DC GENERATOR CHAPTER-9. CONTENTS 1. Generator Principle, Construction & working 2. Parts of a...

-

Upload

brice-lamb -

Category

Documents

-

view

253 -

download

4

Transcript of DC GENERATOR CHAPTER-9. CONTENTS 1. Generator Principle, Construction & working 2. Parts of a...

CONTENTS

1. Generator Principle, Construction & working

2. Parts of a Generator

3. EMF Equation of a Generator

4. Losses and Efficiencies in DC Generators

5. Characteristics of DC generators

What is a Generator?

A generator is a machine that converts

Mechanical energy into Electrical energy.

What is an DC Generator?

A DC generator is an electrical machine which converts

mechanical energy into electrical energy(DC).

The energy conversion is based on Faraday’s Law of

Electromagnetic Induction.

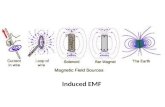

Faraday’s Law of Electromagnetic Induction

According to these law, when an conductor moves in a magnetic field

it cuts magnetic lines of force, due to which an emf is induced in the

conductor.

The magnitude of this induced emf depends upon the rate of change of

flux (magnetic line force) linkage with the conductor.

This emf will cause an current to flow if the conductor circuit is closed.

Basic Parts

The two basic essential parts of an generator are

1) a magnetic field and

2) conductors which move inside that magnetic field.

Yoke

The outer frame of a generator or motor is called as yoke.

Yoke is made up of cast iron or steel.

Yoke provides mechanical strength for whole assembly of the generator

(or motor).

It also carries the magnetic flux produced by the poles.

Poles

Poles are joined to the yoke with the help of screws or welding.

Poles are to support field windings.

Field winding is wound on poles and connected in series or parallel

with armature winding or sometimes separately.

Pole Shoe

Pole shoe is an extended part of the pole which serves two purposes,

(1) to prevent field coils from slipping and

(2) to spread out the flux in air gap uniformly.

Armature Core

Armature core is the rotor of a generator.

Armature core is cylindrical in shape on which slots are provided to

carry armature windings.

Commutator and brushes

As emf is generated in the armature conductors terminals must be

taken out to make use of generated emf.

But if we can't directly solder wires to commutator conductors as they

rotates.

Thus commutator is connected to the armature conductors and

mounted on the same shaft as that of armature core.

Commutator and brushes

Conducting brushes rest on commutator and they slides over when

rotor (hence commutator) rotates.

Thus brushes are physically in contact with armature conductors

hence wires can be connected to brushes.

EMF Equation a DC Generator

Let Ø = flux/pole in Wb (weber)

Z = total no. of armature conductors

P = no. of generator poles

A = no. of parallel paths in armature

N = rotational speed of armature in revolutions per min. (rpm)

E = emf induced in any parallel path in armature

Losses in a DC machine

• Copper losses1. Armature Cu loss2. Field Cu loss3. Loss due to brush contact resistance

• Iron Losses1. Hysteresis loss2. Eddy current loss

• Mechanical losses1. Friction losses2. Windage losses

Copper losses

These losses are the losses due to armature and field copper

windings. Thus copper losses consists of

1. Armature copper loss,

2. Field copper loss and

3. Loss due to brush contact resistance.

Copper losses-Armature Cu Loss

Armature copper loss = Ia2Ra

(Where Ia is Armature current and

Ra is Armature resistance)

This loss is about 30 to 40% of full load losses.

Copper losses-Field Cu Loss

Field copper loss = If2Rf

(where If is field current and Rf is field resistance)

In case of shunt wounded field, this loss is practically constant.

Field copper loss is about 20 to 30% of full load losses.

Copper losses-Loss due to Brush Contact Resistance

There is also brush contact loss due to brush contact resistance

(i.e., resistance between the surface of brush and surface of

commutator).

Generally this loss is included into armature copper loss.

Iron losses (Magnetic losses)

As iron core of the armature is continuously rotating in a

magnetic field, there are some losses taking place in the core.

Therefore iron losses are also known as Core losses.

This loss consists of Hysteresis loss and Eddy current loss.

Iron losses (Magnetic losses)

Hysteresis loss is due to reversal of magnetization of the

armature core.

When the core passes under one pair of poles, it undergoes one

complete cycle of magnetic reversal.

The frequency of magnetic reversal is given by, f=.

(where, P = no. of poles and N = Speed in rpm)

Iron losses (Magnetic losses)

The loss depends upon the volume and grade of the iron,

frequency of magnetic reversals and value of flux density.

Hysteresis loss is given by, Steinmetz formula:

Wh=ηBmax1.6f V (watts)

where, η = Steinmetz hysteresis constant

V = volume of the core in m3

Iron losses (Magnetic losses)Eddy current loss: When the armature core rotates in the magnetic

field, an emf is also induced in the core (just like it induces in armature

conductors), according to the Faraday's law of electromagnetic induction.

Though this induced emf is small, it causes a large current to flow in

the body due to low resistance of the core.

This current is known as eddy current.

The power loss due to this current is known as eddy current loss.

Mechanical Losses

Mechanical losses consists of the losses due to friction in

bearings and commutator.

Air friction loss of rotating armature also contributes.

These losses are about 10 to 20% of full load losses.

Constant and Variable LossesThe losses in a d.c. generator may be sub-divided into

(i) Constant losses,

(ii) Variable losses.(i) Constant losses

Those losses in a d.c. generator which remain constant at all loads are known as

constant losses. The constant losses in a d.c. generator are:

(a) iron losses

(b) mechanical losses

(c) shunt field losses

Constant and Variable Losses

(ii) Variable losses

Those losses in a d.c. generator which vary with load are called variable losses.

