment. Alternative isolation technologies such as ADI’s magnetic or TI’s capacitive isolators do not deliver anywhere near the high voltage insulation protection or noise isolation capabilities that optocouplers deliver.

For more details on this subject, read our white paper at: www.avagoresponsecenter.com/672

Take the Risk out of High Voltage Failure with Certifi ed Avago Optocouplers

Technology You Can Trust

IEC 60747-5-5 Certifi ed

FEATURED PRODUCTS

13Visit www.eeweb.com

Gate Drive IC Simplifies eBike DesignInternational Rectifier, IR, introduced the IR3230SPbF three-phase gate drive IC for eBike inverters providing efficient electric mobility. The IR3230SPbF is a highly integrated three-phase gate drive IC designed specifically to meet the needs of eBike inverters. The new device offers input range up to 60V enabling operation from 48V battery systems, regeneration mode to recharge the battery, and the integration of many protection features to reduce component count and improve system reliability. The IR3230SPbF is available in an SOIC28 package featuring an environmentally friendly, lead-free and RoHS compliant bill of materials. For more information, please click here.

High-Efficiency Mini-POL ConverterRenesas Electronics Corporation has developed the RAA20770X Series of mini-POL [Note 1] converters for ASICs and other large-scale logic circuits in a wide variety of application fields, including personal computers, servers, industrial, office automation and networking equipment. The RAA20770X Series devices achieve the industry’s highest level of miniaturization and power density. Renesas is now releasing six products with different current supply ratings and functionality. To satisfy the first requirement, the new RAA20770X devices perform high-efficiency power conversion during normal load and—typically 90 percent of the time—also execute the frequent transitions to low-power mode quickly. For more information, please click here.

world’s First Quad-Core Cortex-a7 SoCMediaTek Inc. announced the launch of the MT6589, the world’s first commercialized quad-core System on a Chip (SoC). The new quad-core SoC integrates MediaTek’s advanced multi-mode UMTS Rel. 8/HSPA+/TD-SCDMA modem, a power-efficient quad-core Cortex™-A7 CPU subsystem from ARM, PowerVR™ Series5XT GPU from Imagination Technologies, and is delivered in 28nm process technology. It also enables handset makers to reduce time to market, simplify product development and manage product differentiation in a more cost effective way, for any market worldwide. For more information, please click here.

Power Controller with Six dPwM outputsThe UCD3020A device is a digital PWM controllers from Texas Instruments providing a single-chip control solution for digital power-conversion applications. This device allows digital control implementation of a high-performance, high-frequency power supply with flexible configuration of parameters, supervisory, monitoring, and communication functions. The UCD3020A is a fully programmable solution that is configurable to support a wide range of isolated and non-isolated topologies in single- or multiphase configurations. Some examples include interleaved PFC, isolated forward, half-bridge, phase-shifted full bridge, active clamp, and resonant LLC. For more information, please click here.

Optocouplers are the only isolation devices that meet or exceed the IEC 60747-5-5 International Safety Standard for insulation and isolation. Stringent evaluation tests show Avago’s optocouplers deliver outstanding performance on essential safety and deliver exceptional High Voltage protection for your equipment. Alternative isolation technologies such as ADI’s magnetic or TI’s capacitive isolators do not deliver anywhere near the high voltage insulation protection or noise isolation capabilities that optocouplers deliver.

