dennisbuilding.com.audennisbuilding.com.au/img/download/04 Drawings...a3 not to scale plans &...

Transcript of dennisbuilding.com.audennisbuilding.com.au/img/download/04 Drawings...a3 not to scale plans &...

SCALE :

PROJECT MGR :

DATE :

DRAWN :

DRG SIZE :

DESIGN :

WWW.JONESNICHOLSON.COM.AU

THE CONCEPTS AND INFORMATION CONTAINED IN THEDOCUMENT ARE THE COPYRIGHT OF JONES NICHOLSONPty. Ltd. USE OR COPYING OF THE DOCUMENT WITHOUTWRITTEN PERMISSION OF JONES NICHOLSON Pty. Ltd.CONSTITUTES AN INFRINGEMENT OF COPYRIGHT STRUCTURAL DESIGN

ABN: 51 003 316 032CIVIL STRUCTURAL BUILDING SERVICES. .

LAND & HOUSING

CORPORATION

NOV '14

GS

GS

GS

A3NOT TO SCALE

PLANS &DETAILS

Elizabeth St, Kettle & Walker St. 130277

GENERAL

1. THESE DRAWINGS SHALL BE READ IN CONJUNCTION WITH ALL ARCHITECTURAL

AND OTHER CONSULTANTS' DRAWINGS AND SPECIFICATION AND WITH SUCH

OTHER WRITTEN INSTRUCTION AS MAY BE ISSUED DURING THE COURSE OF

THE CONTRACT. ANY DISCREPANCY SHALL BE REFERRED TO THE

SUPERINTENDENT BEFORE PROCEEDING WITH THE WORK.

2. ALL MATERIALS AND WORKMANSHIP SHALL BE IN ACCORDANCE WITH THE

RELEVANT AND CURRENT AUSTRALIAN STANDARDS AND THE NATIONAL

CONSTRUCTION CODE SERIES EXCEPT WHERE VARIED BY THE PROJECT

SPECIFICATION.

3. ALL DIMENSIONS SHOWN SHALL BE VERIFIED BY THE BUILDER ON SITE.

ENGINEERS' DRAWINGS SHALL NOT BE SCALED FOR DIMENSIONS.

4. DURING CONSTRUCTION THE STRUCTURE SHALL BE MAINTAINED IN A STABLE

CONDITION AND NO PART SHALL BE OVERSTRESSED. TEMPORARY BRACING

SHALL BE PROVIDED BY THE BUILDER TO KEEP THE WORKS AND

EXCAVATIONS STABLE AT ALL TIMES.

5. THE BUILDER SHALL GIVE 48 HOURS NOTICE FOR ALL ENGINEERING

INSPECTIONS.

6. THE BUILDER SHALL LOCATE ALL EXISTING SERVICES PRIOR TO

COMMENCEMENT OF CONSTRUCTION. ENGINEER TO BE NOTIFIED.

7. UNLESS NOTED OTHERWISE ALL LEVELS ARE IN METRES AND ALL DIMENSIONS

ARE IN MILLIMETRES.

8. ALL PROPRIETY ITEMS TO BE INSTALLED IN ACCORDANCE WITH

MANUFACTURES SPECIFICATIONS & DETAILS.

FOUNDATIONS & EARTHWORKS

1. THIS FOUNDATION MATERIAL SHALL BE UNIFORM AND BE APPROVED BY A

GEOTECHNICAL ENGINEER FOR THE ALLOWABLE BEARING PRESSURE BEFORE

PLACING REINFORCEMENT OR CONCRETE. PIERS OR BLOCKDOWNS SHALL BE

USED TO ACHIEVE UNIFORM BEARING WHERE NECESSARY.

2. THIS SITE CLASS HAS BEEN DESIGNED IN ACCORDANCE WITH AS 2870

(WHERE APPLICABLE). CONFIRMATION OF SITE CLASSIFICATION IS REQUIRED

BY A GEOTECHNICAL ENGINEER PRIOR TO CONSTRUCTION COMMENCING ON

SITE.

3. FOOTINGS SHALL BE CONCRETED ON THE DAY OF APPROVAL UNLESS

PERMISSION IS GIVEN OTHERWISE.

4. FOOTINGS SHALL BE LOCATED CENTRALLY UNDER WALLS AND COLUMNS

UNLESS NOTED OTHERWISE.

5. BACKFILL TO RETAINING WALLS SHALL BE FREE DRAINING GRANULAR

MATERIAL. PROVIDE SUBSOIL DRAIN AT BASE OF WALL. DO NOT BACKFILL

UNTIL 14 DAYS AFTER CORE FILLING, OR IF APPLICABLE, AFTER RESTRAINING

SLAB OVER HAS BEEN POURED AND CURED FOR 7 DAYS. BACKFILL SHALL BE

COMPACTED TO 98% STANDARD MAXIMUM DRY DENSITY AT OPTIMUM

MOISTURE CONTENT ±2%.

6. FOOTING LEVELS WHERE SHOWN ARE ESTIMATES ONLY AND WILL BE

ESTABLISHED DURING SITE INSPECTION OF WORK IN PROGRESS.

7. PROVIDE ADEQUATE BATTERS OR SHORING TO THE SIDE OF ALL

EXCAVATIONS. REFER TO GEOTECHNICAL ENGINEER FOR RELEVANT ADVICE.

FOOTING

BEARING SURFACE

PIERS IF REQUIRED

2

1

EXCAVATION

I00

EXCAVATION IN ROCK

1. THE CONTRACTOR SHALL SUBMIT HIS PROPOSAL FOR EXCAVATION TO THE

SUPERINTENDENT PRIOR TO COMMENCEMENT OF WORK.

2. THE METHOD SHALL COMPLY WITH ALL THE REQUIREMENTS OF THE DA

CONDITIONS, PARTICULARLY IN RELATION TO NOISE LEVELS, VIBRATION AND

WORK HOURS.

3. VIBRATIONS SHALL NOT EXCEED THAT SPECIFIED IN THE GEOTECHNICAL

REPORT AND ALARMS SHALL BE INSTALLED TO MONITOR THESE

VIBRATIONS. U.N.O.

4. ALL THE REQUIREMENTS OF THE GEOTECHNICAL REPORT FOR THE SITE

SHALL BE OBSERVED AND MET.

CONTRACTOR DESIGNED PILES

1. THE PILES ARE TO BE DESIGNED, INSTALLED AND CERTIFIED BY THE

CONTRACTOR FOR THE LOADS INDICATED ON THE DRAWINGS.

2. THE DESIGN LIFE OF THE PILES IS TO BE A MINIMUM OF 50 YEARS UNLESS

NOTED OTHERWISE IN THE PROJECT INFORMATION TABLE.

