取扱説明書 - Canon Global · Canon EOS 620,650 Canon EOS 650 EF som Canon EOS 620

Customer Expectations Document - Canon...

Transcript of Customer Expectations Document - Canon...

-

imageRUNNER ADVANCE 8095

Customer Expectations Document

Version 4

Systems & Technical Support Division Imaging Systems Group, Canon U.S.A., Inc.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 2

Contents 1. Introduction ............................................................................................................. 6 2. Product Overview ................................................................................................... 6

2.1 Summary of Functions .................................................................................... 8 2.2 Differences between Version 1 and Version 2 ................................................ 9 2.3 High-Resolution Imaging System for Copied and Printed Images ................. 10 2.4 Image Stabilization Control ........................................................................... 10

2.4.1 Automatic Gradation Adjustment ..................................................... 11 2.4.2 Accurate Registration ...................................................................... 11

2.5 Professional Input/Output Accessories ......................................................... 12 2.6 Storage Capabilities ...................................................................................... 13

2.6.1 Mail Box ........................................................................................... 14 2.6.2 Advanced Box .................................................................................. 15 2.6.3 Network............................................................................................ 15 2.6.4 Memory Media ................................................................................. 16

2.7 Security Features .......................................................................................... 17 2.7.1 Device Authentication ...................................................................... 17 2.7.2 Data Security ................................................................................... 18 2.7.3 Document Security .......................................................................... 21 2.7.4 Network Security .............................................................................. 22

3. Machine Dimensions and Space Requirements ................................................ 23 3.1 Dimensions ................................................................................................... 23 3.2 Weight ........................................................................................................... 24 3.3 Installation and Service Space ...................................................................... 24

3.3.1 Minimum Space Requirements to Transport the Machine and Turn Hallway Corners .............................................................................. 25

3.3.2 Installation Space Diagrams ............................................................ 26 3.4 Recommended Floor Space Requirements .................................................. 30 3.5 Floor Structure Requirements ....................................................................... 30 3.6 Network Interface Connectivity ...................................................................... 31

4. Power/Electrical Requirements ........................................................................... 32 4.1 Power Requirements for the Main Unit and Optional Accessories ................ 32

5. Environmental Factors and Requirements ......................................................... 34 5.1 Temperature and Humidity Conditions .......................................................... 34 5.2 Temperature Gradient ................................................................................... 34 5.3 Ventilation ..................................................................................................... 35 5.4 Elevation Limitations ..................................................................................... 35 5.5 Lighting.......................................................................................................... 35 5.6 Sunlight ......................................................................................................... 35 5.7 Ammonia ....................................................................................................... 35

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 3

6. Specifications ....................................................................................................... 36 6.1 Main Unit ....................................................................................................... 36 6.2 Duplex Color Image Reader Unit-C1 ............................................................. 38 6.3 Paper Deck Unit-C1 ...................................................................................... 39 6.4 POD Deck Lite-A1 ......................................................................................... 39 6.5 Document Insertion Unit-K1 .......................................................................... 40 6.6 Paper Folding Unit-H1 ................................................................................... 41 6.7 Staple Finisher-D1 ........................................................................................ 42 6.8 Booklet Finisher-D1 ....................................................................................... 44 6.9 Booklet Finisher-F1 PRO .............................................................................. 47 6.10 Inner Booklet Trimmer-A1 ............................................................................. 51 6.11 Booklet Trimmer-D1 ...................................................................................... 51 6.12 Puncher Unit-BF1 .......................................................................................... 52 6.13 Puncher Unit-BB1 ......................................................................................... 52 6.14 Professional Puncher-C1 and Professional Puncher Integration Unit-B1 ...... 53 6.15 Card Reader-C1 ............................................................................................ 53 6.16 Copy Card Reader-F1 ................................................................................... 54 6.17 Super G3 FAX Board-AF1 ............................................................................. 54

7. System Options .................................................................................................... 55 7.1 PCL Printer Kit .............................................................................................. 55 7.2 PS Printer Kit ................................................................................................. 55 7.3 imagePASS-U1 ............................................................................................. 56 7.4 Direct Print Kit (for PDF/XPS Files) ............................................................... 57 7.5 Expansion Bus .............................................................................................. 57 7.6 Additional Memory Type B (512 MB) ............................................................ 57 7.7 IPSec Board .................................................................................................. 57 7.8 Universal Send Advanced Feature Set ......................................................... 57 7.9 Universal Send Security Feature Set ............................................................ 57 7.10 Universal Send Digital User Signature Kit ..................................................... 58 7.11 Secure Watermark ........................................................................................ 58 7.12 Document Scan Lock Kit ............................................................................... 58 7.13 HDD Data Encryption & Mirroring Kit ............................................................ 59 7.14 HDD Data Erase Kit ...................................................................................... 59 7.15 Encrypted Secure Print Software .................................................................. 59 7.16 Removable Hard Disk Drive Kit ..................................................................... 59 7.17 2.5 inch/80 GB HDD ...................................................................................... 60 7.18 2.5 inch/250 GB HDD .................................................................................... 60 7.19 Remote Operator's Software Kit .................................................................... 60 7.20 USB Device Port-A1 ...................................................................................... 60 7.21 Multimedia Reader/Writer-A1 ........................................................................ 60 7.22 Wireless LAN Board ...................................................................................... 61 7.23 Web Access Software ................................................................................... 61 7.24 Super G3 FAX Board-AF1 ............................................................................. 61 7.25 Super G3 2nd Line Fax Board-AF1 ............................................................... 61 7.26 Super G3 3rd/4th Line Fax Board-AE1 ......................................................... 62 7.27 Remote Fax Kit-A1 ........................................................................................ 62 7.28 FAX Board Attachment Kit-A1 ....................................................................... 62 7.29 Other imageRUNNER ADVANCE 8095 Main Unit Accessory Options ......... 62

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 4

8. Installation Review................................................................................................ 63 8.1 Installation Time ............................................................................................ 63 8.2 Customer Installation Responsibilities ........................................................... 64

9. Consumable Items ................................................................................................ 64 9.1 Usage Conditions .......................................................................................... 65 9.2 Consumable Parts ......................................................................................... 65

9.2.1 Estimated Life of Consumables ....................................................... 65 10. Toner Bottle Yields ............................................................................................... 65 11. Waste Toner Yields ............................................................................................... 66 12. Estimated Performance Standards ..................................................................... 66 13. Optimum Monthly Product Performance ............................................................ 67 14. Machine Productivity ............................................................................................ 68

14.1 Print Speed ................................................................................................... 68 14.2 Mixed Paper Weight Job Productivity ............................................................ 69 14.3 Paper and Toner Replacement ..................................................................... 69