For more details on this subject, read our white paper at: www.avagoresponsecenter.com/672

Take the Risk out of High Voltage Failure with Certifi ed Avago Optocouplers

Technology You Can Trust

IEC 60747-5-5 Certifi ed

EEWeb PULSE PROJECT

14 EEWeb | Electrical Engineering Community

Magneto-InductiveSensor Technology

OverviewAndrew Leuzinger &

Andrew TaylorPNI Sensors

EEWeb PULSE PROJECT

15Visit www.eeweb.com

Magneto-InductiveSensor Technology

OverviewAndrew Leuzinger &

Andrew TaylorPNI SensorsPNI Sensor Corporation

EEWeb PULSE PROJECT

16 EEWeb | Electrical Engineering Community

HOW MAGNETO-INDUCTIVE SENSING WORKS

A picture of PNI’s MS2100 2-axis magneto-inductive (MI) sensor, incorporating two PNI MI sensors and PNI’s control ASIC, is shown in Figure 1. PNI’s MI sensors typically are used in an L/R oscillation circuit, with a basic circuit shown in Figure 2.

HE represents the external magnetic field parallel to the coil. The total magnetic field the sensor experiences, H, is a function of the external magnetic field and the magnetic field established by the current running through the circuit, I. This can be expressed as:

where k0 is a constant that depends on certain physical parameters of the sensor.

For the circuit shown, assuming a “0” value (0V or some value less than the trigger value) on the input to the Schmitt trigger, A, the Output value will be inverted to a logical “1” at some voltage VS. This gradually will drive the voltage up across the MI sensor until the voltage at A reaches the trigger threshold for the Schmitt Trigger, VH. At this point, the Schmitt Trigger will see the voltage at A as a logical “1”, and the output will become a logical “0”. This will drive the voltage down across the MI sensor, setting up an oscillation as depicted below in Figure 3. Note that the current, I, essentially mimics the voltage waveform at A.

H = k0I + HE

Voltageat Output

Voltageat “A”

VS

0

VH

VL0

VS

H

µ(H)

PNI’s MI sensors incorporate a solenoidal-geometry coil wrapped around a high-permeability magnetic core. The inductance of a highly permeable material will vary with the applied magnetic field. Consequently, the sensor’s inductance, μ, is a function of the magnetic field, H, as depicted in Figure 4.

For the circuit depicted in Figure 1, the bias resistance, RB, and drive voltage on the Schmitt Trigger, VS, are selected such that the sensor’s magnetic field is in the non-linear regime of the permeability curve. Figure 5 depicts the voltage output when the circuit is driven with either a positive or negative bias, but with no applied external magnetic field. Note that the period of oscillation is the same whether the circuit is positively or negatively biased.

When an external magnetic field, such as Earth’s magnetic field, is applied, this causes both the positively and negatively biased curves to shift in the same direction. As depicted in Figure 6, this shift causes the inductance to increase when the circuit is positively biased and to decrease when negatively

Figure 1: PNI’s MS2100 2-Axis MI Sensor

Figure 2: Basic MI Sensing Circuit

Figure 3: Waveforms for Basic Oscillator Circuit

Figure 4: Inductance (μ) of Highly Permeable Material Vs. Magnetic Field (H)

HE

Output

Schmitt Trigger

A

RB

MI Sensor

I

EEWeb PULSE PROJECT

17Visit www.eeweb.com

H

µ(H)

HL - HS HH - HS HL HH

PositiveBias

Polarity

NegativeBias

Polarity

H

µ(H)

HL - HS HH - HS

+HE+HE +HE +HE

HL HH

PositiveBias

Polarity

NegativeBias

Polarity

biased. This, in turn, causes the period between cycles, τ, to increase for the positively biased circuit and decrease for the negatively biased circuit.

By measuring the time to complete a fixed number of oscillations that occur in the forward and reverse polarity directions and taking the difference between these two values, it is possible to derive the strength of the external magnetic field. This represents the underlying principle to PNI’s magneto-inductive sensing technology.

DISCUSSION

Magneto-inductive sensing has some particularly useful attributes that set it apart from other magnetic sensing technologies. Specifically:

• The output is inherently digital. The output from PNI’s ASIC is a clearly defined number, and this number is directly related to the applied magnetic field. Most other technologies provide an analog output which requires additional component hardware, such as amplifiers and analog-to-digital converters.