3. DESIGN AND INSTALLATION OF PILES IS TO BE IN ACCORDANCE WITH AS2159

AND TO INCLUDE ALLOWANCE FOR INDUCED MOMENTS IN PILES DUE TO

CONSTRUCTION TOLERANCES.

INSITU BORED CONCRETE PILES

1. ALL WORKMANSHIP AND MATERIALS SHALL BE IN ACCORDANCE WITH

AS2159 PILING DESIGN & INSTALLATION CURRENT EDITIONS WITH

AMENDMENTS, EXCEPT WHERE VARIED BY THE CONTRACT DOCUMENTS.

2. ALL DESIGN AND INSTALLATION SHALL BE COMPLETED BY AN EXPERIENCED

CONTRACTOR SPECIALISING IN FOUNDATION ENGINEERING AND SHALL BE IN

ACCORDANCE WITH AS2159.SUBMIT DETAILS OF PROPOSED DRILLING

METHODS, EQUIPMENT AND SEQUENCE. GIVE NOTICE SO THAT INSPECTION

MAY BE MADE OF THE FOLLOWING AS APPLICABLE:

- AT COMPLETION OF EXCAVATION OF PIERS

- REINFORCEMENT OF PIER

3. SETTING OUT - PEG THE POSITION OF EACH PILE AND ESTABLISH A GRID

OF RECOVERY PEGS TO ENABLE THE SETTING OUT TO BE CHECKED AT ANY

TIME. PILES AND OR PIERS SHALL BE LOCATED WITHIN 75mm OF THE PLAN

LOCATIONS AS SHOWN ON THE ENGINEERING DRAWINGS.

4. PIERS SHALL BE POURED WITHIN 24 HOURS OF EXCAVATION UNLESS

OTHERWISE AGREED.

5. PIER WALL SHALL BE MAINTAINED STABLE PRIOR TO POURING CONCRETE.

6. PIER BASES SHALL BE LEVEL AND FREE OF ALL LOOSE MATERIAL.

7. REMOVE ALL FREE WATER FROM PIERS BEFORE POURING.

8. CONFIRM BEARING PRESSURE AT BASE OF ALL PIERS BY GEOTECHNICAL

TESTING/INSPECTIONS.

9. CONCRETE SHALL BE PLACED IN SUCH A MANNER SO AS TO AVOID

SEGREGATION.

10. REFER ALSO TO CONCRETE NOTES.

11. THE PILE DEPTHS SHOWN ON THE ENGINEERS DRAWINGS ARE PROVISIONAL.

ACTUAL PILE LENGTHS ARE TO BE MEASURED BY THE CONTRACTOR AND

APPROVED BY THE SUPERINTENDENT.

12. OBSERVE SAFE-WORKING PRACTICES, INCLUDING THE RELEVANT PRACTICES

RECOMMENDED IN AS2159 APPENDIX B.

13. PROVIDE & INSTALL FACILITIES NECESSARY FOR INSPECTION OF PILING

INCLUDING SAFE ACCESS, LIGHTING, VENTILATION AND THE LIKE.

14. REFER TO DRAWINGS FOR ALL OTHER PIER INFORMATION.

15. RECORD THE RELEVANT INFORMATION AS LISTED IN AS2159. AND FORWARD

TO ENGINEER/SUPERINTENDENT COPIES OF EACH RECORD TO THE

SUPERINTENDENT.

16. PROVIDE A SURVEY OF ALL PILES/PIERS AFTER INSTALLATION INCLUDING

THE LENGTH FROM THE UNDERSIDE OF THE PILE CAP OR FOUNDATION,

BEAM TO THE TOE OF THE PILE/PIER AND THE LEVEL OF THE

SURROUNDING GROUND AT THE TIME WHEN THE PILE IS INSTALLED.

TEMPORARY ANCHORS AND ROCKBOLTS

1. TEMPORARY GROUND ANCHORS AND ROCKBOLTS ARE TO BE DESIGNED,

INSTALLED, TESTED AND CERTIFIED BY THE CONTRACTOR FOR THE LOADS

INDICATED ON THE DRAWINGS.

2. THE DESIGN LIFE OF THE TEMPORARY ANCHORS IS TO BE A MINIMUM OF 2

YEARS UNLESS NOTED OTHERWISE.

3. PROVIDE DESIGN DETAILS, INSTALLATION METHOD STATEMENTS AND TESTING

PROPOSAL TO ENGINEER FOR REVIEW BEFORE COMMENCING ON SITE.

4. CONTRACTORS DESIGN TO INCLUDE ALL PARTS OF THE GROUND ANCHORS,

ANCHOR HEADS AND BEARING PLATES ETC.

5. ANCHORS ARE TO BE INSTALLED WITH THE RESIDUAL LOAD AS SPECIFIED ON

THE DRAWINGS. IF NO RESIDUAL LOAD IS STATED, REQUEST CLARIFICATION

FROM THE ENGINEER.

6. REFER TO GEOTECHNICAL REPORT FOR DESIGN PARAMETERS.

CONCRETE

1. ALL WORKMANSHIP AND MATERIALS SHALL BE IN ACCORDANCE WITH AS

3600 AND AS 3610 CURRENT EDITIONS WITH AMENDMENTS, EXCEPT WHERE

VARIED BY THE CONTRACT DOCUMENTS.

2. PROJECT CONTROL TESTING SHALL BE CARRIED OUT IN ACCORDANCE WITH

AS 3600.

3. CONCRETE TO BE PROPORTIONED TO LIMIT DRYING SHRINKAGE TO SATISFY

PROJECT INFORMATION TABLE.

4. NO ADMIXTURES SHALL BE USED IN CONCRETE UNLESS APPROVED IN

WRITING.

5. CLEAR CONCRETE COVER TO ALL REINFORCEMENT SHALL BE AS NOTED IN

THE PROJECT INFORMATION TABLE UNLESS SHOWN OTHERWISE.

6. WHERE CONCRETE IS POURED ON A VAPOUR PROOF MEMBRANE 0.2mm

MINIMUM THICKNESS, THE COVER TO CONCRETE CAST AGAINST GROUND MAY

BE REDUCED BY 10mm.

7. CONCRETE SIZES SHOWN DO NOT INCLUDE THICKNESS OF APPLIED FINISHES.

NO FINISH WHICH DECREASES COVER IS ALLOWED WITHOUT THE WRITTEN

APPROVAL OF THE ENGINEER.

8. DEPTHS OF BEAMS ARE GIVEN FIRST AND INCLUDE SLAB THICKNESS.

9. FOR CHAMFERS DRIP GROOVES, REGLETS, ETC. REFER TO ARCHITECT'S

DETAILS. MAINTAIN COVER TO REINFORCEMENT AT THESE DETAILS.

