D09.06.02.presentation

-

Upload

relhy-project -

Category

Technology

-

view

560 -

download

0

Transcript of D09.06.02.presentation

Innovative Solid Oxide Electrolyser Stacks for Efficient and Reliable Hydrogen production

Towards durable and efficient high temperature Towards durable and efficient high temperature steam electrolysis: the RelHy projectsteam electrolysis: the RelHy project

Florence LefebvreFlorence Lefebvre--JoudJoud

23rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

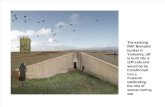

Concept of RelHyConcept of RelHy

RelHy25-cell stack prototype,operated at

800°C

Cells

SRUs

5-cell Stacks

Materials optimisationDurable electrodes/electrolyte, Sealing, Material compatibility and stability, Cost effective materials and processes

Design innovationsThermo mechanics, Tightness, Water management

State of the Art

• Good cells• No compromise

in stacks nor SRUsbetween durability and efficiency

Integration of optimised materials and innovative design in areliable and efficient

laboratory electrolyser prototype

Instru

mente

d

constituting a bridge between current good performing cells and reliable and efficient SOEC stack prototype operated at 800°C with cost effective materials.

33rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

SoASoA: Main : Main resultsresults

of Hiof Hi22

HH22

i-V curves obtained at DTU-Risoe on 5x5cm2 solid oxide cells

-High performances obtained on SOFC cells operated in the electrolysis mode (ex: 2 A.cm-2

at 1.4V at 850°C)

-Low degradation rate obtained up to 1500 hrs: ~3% per 1000 hrs at -0.25A/cm²

and -0.5A/cm²

, 800-850°C and absolute humidity up to 70%.

-Degradation rate observed to decrease with decreasing the current density and with increasing temperature.

At the single cell level:

M. Mogensen, S. H. Jensen, A. Hauch, I. Chorkendorff, and T. Jacobsen. Lucerne (2006).Jensen, S. H., Larsen, P. H., and Mogensen, M. Inter. J. Hydrogen Energy (2008).

Compromise between the cell performance and its durability required

43rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

SoASoA: Main : Main resultsresults

of Hiof Hi22

HH22

-Degradation rate ~ 10% per 1000hrs obtained with complete SRU at -0.5A/cm²

and 850°C (i.e. x3 compared to single cells)

-Degradation rate ≥

15% per 1000hrs obtained with 5-cell SOEC Stack at -0.3A/cm², 800°C, 50% absolute humidity and 50% steam to H2

conversion rate over test duration of 2000 hrs.

-Adding a coated interconnect to the O2

electrode lower cell performance and lower the degradation rate of the cell

At the Single Repeating Unit and short stack levels:

Major influence of stack environment on cell performance and durability

53rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

SoASoA: Results at : Results at CERAMATEC / INLCERAMATEC / INL

Degradation rate ~ 10% per 1000hrs

C. Stoots, J.E. O’Brien, G.L. Hawkes, J.S. Herring, J.J. Hartvigsen, Workshop on HTE, Roskilde, Denmark, 2006

25-cell

Ceramatec

Stack

Ageing

curve

at

800-830°C

Similar trends obtained in the US program on larger stacks

63rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

SoASoA: What about SOFC : What about SOFC performance/durability compromise ?performance/durability compromise ?

•

SOFC stacks 1 -

10kW currently tested with continuously increasing performances and durability (Real SOFC project, SECA prog., etc.)

•

Ex: TOFC short stack operated 13000 hrs with an overall voltage degradation rate ~ 1% per 1000 hrs,

•

Ex: TOFC 50 or 75-cell stacks (≥1 kW) tested at FU up to 92% with degradation rates below 0.5% per 1000 hrs, especially by improvement of metal alloy interconnects and coatings

I.C. Vinke, R. Erben, R-H Song, J. Kiviaho Lucerne (2006)N. Christiansen, J.B. Hansen, H. Holm-Larsen, M. Linderoth, P.H. Larsen, P.V. Hendriksen, M. Mogensen Lucerne (2006)

TOFC 75 cell stack concept

Development of metallic interconnects with ceramic coating: ASR~0.5Ω.cm-2

Short stack ageing test for 13000hrs

Major progresses achieved regarding performance / durability compromise

in SOFC environment

73rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

Ambition of the RelHy projetAmbition of the RelHy projet

RelHy25-cell stack prototype,operated at

800°C

Cells

SRUs

5-cell Stacks

Materials optimisationDurable electrodes/electrolyte, Sealing, Material compatibility and stability, Cost effective materials and processes