15. Media Usage/Compatibility .................................................................................. 69 15.1 Media Characteristics by Media Library Parameters ..................................... 69 15.2 Paper Handling and Storage ......................................................................... 70 15.3 Paper Grain and Curl .................................................................................... 71 15.4 Note for Customers Who Cut Their Own Paper ............................................ 72 15.5 Media Feed Locations ................................................................................... 72 15.6 Paper Sizes and Feed Location Chart .......................................................... 75

16. Image Quality Capabilities ................................................................................... 76 16.1 Customer-Defined Image Quality Adjustments and Recommendations ........ 76

16.1.1 Adjust Image Quality Modes ............................................................ 77 16.1.2 Paper Type Management Settings .................................................. 77

17. Responsibility Matrix ............................................................................................ 78

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 5

IMPORTANT The purpose of this Customer Expectations Document is to explain the current features and capabilities of the imageRUNNER ADVANCE 8095, and provide customers information about what to expect before purchasing the machine. The information included in this document has been pulled from various sources, including product reference guides, service guides, and user manuals, as well as from the results from internal Canon testing. Specifications and other information contained herein may vary slightly, and in a non-material way, from actual device values, including those found in advertising and other printed matter. Part numbers, yield information, and specifications are subject to change without notice. Accordingly, the latest specifications for the machine may not be found in this document. As new information becomes available, this document will be revised. Canon authorized dealers can access the latest revision of this document from the Download Center page in the e-Support Web site (support.cusa.canon.com).

DISCLAIMER NEITHER CANON NOR ITS SUPPLIERS NOR ANY AUTHORIZED SERVICE PROVIDER SHALL BE LIABLE FOR PERSONAL INJURY OR PROPERTY DAMAGE (UNLESS CAUSED SOLELY AND DIRECTLY BY THE NEGLIGENCE OF CANON OR ANY AUTHORIZED SERVICE PROVIDER), LOSS OF REVENUE OR PROFIT, FAILURE TO REALIZE SAVINGS OR OTHER BENEFITS, EXPENDITURES FOR SUBSTITUTE EQUIPMENT OR SERVICES, LOSS OR CORRUPTION OF DATA, INCLUDING, WITHOUT LIMITATION, DATA STORED ON THE PRODUCT’S HARD DISK DRIVE, STORAGE CHARGES OR OTHER SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES CAUSED BY THE USE, MISUSE OR INABILITY TO USE THE PRODUCT, REGARDLESS OF THE LEGAL THEORY ON WHICH THE CLAIM IS BASED AND EVEN IF CANON OR ITS SUPPLIERS OR ANY AUTHORIZED SERVICE PROVIDER HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. NOR SHALL RECOVERY OF ANY KIND AGAINST CANON OR ITS SUPPLIERS OR ANY AUTHORIZED SERVICE PROVIDER BE GREATER IN AMOUNT THAN THE PURCHASE PRICE OF THE PRODUCT CAUSING THE ALLEGED DAMAGE. WITHOUT LIMITING THE FOREGOING, THE PURCHASER ASSUMES ALL RISKS AND LIABILITY FOR LOSS, DAMAGE OR INJURY TO PERSONS AND THE PROPERTY OF THE PURCHASER OR OTHERS ARISING OUT OF THE POSSESSION, USE, MISUSE, OR INABILITY TO USE THE PRODUCT NOT CAUSED SOLELY AND DIRECTLY BY THE NEGLIGENCE OF CANON OR ANY AUTHORIZED SERVICE PROVIDER. Copyright 2011 by Canon U.S.A., Inc. All rights reserved. Product and company names used herein are, or may be, the registered trademarks or trademarks of their respective owners.

http://www.support.cusa.canon.com/�

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 6

1. Introduction The Canon imageRUNNER ADVANCE 8095 Customer Expectations Document contains information about the features and capabilities of the Canon imageRUNNER ADVANCE 8095. This document should be used as part of the presale and pre-installation planning process to help clarify the requirements and responsibilities associated with supporting, owning, and operating the imageRUNNER ADVANCE 8095. It is also recommended that those interested in purchasing the imageRUNNER ADVANCE 8095 have, and familiarize themselves with, the information in this document prior to making their purchase.

2. Product Overview The Canon imageRUNNER ADVANCE 8095 brings the following capabilities to users in a high-volume, light-production office environment: • Speeds of up to 95 ppm (pages per minute) (LTR, Black-and-White). • Single pass duplex document feeder with two-sided black-and-white scanning

speeds of up to 200 ipm (images per minute), two-sided color scanning speeds of up to 100 ipm, and 300-sheet capacity.

• Large 10.4” high-resolution TFT screen (800 x 600 pixels), tilt-and-swivel control panel.

• Standard 80 GB hard disk drive, with an option to expand the machine’s memory to 250 GB.

• Finishing options, such as a staple or booklet finishers, professional puncher, document insertion unit, paper folding unit, inner booklet trimmer, or an external booklet trimmer.

• A maximum paper size of 13” x 19 1/4” is supported. Multiple paper sources, complemented by air-assisted feeding, can hold up to 7,700 sheets of paper for exceptional reliability.

• True 1,200 dpi printing at the engine’s rated speed. • Standard USB memory support. One USB port is on the control panel and can be

used for scanning, printing, or direct printing from a USB memory stick. One USB port is on the rear of the machine, and can only be used to attach a USB keyboard, third-party card reader, direct printing, or for servicing the machine.

• Induction Heating Technology for quick warm up times and first copy output times.

• Standard Universal Send and UFR II printing. • New pO (Precise Output) Toner Technology – A newly developed pO toner that

helps to reproduce images more accurately, and improves the evenness of solid black and halftones.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 7

• Version 2 offers several feature enhancements over version 1, and is equipped with the ARCnet (Attachable Resource Computer Network) communication cable. The ARCnet communication cable is necessary to attach the new optional Booklet Finisher-F1 PRO to the V2 engine. The Booklet Finisher-F1 PRO offers improved finishing speeds compared to the optional Booklet Finisher-D1.

• The Booklet Finisher-F1 PRO and Booklet Trimmer-D1 cannot be purchased separately. They can only be purchased as part of the V2 engine.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 8

2.1 Summary of Functions

Function imageRUNNER ADVANCE 8095 Print Speed (LTR) B&W 95 ppm Scan Speed (LTR, 300 dpi)

B&W 2-Sided: 200 ipm, 1-Sided: 120 ipm Color 2-Sided: 100 ipm, 1-Sided: 85 ipm

DADF Standard Single Pass Duplex DADF Capacity 300 sheets (20 lb bond (80 g/m²)) Engine Resolution 1,200 x 1,200 dpi Gradations 256 levels

Paper Size Min 5 1/2” x 7 1/8”*1, 4” x 5 7/8”*2, 4” x 7 1/8”*3

Max 13” x 19 1/4”

Paper Weight Drawers 14 lb bond to 80 lb cover (52 to 220 g/m²) Multi-Purpose Tray 14 lb bond to 140 lb index (52 to 256 g/m²)

HDD Capacity Standard 80 GB, Maximum 250 GB

Printer Memory Main Controller 1: 1.5 GB Standard Main Controller 2: 2 GB Maximum