10. NO HOLES, CHASES, BLOCKOUTS, DUCTS OR EMBEDMENT OF PIPES OTHER

THAN THOSE SHOWN ON THE STRUCTURAL DRAWINGS SHALL BE MADE IN

CONCRETE MEMBERS WITHOUT THE PRIOR WRITTEN APPROVAL OF THE

ENGINEER.

11. CONSTRUCTION JOINTS WHERE NOT SHOWN SHALL BE LOCATED TO THE

APPROVAL OF THE ENGINEER.

12. ALL CONCRETE COLUMNS GREATER THAN 1.2 METRES IN HEIGHT SHALL BE

POURED A MINIMUM OF 4 HOURS PRIOR TO SLAB OR BEAM OVER.

13. CONCRETE SHALL BE MECHANICALLY VIBRATED TO ACHIEVE A DENSE

HOMOGENEOUS MASS COMPLETELY FILLING THE FORMWORK THOROUGHLY

EMBEDDING THE REINFORCEMENT AND FREE OF STONE POCKETS OR VOIDS.

ALL CONCRETE INCLUDING SLABS ON GROUND AND FOOTINGS SHALL BE

COMPACTED WITH MECHANICAL VIBRATORS.

14. CURING OF ALL CONCRETE IS TO BE ACHIEVED BY KEEPING SURFACES

CONTINUOUSLY WET FOR A PERIOD OF THREE DAYS, AND THE PREVENTION

OF LOSS OF MOISTURE FOR A TOTAL OF 7 DAYS FOLLOWED BY A

GRADUAL DRYING OUT. CURING COMPOUNDS MAY BE USED BUT MUST BE

COMPATIBLE WITH THE PROPOSED FLOOR FINISHED & BE INSTALLED IN

ACCORDANCE WITH MANUFACTURERS SPECIFICATIONS. POLYTHENE SHEETING

OR WET HESSIAN MAY BE USED IF PROTECTED FROM WIND AND TRAFFIC.

15. CONSTRUCTION SUPPORT PROPPING IS TO BE LEFT IN PLACE WHERE

NEEDED TO AVOID OVERSTRESSING THE STRUCTURE DUE TO CONSTRUCTION

LOADING. NO BRICKWORK OR PARTITION WALLS ARE TO BE CONSTRUCTED

ON SUSPENDED LEVELS UNTIL SEVEN DAYS AFTER PROPPING HAS BEEN

REMOVED AND THE SLAB PRE-LOADED WITH THE BRICKS OR UNITS TO BE

USED IN THE WALL.

16. REPAIRS TO CONCRETE SHALL NOT BE ATTEMPTED WITHOUT THE

PERMISSION OF THE ENGINEER.

17. CAST-IN FIXINGS, BOLTS ETC. SHALL NOT BE ALTERED WITHOUT THE

PERMISSION OF THE ENGINEER.

18. THE CONCRETE SHALL BE PLACED IN SUCH A MANNER AS TO AVOID

SEGREGATION OR LOSS OF MATERIALS. MAXIMUM FALL OF CONCRETE =

1500mm OR USE ENCLOSED CHUTES OR SIMILAR.

19. SULPHATE RESISTANT CONCRETE TO BE USED IN ALL FOOTINGS, PILES AND

PILE CAPS IF REQUIRED BY THE PROJECT DESIGN INFORMATION.

REINFORCEMENT

1. REINFORCEMENT IS REPRESENTED DIAGRAMMATICALLY AND NOT

NECESSARILY IN TRUE PROJECTION.

2. SPLICES IN REINFORCEMENT SHALL BE MADE ONLY IN POSITIONS SHOWN OR

0THERWISE APPROVED IN WRITING BY THE ENGINEER. LAPS SHALL BE IN

ACCORDANCE WITH THE LAP TABLE.

3. WELDING OF REINFORCEMENT SHALL NOT BE PERMITTED UNLESS SHOWN ON

THE STRUCTURAL DRAWINGS OR APPROVED BY THE ENGINEER.

4. FABRIC SHALL BE LAPPED 2 TRANSVERSE WIRES PLUS 50mm. WHERE

FABRIC LAPS, SHEETS TO HAVE MAXIMUM 2 LAYERS AT ANY POINT, CUT

BACK FABRIC AT CORNERS AS REQUIRED.

5. BUNDLED BARS SHALL BE TIED TOGETHER AT 30 BAR DIAMETER CENTERS

WITH 3 WRAPS OF THE WIRE.

6. FIRE RATING MESH F41 SHALL BE GALVANISED, HAVE 20mm COVER AND BE

TIED USING GALVANISED TIE WIRE

7. WHERE TRANSVERSE TIE BARS ARE NOT SHOWN PROVIDE N12-400 LAPPED

AS REQUIRED.

8. JOGGLES TO BARS SHALL COMPRISE A LENGTH OF 12 BAR DIAMETERS

BETWEEN BEGINNING AND END OF AN OFFSET OF 1 BAR DIAMETER.

9. ALL REINFORCEMENT SHALL BE FIRMLY SUPPORTED ON MILD STEEL

PLASTIC TIPPED CHAIRS, PLASTIC CHAIRS OR CONCRETE CHAIRS AT NOT

GREATER THAN 1 METRE CENTRES BOTH WAYS, AND 800 EACH WAY FOR

FABRIC. WHEN POURED ON GROUND PROVIDE PLATES UNDER ALL BAR

CHAIRS. PLASTIC TIPPED STEEL CHAIRS SHALL NOT BE USED ON EXPOSED

FACES.

10. REINFORCEMENT WITHIN FLOOR OR WALL ELEMENT OF A WET AREA SHALL

BE BONDED TO THE EARTHING SYSTEM IF CONDUCTIVE PIPING EXISTS WITHIN

THE ELEMENT. IT SHALL BE BONDED IN ACCORDANCE WITH AS 3000.

11. REINFORCEMENT SYMBOLS:

R- GRADE 250 R HOT ROLLED PLAIN BARS TO AS 4671

S- GRADE 230 S HOT ROLLED DEFORMED BARS TO AS 4671

N- DEFORMED BAR NORMAL DUCTILITY TO AS/NZS 4671 GRADE D500N

L- DEFORMED BAR LOW DUCTILITY TO AS/NZS 4671 GRADE D500L

RN- RECTANGULAR WIRE MESH NORMAL DUCTILITY TO AS/NZS 467

RL- RECTANGULAR WIRE MESH LOW DUCTILITY TO AS 4671

SN- SQUARE WIRE MESH NORMAL DUCTILITY TO AS 467

SL- SQUARE WIRE MESH LOW DUCTILITY TO AS/NZS 4671

12. THE LAP TABLES ARE BASED ON 32MPa CONCRETE WITH 25mm MINIMUM

COVER GENERALLY & 30mm COVER FOR BEAMS & COLUMNS.

