Development of Cryogenic Actuator Materials for Switches ... · Neutron Source”, Advances in...

Transcript of Development of Cryogenic Actuator Materials for Switches ... · Neutron Source”, Advances in...

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 1

Development of Cryogenic Actuator Materials for Switches, Seals and Valves

Raj VaidyanathanUniversity of Central Florida

Start Date = July 2002Planned Completion = December 2006

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 2

Research Goals and Objectives• Develop shape memory alloy based cryogenic actuator materials

for hydrogen related technologies• Lower the operating temperature range of shape memory alloys• Approach

– Alloy development• NiTiFe alloys• Composition control• Thermomechanical processing

– Materials testing and evaluation• Dilatometry• Differential scanning calorimetry• Indentation• Neutron diffraction at stress and temperature (at Los Alamos National

Laboratory)• Mechanical testing (dynamic mechanical analyzer)

– Cryogenic actuator design and prototype construction• Switches, seals and valves

“Cold” shape “Hot” shape

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 3

Relevance to Current State-of-the-Art• Shape memory materials integrate sensory and actuation functions -

hence incorporation of shape memory elements in existing deviceseliminates sensors and active controls, e.g., gas gap and liquid gap switches for thermal conduction

• Existing commercially available shape memory alloys are not optimized for operation at cryogenic temperature - the alloy development aspect of this project enables their use as cryogenic actuator materials

Relevance to NASA• The immediate benefit to NASA KSC is the development of a shape memory

thermal conduction switch for application in cryogenic liquefaction, densification and zero boil-off systems

• Cryogenic actuators for spacecraft, spaceport and hydrogen technologies • Broader impacts

– An active and diverse partnership between a state-university (UCF), a major US national laboratory (Los Alamos National Laboratory) and NASA

– Realization of the commercialization potential of cryogenic shape memory alloys

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 4

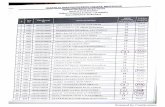

Budget, Schedule and Deliverables

Hot isostatic processing + alloy optimization

Cryogenic testing at Los Alamos National Lab

Patent application + extension to other prototype configurations

3$167K

2.52$155K

1.51 $130K

0.5YEAR/COST

TASK

Indentation

Calorimetry and dilatometry (LHe)

Prototype design, fabrication, testing and modification

LN2 testing and demonstration of effect

Thermomechanical processing

Arc melting of alloys

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 5

Anticipated Technology End Use• Thermal switches for

– cryogenic liquefaction, densification and zero boil-off systems– minimizing parasitic heat loads for redundant cryocoolers not in

active use– controlling heat flow to a radiator that has periodic day/night cycles

(e.g., moon)– controlling heat transfer between two cryogenic storage tanks that

have varying heat loads (e.g., oxygen and methane on Mars)• Extension of shape memory alloy actuator elements developed to

cryogenic seals, valves, fluid-line repair and self-healing gaskets for hydrogen related technologies

• Development of ambient technologies relevant to NASA such as debris-less separation and latch/release mechanisms are also expected to be favorably impacted

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 6

Accomplishments and Results - Overview

77 K 298 K

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 7

Accomplishments and Results – Year 3• Successful commissioning of a liquid helium dilatometer to detect

shape changes to 20 K

-2000

-1500

-1000

-500

0

500

-250 -200 -150 -100 -50 0 50sh

ape

chan

ge (a

.u.)

temperature (deg C)

24.93

24.94

24.95

24.96

24.97

24.98

24.99

25

25.01

-300 -250 -200 -150 -100 -50 0 50

shap

e ch

ange

(a.u

.)

temperature (deg C)

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 8

Accomplishments and Results – Year 3• Successful commissioning of a dynamic mechanical analyzer;

mechanical testing at temperatures as low as 120 K

0

50

100

150

200

250

0 0.01 0.02 0.03 0.04 0.05

stre

ss (M

Pa)

strain

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 9

Accomplishments and Results – Year 3• Successful design, fabrication and testing of a low hysteresis

thermal conduction switch; modifications needed to minimize thermal gradient

Max: 95.6 MPa

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 10

Accomplishments and Results – Year 3• Successful modification of neutron diffraction set up at Los

Alamos National Laboratory for neutron diffraction measurements during loading at cryogenic temperatures - design

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 11

Accomplishments and Results – Year 3• Successful modification of neutron diffraction set up at Los

Alamos National Laboratory for neutron diffraction measurements during loading at cryogenic temperatures - implementation

Temperature Vs. Time

90

110

130

150

170

190

210

230

250

270

290

310

0.13 0.19 0.25 0.30 0.36 0.41 0.47 0.52 0.58 0.63 0.69

Time (hours)

Tem

pera

ture

(K)

TC1TC2TC3TC4TC5TC6TC7TC8

• Steady state in 18 minutes• 16 L/hr of LN2

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 12

Accomplishments and Results – Year 3• Phase transformation with application of stress at 92 K

R → B19′

2.9 2.95 3 3.05 3.1 3.15 3.2d-spacing (Angstroms)

norm

aliz

ed in

tens

ity (a

.u.)