Copy Standard

Store

Mail Box Standard Advanced Box Standard Memory Media Support Standard (USB)

Print

UFR II Standard PCL Optional (w/PCL Printer Kit-AH1)

Direct Print Standard (JPEG, TIFF), Optional (PDF, XPS*4) (w Direct Printer Kit-H1 or PS Printer Kit-AH1 (PDF only))

PostScript Optional (w/PS Printer Kit-AH1 or imagePASS-U1) imagePASS (Piggyback) Optional (w/imagePASS-U1)

Send

Universal Send Standard

PDF High Compression Standard

PDF Advanced Feature Set

Optional

PDF Security Feature Set Optional

PDF Digital User Signature

Optional

Fax Optional

Network Standard Ethernet 10/100/1000 Base-TX, Optional Wireless LAN Remote UI Standard MEAP Capability Standard Access Management System Standard *1 When no finisher is attached. *2 The Staple Finisher-D1 or Booklet Finisher-D1 is attached. *3 The Booklet Finisher-F1 PRO is attached. *4 Direct Print XPS files can only be printed from the Remote UI.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 9

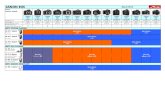

2.2 Differences between Version 1 and Version 2 : Available –: Unavailable

Feature imageRUNNER ADVANCE 8105 Version 1 Version 2

Finishers and Accessories IPC Serial Communication ARCnet Communication – Booklet Finisher-D1 Staple Finisher-D1 Booklet Finisher-F1 PRO – Puncher Unit-BB1 – *1 Puncher Unit-BF1 *2 Booklet Trimmer-D1 – *1 Inner Booklet Trimmer-A1 *2 Document Insertion Unit-K1 (Current)*3 *2 Document Insertion Unit-K1 (New)*4 Paper Folding Unit-H1 (Current)*3 *2 Paper Folding Unit-H1 (New)*4 Professional Puncher-C1 & Professional Puncher Integration Unit-B1 (Current)*3

*2

Professional Puncher-C1 & Professional Puncher Integration Unit-B1 (New)*4 Copy Card Reader-F1 *5

User Interface Enhancements Customizable User Interface *5 Display Favorite Web Pages on the Main Menu *5

Paper Handling Enhancements Tab Paper Pick-Up from Paper Drawer 3 or 4 Paper Type Assignment through Remote UI *5

Document Feeder Enhancements Free Size Paper 2-Sided Scan *5

Finishing Enhancements Booklet Folding without Stitch Letter/Legal Size Double Parallel Folding *5

Scan and Store Preview Documents in the Advanced Box/Memory Media

*5 URL Send for Advanced Box *5 *1 Only available with the Booklet Finisher-F1 PRO. *2 Only available with the Staple Finisher-D1 and Booklet Finisher-D1. *3 The current accessory is not compatible with the Booklet Finisher-F1 PRO, and cannot be upgraded.

The current accessory is only compatible with the Staple Finisher-D1 and Booklet Finisher-D1. *4 The new accessory has the same name as the current accessory, but has a different item code and

serial number block for identification than the current accessory. This accessory is compatible with the Staple Finisher-D1, Booklet Finisher-D1, and Booklet Finisher-F1 PRO.

*5 Available for version 1 when upgrading the firmware to v30.08.01 or later.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 10

Differences between Version 1 and Version 2 Table Continued : Available –: Unavailable

Feature imageRUNNER ADVANCE 8105 Version 1 Version 2

Scan and Send PDF Version Control *5 Auto Complete E-Mail Address *5 Display Waiting Time for Print Interrupt Job for Print/Fax *5 Job Hold *5 JDF Parser *5 Enable/Disable Settings for Scan/Print with Memory Media

*5 Fax Capabilities

Super G3 FAX Board-AF1 – *6 Super G3 2nd Line Fax Board-AF1 – *6,*7 Super G3 3rd/4th Line Fax Board-AE1 – *6,*7 Remote Fax Kit-A1 – *6,*8 FAX Board Attachment Kit-A1 – *6,*9

Environmental Feature Enhancements Energy Conservation Technology *5 *5 Available for version 1 when upgrading the firmware to v30.08.01 or later. *6 Firmware v40.13 or later is needed to use the fax capabilities. *7 Not compatible when the Booklet Finisher-F1 PRO is installed. *8 The Remote Fax Kit-A1 and Super G3 FAX Board-AF1 cannot be installed at the same time. *9 Required to use the Fax function when the Booklet Finisher-F1 PRO is installed.

2.3 High-Resolution Imaging System for Copied and Printed Images

The imageRUNNER ADVANCE 8095 provides a high-resolution imaging system. This system renders images at a 1,200 x 1,200 dpi print resolution, which delivers the highest level of speed and image quality. Object-optimized imaging also helps to achieve superior print quality. Text and lines are processed with a high priority given to resolution, and images and graphics are processed with a high priority given to gradation. This high-resolution imaging system coupled with the Density Detection Adjustment mode, a feature that refines thin, fine text, and lines while the device is rendering images at 1,200 x 1,200 dpi, minimizes faint output and delivers quality prints.

2.4 Image Stabilization Control The quality of printed images is affected by changes in the environment, such as temperature and humidity, in which the machine is installed. Image quality is also affected by the deterioration of image formation parts through extended use. The imageRUNNER ADVANCE 8095 reduces these issues, stabilizes image production, and maintains consistency with features, such as the Auto Gradation Adjustment mode, Density Detection, and accurate registration (± 1.0 mm).

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 11

2.4.1 Automatic Gradation Adjustment Automatic Gradation Adjustment is a function that helps to automatically adjust toner density. Select from the Quick Adjustment mode or Full Adjustment mode. The Quick Adjustment mode quickly and simply adjusts the gradation and density by performing calibration without outputting test prints. The Full Adjustment mode performs a precise calibration by outputting and scanning test prints. For more information on the Automatic Gradation Adjustment modes, see “Adjustment/Maintenance,” in the Settings/Registration e-Manual included with the machine. The imageRUNNER ADVANCE 8095 also automatically detects and compensates when there is a deviation from the specified ideal density. This keeps the density of halftone areas constant, and produces a stable image without density fluctuations. Patches for keeping the halftone density constant are applied between every 6,000 sheets on the drum.