TENSION LAP LENGTH FOR DEFORMED BARS IN

WALLS & SLABS LESS THAN 300mm THICK

N12

500

N16

700

N20

950

N24

1250

N28

-

N32

-

N36

-

TENSION LAP LENGTH FOR DEFORMED BARS IN

BEAMS, COLUMNS & SLABS GREATER THAN 300mm THICK

N12

600

N16

900

N20

1200

N24

1550

N28

1950

N32

2300

N36

2700

13. INCREASE TABULATED VALUES BY NOMINATED % IN THE FOLLOWING CASES

• 25MPa CONCRETE 15%

• SLIP FORM CONSTRUCTION INCREASE BY 30%

• LIGHTWEIGHT CONCRETE 30%

• 3 BUNDLE BARS 20%

• 4 BUNDLE BARS 33%

FORMWORK

1. THE DESIGN, CONSTRUCTION AND PERFORMANCE OF THE FORMWORK AND

FALSEWORK IS THE RESPONSIBILITY OF THE BUILDER.

2. DESIGN AND CONSTRUCTION AND STRIPPING TIMES SHALL COMPLY WITH AS

3610 AND AS 3600 UNLESS OTHERWISE APPROVED BY THE ENGINEER.

3. DURING CONSTRUCTION, SUPPORT PROPPING SHALL BE PROVIDED WHERE

LOADS FROM STACKED MATERIALS, FORMWORK AND OTHER SUPPORTED

SLABS INDUCE LOADS IN A SLAB OR BEAM WHICH EXCEED THE DESIGN LOAD

FOR STRENGTH OR SERVICEABILITY AT THAT AGE. ONCE THE NOMINATED 28

DAYS STRENGTH HAS BEEN ATTAINED, THESE LOADS SHALL NOT EXCEED

THE DESIGN SUPERIMPOSED LOADS SET OUT IN THE GENERAL NOTES.

4. IN MULTI-STOREY CONSTRUCTION SUFFICIENT PROPPING SHALL BE PROVIDED

AT LEVELS BELOW THE FLOOR BEING CAST. PROP REMOVAL IS TO BE

PROGRAMMED TO AVOID DISTRESS TO PREVIOUSLY CAST FLOORS. RE-SHORING

OR BACK-PROPPING IS SUBJECT TO THE APPROVAL OF THE PROJECT DESIGN

ENGINEER.

5. AREAS THAT ARE SUBJECT TO HIGH LOAD, HIGH STRESS OR THAT ARE

DEFLECTION SENSITIVE (ie CANTILEVERS) SHOULD BE BACKPROPPED FOR THE

DURATION OF CONSTRUCTION AND THEN DE-PROPPED FROM THE TOP TO THE

BOTTOM WHEN FULL CHARACTERISTIC STRENGTH HAS BEEN ACHIEVED.

6. THE FORMWORK SHALL BE DESIGNED TO RELY ON NO RESTRAINT OR SUPPORT

FROM THE PERMANENT STRUCTURE WITHOUT PRIOR APPROVAL FROM THE

PROJECT DESIGN ENGINEER.

7. FORMWORK SHALL BE DESIGNED TO ACCOMMODATE MOVEMENTS DUE TO

POST-TENSIONING.

8. DESIGN INFORMATION CONCERNING THE FOUNDATION FORMWORK SHALL BE

DETERMINED FROM THE CONDITIONS EXISTING ON SITE AT THE TIME OF

CONSTRUCTION. REFER ALSO TO THE GEOTECHNICAL REPORT WHERE

AVAILABLE.

9. UNLESS NOTED OTHERWISE PROVIDE UPWARD CAMBER TO FORMWORK OF

CANTILEVERS OF L/120, WHERE L IS THE SHORTEST PROJECTION BEYOND

COLUMN OR WALL FACE, AND TO FORMWORK OF SLABS WHERE NOTED ON

PLAN. MAINTAIN THE SLAB AND BEAM DEPTHS SHOWN.

10. FOR CONCRETE FINISHES & FORMWORK CLASS REFER TO ARCHITECTURAL

DOCUMENTATION.

CONSTRUCTION JOINTS

1. CONSTRUCTION JOINTS SHALL BE USED ONLY WHERE SHOWN ON THE

DRAWINGS, AND NO CONSTRUCTION JOINT SHOWN ON THE DRAWINGS SHALL

BE OMITTED UNLESS APPROVED IN WRITING BY THE SUPERINTENDENT.

LOCATION OF CONSTRUCTION JOINTS ARE SHOWN THUS CJ.

2. CONSTRUCTION JOINTS WHERE NOT SHOWN SHALL BE LOCATED TO THE

APPROVAL OF THE DESIGN ENGINEER.

LINTELS

1. UNLESS OTHER SUPPORT IS SPECIFIED, PROVIDE PROPRIETY LINTEL (PRE-

CAST OR GALINTEL) INSTALLED TO MANUFACTURERS SPECIFICATIONS FOR

ALL OPENINGS UNDER 3000mm

2. ALTERNATIVELY PROVIDE LINTELS IN ACCORDANCE WITH TABLE BELOW

(ONE TO EACH LEAF OF WALL)

3. REFER TO PROJECT DESIGN INFORMATION TABLE FOR DURABILITY

REQUIREMENT.

UP TO 1500mm

1500mm TO 2100mm

2100mm TO 3000mm

OVER 3000mm

SPAN

90 x 90 x 6 EA

100 x 100 x 6 EA

150 x 90 x 8 UA

REFER TO DETAILS

LINTEL

230mm LONGER THAN 0PENING

LENGTH

450mm LONGER THAN 0PENING

450mm LONGER THAN 0PENING

REFER TO DETAILS

STEELWORK

1. ALL WORKMANSHIP AND MATERIALS SHALL BE IN ACCORDANCE WITH AS 4100

AND AS 1554 EXCEPT WHERE VARIED BY THE CONTRACT DOCUMENTS.

2. ALL STEEL SHALL BE IN ACCORDANCE WITH AS 3678 AND AS 3679 TO GRADE

250 UNLESS NOTED.

3. A PDF COPY OF WORKSHOP FABRICATION DRAWINGS SHALL BE SUBMITTED TO

THE ENGINEER FOR REVIEW AT LEAST 14 DAYS PRIOR TO COMMENCEMENT OF

FABRICATION AND PERMISSION TO USE OBTAINED PRIOR TO FABRICATION.

PERMISSION TO USE DOES NOT RELIEVE THE BUILDER OF THE FULL

RESPONSIBILITY FOR DIMENSIONS, FIT AND COMPLIANCE WITH ARCHITECTURAL

AND ENGINEERING DRAWINGS.