125 MPa8 MPa

68 MPa90 MPa

425 MPa

225 MPa350 MPa

288 MPa350 MPa

175 MPa

228 MPa210 MPa

155 MPa160 MPa

114 MPa

152 MPa132 MPa

8 MPa

R-phase

B19'

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 13

Accomplishments and Results – Year 3

2.95 3 3.05 3.1 3.15

norm

aliz

ed in

tens

ity (a

.u.)

d-spacing (Angstroms)

158K

150K

162K164K

170K168K166K

160K

156K154K152K

• Controlled heating under a constant stress of 44 MPa• ~ 2% strain recovery between 160 K and 162 K• One-time, high-stroke, actuator applications like self-healing

gaskets, safety valves and release mechanisms

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 14

Accomplishments and Results – Year 3• Controlled heating under a constant stress of 44 MPa• Cyclic, low-stroke / low-hysteresis, actuator applications like

thermal conduction switches

1.3 1.32 1.34 1.36 1.38 1.4

norm

aliz

ed in

tens

ity (a

.u.)

d-spacing (Angstroms)

243K

231K233K235K237K239K241K

2 2.05 2.1 2.15 2.2 2.25 2.3

norm

aliz

ed in

tens

ity (a

.u.)

d-spacing (Angstroms)

243K

231K

233K

235K

237K

239K

241K

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 15

Partnerships and Collaborations• NASA Kennedy Space Center ($120K): Development of a

prototype conduction switch• Los Alamos National Laboratory (DOE) ($100K): Capability for

testing shape memory alloys at low temperatures • National Science Foundation CAREER ($450K): Deformation

studies in shape memory alloys• UCF-UF Space Research Initiative ($485K): Experimental and

Computational mechanics of shape memory materials • UCF Presidential Equipment ($57K): Support for a low temperature

differential scanning calorimeter and a low temperature mechanical analyzer

• Sierra Lobo at NASA KSC: Assistance with developing a cryogenic testing capability at Los Alamos

• NASA’s flow liner problem: Flow liner testing piggy-backed on shape memory alloy testing setup

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 16

Publications• S. Rajagopalan, A.L. Little, M.A.M. Bourke and R. Vaidyanathan, “Elastic Modulus of B19’ Shape-Memory

NiTi from in situ Neutron Diffraction during Loading, Instrumented Nanoindentation and Extensometry”, Appl. Phys. Lett. (2005) 86 081901-3.

• C.R. Rathod, V. Livescu, B. Clausen, M.A.M. Bourke, W.U. Notardonato, M. Femminineo and R. Vaidyanathan, “Neutron Diffraction Characterization of Residual Strain in Welded INCONEL 718 for NASA Space Shuttle Flow Liners”, Advances in Cryogenic Engineering, American Institute of Physics, (2004) 50A 167-175.

• V.B. Krishnan, J.D. Singh, T.R. Woodruff, W.U. Notardonato and R. Vaidyanathan, “A Shape Memory Alloy Based Cryogenic Thermal Conduction Switch”, Advances in Cryogenic Engineering, American Institute of Physics, (2004) 50A 26-33.

• V. Livescu, T.R. Woodruff, B. Clausen, T. Sisneros, M.A.M. Bourke, W.U. Notardonato and R. Vaidyanathan, “Design and Rationale for an in situ Cryogenic Deformation Capability at a Neutron Source”, Advances in Cryogenic Engineering, American Institute of Physics, (2004) 50A 83-89.

• C.R. Rathod, S. Rajagopalan and R. Vaidyanathan, “Mechanical Characterization of Shape-Memory Alloys using Diffraction and Instrumented Indentation”, Shape-Memory and SuperelasticTechnologies, International Organization on Shape-Memory and Superelastic Technology, (2004) 331-339.

• V. Krishnan, W.U. Notardonato and R. Vaidyanathan, “Design, Fabrication and Testing of a Shape Memory Alloy based Cryogenic Thermal Conduction Switch”, Smart Mater. Struct. (2004) submitted.

• J. L. Lemanski, V. B. Krishnan, R. Mahadevan Manjeri, W. Notardonato and R. Vaidyanathan, “A Low Hysteresis NiTiFe Shape Memory Alloy based Thermal Conduction Switch”, Advances in Cryogenic Engineering, American Institute of Physics, (2005) submitted.

• C.R. Rathod, B.C. Clausen, M.A.M. Bourke and R. Vaidyanathan, “A Neutron Diffraction Investigation of Hysteresis Reduction and Increase in Linearity in the Stress-Strain Response of Superelastic NiTi”, Appl. Phys. Lett. (2005) submitted.

• 3 manuscripts under preparation

Florida Universities Hydrogen Review 2005Florida Solar Energy Center November 1-4, 2005

Cryogenic Actuators – Raj Vaidyanathan – UCF 17

Future Plans• Optimization of thermomechanical processing

– for wire drawing– based on dynamic mechanical analyzer results

• Overcome heterogenity issue– improve mixing– pre-alloyed powders– vacuum quenching

• Hot isostatic processing• Extension to other prototype configurations - self-healing gaskets• Patent application for thermal conduction switch with a

configuration that minimizes the thermal gradient• Contract with NASA KSC contractor ASRC to supply shape

memory actuator elements for use in a low temperature convective heat pipe type thermal conduction switch; start date November 1, 2005; potential patent

• Commercial partner or SBIR/STTR funding