2.4.2 Accurate Registration Image registration can be finely adjusted by manually specifying an exact adjustment value (within one millimeter) for every user-specified paper type. For more information, see “Adjusting the Image Position on a Custom Paper Type,” in the Settings/Registration e-Manual included with the machine.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 12

2.5 Professional Input/Output Accessories The imageRUNNER ADVANCE 8105 features many input and output accessories that enable customers working in light-production or high-volume office environments to complete large jobs directly from the machine. An IPC (Inter Process Communication) cable can be connected to the serial communication finishers and accessories on Version 1 and Version 2 machines. The Booklet Finisher-D1, Staple Finisher-D1, Inner Booklet Trimmer-A1, and Puncher Unit-BF1 can only be connected with an IPC cable. Version 2 can also use an ARCnet communications cable that provides the main unit’s engine information about the ARCnet compatible accessories that are attached, and if they are working properly. The Booklet Finisher-F1 PRO, Booklet Trimmer-D1, and Puncher Unit-BB1 can only be connected with the ARCnet communications cable. The ARCnet cable enables seamless communication between the main unit and the accessories, as there is no significant communication delay, regardless of the many accessories that are connected. Customers must select ARCnet or IPC compatible accessories. ARCnet and IPC communication cables cannot be used at the same time. For more information on the input and output accessories that can be attached to the machine, see “Specifications,” on p. 36. Input Accessories • Duplex Color Image Reader Unit-C1 (Standard) • Paper Deck Unit-C1 • POD Deck Lite-A1 Finishing (Output) Accessories • Staple Finisher-D1 • Booklet Finisher-D1 • Booklet Finisher-F1 PRO • Inner Booklet Trimmer-A1 (Installed inside the Booklet Finisher-D1) • Booklet Trimmer-D1 • Puncher Unit-BF1 (Installed inside the Booklet Finisher-D1) • Puncher Unit-BB1 (Installed inside the Booklet Finisher-F1 PRO) • Professional Puncher-C1 & Professional Puncher Integration Unit-B1 • Document Insertion Unit-K1 • Paper Folding Insertion Unit-H1

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 13

2.6 Storage Capabilities The imageRUNNER ADVANCE 8095 offers four built-in storage methods with flexible linkage to external systems for storing scanned documents and accessing stored files. • Mail Box • Advanced Box • Network • Memory Media

IMPORTANT • Canon U.S.A., Inc. is not responsible for any damages caused to user data that

is stored on the hard disk drive of the machine. It is the customer’s responsibility to create and maintain a data backup plan. Canon U.S.A., Inc. offers several security options to enhance document handling and storage security needs. See “System Options,” on p. 54.

• It is strongly recommended to back up the data stored on the hard disk drive.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 14

2.6.1 Mail Box The Mail Box is a data storage area that stores and handles files for printing. The Mail Box function enables users to store files that are scanned with this machine, or data sent from a personal computer via the printer driver. The stored files can be previewed or printed anytime using the desired settings. Also, the file format of the scanned documents can be converted into another format, such as TIFF, PDF, and JPEG, to send via e-mail using the Send function. Up to 100 mailboxes can be used, and a name or password can be set for each mailbox. In addition, various editing features are available, such as merging separately stored files into one file, and erasing unnecessary pages from a file.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 15

2.6.2 Advanced Box Advanced Box is a storage area in the machine that stores scanned documents and Microsoft Office files that can be used on a computer. There are two types of storage in the Advanced Box: the Shared Space and the Personal Space. Shared Folders • An open access storage space. Ideal as a shared storage space by multiple

users (for example, team, group, or department members). • Subfolders can be created. • Up to 1,000 files/folders (main and sub) can be saved in each level. Personal Folders • Access is restricted to the set user only. Authentication must be set up to

enable a personal folder. • Subfolders can be created. • Up to 1,000 files/folders (main and sub) can be saved in each level. Documents can be scanned with this machine, stored in the PDF, JPEG, or TIFF file format, and can also be previewed or printed on this machine at any time with the desired print settings. The Advanced Box can be opened to the public as an SMB (Server Message Block) server or WebDAV (Distributed Authoring and Versioning) server. This enables the user to access the Advanced Box from a computer, and store and share files in their native format, such as MS Word, Excel, and PowerPoint. To view and print these native format files from the Advanced Box, the user must access them via a computer. The standard storage space for the Advanced Box is approximately 10 GB. However, the standard Advanced Box storage capacity can be increased to 113 GB if the optional 2.5 inch/250 GB HDD is installed.

IMPORTANT It is strongly recommended to protect the Advanced Box folders from viruses. If the user’s computer system has an antivirus system in place, add the Advanced Box folders to its list of folders to scan and protect.

2.6.3 Network

The imageRUNNER ADVANCE 8095 is equipped with a collaboration function that enables it to be connected to other imageRUNNER ADVANCE machines via the SMB/ WebDAV protocol. When the machine is connected to other machines, a user can select an Advanced Box in another machine (if it is on the network) to store files or print a file that is stored in another machine on this machine.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 16

2.6.4 Memory Media Memory Media is storage that can be used by attaching a USB memory stick to the USB port on the control panel. A document can be scanned with this machine and stored in memory media in the PDF, JPEG, or TIFF file format, and also the file stored in the memory media can be printed on this machine at any time with the desired print settings. If the optional USB Device Port-A1 and Multimedia Reader/Writer-A1 are installed, an SD card, Memory Stick, Compact Flash card, and Microdrive can be used. For more information, see “USB Device Port-A1,” on p. 60, and “Multimedia Reader/Writer-A1,” on p. 60.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 17

2.7 Security Features The imageRUNNER ADVANCE 8095 includes a comprehensive set of security features, such as Device Authentication, Data Security, Document Security, and Network Security.

2.7.1 Device Authentication There are two ways to authenticate users at the device. • Department ID Management - Register a Department ID and password for

each department, and manage the machine by limiting its use to only those who enter the correct Department ID and password. Department IDs and passwords for up to 1,000 departments can be registered. Use Department ID Management to keep track of the copy, scan, and print totals for each department. The following settings can be specified: - Turn Department ID Management ‘On’ or ‘Off’. - Register the Department ID and password. - Set page limits for scans, prints, and copies. - Set whether to use Department ID Management for the Mail Box, Send, and

Network Scan functions. If the Copy function is specified, it is automatically restricted when Department ID Management is set.

- Set up copy, scan, and print restrictions.

• SSO-H (Single Sign-On H) - A user authentication system that enables the functions of the machine and MEAP applications, etc., to be used after being authenticated once. SSO-H has two compatible user authentication systems (Domain Authentication and Local Device Authentication). Domain Authentication is linked to a domain controller in a Windows Active Directory environment on a network. Local Device Authentication uses a database inside the machine to authenticate users. Administrators can use one of these two systems or both at the same time. The Access Management System is a subset of the SSO-H authentication system.

• Access Management System - The standard AMS (Access Management

System) enables system administrators to restrict various Copy, Print, Scan, Mail Box, and Send functions that each user can use. Once the AMS is activated, a Function Level Log-In can be used to authenticate users for specific machine functions only. SSO-H must be activated to use the Log-In feature of the AMS.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 18

2.7.2 Data Security The imageRUNNER ADVANCE 8095 offers several ways to protect and secure data. It is strongly recommended that a back up and security system is in place, along with an antivirus protection system to make sure that no data on the hard disk drives are lost, stolen, or compromised. There are several security methods available from Canon U.S.A., Inc. that appropriately addresses a customers’ need for securing data. If a customer has any data security concerns, please contact the dealer for more information. 1. Customer Accessible HDD Initialization Function (Initialize All Data/Settings) 2. Optional Document Scan Lock Kit 3. imageRUNNER ADVANCE Trusted Platform Module 4. Optional Security Kits (HDD Data Erase Kit and HDD Encryption &

Mirroring Kit) 5. Optional Removable Hard Disk Kit

CAUTION Canon U.S.A., Inc. is not liable for any damages resulting from the loss or corruption of data. (See page 5 for further details.)