4. ALL WELDS SHALL BE 6mm CONTINUOUS FILLET TYPE GP (GENERAL PURPOSE)

UNLESS NOTED OTHERWISE. BUTT WELDS SHALL BE COMPLETE PENETRATION

WELDS TO AS 1554. FOR STEEL LESS THAN 6mm THICK, FILLET WELD

THICKNESS TO MATCH THE BASE METAL THICKNESS.

5. ALL PLATES SHALL BE 10mm THICK UNLESS NOTED OTHERWISE.

6. STEELWORK TO BE CONCRETE ENCASED SHALL BE WRAPPED WITH F41

STEELWIRE FABRIC AND SHALL BE 50mm MINIMUM CONCRETE COVER TO THE

STRUCTURAL STEEL.

7. PROVIDE SEAL PLATES TO ALL HOLLOW SECTIONS. PROVIDE VENT HOLES TO

HOLLOW MEMBERS AND DRAIN HOLES TO ALL MEMBERS TO BE HOT DIP

GALVANISED.

8. STRUCTURAL STEELWORK SHALL HAVE THE SURFACE TREATMENT SPECIFIED

IN THE PROJECT INFORMATION TABLE.

9. THE BUILDER SHALL PROVIDE ALL CLEATS AND DRILL ALL HOLES NECESSARY

FOR FIXING STEEL TO STEEL AND TIMBER TO STEEL WHETHER OR NOT

DETAILED ON THE DRAWINGS.

10. ALL STRUCTURAL STEEL MEMBERS TO BE PROVIDED WITH THE FIRE RATING

TO NCC BCA REQUIREMENTS. PCA (or ARCHITECT) TO CONFIRM.

11. PURLINS & GIRTS - ALL GIRTS AND PURLINS TO BE PROVIDED WITH BRIDGING

AS SPECIFIED ON THE DRAWINGS. e.g. 2 ROWS OF BRIDGING INDICATES THAT

EACH SPAN OF THE PURLINS TO HAVE 2 ROWS OF BRIDGING. WHERE NO

BRIDGING IS DETAILED ON THE DRAWINGS PROVIDE THE MINIMUM BRIDGING

REQUIRED BY THE MANUFACTURER. MAXIMUM SPACING OF BRIDGING NOT TO

EXCEED 20 x DEPTH OF PURLIN.

12. WHERE A CONTINUOUS INSULATION LAYER IS REQUIRED ABOVE THE PURLINS

PROVIDE A BRADFORD ASHGRID SYSTEM (OR APPROVED EQUIVALENT)

INSTALLED IN ACCORDANCE WITH MANUFACTURERS SPECIFICATIONS

13. BOLTS:-

• 4.6/S: COMMERCIAL BOLTS OF GRADE 4.6 TO AS 111, SNUG TIGHTENED.

• 8.8/S: HIGH STRENGTH STRUCTURAL BOLTS OF GRADE 8.8 TO AS 1252, SNUG

TIGHTENED.

• 8.8/TB: HIGH STRENGTH STRUCTURAL BOLTS OF GRADE 8.8 TO AS 1252

FULLY TENSIONED TO AS 41000 AS A BEARING JOINT.

• 8.8/TF: HIGH STRENGTH STRUCTURAL BOLTS OF GRADE 8.8 TO AS 1252 FULLY

TENSIONED AS A FRICTION JOINT WITH FACING SURFACES LEFT UNCOATED.

• ALL BOLTS SHALL BE M20 GRADE 8.8/S UNLESS NOTED OTHERWISE.

• NO CONNECTION SHALL HAVE LESS THAN 2 BOLTS.

• ALL BOLTS, NUTS AND WASHERS TO BE GALVANISED TO AS 4680 TABLES 1

& 2.

• TB AND TF BOLTS TO BE INSTALLED USING APPROVED LOAD INDICATING

WASHERS, OR BY TURN OF NUT CONTROL OF TENSIONING.

TIMBER

1. ALL TIMBER DESIGN AND CONSTRUCTION SHALL BE TO AS 1720 OR AS 1684

WHERE APPROPRIATE. ALL SOFTWOOD SHALL BE GRADE MGP10 UNLESS

NOTED OTHERWISE. ALL HARDWOOD SHALL BE MINIMUM GRADE F11 U.N.O.

2. DURABILITY GRADE OF ALL TIMBERS TO COMPLY WITH THE PROJECT

INFORMATION TABLE.

3. ALL BOLTS IN TIMBER CONSTRUCTION SHALL BE MINIMUM M16 UNLESS NOTED

OTHERWISE AND SHALL BE GALVANISED. BOLTS SHALL BE RETIGHTENED AT

THE END OF THE MAINTENANCE PERIOD. ALL TRUSSES AND RAFTERS SHALL

BE FIXED TO TOP PLATE WITH METAL PLATE CONNECTORS

FRAMING AND BRACING

1. ALL BRACING AND TIE DOWNS TO BE IN ACCORDANCE WITH AS1684

2. UNLESS NOTED OTHERWISE PROVIDE THE MINIMUM FOR

3. ROOFS AND HORIZONTAL BRACING - USE DIAGONAL CROSS STRAP

BRACING THROUGHOUT ROOF. SCREW FIX TO EACH RAFTER,PURLIN OR

TRUSS AND SECURELY FASTEN TO TOP PLATE/BEAM AT ENDS.

4. STUD WALLS - STRAP TOP & BOTTOM PLATE TO A MINIMUM OF EVERY

SECOND STUD SECURE FLOOR PLATE TO SLAB BELOW WITH M12 CHEMICAL

ANCHORS AT 1200mm MAX CTS OR SECURE EVERY SECOND STUD TO

FLOOR BEARERS BELOW

5. MASONRY WALLS - FASTEN TOP PLATE TO BRICKWORK USING ROOF

STRAPS (SIMILAR M.E.T. 7.1 OR APPROVED EQUIVALENT) AT A MAXIMUM

OF 1200mm SPACING ANCHORED 15 C/S DOWN PROVIDE STRAPS EACH

SIDE OF ALL OPENINGS PROVIDE ADDITIONAL HOLD DOWNS AS DETAILED

6. VERTICAL BRACING - PROVIDE VERTICAL BRACING IN ACCORDANCE WITH

AS 1684. PROVIDE ADDITIONAL VERTICAL BRACING WHERE SHOWN AND AS

DETAILED ON THESE DRAWINGS

CONCRETE DESIGN

CEMENT TYPE

LIMIT DRYING SHRINKAGE AT 56 DAYS

SULPHATE RESISTANCE CONCRETE BELOW GROUND

PROVIDE 50mm SIDE COVER TO TIES FOR ALL BEAMS U.N.O.