Design innovationsThermo mechanics, Tightness, Water management

State of the Art

• Good cells• No compromise

in stacks nor SRUsbetween durability and efficiency

Integration of optimised materials and innovative design in areliable and efficient

laboratory electrolyser prototype

Instru

mente

d

Acheive high cell performances at 800°C(~0.03 gH2/cm2/hr, i.e. ~ 1 A/cm2 at ≤1.5V with water conversion >60% )

Decrease degradation rate of SRUs to ~1% per 1000 hr.

Integrate most promising materials and design innovations at laboratory scale in a 25-cell electrolyser stack prototype to be operated until the end of the project.

•

Take advantage of SOFC know-how (cell materials, metallic interconnects and ceramic coating, seals, etc.)

•

Transfer the SOFC optimisation methodology to SOEC

83rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

HTSEHTSE

specifications in 2 cases specifications in 2 cases coupled to nuclear and to renewable energycoupled to nuclear and to renewable energy

Nuclear WindShort Medium Short Medium

Degradation (µ/h) 10 5 15 5

Lifetime (hrs) 10 000 20 000 16 000 40 000

Thermal cycles/year 2 5 7 14

Voltage/cell (V) 1.5 1.45 1.7 1.55

Current (A/cm2) 1.5 2.0 1.0 1.5

Pressure max (bar) 50 50 20 30

Active Area (cm2) 400 800 300 600

Start up from 600 C < 4 h < 4h < 2 < 1h

Turn down to 20 % ? ? < 2 min. < 30 sec.

0,7% per 1000hrs at 1.5V

Pertinence of RelHy target: step from current SoA towards industrial application(Under pressure operations to be addressed)

93rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

Approach and project Approach and project structurestructure

RelHyInnovative Laboratory Electrolyser Prototype

Material Prototyping Testing & Analysis

Modelling and simulation

Competitiveness assessment

Key words: significance and reproducibility of results between partners

common single repeating units (SRUs) and short stacks

common testing and analysing protocols

definition of a reference performance/durability level to compare to

103rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

Reference material selectionReference material selection

•

Cell materials – for the 2 geometries ESC and CSC

ESC (ECN)–

Electrode H2

: Ni-CGO–

Electrolyte

: 3YSZ–

Electrode O2

: YDC-LSCF–

Active surface : 100 cm²

CSC (DTU Risoe)-

Electrode H2

: Ni-YSZ -

Electrolyte

: 8YSZ-

Electrode O2

: YSZ-LS-

Active Surface : 100 cm²

•Interconnects and coatingCrofer

+ LSM coating on the O2

side and NiO

coating on the H2

side

•

SealsPre-sintered glass bars for

reproducibility during assembly

NiO coating fuel side

LSM coating oxidant side

113rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

SRU and short stack SRU and short stack developmentdevelopment

Criteria for SRU geometry:•

Able to integrate ESC and CSC•

«

Easy

»

to assemble•

« Easy » to model •

Close to standard TOFC geometryupper interconnect

cell (120mm by 120mm)

pre-sintered glass bars

mica foil

lower interconnect (150mm by 150mm by 10mm) metallic bars for

current distribution

Short stack:•

Based on TOFC Alpha standard design,

•

Integrates CSC (DTU Risoe)•

Modified to integrate ESC from ECN as well

123rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

SRU ready for testingSRU ready for testing

Air side

H2

/H2

O side

133rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

Testing protocol definitionTesting protocol definition

•

Heating, Sealing and Ni reduction following cell manufacturer recommendations

•

Test start-up –

OCV stabilisation at 800°C under H2

with 3 vol.% H2

O

•

Operation in fuel cell mode

at 800°C to check SRU performance –

EIS at OCV , j-V curves and EIS = f(j)

•

Operation in Electrolysis Mode at 800°C:–

Change of humidity 50 vol.% Hum (H2

10%/N2

40%) and stabilisation at OCV, –

EIS at OCV, j-V curves V≤1.5V, EIS = f(j),–

Change of humidity 70 vol.% Hum (H2

10%/N2

40%) and stabilisation at OCV, –

EIS at OCV, j-V curves V≤1.5V, EIS = f(j),–

Change of humidity 90 vol.% Hum (H2

10%/N2

40%) and stabilisation at OCV, –

EIS at OCV, j-V curves V≤1.5V, EIS = f(j),–

Back to 50 vol.% Hum to change operation temperature to 750°C

•

Operation in Electrolysis Mode at 750°C

•

Operation in Electrolysis Mode at 850°C:

