Dynamic Ionizing Blower Station Static Combi Cleaner SCC · Static Combi Cleaner allows it to be...

Transcript of Dynamic Ionizing Blower Station Static Combi Cleaner SCC · Static Combi Cleaner allows it to be...

electrostatic innovations

electrostaticdischarging

Dynamic Ionizing Blower Station Static Combi Cleaner SCC

Unbeatable results –ultimate flexibility in use

1

Mode of function:

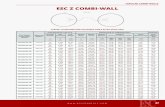

Ionizing bars attached at the inlet and outlet point neutralize the plastic surfaces. The patented variable-speed rotary nozzles mounted in-between capture the particles carrying static charges and propel them in the direction of the extraction channel where they are eliminated safely and thoroughly. The integrated variable-speed control of the cleaning nozzles keeps an even and pressure-independent rotary speed that, in turn, guarantees a consistent and excellent cleaning result with its pulsating and highly efficient air cleaning effect. Rotary speed and air velocity can be adapted to optimized cleaning requirements. The Static Combi Cleaner is made in various installation sizes. The number of nozzles depends on the size and shape of the components to be cleaned. Working width and extraction direction are adjustable depending on customer requirements.

Most plastic and synthetic materials in use today have a very strong tendency to create static surface charges, with the effect that the surfaces have a similarly powerful tendency to attract air-borne particles. This can result in major problems and loss of quality during certain processes. Eliminating dust and dirt settling on three-dimensional and structured surfaces with conventional methods is noto-riously difficult. Due to their geometry, components such as product carriers that are in continuous revolving operation are also very difficult to clean down. The dynamic ionizing blower station has been specially developed for applications such as these.

The system is perfect for upstream installation ahead of painting plants, for instance for:

Car industry• Plastictrims,dashboards,carbumpers• Diffusinglensesandother automotive parts• Cleaningextrusionsheetmetalpanels

Electrical industry•Mobiletelephonecasings, displays, work piece carriers, trays, TV components

Printing industry• Padprinting,UVcoatingforscreen printing, vignette embossing

Furniture and chipboard manufacture• Cleaningthechipboardafter short-cycle laminating presses• Furnitureandresin-bondedboard cleaning

Plastic injection molding: • Blowingoutinjectionmolds after ejection

Clear benefits, many options – the Static Combi Cleaner convinces in many production processes

electrostaticinnovations

2

Y Non-contacting surface cleaning, no brushes, no height adjustment

Y No extra dust elimination work

Y Enhanced production quality

Y Smooth production processes

Y Minimized costs, fewer downtimes

The Static Combi Cleaner works in an embedded system and removes troublesome dust and material particles from car parts before painting. The particles removed in this station are carried to a filtered extraction station by applying a target directed air blast. Unwanted dust and production particles on surfaces are cleaned safely and fully before painting.

BEnEFITSCleaning car bumpers

Cleaning motorbike fairings

Cleaning of wheel-rims

Cleaning car diffusing lenses

electrostaticinnovations

3

Integrated ionizing bars remove static charges from the work pieces. At the heart of the system are rotating cleaning nozzles with speed control which uses cleaned compressed air to remove all particles from the surface of the work pieces.The rotary speed control guarantees the even, pressure-independent and pulsating effect of the compressed air and accom-plishes a consistent and perfect cleaning result. The particles whirl up and are vacuumed off upwards. Working width and extraction direction are adjustable depending on customer requirements.

Integrated solution – Static Combi Cleaner SCC with extraction enclosure

Combi Cleaner for cleaning mobile phone displays:Discharge bars mounted in the inlet and outlet of the extraction enclosure, speed-controlled rotating nozzle and side-mounted extraction nozzle

Custom design for cleaning cable rolls

4

Ideal for complex requirements

Cleaning equipped and non-equipped product carriers and traysDue to their geometry, components such as product carriers that are in continuous revolving operation are difficult to clean down. Our Static Combi Cleaner has been specially developed for applications such as these.

In line with a wide variety of different requirements, the Static Combi Cleaner for non-contacting cleaning is available in various systems and sizes for …

… cleaning car trim parts… cleaning car diffusing lenses… cleaning IMD parts… cleaning plastic components… in embossing machines

Here are just some examples from a number of very different production processes.

Cleaning electronic PCBs before equippingDuring the fully automated production process, machining and abrasion dust is removed from the conveyor system.

Cleaning plastic parts in screen printing or pad printingBefore the actual printing process, the surface to be printed is cleaned and static charges are neutralized to avoid further pollution. Dust and particles are extracted and carried into a filter station.

The rotating cleaning nozzles with speed control remove dust particles or punching chips from the work piece carriers. The particles are whirled up and vacuumed off via the lateral, bottom-mounted extraction enclosures.Induction sensors with logic control guarantee the exact time-controlled actuation of the cleaning nozzles and prevent unnecessary air consumption.

5

Plastic board cleaning / laminating unitCleaning high-gloss boards ahead of a foil laminating unit. Hydraulic rotating cleaning nozzles generate a pulsating air flow (greater than 100m/s), lift the particles off the surface of board and propel them in the direction of the extraction channel.The two-sided Static Combi Cleaner operates without making contact and without the need for adjustment to match the thickness of the board. No height adjustment is required. Benefits: As the system has no wearing parts such as brushes, it is virtually maintenance-free.