ELEMENT STRENGTH COVER EXT COVER INT

- "GP"

- 800 MICRONS

- NO

PROJECT INFORMATION TABLE

STEELWORK FINISHES

INTERNAL

BUILT INTO MASONRY

EXTERNAL

LOCATION TYPE CODE

• FOR FINISH TYPE & CODE REFER TO STANDARD AS/NZS 2312

• FOR DECORATIVE FINISH REFER TO ARCHITECTURAL OR OWNERS

SPECIFICATIONS

ALK4

HDG 600

HDG 600

PAINT SYSTEM

GALVANISED

GALVANISED

GEOTECHNICAL INFORMATION

COMPANY REPORT No. DATED

NOT AVAILABLE

FOUNDATIONS

SITE CLASSIFICATION FOUNDATION MATERIAL ALLOW BEARING CAP

"M" CLAY 100 kPa

FOOTINGS

SLAB ON GROUND

25 MPa

32 MPa

50

40

-

25

THE TABLES BELOW ARE TO BE READ IN CONJUNCTION WITH THE

ADJACENT NOTES

EARTHQUAKE DESIGN PARAMETERS

IMPORTANCE LEVEL

SITE SUB-SOIL CLASS

ACCELERATION CO-EFFICIENT

DESIGN CATEGORY

= 2

= Be

= 0.08

= II

WIND DESIGN PARAMETERS

REGION

IMPORTANCE LEVEL

REGIONAL WIND SPEED

TERRAIN CATEGORY

TOPOGRAPHIC MULTIPLIER

= A2

= 2

= V500 = 45m/s

= 3

= 1.0

SAFETY IN DESIGNTHERE ARE INHERENT RISKS WITH CONSTRUCTING, MAINTAINING, OPERATING,

DEMOLISHING, DISMANTLING AND DISPOSING THIS DESIGN THAT ARE TYPICAL

OF SIMILAR DESIGNS. AS FAR AS IS REASONABLY PRACTICABLE RISKS HAVE

BEEN ELIMINATED OR MINIMISED THROUGH THE DESIGN PROCESS. HAZARD

CONTROLS MUST STILL BE IMPLEMENTED BY THE CONTRACTOR, OWNER OR

OPERATOR TO ENSURE THE SAFETY OF WORKERS.

• JONES NICHOLSON'S ASSESSMENT DID NOT IDENTIFY ANY UNIQUE RISKS

ASSOCIATED WITH THE DESIGN

Job No.

COOPER ST, MOREHEAD ST, WALKER ST REDFERN NSW

130277

STRUCTURAL DRAWING LIST

No. DRAWING LIST

S001 COVER SHEET

S002 DETAILS

COMPOSITE METAL DECKING1. PANELS TO BE INSTALLED IN ACCORDANCE WITH MANUFACTURERS DETAILS.

2. BEFORE PANELS ARE LAID, TOP COURSE OF BRICKWORK IS TO BE STRAIGHT

AND LEVEL. IF REQUIRED PROVIDE LAYER OF SMOOTH HARD MORTAR. SLIP

JOINTS SHALL BE PROVIDED AT ALL MASONRY SUPPORTS UNLESS NOTED

OTHERWISE.

3. BEFORE CONCRETE IS PLACED, ANY ACCUMULATED DEBRIS, GREASE OR ANY

OTHER SUBSTANCE WILL NEED TO BE REMOVED TO ENSURE CLEAN BONDING

SURFACE. ANY PONDED RAINWATER SHOULD BE REMOVED.

4. UNLESS NOTED OTHERWISE PROPPING OF METAL DECKING SHALL BE IN

ACCORDANCE WITH MANUFACTURERS SPECIFICATIONS.

5. PROPS SHOULD NOT BE REMOVED UNTIL CONCRETE HAS REACHED SPECIFIED

DESIGN STRENGTH

SAFETY UPGRADE WORKS STAGE 3 REDFERN

REDFERN STAGE 3 SAFETY UPGRADE

TENDER ISSUE

AMDT DATE BY DESCRIPTION

1 11.11.14 GS FOR TENDER2 22.11.14 GS Amended to attend architects comments

ST3 S10

SCALE :

PROJECT MGR :

DATE :

DRAWN :

DRG SIZE :

DESIGN :

WWW.JONESNICHOLSON.COM.AU

THE CONCEPTS AND INFORMATION CONTAINED IN THEDOCUMENT ARE THE COPYRIGHT OF JONES NICHOLSONPty. Ltd. USE OR COPYING OF THE DOCUMENT WITHOUTWRITTEN PERMISSION OF JONES NICHOLSON Pty. Ltd.CONSTITUTES AN INFRINGEMENT OF COPYRIGHT STRUCTURAL DESIGN

ABN: 51 003 316 032CIVIL STRUCTURAL BUILDING SERVICES. .

LAND & HOUSING

CORPORATION

NOV '14

GS

GS

GS

A3NOT TO SCALE

PLANS &DETAILS

Elizabeth St, Kettle & Walker St. 130277REDFERN STAGE 3 SAFETY UPGRADE

1N12 edge barall around

Typical edgethickening

All footings to be poured on natural, firm ground free fromroots and/or organic material, with a safe bearing capacityof 100 kPa

CONCRETE STRENGTH

RAFT SLABS f'c = 25 MPa

BONDEK SLAB f'c = 32 MPa

COVER TOREINFORCEMENTFootings 50 mmSlab on ground 40 mm topBondek 30 mm top

ACCESS WALKWAY TO No 60 - 62

PROPOSED RAFT SLAB UNDER RAMP

B

B

C

C

Proposed brick retainingwall over slab

Raft slab edgethickenings

Raft slabinternalthickenings

For reinforcement details, dimensions, recommendations, usesimilar details as per the typical garbage bay slab details.

B

B

Ramp up

CC

Expansion jointin Bondek

Expansion jointin Bondek

Direction ofBondek ribs

PROPOSED 130 THICK BONDEK SLAB RAMP

AMDT DATE BY DESCRIPTION

1 11.11.14 GS FOR TENDER

TENDER ISSUE

120 Thick slab SL82Top fabric, pouredon well compactedground

N12 bent barsat 200 mm ctsTotal length >=2000 mm

2 22.11.14 GS Amended to attend architects comments

BJ

BJ

ST3 S11

SCALE :

PROJECT MGR :

DATE :

DRAWN :

DRG SIZE :

DESIGN :

WWW.JONESNICHOLSON.COM.AU

THE CONCEPTS AND INFORMATION CONTAINED IN THEDOCUMENT ARE THE COPYRIGHT OF JONES NICHOLSONPty. Ltd. USE OR COPYING OF THE DOCUMENT WITHOUTWRITTEN PERMISSION OF JONES NICHOLSON Pty. Ltd.CONSTITUTES AN INFRINGEMENT OF COPYRIGHT STRUCTURAL DESIGN

ABN: 51 003 316 032CIVIL STRUCTURAL BUILDING SERVICES. .