•

Durability test at 800°C (-1 A/cm2

under 90 vol.% Hum/10 vol.% H2

)

143rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

Test matrixTest matrix

Partner 1 Partner 2 Partner 3 Partner 4

Reference test Campaign (on going)

- Reference ESC

- Reference CSC + ageing

-

- Reference ESC + ageing--

- Reference CSC

- Reference CSC with Sh. Stack coating

- Reference ESC with Sh. Stack coating

- Short stack with CSC + ageing

- Short stack with ESC + ageing

Optimisation test campaign: with effect and reproducibility measurement on:

-

Cathode material

-

Electrolyte material

-

Coating material

-

Sealing material

153rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

ESC ESC ––

Results in the SOFC modeResults in the SOFC mode

0

0,2

0,4

0,6

0,8

1

1,2

0 0,1 0,2 0,3 0,4 0,5 0,6 0,7

i (A.cm-2)

E (V

)

0

0,05

0,1

0,15

0,2

0,25

0,3

0,35

P (W.cm

-2)

800°C, Air=1200 mL/min, H2

=1200 mL/min

Satisfactory tightness Satisfactory cell ASR (0.9 Ω.cm2

@ 0.7 V)

163rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

0,8

0,9

1

1,1

1,2

1,3

1,4

1,5

1,6

-0,8 -0,6 -0,4 -0,2 0

i (A.cm-2)

E (V)

I ( A.cm-2)

ESC ESC ––

First First ResultsResults

in the HTE mode in the HTE mode

50% H2 O-10% H2 -40% N2

70% H2 O-10% H2 -20% N2

90% H2 O-10% H2

800°C, Air=1200 mL/min, H2

O/H2

/N2

=1200 mL/min

OCV in agreement with pH2

OASR ranging between 0.8 and 0.9 Ω.cm2 @ 1.32 V

First results not far from RelHy target on performance

173rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

MélangeQtot =1200 mL/min

ASR (ohm.cm2) @

0.7V SOFC1.32V EHT

H2 Production @ 1.32V

Fuel Utilization / Water conversion

@0.7V SOFC,

1.32V et 1.5V

Production H2

@ 1.5V

SOFC 100% H2 0.9 ± 0.01 25%

EHT 50%H2 O - 10%H2 - 40%N2

0.86 ± 0.0350 A

18.7 mg/cm2/h62% - 87%

70 A26.2 mg/cm2/h

EHT 70%H2 O - 10%H2 - 20%N2

0.84 ± 0.0153 A

19.8 mg/cm2/h47% - 67%

75 A28 mg/cm2/h

EHT 90%H2 O - 10%H2

0.77 ± 0.0256 A

20.9 mg/cm2/h39% - 55%

80 A29.9 mg/cm2/h

ESC ESC ––

SummarySummary

of First of First resultsresults

in in the HTE mode the HTE mode atat

800800°°CC

183rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

ConclusionsConclusions

RelHy project: aims at reaching a pertinent compromise between performance and durability

Quantified targets in agreement with industrial specifications in two cases (nuclear and renewable coupling)

Experimental tools (SRUs and short stacks), protocols and test matrix developed and available

Reference performances and reproducibility being established

Modelling tools from the microstructure level to the complete SRU level under construction

Material developments (cathode, electrolyte, interconnect coating and seals) for second iteration under progress

193rd International Workshop on High Temperature Water Electrolysis / Karlsruhe Germany / 9-10 June 2009

Acknowledgment to the «

RelHy team

»

Gislaine

Ehora and Jacob Bowen at DTU Risoe

Jan Peter Ouweltjes and Bert Rietveld at ECN

Annabelle Brisse and Mohsine Zahid

at EIfER

Qiong Cai and Nigel Brandon at Imperial College

Thomas Nietsch

at Helion

Jens Ulrik Nielsen at TOFC

and John Boegild Hansen at Haldor

Topsoe

Marie Petitjean, Hervé

Sassoulas, Gatien

Fleury, ….. at CEA