The variable losses in a d.c. generator are:

(a) Copper loss in armature winding ( Ia2 Ra)

(b) Copper loss in series field winding ( Ise2 Rse)

Total losses = Constant losses + Variable losses

Note: Field Cu loss is constant for shunt and compound generators.

Characteristics of DC generator

• Generally, following three characteristics of DC generators are taken

into considerations:

(i) Open Circuit Characteristic (O.C.C.),

(ii) Internal or Total Characteristic and

(iii) External Characteristic.

1.Open Circuit Characteristic (O.C.C.)- (E0/If)

• Open circuit characteristic is also known as magnetic characteristic or

no-load saturation characteristic.

• This characteristic shows the relation between generated emf at no

load (E0) and the field current (If) at the given fixed speed.

• The O.C.C. curve is just the magnetization curve and it is practically

similar for all type of generators.

Open Circuit Characteristic (O.C.C.)- (E0/If)

• The data for O.C.C. curve is obtained by operating the generator at no

load and keeping speed constant.

• Field current is varied and the corresponding terminal voltage is

recorded.

Open Circuit Characteristic (O.C.C.)

The above figure shows a typical no-load saturation curve or open circuit characteristics for all types of DC generators.

2. Internal or Total Characteristic (E/Ia)• The internal characteristic curve shows the relation between the on-load

generated emf (Eg) and the armature current (Ia).

• The on-load generated emf Eg is always less than E0 due to armature

reaction.

• Eg can be determined by subtracting the drop due to demagnetizing effect

of armature reaction from no-load voltage E0.

• Therefore, internal characteristic curve lies below O.C.C. curve.

3.External Characteristic (V/IL)

• The external characteristic curve shows the relation between the terminal

voltage (V) and load current (IL).

• The terminal voltage V is less than generated emf Eg due to voltage drop in

the armature circuit.

• Therefore the external characteristic curve lies below the internal

characteristic curve.

• External characteristics are very important to determine the suitability of a

generator for a given purpose.

Characteristics of separately excited DC Generator

• If there is no armature reaction and armature voltage drop, voltage

will remain constant for any load current.

• Thus the straight line AB in above figure represents the no-load

voltage Vs. load current IL.

• Due to demagnetizing effect of armature reaction the on-load

generated emf is less than the no-load voltage.

Characteristics of separately excited DC Generator

• The curve AC represents the on-load generated emf Eg vs. load

current IL i.e. internal characteristic.

• The curve AD represents the terminal voltage vs. load current i.e.

external characteristic.

Characteristics of DC Series Generator• The curve AB in above figure identical to open circuit characteristic

(O.C.C.) curve.

• This is because, in DC series generators field winding is connected in

series with armature and load.

• Hence, here load current is similar to field current.

• The curve OC and OD represents internal and external characteristic

respectively.

Characteristics of DC Shunt Generator• When load resistance is decreased in DC shunt generator, the load

current increases.

• But, load resistance can be decreased upto a certain limit, beyond this

limit any further decrease in load resistance results in decreasing load

current and terminal voltage.

• Consequently, the external characteristic curve turns back as shown

by dotted line in above figure.

Characteristics of DC Compound Generator• The above figure shows the external characteristic of DC compound

generators.

• If series winding is adjusted so that, increase in load current causes

increase in terminal voltage then the generator is called to be over

compounded.

• The external characteristic for over compounded generator is shown

by the curve AB in above figure.

Characteristics of DC Compound Generator

• If series winding is adjusted so that, terminal voltage remains

constant even the load current is increased, then the generator is

called to be flat compounded.

• The external characteristic for a flat compounded generator is shown

by the curve AC.

Characteristics of DC Compound Generator

• If the series winding has lesser number of turns than that would be

required to be flat compounded, then the generator is called to be

under compounded.

• The external characteristics for an under compounded generator is

shown by the curve AD.

Classification of DC Generator

• DC machines (i.e. DC generators or DC motors) can be classified on

the basis of configuration of their excitation winding.

• Field winding may be connected to armature winding (in series or

parallel) or it may be separately excited.

• This divides DC machines in two main types.

Classification of DC Generator

Generally DC generators are classified according to the ways of

excitation of their fields. There are three methods of excitation.

• Field coils excited by permanent magnets – Permanent magnet DC generators

• Field coils excited by some external source – Separately excited DC generators

• Field coils excited by the generator itself – Self excited DC generators

Permanent magnet DC generators• When the flux in the magnetic circuit is established by the help of

permanent magnets then it is known as Permanent magnet dc generator.

• It consists of an armature and one or several permanent magnets situated

around the armature.

• This type of dc generators generates very low power.

• So, they are rarely found in industrial applications.

• They are normally used in small applications like dynamos in motor cycles.

Separately Excited DC Generator• These are the generators whose field magnets are energized by some

external dc source such as battery .

Self-excited DC Generators

• These are the generators whose field magnets are energized by the

current supplied by themselves.

Series Wound Generator

• In these type of generators, the field windings are connected in series

with armature conductors

Shunt Wound DC Generators

• In these type of DC generators the field windings are connected in

parallel with armature conductors.

Compound wound generators

• Compound wound generators have both series field winding and

shunt field winding.

• One winding is placed in series with the armature and the other is

placed in parallel with the armature.

• This type of DC generators may be of two types- short shunt

compound wound generator and long shunt compound wound

generator.

Short Shunt Compound Wound DC Generator• The generators in which only shunt field winding is in parallel with the

armature winding.

Long Shunt Compound Wound DC Generator• The generators in which shunt field winding is in parallel with both

series field and armature winding.

Cumulative and Differential Compound Generator

• In a compound wound generator, the shunt field is stronger than the

series field.

• When the series field assists the shunt field, generator is said to be

commutatively compound wound.

• On the other hand if series field opposes the shunt field, the

generator is said to be differentially compound wound.