• Very high resolution, on the order of 10 nT, can be obtained with the basic circuit. In comparison, competing technologies either cannot achieve this level of resolution due to inherent noise floors, or it can be comparatively expensive due to the need for costly external components.

Figure 5: (left) Sensor Circuit Operation with No Applied External Field

Figure 6: (bottom) Sensor Circuit Operation with Applied External Field

EEWeb PULSE PROJECT

18 EEWeb | Electrical Engineering Community

• Low power consumption. Power consumption with MI technology is inversely proportional to the sample rate, such that at an 8 Hz sample rate power consumption is typically 1.5 mW, while at a 300 Hz sample rate it is typically 7.5 mW. In comparison, magneto-resistive (MR) sensors generally consume around 15 mW to 30 mW, making MI technology 2x to 20x more power efficient, depending on the implementation.

• No need to set/reset MI sensors. Competitive technologies, such as MR, often require sending a high current pulse through the sensor in order to reset the magnetic domains within the core material. This pulse mandates the ability to generate a large peak power, on the order of several watts, and this power spike can cause problems with other components within a users system. Such a set/reset signal is not required with MI sensors.

• Output is inherently stable over temperature. The reverse/forward biasing nature of PNI’s MI circuit athermalizes the output since changes in the bias resistance or inductance due to temperature are experienced in both the forward and revers directions, and are thus cancelled.

• No hysteresis. PNI’s MI sensor design and the forward/reverse biasing nature of the MI circuit result in virtually no hysteresis. Since hysteresis directly affects the accuracy of measurement, PNI’s MI sensors can be used for applications that require high accuracy.

For a more detailed discussion of magneto-inductive technology, see Slawomir Tumanski’s article “Induction coil sensors – a review” in Measurement Science and Technology, 18 (2007) R31-R46. For information on all of PNI’s discrete sensing components and compassing modules, go to www.pnicorp.com.

EEWeb PULSE SPECIAL FEATURE

20 EEWeb | Electrical Engineering Community

Episode 2.3Running an RTOSfor the First Time

EEWeb PULSE SPECIAL FEATURE

21Visit www.eeweb.com

Episode 2.3Running an RTOSfor the First Time

In this episode of MCU Wars, Jean Labrosse of Micrium and Richard Barry of FreeRTOS dis-cuss the initial challenges of getting an RTOS running for the first time and where you can find additional information once you are up and running.

This series was filmed at DevCon 2012 by Renesas in Anaheim, California. DevCon pro-vides an environment for valuable technical information exchange and access to Renesas’ technology experts and partenrs from around the world.

EEWeb PULSE SPECIAL FEATURE

22 EEWeb | Electrical Engineering Community

There are a couple things you have to consider. First of all, what do you already know about RTOS’? Luckily, Micrium offers a series of books that

we’ve written with Renesas on SH7216 and this book on the RS62N. In this book,

we actually explain everything about what a real-time Kernel is. In fact, in Part 2, which contains about a third of the book, we talk about the RX62N specifically and give examples of using the real-time Kernel in the RX62N. The next step is how do you actually use it in an application. The good news is, since we have already ported all of our software to these different CPU architectures, it makes it a lot easier for customers to start using real-time Kernels.

If you want to get up and running and if we have done our job well, then that is very easy. Again, we support all of the Renesas processors and the way

I like FreeRTOS to work is that every efficient port comes with an official demo

application. You can get on to the website and download that without even giving your e-mail address and there will be—for every official port—a demo which you can just compile straight away. If you are using the same hardware platform, then it will just run straight away. There is nothing to do in that sense. You then have a working platform, which is preconfigured correctly that you can take out of the demo code and add in your own code. As Jean alluded to, getting the Kernel up and running and using it appropriately and getting the maximum benefit from it are two completely different things. The second point is really an education issue. Like Jean, I have a tutorial book, which takes people from the very beginning of the basics of multi-tasking all the way through to more advanced topics like interrupt management and strategies. We also have an RX62N edition of that book, which is one of five editions. People that want to go further than that, or people who work in large organizations that are investing time in learning FreeRTOS, we provide full training courses as well where you can select modules from that so you can tailor it to your level of knowledge. To get the benefit out of using a Kernel, you really have to understand how to use it and not just try to take your Super-Loop Architecture and run it in a task.