• Initialize All Data/Settings Function – The Initialize All Data/Settings function is a standard function on all Canon devices. This setting is available in the Management Mode, to which the system administrator must authenticate. Performing this function, erases all user information on the hard disk drive of the machine (e.g., contact information, Advance Box and Mail Box data, network settings, and image data).

IMPORTANT The Initialize All Data/Settings function performs the following procedure if the optional HDD Data Erase Kit is NOT installed: - Deletes the FAT (File Allocation Table) - Overwrites the target HDD data area with “0” (zeros) one time

• Document Scan Lock Kit – The Document Scan Lock Kit embeds an invisible

code over the entire surface of a printed document, which identifies which printer printed the document, and enables the user to track who printed the document. The Document Scan Lock system is tamper resistant, and if someone tries to copy the document, the Document Scan Lock system checks to see if the person has the proper permissions to reproduce it. A password may be required to enable the reproduction of the document. For more information on the Document Scan Lock Kit, see “Document Scan Lock Kit,” on p. 58.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 19

• TPM (Trusted Platform Module) - TPM is a standard security chip (tamper resistant hardware) installed in the imageRUNNER ADVANCE 8095. The TPM provides a facility for the secure generation of cryptographic keys, encrypts information stored on the internal HDD, and decrypts information read from the internal HDD. The public keys to encrypt confidential information are securely controlled by the TPM chip, and they can only be decrypted if the TPM releases the associated decryption key. If the HDD is removed from the machine, it will be difficult to retrieve data off that HDD since the encryption key for that data is stored in a separate location within the TPM.

CAUTION

Once the TPM setting is activated, if the end user fails to back up the TPM key, or if the end user loses the TPM key, it may result in permanent, unrecoverable data loss, for which Canon U.S.A., Inc. is not liable. (See page 5 for further details.)

IMPORTANT • If the TPM setting is activated and the TPM chip fails, the confidential

information stored on the chip can only be recovered if Canon’s service representative replaces the TPM chip and restores the original TPM key to the new chip. Immediately, back up the TPM key on a USB memory stick, after the TPM setting is activated.

• Only the Administrator of the machine can back up the TPM key. • For security reasons, the TPM key can only be backed up once. Store the

USB memory with the backup data in a safe place. • For the back up of the TPM key, it is recommended that a USB memory stick

(supported system file: FAT32) with free space of 10 MB or more is used. • The TPM seals the hardware components associated with the data, and the

data cannot be accessed unless the specific TPM key is issued by the TPM chip. Therefore, setting the TPM mode to ‘On’, may affect service procedures and service costs (if not handled properly). It is strongly recommended that the Administrator who has access to the TPM key be present for all service calls to prevent the loss of data and productivity of the machine.

• Removable Hard Disk Kit - The optional Removable Hard Disk Drive Kit

provides the capability to physically remove the hard disk drive from the machine so it may be placed in a secured location. The hard disk drive can easily be removed for secure storage on a frequent basis, and can easily be reinstalled for normal machine use. This option provides another layer of data security for government agencies and corporate enterprises that need to ensure that data stored on the hard disk is physically secure when the machine is not in use. For more information on the Removable Hard Disk Drive Kit, see “Removable Hard Disk Drive Kit,” on p. 59.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 20

• HDD Data Erase Kit - The optional HDD Data Erase Kit is available for those environments that require additional data security measures. This optional kit automatically overwrites image data that is written to the hard drive following each job performed at the machine. The HDD Data Erase Kit overwrites up to three times with random data, depending on the preferences set by the system administrator. Other settings for the overwrite kit include the ability to overwrite once with null data and overwrite once with random data. For more information on the HDD Data Erase Kit, see “HDD Data Erase Kit,” on p. 59.

IMPORTANT An increase in the amount of times the HDD Data Erase Kit overwrites data, results in a loss of job productivity.

• HDD Data Encryption & Mirroring Kit - The optional HDD Encryption feature

is another security tool available for environments requiring additional data security measures, and can be used in conjunction with the HDD Data Erase feature to provide even greater security for data stored on the internal HDD. The HDD encryption chip is Common Criteria Certified (EAL level 3), and applies 256-bit AES (Advanced Encryption Standard) encryption to all data prior to being written on the HDD. This adds an additional layer of security to files stored on the HDD. The Mirroring function provides redundancy when utilized with an additional hard disk drive of the same storage capacity. This preserves company data if one hard disk drive fails. For more information on the HDD Data Encryption & Mirroring Kit, see “HDD Data Encryption & Mirroring Kit,” on p. 59.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 21

2.7.3 Document Security The imageRUNNER ADVANCE 8095 offers several document security modes to protect printed and distributed documents. • PDF Visible Digital Signature – The PDF Visible Signatures mode enables

the user to view the device signature and user signature on a PDF file. Visible digital signatures and user signatures are displayed on the first page of the PDF file to account for the origin of the document. The system administrator of the machine can set the Visible Signatures mode for all PDF documents or certain PDF documents created on the machine. This mode differentiates from the Digital Signature mode in that instead of having to access digital signature information from the document properties from the File menu, this information is displayed prominently on the first page of the document in the background, and is printed along with the document data, thereby deterring improper distribution of sensitive documents.

• Adobe LiveCycle Rights Management ES Server Integration – Adobe

LiveCycle enables Administrators to set automatic document privileges and apply security policies by creating Policy Protected PDF files on the machine, even after document creation, using the Adobe LiveCycle Rights Management ES Server. Once a Policy Protected PDF document is created on the machine with this feature enabled, the PDF extension in Adobe Reader, upon attempt by a user to open a protected PDF, contacts the Rights Management Server to check the latest authorized users, expiration, auditing, and watermarking policies set by the administrator. These latest policies are then enforced by that application to ensure the information in that document remains secure.

IMPORTANT • To generate a PDF linked with Adobe LiveCycle Rights Management ES

Server, the Adobe LiveCycle Rights Management ES Server must be licensed, pre-configured by a system administrator, and the machine must be connected to the Intranet or Internet.