LAND & HOUSING

CORPORATION

NOV '14

GS

GS

GS

A3NOT TO SCALE

PLANS &DETAILS

Elizabeth St, Kettle & Walker St. 130277REDFERN STAGE 3 SAFETY UPGRADE

100 100

10mm Abelflex with 10x10mastic sealant

1N12 edge barboth sides of joint

EXPANSION JOINT DETAILIN BONDEK SLAB (RAMP)

Install flashing tocreate drip

100 mm conventionalformwork each side of joint

Provide adequate ventilation tovoid under Bondek slab

SL82 Top fabric

230

Waterproofingby others`

350

Ag. line, gravelencased andconnected to freeoutlet`

110VOID`

For reinforcement use similar details as pergarbge bay slabs

1.0mm BondekSlip jointSLO (typ)

10mm Abelflex with 10x10mastic sealant

130 slab, SL82top fabric

N12 cross rods

Balustrade to BCAby others

N12-300 'L' bars,hob reinforcement.Height of hob toarchitects details

SECTION B-B

For slip joints 'SLO' overbrick walls use 2 layers ofmalthid

Raft slab

BUTT JOINT BJ10mm Abelflex with 10x10mastic sealant

Mass concrete

Massconcrete

SECTION C-CRAMP START

VOID

BONDEK

CONCRETEf'c = 25 MPa

CONCRETE f'c = 25 MPa

75mm minimumthickness ofconcrete topping

Provide 'BJ' type of jointsbetween all new concretetoppings and all surroundingvertical surfaces

SL82 Top and bottom forall topping thicknessest >= 150 mm

SL82 Top and bottom forall topping thicknesses150 > t >= 75 mm

EXISTING CONCRETE SLAB

BJ

Thin special topping,refer to separate detail

TYPICAL TOPPING DETAILS

For location of topping slabs refer to architectural plans

75

mm

ma

x

DETAIL FOR THIN TOPPINGSt < = 75 mm

Install a vapour proof membranethroughout to separate oldconcrete slab surface from newconcrete topping. Do NOT installmembrane in area where thintopping t < 75mm is required.

AMDT DATE BY DESCRIPTION

1 11.11.14 GS FOR TENDER

TENDER ISSUE

150

2 22.11.14 GS Amended to attend architects comments

SCALE :

PROJECT MGR :

DATE :

DRAWN :

DRG SIZE :

DESIGN :

WWW.JONESNICHOLSON.COM.AU

THE CONCEPTS AND INFORMATION CONTAINED IN THEDOCUMENT ARE THE COPYRIGHT OF JONES NICHOLSONPty. Ltd. USE OR COPYING OF THE DOCUMENT WITHOUTWRITTEN PERMISSION OF JONES NICHOLSON Pty. Ltd.CONSTITUTES AN INFRINGEMENT OF COPYRIGHT STRUCTURAL DESIGN

ABN: 51 003 316 032CIVIL STRUCTURAL BUILDING SERVICES. .

LAND & HOUSING

CORPORATION

NOV '14

GS

GS

GS

A3NOT TO SCALE

PLANS &DETAILS

Elizabeth St, Kettle & Walker St. 130277

For locations of new footpaths refer to architectural plans

AMDT DATE BY DESCRIPTION

1 11.11.14 GS FOR TENDER

TENDER ISSUE

REDFERN STAGE 3 SAFETY UPGRADE2 22.11.14 GS Amended to attend architects comments

ST3 S13

SCALE :

PROJECT MGR :

DATE :

DRAWN :

DRG SIZE :

DESIGN :

WWW.JONESNICHOLSON.COM.AU

THE CONCEPTS AND INFORMATION CONTAINED IN THEDOCUMENT ARE THE COPYRIGHT OF JONES NICHOLSONPty. Ltd. USE OR COPYING OF THE DOCUMENT WITHOUTWRITTEN PERMISSION OF JONES NICHOLSON Pty. Ltd.CONSTITUTES AN INFRINGEMENT OF COPYRIGHT STRUCTURAL DESIGN

ABN: 51 003 316 032CIVIL STRUCTURAL BUILDING SERVICES. .

LAND & HOUSING

CORPORATION

NOV '14

GS

GS

GS

A3NOT TO SCALE

PLANS &DETAILS

Elizabeth St, Kettle & Walker St. 130277AMDT DATE BY DESCRIPTION

1 11.11.14 GS FOR TENDER

TENDER ISSUE

LETTER BOXES

SF1 PF1

SF1 PF1

450

450

4-L12 TM Top

R6 Ties - 600 cts

4-L12 TM Btm

STRIP FOOTING 'SF1'

All footings to be poured on natural, firm ground free fromroots and/or organic material, with a safe bearing capacityof 100 kPa

REDFERN STAGE 3 SAFETY UPGRADE

LETTER BOXES & ISOLATED PIERS TYPICAL PLAN

LETTER BOXES & ISOLATED PIERS TYPICAL ELEVATIONS

Pad footing 'PF1' to be 500square x 450 deep massconcrete

2 22.11.14 GS Amended to attend architects comments

ST3 S14

SCALE :

PROJECT MGR :

DATE :

DRAWN :

DRG SIZE :

DESIGN :

WWW.JONESNICHOLSON.COM.AU

THE CONCEPTS AND INFORMATION CONTAINED IN THEDOCUMENT ARE THE COPYRIGHT OF JONES NICHOLSONPty. Ltd. USE OR COPYING OF THE DOCUMENT WITHOUTWRITTEN PERMISSION OF JONES NICHOLSON Pty. Ltd.CONSTITUTES AN INFRINGEMENT OF COPYRIGHT

ABN: 51 003 316 032CIVIL STRUCTURAL BUILDING SERVICES. .