The other aspect I’d like to add to that is that it depends on if you are a developer just looking for a Kernel or looking for other services. That’s an important thing.

You want to get a Kernel that also has the capability of supporting other services. If

you are looking into network and connectivity, you might need a TCP/IP stack or USB stack. Again, Micrium has written a couple books, one on USB devices and one on TCP/IP to get the full spectrum of additional services.

This is a point where my offering and Jean’s offering differ quite a bit. Generally, a lot of the work I’m involved in is taking driver libraries—either USB or smaller peripherals—that are provided

for free by other people and making them multitasking-aware and event-driven

and basically re-engineering them to work well in the multitasking environment. Then, if people want to go up a level in complexity or they want a commercial product, then because FreeRTOS has become so popular, there have been whole ecosystems built around it. I’ve picked certain partners who can provide these components as commercial-supported components—they’re not free. My partners are all experts in their field and are people who have worked with these particular products for years and years. They themselves support FreeRTOS, so you can buy these products with FreeRTOS in them.

What are the challenges in getting an RTOS running for

the first time?

Jean

richard

Jean

richard

(Above): Development boards by Renesas

EEWeb PULSE SPECIAL FEATURE

23Visit www.eeweb.com

To view this episode of MCU Wars and other EEWeb videos:

Click Here

But each on handles a separate aspect of a middleware component, so one partner is TCP/IP and another partner is USB and another File System or

they’re all under the same umbrella.

You can get them all under the same umbrella—there are different people doing it. You can buy integration services and have delivered for you

and have an off-the-shelf platform or a custom-platform and so you want the

Kernel or TCP/IP delivered to you as a single package for support queries. At that point it becomes quite similar.

The difference with Micrium, to a certain extent, is that all our software is written by all of our people, so we follow the exact same coding conventions, the quality of

the code is absolutely impeccable and you couldn’t tell who wrote the code for the

TCPIP stack or USB stack because we all follow the same coding conventions. Of course, everything comes from one source, so you know it’s all fully integrated and thought of up front. There is no searching for code from a third party integrated with another file system or USB system so everything is integrated. We go through great lengths to make sure everything is compatible.

The single point of reference is the FreeRTOS website, unsurprisingly, which is www.freertos.org. On the site, there is the API reference manual

and information on all of the partners, there is a documentation page for every

single demo we provide so you can get something up an running quickly just by following all of the steps. You can find information on all of our partners. One of our biggest partners in Wittenstein, who do a safety-certified version that has the same usage model as FreeRTOS, but it has been completely re-engineered to be certifiable and has been certified in lots of different applications. It’s all there in one place.

For more information, you can go to the Micrium website, www.micrium.com. On the website, we have a whole lot of information on all the ports for our

processing architectures we support as well as example projects that we’ve

provided. You can also download all the PDF books that I’ve shown you, which are all available for free download. Micrium offers real-time Kernels, Micro μC/OS-II, which has been used recently in the Mars Rover, so we are on the surface analysis module, so it’s a very interesting application.

Jean

richard

Jean

Where can you get additional information about each of your

offerings?

richard

Jean

Continued in episode 4...