• Encrypted PDF and PDF/A-1b documents are not compatible with Adobe LiveCycle Rights Management ES Server.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 22

2.7.4 Network Security The imageRUNNER ADVANCE 8095 secures network communications by using IP Address and MAC (Media Access Control) Address filters, encryption and authentication, and network port and application access control. • IP Address and MAC Address Filters – IP Address Filter performs a function

similar to many firewalls. It permits or rejects incoming packets from up to eight IP addresses or ranges of IP addresses. Also, IP address filters to outbound connections can be applied. For example, if such functions as Remote Copy and Universal Send are used, system administrators can block or restrict users from sending files to specific IP addresses. This helps to minimize the risk of data being sent out of the company to systems that are not trusted. MAC Address Filter permits or rejects access for up to 100 MAC addresses. It is useful for environments that use DHCP (Dynamic Host Configuration Protocol) for IP address assignments. If DHCP leases expire and a new IP address is issued to a certain system, the filter can still identify the system’s MAC address, and permit or reject access to the machine. MAC addresses can be easily added, edited, or deleted through the Remote UI. MAC Address Filter takes a higher priority than IP Address Filter, which prevents unknown systems from attacking the machine.

• Encryption and Authentication – SSL (Secure Sockets Layer) protects data

transferred over the network by encrypting file names and formats. The System Administrator can also add IPSec capabilities to secure Internet Protocol (IP) communications from lower layer protocols, such as TCP (Transmission Control Protocol) and UDP (User Datagram Protocol) by authenticating and encrypting each IP packet of a data stream across the Internet. Additionally, the imageRUNNER ADVANCE 8095 supports IEEE 802.1x, which provides port-based authentication. Authentication involves communications between a supplicant, authenticator, and authentication server. The supplicant is authentication software on a client device. The client device (the imageRUNNER ADVANCE 8095) needs the supplicant to provide credentials, such as user names/passwords or digital certificates, to the authenticator (a wireless access point). The authenticator then forwards the credentials to the authentication server (generally a RADIUS database) for verification. If the credentials are valid in the authentication server database, the client device is allowed to access resources located on the protected side of the network.

• Network Port and Application Access Control – Network Port and

Application Access Control enables system administrators to set up only the necessary protocols, such as IPP, FTP, SNTP, SNMP, RAW, LPD, and others for transferring data. These protocols can be switched on and off. The administrator can also disable unneeded services, protocols, ports, and the potential paths of attack so that attacks on the machine can be minimized.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 23

3. Machine Dimensions and Space Requirements 3.1 Dimensions

The following table includes the width, height, and depth dimensions (in inches and millimeters) of the main unit and optional accessories.

Unit Width Depth Height Main Unit*1 53.4” 1,481 mm 30.4” 770 mm 49.25” 1,252 mm Duplex Color Image Reader Unit-C1 25.0” 635 mm 23.9” 605 mm 10.0” 253 mm

POD Deck Lite-A1 23.6” 601 mm 24.5” 621 mm 22.5” 570 mm Paper Deck Unit-C1 12.75” 323 mm 23.0” 583 mm 22.5" 570 mm Document Insertion Unit-K1 29.4” 746 mm 31.25” 793 mm 55.4” 1,407 mm Paper Folding Unit-H1 13.25” 336 mm 31.25” 793 mm 46.9” 1,190 mm Staple Finisher-D1*2 30.75” 782 mm 30.1” 765 mm 41.0” 1,040 mm Booklet Finisher-D1*2 35.25” 896 mm 30.1” 765 mm 41.0” 1,040 mm Booklet Finisher-F1 PRO*2 41.75” 1,060 mm 31.25” 792 mm 46.5” 1,180 mm Puncher Unit-BF1*3 3.75” 95 mm 28.1” 715 mm 15.5” 392 mm Puncher Unit-BB1*4 3.1” 78 mm 25.8” 655 mm 5.2” 131 mm Professional Puncher-C1 & Professional Puncher Integration Unit-B1

21.8” 555 mm 31.25” 792 mm 41.0” 1,040 mm

Inner Booklet Trimmer-A1*3 9.9” 251 mm 24.6” 625 mm 15.9” 403 mm Booklet Trimmer-D1*5 62.0” 1,575 mm 31.25” 792 mm 41.0” 1,040 mm Card Reader-C1 3.5” 88 mm 4.0” 100 mm 1.25” 32 mm Copy Card Reader-F1 3.5” 88 mm 3 3/4” 96 mm 1.6” 40 mm imagePASS-U1 5.5” 140 mm 13.6” 345 mm 12.6” 320 mm *1 The height is measured to the top of the Upright Control Panel in the standard position, and

the width is measured to the right edge of the Upright Control Panel in the extended position. *2 The auxiliary tray is extended. *3 Installed inside the optional Staple Finisher-D1 or Booklet Finisher-D1. *4 Installed inside the optional Booklet Finisher-F1 PRO. *5 The optional Booklet Trimmer-D1 can only be used with the optional Booklet Finisher-F1

PRO.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 24

3.2 Weight The approximate weights of the main unit, feeder, and finishing options (in pounds and kilograms) are listed in the table below.

Unit Weight Main Unit w/Duplex Color Image Reader Unit-C1 and Consumables 534 lb 242 kg Duplex Color Image Reader Unit-C1 86.9 lb 39.4 kg POD Deck Lite-A1 110 lb 50 kg Paper Deck Unit-C1 81.6 lb 37 kg Document Insertion Unit-K1 134 lb 61 kg Paper Folding Unit-H1 157 lb 71 kg Staple Finisher-D1 134 lb 61 kg Booklet Finisher-D1 238 lb 108 kg Booklet Finisher-F1 PRO 397 lb 180 kg Puncher Unit-BF1*1 8.2 lb 3.7 kg Puncher Unit-BB1*2 6.6 lb 3 kg Professional Puncher-C1 & Professional Puncher Integration Unit-B1 264.2 lb 120 kg Inner Booklet Trimmer-A1*1 70.5 lb 32 kg Booklet Trimmer-D1*3 335 lb 152 kg Card Reader-C1 10.4 oz 0.3 kg Copy Card Reader-F1 7.1 oz 0.2 kg imagePASS-U1 15.4 lb 7 kg *1 Installed inside the optional Staple Finisher-D1 or Booklet Finisher-D1. *2 Installed inside the optional Booklet Finisher-F1 PRO. *3 The optional Booklet Trimmer-D1 can be used only with the optional Booklet Finisher-F1

PRO.

3.3 Installation and Service Space The installation site must provide enough space for unrestricted operation, maintenance work, and proper ventilation. The machine dimensions are in diagrams on the following pages. Every attempt should be made to install the equipment in a room that allows for the proper servicing and maintenance of the equipment, and ensures that issues, such as ventilation, odors, and dust accumulation are not a concern.

IMPORTANT • Keep the back of the machine at least 31.5” (800 mm) away from a wall (if the

optional Paper Folding Unit-H1, Professional Puncher-C1 and Professional Puncher Integration Unit-B1, or Document Insertion Unit-K1 is attached). For all other configurations, keep the back of the machine at least 4” (100 mm) away from a wall.