Chipboard surface cleaningThe projecting sections of the melamine coating are trimmed at the edges of the chipboard panel. The conventional practice of blowing off the particles or melamine chips with fishtail nozzles provided an inadequate surface cleaning effect. The outcome: loss of quality caused by dents and indentations during final stacking. Things are different when using the Static Combi Cleaners whose rotating nozzles generate a pulsating air flow, lift off the particles and carry them into a central dis-posal unit. The result: An optimum cleaning quality which meets the most exacting stan-dards.Retrofitting into existing edge cleaning units is easy and has been readily and successfully adopted by many chipboard manufacturers.

Cleaning laminated floor boardsWithout making contact, the rotating cleaning nozzles catch the statically discharged milling particles and propel them in the direction of the extraction channel.Rotary speed and air velocity are adapted to optimize cleaning requirements.The unit operates without brushes and moistening system.Working width and extraction station are adapted to suit customer requirements.

Clean solutions for wooden flooring production, chipboard and furniture industry

electrostaticinnovations

6

nCS-16 system for the permanent and simultaneous monitoring of as many as 16 rotating cleaning nozzles.

Clear benefits with the dynamic ion blower stationThe integrated variable-speed control of the cleaning nozzles keeps an even and pressure independent rotary speed that, in turn, guarantees a consistent and excellent cleaning result with its pulsating and highly efficient air cleaning effect even at larger distances.Unit dimensions and design are adjustable to individual customer requirements.

Unique cleaning results to the power of three – three-dimensional surfaces

No good painting results without clean surfaces. To ensure ultimate cleanliness, many different methods have been used in practice, ranging from dust-binding cloths, air pistols and air strips right through to brush systems and even ostrich feathers. And none with sustained and satisfactory results, particularly when it comes to three-dimensional surfaces.

7

By changing the working nozzles, the air velocity can be adapted to suit the requirements of optimized cleaning.

The cleaning blow angle of the working nozzles is infinitely variable and has no effect on the nozzle rotation speed.

The integrated speed control keeps the nozzle rotation speed at a constant level, regardless of operating pressure.

The precision ball bearings are easy to exchange.

The optional electronic NCS-16 monitoring system allows the function of the rotating nozzles to be permanently monitored, for instance at concealed installation points.

BEnEFITS

Uncompromisingly clean surfaces for perfect paint results – guaranteed with the Static Combi Cleaner!

Y

Y

Y

Y

Y

electrostaticinnovations

8

Effective cleaning of metal parts before powder coating

Metal parts are sand-blasted and auto-matically fed to the painting station. This generates dust deposits which cause substandard painting results. Owing to the different shapes of the metal, brush system are also unable to fully remove these deposits.

The effective alternative: the non-contacting Static Combi Cleaner. Its rotating nozzles can be individually enabled and disabled, rapidly matching the size and shape of the metal parts. Problem zones such as flask base or flask head can be cleaned with perfect results by realigning the direction of the nozzles.

The pressurized flasks shown in the picture rotate round their own axis in the operating zone of the Static Combi Cleaner. All the surfaces are cleaned without making contact via the rotating nozzles using pulsating compressed air, before the flasks move into the powder coating station. Using a sensor and a magnetic valve, the rotating nozzles are controlled and activated only as required.

9

The extremely compact design of the Static Combi Cleaner allows it to be adapted to virtually any handling system. The dynamic ionizing equipment eliminates static charges from metal parts and makes sure that the plastic particles, once removed, do not settle on other parts of the mold. Matching the outlines or the problem area of the tool, different nozzle geometries can be used.

After the tool opens, the handling system removes the plastic parts. During the extension movement in the x- or y-axis, the compressed-air operated rotating nozzles use a pulsating air flow to eliminate deposits fully from the injection mold.Another option exists involving the movement of the moldings in the Static Combi Cleaner zone with extraction function after the parts are removed by a handling or robot system.

Compact efficiency – cleaning injection molds with ionized air

electrostaticinnovations

10

Manual ionization blower pistol for use in explosion hazard zones EXPR36

The Eltex ionization blower pistol for use in explosion hazard zones is used mainly in paintshops. Before painting, the parts are blown off with ionized air and carried to the painting station totally free of dust.

Manual ionization blower pistol with rotating compressed air nozzle PR36 and EXPR36

The convenient PR36 ionization blower pistol allows the perfect cleaning of all statically charges workpieces. The centrally located ionization tips and the rotating air nozzles remove every trace of dust and particles. The specific speed of rotation and the infinitely adjustable angle of contact of the cleaning nozzles make the PR36 a true multitalent in a wide variety of applications and uses.This blower pistol is also available in EX-version.

Best ionizing effect in handy size

electrostatic innovations

Eltex-Elektrostatik-GmbHBlauenstraße 67 – 6979576 Weil am Rhein, GermanyPhone +49 7621 7905-230 Fax +49 7621 [email protected] www.eltex.com