BeStar®

ACOUSTICS & SENSORS

Teamwork • Technology • Invention • Listen • Hear

PRODUCTSSpeakers

Buzzers

Piezo Elements

Back-up Alarms

Horns

Sirens/Bells

Beacons

Microphones

Sensors

INDUSTRIESAutomotive

Durables

Medical

Industrial

Mobile

Fire / Safety

Security

Consumer

Leisure

QS9000 • TS/ ISO16949 • ISO14001 • ISO13485 • ISO9001

bestartech.com | [email protected] | 520.439.9204

Preferred acoustic componentsupplier to OEMs worldwide

Dual 15A/Single 30A Step-Down Power ModuleISL8225MThe ISL8225M is a fully-encapsulated step-down switching power supply that can deliver up to 100W output power from a small 17mm square PCB footprint. The two 15A outputs may be used independently or combined to deliver a single 30A output. Designing a high-performance board-mounted power supply has never been simpler -- only a few external components are needed to create a very dense and reliable power solution.

Automatic current sharing and phase interleaving allow up to six modules to be paralleled for 180A output capability. 1.5% output voltage accuracy, differential remote voltage sensing and fast transient response create a very high-performance power system. Built-in output over-voltage, over-current and over-temperature protection enhance system reliability.

The ISL8225M is available in a thermally-enhanced QFN package. Excellent efficiency and low thermal resistance permit full power operation without heat sinks or fans. In addition, the QFN package with external leads permits easy probing and visual solder inspection.

Related Resources• See AN1789 “ISL8225MEVAL2Z 6-Phase, 90A Evaluation

Board Setup Procedure”

• See AN1790 “ISL8225MEVAL3Z 30A, Single Output Evaluation Board Setup Procedure”

• See AN1793, “ISL8225MEVAL4Z Dual 15A/Optional 30A Cascadable Evaluation Board”

• See ISL8225M 110A Thermal Performance Video

Features• Fully-encapsulated dual step-down switching power supply

• Up to 100W output from a 17mm square PCB footprint

• Dual 15A or single 30A output

• Up to 95% conversion efficiency

• 4.5V to 20V input voltage range

• 0.6V to 6V output voltage range

• 1.5% output voltage accuracy with differential remote sensing

• Up to six modules may be paralleled to support 180A output current

• Output over-voltage, over-current and over-temperature protection

• Full power operation without heat sinks or fans

• QFN package with exposed leads permits easy probing and visual solder inspection

Applications• Computing, networking and telecom infrastructure

equipment

• Industrial and medical equipment

• General purpose point-of-load (POL) power

FIGURE 1. COMPLETE 30A STEP-DOWN POWER SUPPLY FIGURE 2. SMALL FOOTPRINT WITH HIGH POWER DENSITY

[email protected] TO 20VVOUT

4.7µF

4x22µF

ISL8225M

VIN1

VSEN2-

VSEN1+EN/FF1EN/FF2

VMON2

VMON1

SGN

D

PGN

D

VOUT1

VSEN1-

MO

DE

COMP2

COMP1

VIN

OFF 1kΩ5x100µF

470pF

1kΩ

VCC

RSET

NOTE: ALL PINS NOT SHOWN ARE FLOATING.

VIN2 VOUT2VIN2

ON

17mm 17mm

7.5mm

December 3, 2012FN7822.0

Intersil (and design) is a registered trademark of Intersil Americas Inc. Copyright Intersil Americas Inc. 2012All Rights Reserved. All other trademarks mentioned are the property of their respective owners.