• Make sure that approximately 19 3/4” (500 mm) of space is left around the front, left, and right sides of the machine for the proper servicing of the equipment.

• The floor must be level (with no bows) and flat for the stabilization and support of the machine.

• The minimum doorway opening that the machine passes through prior to installation must be at least 30 1/2” wide.

• The machine should not be moved once it is in place.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 25

3.3.1 Minimum Space Requirements to Transport the Machine and Turn Hallway Corners The following table represents the minimum width that is necessary to turn hallway corners and transport the machine to its final installation site.

Equipment Dimensions When Transporting (Depth x Width) Minimum Corridor Width

Required

Main Unit 30 3/8” x 25 3/8” (770 mm x 645 mm)

59 1/4” (1,505 mm)

POD Deck Lite-A1 24 1/2” x 23 5/8” (621 mm x 601 mm)

53 3/4” (1,365 mm)

Paper Deck Unit-C1 23” x 12 3/4” (583 mm x 323 mm)

46” (1,167 mm)

Staple Finisher-D1 30 1/8” x 25 3/4” (765 mm x 654 mm)

59 1/4” (1,505 mm)

Booklet Finisher-D1 30 1/8” x 30 1/4” (765 mm x 767 mm)

62 3/8” (1,583 mm)

Booklet Finisher-F1 PRO 31 1/4” x 31 1/2” (792 mm x 800 mm)

64” (1,626 mm)

Booklet Trimmer-D1 31 1/4” x 62” (792 mm x 1,575 mm)

89 1/8” (2,263 mm)

Document Insertion Unit-K1

31 1/4” x 29 3/8” (793 mm x 746 mm)

62 5/8” (1,589 mm)

Paper Folding Unit-H1 31 1/4” x 13 1/4” (793 mm x 336 mm)

53 5/8” (1,361 mm)

Professional Puncher-C1 31 1/4” x 12” (792 mm x 305 mm)

53 1/8” (1,349 mm)

Professional Puncher Integration Unit-B1

31 1/4” x 9 7/8” (792 mm x 250 mm)

52 3/8” (1,331 mm)

imagePASS-U1 13 5/8” x 5 1/2” (345 mm x 140 mm)

34 3/8” (872 mm)

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 26

3.3.2 Installation Space Diagrams The approximate installation space requirements may differ, depending on how the machine is configured and the optional accessories attached. The diagrams below show the minimum and maximum configurations with the Booklet Finisher-D1 and Booklet Finisher-F1 PRO.

There must be enough space around the machine. The following diagrams show the minimum dimensions; whenever possible, be sure there will be more space than indicated.

Minimum Configuration with the Booklet Finisher-D1

[1] Duplex Color Image Reader Unit-C1 [2] Booklet Finisher-D1

[3] Upright Control Panel

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 27

There must be enough space around the machine. The following diagrams show the

minimum dimensions; whenever possible, be sure there will be more space than indicated.

Minimum Configuration with the Booklet Finisher-F1 PRO

[1] Duplex Color Image Reader Unit-C1 [2] Booklet Finisher-F1 PRO

[3] Upright Control Panel

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 28

Maximum Configuration with the Booklet Finisher-D1

[1] Duplex Color Image Reader Unit-C1 [2] POD Deck Lite-A1

[3] Document Insertion Unit-K1 [4] Professional Puncher-C1

[5] Professional Puncher Integration Unit-B1 [6] Paper Folding Unit-H1

[7] Booklet Finisher-D1 [8] Upright Control Panel

IMPORTANT • The maximum configuration (fully configured machine above) includes the

Duplex Color Image Reader Unit-C1, Document Insertion Unit-K1, Professional Puncher-C1 and Professional Puncher Integration Unit-B1, Paper Folding Unit-H1, and Booklet Finisher-D1.

• The fully configured width of the machine includes opening space for the POD Deck and the extended tray of the Booklet Finisher-D1.

• There needs to be approximately 1/5” (5 mm) of space in between each accessory attached.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 29

Maximum Configuration with the Booklet Finisher-F1 PRO

[1] Duplex Color Image Reader Unit-C1 [2] POD Deck Lite-A1

[3] Document Insertion Unit-K1 [4] Professional Puncher-C1

[5] Professional Puncher Integration Unit-B1 [6] Paper Folding Unit-H1

[7] Booklet Finisher-F1 PRO [8] Booklet Trimmer-D1

[9] Upright Control Panel

IMPORTANT • The maximum configuration (fully configured machine above) includes the

Duplex Color Image Reader Unit-C1, Document Insertion Unit-K1, Professional Puncher-C1 and Professional Puncher Integration Unit-B1, Paper Folding Unit-H1, Booklet Finisher-F1 PRO, and the Booklet Trimmer-D1.

• The fully configured width of the machine includes opening space for the POD Deck and the extended tray of the Booklet Trimmer-D1.

• There needs to be approximately 1/5” (5 mm) of space in between each accessory attached.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 30

3.4 Recommended Floor Space Requirements For a fully configured imageRUNNER ADVANCE 8095, as shown in the diagram on p. 27, it is recommended that there be at least 18.5’ (W) x 9.6’ (D) of level floor space.

IMPORTANT • The imageRUNNER ADVANCE 8095 was created to be modular in design. Floor

space, budget, monthly copy/print volume, and applications will determine which configuration will work best.

• Only one optional finisher unit (Staple Finisher-D1, Booklet Finisher-D1, or Booklet Finisher-F1 PRO) can be attached to the machine.

• The optional Booklet Trimmer-D1 can only be attached to the Booklet Finisher-F1 PRO.

• Only one paper feeding unit (POD Deck Lite-A1 or Paper Deck Unit-C1) can be attached to the machine.

3.5 Floor Structure Requirements

The floor on which this machine is installed must have strength of at least 61.5 lb/ft2 (30 kg/m2). If the floor does not have this level of strength, consult a building contractor before installing the machine. The weight of the machine is distributed on the floor through the adjusters and wheels. Do not install the machine on an unstable floor or platform.