LIGHTING SCHEDULE

TYPE DESCRIPTION LAMP MODEL MANUFACTURE (SUPPLIER)

B1 NEW VANDAL PROOF, SURFACE MOUNTED, VERTICALLY ALIGNED LED BATTEN AT 3000 AFFL 12W LED 4000K VANDALED PIERLITE

E-B1 REPLACE EXISTING BATTEN WITH NEW VANDAL PROOF, SURFACE MOUNTED, VERTICALLY ALIGNED LED BATTEN AT 3000 AFFL

12W LED 4000K VANDALED PIERLITE

E-B2 REPLACE EXISTING BATTEN NEW VANDAL PROOF LED BATTEN, MOUNTED ON EXISTING OUTREACH POLE AT 3000 AFFL

12W LED 4000K VANDALED PIERLITE

E-B3 REPLACE EXISTING BATTEN NEW VANDAL PROOF, CEILING MOUNTED, LED BATTEN AT 3000 AFFL

12W LED 4000K VANDALED PIERLITE

P1 NEW LED FITTING ON 4M ROUND MATT BLACK POLE TO MATCH 36W LED 4200K HEDO LED – 36 LED AURORA LIGHTING

E-P1 REPLACE EXISTING POLE AND FITTING WITH NEW LED FITTING ON 4M ROUND MATT BLACK POLE TO MATCH

36W LED 4200K HEDO LED – 36 LED AURORA LIGHTING

E-W1 REPLACE EXISTING WALL MOUNTED FLOOD LIGHT WITH NEW WALL MOUNTED FLOOD LIGHT AT 9000 AFFL

24W LED 4100K HUNTSMAN PIERLITE

D-B DELETE EXISTING BATTEN, MOUNTING KIT, WIRING AND CONDUIT AND MAKE SURFACE GOOD

D-P DELETE EXISTING POLE, LUMINAIRE AND MAKE SURFACE GOOD

DTDT

SEPT 14A1

1:100TS

STAGE 3 SAFTEY UPGRADE

Elizabeth St, Walker St & Kettle St,Redfern

FACS

130277E01 A

ELECTRICAL DESIGNNOTES, SCHEDULE &

LEGEND1 12.09.14 DT PRELIMINARY ISSUE

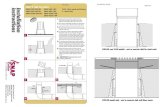

LIGHT POLE TO BE DESIGNED

AND DETAILED BY OTHERS

LIGHT POLE TO FOOTING

CONNECTION TO

MANUFACTURES SPECIFICATION

CABLES AND CONDUITS

IN GROUND

MARKER TAPE

TYPICAL POLE LAYOUTTYPICAL CONDUIT IN TRENCH DETAIL

FINISH GROUND/ CARPARK

PAVEMENT SURFACE

IDENTIFICATION TAPE

BEDDING AND BACK FILL TO

TRENCH TO BE COMPACTED

IN 100mm LAYER TO 100%

SMD min

MIN

150

250

500

1. THESE DRAWINGS SHALL BE READ IN CONJUNCTION WITH ALL ARCHITECTURAL

AND OTHER CONSULTANTS DRAWINGS AND SPECIFICATION AND WITH SUCH

OTHER WRITTEN INSTRUCTION AS MAY BE ISSUED DURING THE COURSE OF THE

CONTRACT. ANY DISCREPANCY SHALL BE REFERRED TO THE SUPERINTENDENT

BEFORE PROCEDDING WITH THE WORK.

2. ALL MATERIALS AND WORKMANSHIP SHALL BE IN ACCORDANCE WITH THE

RELEVANT AND CURRENT AUSTRALIAN STANDARDS AND THE BUILDING CODE OF

AUSTRALIA EXCEPT WHERE VARIED BY THE PROJECT SPECIFICATION. REFER TO

16.

3. ALL DIMENSIONS SHOWN SHALL BE VERIFIED BY THE CONTRACTOR ON SITE.

ENGINEERS DRAWINGS SHALL NOT BE SCALED FOR DIMENSIONS.

4. THE CONTRACTOR SHOULD REPORT ANY DISCREPANCIES ON THE DRAWINGS TO

THE ENGINEER RESPONISBLE FOR THE DESIGN.

5. UNLESS NOTED OTHERWISE ALL LEVELS ARE IN METRES AND ALL DIMENSIONS

ARE IN MILLIMETRES.

6. CONTRACTOR IS NOT TO ENTER UPON NOR DO ANY WORK WITHIN ADJACENT

LANDS WITHOUT THE PERMISSION OF THE OWNER. SURPLUS EXCAVATED

MATERIAL SHALL BE PLACED WHERE DIRECTED OR REMOVED FROM SITE.

7. ALLOW TO CO-ORDINATE WITH THE EXISTING STRUCTURE AND SERVICES IN THE

BUILDING, ALLOWING FOR ANY ADDITIONAL WORKS THAT MAY BE REQUIRED TO

CO-ORDINATE WITH THESE SERVICE.

8. ALLOW FOR OUT OF HOURS WORKS,

9. ELECTRICAL CONTRACTOR TO CLEAN ALL FITTINGS AT PRACTICAL COMPLETION.

GENERAL NOTES

1. ALL EXTERNAL LIGHTING TO BE CONTROLLED VIA A PE CELL AND TIMECLOCK

AS PER BCA SECTION J6

2. ALL SURFACE MOUNTED BATTEN IN THE INTERNAL COMMON AREA TO BE

REPLACED WITH TYPE B2 FITTINGS

LIGHTING

STAGE 3 SAFTEY UPGRADEELIZABETH ST, WALKER ST & KETTLE ST, REDFERN

3D RENDER OF LIGHT CALCULATION

ELIZABETH ST

KETTLE ST

LOCATION PLAN

WALKER ST

ELIZABETH ST

KETTLE ST

AMDT DATE BY DESCRIPTION

A 24.11.14 DT TENDER ISSUE

SCALE :

PROJECT MGR :

DATE :

DRAWN :

DRG SIZE :

DESIGN :

WWW.JONESNICHOLSON.COM.AU

THE CONCEPTS AND INFORMATION CONTAINED IN THEDOCUMENT ARE THE COPYRIGHT OF JONES NICHOLSONPty. Ltd. USE OR COPYING OF THE DOCUMENT WITHOUTWRITTEN PERMISSION OF JONES NICHOLSON Pty. Ltd.CONSTITUTES AN INFRINGEMENT OF COPYRIGHT

ABN: 51 003 316 032CIVIL STRUCTURAL BUILDING SERVICES. .

DTDT

SEPT 14A1

1:100TS

STAGE 3 SAFTEY UPGRADE

Elizabeth St, Walker St & Kettle St,Redfern

FACS

130277E02 A

ELECTRICAL DESIGNEXTERNAL LIGHTING

P1

DP

EP1

EP1

EP1

EP1

DP

EP1

DP

EP1

EP1EP1

EP1

EP1

EP1

EP1

P1P1

P1P1

P1

P1

P1

P1

P1

P1

P1

EP1

EP1

EP1

EB1

DB1

DB1

EB1

EB2

EB2

DB

DB

EB3

EB3

EB3

EB3

EB3

EB3

EB3

EB3

EB3

EB3

EB3

EB3

EB3

EB3

EB3

EB2

DB

RB1

EB1

DB

DB

EB1

EB1

EB1

EB1

EB3

EB1

EW1

EB1

B1

B1

P1

B1

EP1

EB3

EB3

1 12.09.14 DT PRELIMINARY ISSUEAMDT DATE BY DESCRIPTION

A 24.11.14 DT TENDER ISSUE