Get the Datasheet and Order Eval Boards

http://www.intersil.com

EEWeb PULSE TECH ARTICLE

26 EEWeb | Electrical Engineering Community

PowerInterfacing

the FundamentalComponent of theInternet of Things

Roderick BaconIntersil Corp

EEWeb PULSE TECH ARTICLE

2928 Visit www.eeweb.comEEWeb | Electrical Engineering Community

EEWeb PULSE TECH ARTICLE

27Visit www.eeweb.com

PowerInterfacing

the FundamentalComponent of theInternet of Things

Roderick BaconIntersil Corp

EEWeb PULSE TECH ARTICLE

2928 Visit www.eeweb.comEEWeb | Electrical Engineering Community

The Internet of Things (IoT) was first enunciated by Kevin Ashton in 1999, as a way to link radio frequency identification (RFID) technology used in supply chain management to the internet.[1] A more recent revision by Mr. Ashton in 2009 of what the IoT vision represents is depicted by the following statement: “If we had computers that knew everything there was to know about things—using data they gathered without any help from us—we would be able to track and count everything, and greatly reduce waste, loss and cost. We would know when things needed replacing, repairing or recalling, and whether they were fresh or past their best.”[1] IoT is a new burgeoning field combining sensing, embedded computing, and communication technologies. IoT is a field that incorporates the entire computing landscape

EEWeb PULSE TECH ARTICLE

28 EEWeb | Electrical Engineering Community

from cloud computing down to microcontrollers that locally processes the data retrieved from environmental sensors that can track/record light, heat, proximity, and motion. IoT begins at the point of recording the state of the environment or an object, as such the embedded module that is constructed to gather this data is the most fundamental (and critical) component. The embedded module that is tasked with recording environmental state data is composed of three key components: sensor(s), an embedded CPU, and a low power radio. The sensor directly measures environmental data like proximity, heat, light, and motion. The data stored in the sensor is retrieved by the embedded CPU, which at this point is a microcontroller (MCU). The MCU will locally process the sensor data against baseline reference data. Once the sensor data is processed, based on what is required, the data can be stored locally in the module on the MCU or off chip memory where it can be transmitted through a low power radio frequency integrated circuit (RFIC) transceiver to the targeted data repository. The end target data repository can be anything in the IoT universe from the pervasive smartphone or through a wireless router to a hard drive on the network. Figure 1 illustrates the components that make up a typical IoT embedded module for recording environmental data. Due to semiconductor process technology voltage limitations, typical components of the IoT embedded module work well with the standard 3.3V voltage rail.

For the IoT embedded module to operate autonomously in the field, the power source or battery must be selected in accordance with the desired performance of the embedded module for environmental state sampling. The two key performance variables to consider are these: how many different kinds of data can be recorded along with which wireless technologies to support; and how long can the embedded module last in the field for the chosen battery technology and configuration. To maximize performance, the interface between the embedded module and the selected battery has to be a switching regulator. A low dropout (LDO) regulator or charge pump do not offer the same performance that a switching regulator can provide with battery powered applications. With switching regulators there are three primary choices in regards to architecture: Buck, Boost, and Buck-Boost.

The three switching regulator architectures each come with a tradeoff between what battery technology can be chosen and cost of the regulator. The buck regulator is the regulator that can only convert an input voltage that is equal to or higher than the desired voltage on the output. Figure 2 illustrates the simplified block diagram of the buck regulator. Referencing Figure 2, the buck regulator operates by driving the Q1 power transistor with a duty cycle ratio computed by dividing the on-time of the Q1 power transistor divided by the total period of a switching cycle as depicted by the waveforms in Figure 2. The buck regulator is controlled by an internal clock that causes it to switch once every cycle except during light load conditions, where many buck regulators vary the switching frequency to maximize efficiency. The output voltage is computed by the duty cycle control of the Q1 power transistor. The Q2 power transistor is just the complementary of the Q1 power transistor (minus some non-overlap time that is enforced to prevent shoot thru currents that can damage the power transistor configuration). The boost regulator is the regulator that can only convert an input voltage that is equal to or lower than the desired voltage on the output. Figure 3 illustrates the simplified block diagram of the boost regulator. Referencing Figure 3, the boost regulator operates by driving the Q1 power transistor with a duty cycle ratio computed by dividing the on-time of the Q1 power transistor divided by the total period of a switching cycle as depicted by the waveforms in Figure 3. The boost regulator is controlled by an internal clock that causes it to switch ounce every cycle, except during light load conditions where many boost regulators vary the switching frequency to maximize efficiency. The output voltage is computed by the duty

IoT EmdeddedModule

Low Power RFTransceiver

DRAM/FLASH

RTCµC

Sensors

Ambient Light/Proximity Sensing

MEMS:Motion Sensing

IoT EmdeddedModule

Low Power RFTransceiver

DRAM/FLASH

RTCµC

Sensors

Ambient Light/Proximity Sensing

MEMS:Motion Sensing

Figure 1: Fundamental IoT embedded module components

lash

EEWeb PULSE TECH ARTICLE

29Visit www.eeweb.com

cycle control of the Q1 power transistor. The Q2 power transistor complements the Q1 power transistor (minus some non-overlap time that is enforced to prevent shoot through currents that can damage the power transistor configuration). As can be noted, the boost and buck regulators can be constructed with only two power transistors.

Continued in Part 2...

References:[1] Kevin Ashton, “That ‘Internet of Things’ Thing,” RFID Journal, 22 June 2009. (http://www.rfidjournal.com/article/view/4986) Retrieved 27 November 2012.

[2] Elise Ackerman, “Could An Internet Of Things Startup Be The Next Microsoft? Three Hobby Kits Hold Promise,” Forbes (QUBITS blog), 4 November 2012. (http://www.forbes.com/sites/eliseackerman/2012/11/04/could-an-internet-of-things-startup-be-the-next-microsoft-three-hobby-kits-hold-promise/) Retrieved 27 November 2012.

[3] Bin Guo, Daqing Zhang, and Zhu Wang, “Living with Internet of Things: The Emergence of Embedded Intelligence,” IEEE International Conference on Internet of Things, and Cyber, Physical and Social Computing, 2011, pp. 297-304.

[4] Steve Lohr, “Looking to Industry for the Next Digital Disruption,” The New York Times, 23 November 2012. (http://www.nytimes.com/2012/11/24/technology/internet/ge-looks-to-industry-for-the-next-digital-disruption.html?adxnnl=1&ref=stevelohr&adxnnlx=1354215868-ZSECTykr3eE1WWREYeeRYw) Retrieved 26 November 2012.

About the AuthorRoderick Bacon is a Staff Strategic Applications Engineer at Intersil. He joined Intersil in August of 2012. Prior to Intersil, and since 1999, he has held positions in IC design, applications, and product definition within power management. He received a BSEE in 1999 from the University of California at Davis (UC Davis).

VIN

CIN

COUT

ON

ON

OFF

OFF

Q1

L

Q2

Q1

DUTY CYCLE [D]=

Q2

VOUT

SwitchingPeriod

ON[tON_Q1]Switching Period[TQ1]

ControlCircuitry

D= =tON

TVOUT

VIN

Figure 2: Buck regulator simplified block diagram, power transistor waveforms and duty cycle computation.

Figure 3: Boost regulator simplified block diagram, power transistor waveforms, and duty cycle computation.

VIN

CIN

COUT

ON

ON

OFF

OFF

Q1

L

Q2

Q1

DUTY CYCLE [D]=

Q2

VOUT

SwitchingPeriod

ON[tON_Q1]Switching Period[TQ1]

ControlCircuitry

D= =tON

TVOUT–VIN

VOUT

Transform Your iPhone, iPad or iPod into an Oscilloscope

with the iMSO-104

Experience the iMSO-104 as Joe Wolin, co-founder of EEWeb,

gives you an in-depth look into the future of oscilloscopes.

2012

UBM ELECTRONICSUBM ELECTRONICS

WINNER

Begin Your Experience NowBegin Your Experience Now

NXP’s proven interface products enable medical and health system designers

to add features with minimal modifications. Within our portfolio you’ll find LCD

displays and capacitive touch interfaces, system connectivity bridges & UARTs, LED

controllers, real-time clocks, and I2C-bus peripherals & enablers.

To learn more, visit http://www.nxp.com/campaigns/medical-interfaces/2248

Breathe new life into medical product interfaces