18.5’ (5.6 m)

9.6’

(2.9

m)

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 31

3.6 Network Interface Connectivity A standard Ethernet 10/100/1000 Base-TX interface jack (RJ-45) for device installation, monitoring, Mail Box and Advanced Box access via the Remote UI, ships standard with all configurations. A Wireless LAN connection can be obtained with the optional Wireless LAN Board-B1. (See “Wireless LAN Board,” on p. 61. Standard support for up to two USB 2.0 High-Speed interface ports ships standard with all configurations. One USB port is on the control panel and can be used for scanning, printing, or direct printing from a USB memory stick. One USB port is on the rear of the machine, and can only be used to attach a USB keyboard, third-party card reader, direct printing, or for servicing the machine.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 32

4. Power/Electrical Requirements The imageRUNNER ADVANCE 8095 requires a NEMA 5-20 receptacle for the main unit.

4.1 Power Requirements for the Main Unit and Optional Accessories

Part or Accessory Power Supply Power Supply Cord/Plug Specifications

Length of Power Cord

Main Unit 1-120 V/20 A outlet NEMA 5-20 8.5’ (2.6 m)

Duplex Color Image Reader Unit-C1*1 From the main unit — —

Paper Deck Unit-C1*1 From the main unit — —

POD Deck Lite-A1 1-120 V/15 A outlet NEMA 5-15 8.5’ (2.6 m)

Staple Finisher-D1 1-120 V/15 A outlet NEMA 5-15 6.7’ (2.0 m) Booklet Finisher-D1 1-120 V/15 A outlet NEMA 5-15 6.7’ (2.0 m) Booklet Finisher-F1 PRO 1-120 V/15 A outlet NEMA 5-15 6.7’ (2.0 m) Document Insertion Unit-K1 1-120 V/15 A outlet NEMA 5-15 6.7’ (2.0 m)

Paper Folding Unit-H1*1 From the finisher — —

Professional Puncher-C1 & Professional Puncher Integration Unit-B1*2

1-120 V/15 A outlet NEMA 5-15 6.7’ (2.0 m)

Puncher Unit-BF1*1 From the finisher — —

Puncher Unit-BB1*1 From the finisher — — Inner Booklet Trimmer-A1*1 From the finisher — —

Booklet Trimmer-D1*3 From the finisher. — —

imagePASS-U1 1-120 V/15 A outlet NEMA 5-15 6.7’ (2.0 m) *1 Does not require any additional outlets. *2 The Professional Puncher Integration Unit-B1 provides the Professional Puncher-C1 with

power. *3 The optional Booklet Trimmer-D1 can only be used with the optional Booklet Finisher-F1

PRO.

NEMA 5-20 Receptacle

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 33

The following illustration shows the power outlets and voltage requirements of each optional accessory item.

IMPORTANT • We recommend an additional standard 120 V/15 A outlet for service tools, such

as a laptop computer or vacuum that may be used when servicing or configuring the machine.

• Use only dedicated and properly grounded outlets for the main unit and imagePASS. It is also strongly suggested to use dedicated and properly grounded outlets for each optional accessory. Do not use extension cords. The ground connection serves to provide the internal electronics with a reference voltage. Faulty or poor ground sources will cause this reference voltage to fall into a range that no longer serves as a reliable reference voltage. The internal logic and programming of the imageRUNNER ADVANCE 8095 will not perform reliably because there is an insufficient difference between the internal operating signal voltages and the poor ground reference signal. A qualified electrician can measure and provide the ground source that the imageRUNNER ADVANCE 8095 or any computer controlled office equipment requires.

• Before installation, confirm that all necessary receptacles are available.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 34

5. Environmental Factors and Requirements This section describes the necessary environmental factors and requirements in which the machine should be operated to achieve the best image quality and print results. NOTE

It may be necessary to use a humidifier or dehumidifier to attain the proper humidity levels for optimal machine performance.

5.1 Temperature and Humidity Conditions

The optimal humidity range is 25% to 75% RH (Relative Humidity) with a room temperature of 59°F to 81.5°F (15°C to 27.5°C). The machine contains intelligent technology that can sense the environmental temperature, and optimize its performance if operated outside the temperature range. However, productivity, paper feeding, image quality, and reliability may be affected if the machine is operated outside of these guidelines. The machine should not be installed in locations with significant shifts in temperature or humidity. Areas containing water, or equipment that can significantly alter room temperature or humidity, such as a space heater, stove, or portable air conditioner, should be avoided. The optimal humidity range for storing paper is 25% to 75% RH (Relative Humidity) with a room temperature of 59°F to 81.5°F (15°C to 27.5°C). Storing paper in a location that does not meet these specifications may affect paper feeding and image quality. For example, if the humidity is too high, paper curling and paper jams will increase. If the humidity is too low, paper may shrink or lose resistance, and toner will not adhere to the paper as well.

5.2 Temperature Gradient Using an air conditioner during the winter, or if a sudden temperature change occurs, may have an adverse affect on image positioning. Sudden temperature changes may cause the paper to bend or contract, cause the machine to malfunction, and form condensation. To avoid these issues, control the temperature gradient so that temperature fluctuations do not exceed 18°F per hour or 10°C per hour.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 35

5.3 Ventilation Ensure that there is an air exchange rate of at least 1.5 times per hour, and at least 3,885 ft3 (110 m3) of space in the location where the machine will be installed. This machine generates a slight amount of ozone during normal use. Although sensitivity to ozone may vary, this amount is not harmful. Ozone may be more noticeable during extended use or long production runs, especially in poorly ventilated rooms. It is recommended that the room be appropriately ventilated, sufficient to maintain a comfortable working environment, in areas of machine operation.

5.4 Elevation Limitations Install this machine at an elevation below 13,123’ (4,000 m) and at an air pressure less than 607.8 hPa.

5.5 Lighting We recommend installing the machine in a location with at least 500 lux (29 1/2” (75 cm) above the floor) for normal operation and maintenance.

5.6 Sunlight Avoid installing the machine in direct sunlight. Direct sunlight has adverse affects on toner consistency and image quality. If direct sunlight is unavoidable, use curtains to shade the machine. Be sure that the curtains do not block the machine’s ventilation slots or louvers, or interfere with the electrical cord or power supply.

5.7 Ammonia Avoid installing the machine where ammonia is emitted. In a sufficient amount, ammonia will attack the surfaces of the machine’s paper feed and image quality components, thereby shortening their useful life and increasing the need for periodic and remedial maintenance. A professional assessment of the air quality in the room in which the machine is to be installed is recommended prior to its installation.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 36

6. Specifications This chapter explains the specifications of the main unit and optional accessories. The specifications provided are approximate values, for reference only, and are subject to change without notice for product improvement or future release.

6.1 Main Unit

Item Specifications

Name Canon imageRUNNER ADVANCE 8095

Type Reader-, Printer-Separated Console

Developing System Dry Single Component Toner Projection

Resolution for Writing Up to 1,200 dpi x 1,200 dpi

Paper Weight and Type

Paper Drawers 1 and 2: Weight: 14 lb bond to 80 lb cover (52 to 220 g/m²) Type*1: Thin, Plain, Heavy, Color, Recycled, Pre-Punched, Bond, and

Letterhead Paper Drawers 3 and 4: Weight: 14 lb bond to 80 lb cover (52 to 220 g/m²) Type*1: Thin, Plain, Heavy, Color, Recycled, Pre-Punched, Tab, Bond, and

Letterhead Multi-Purpose Tray: Weight: 14 lb bond to 140 lb index (52 to 256 g/m²) Type*1: Thin, Plain, Heavy, Color, Recycled, Pre-Punched, Bond,

Transparency, Tracing, Labels, and Letterhead *1 Printing conditions may vary, depending on the paper type. For more

information on paper types, see the Basic Operations e-Manual.

Paper Size

Paper Drawers 1 and 2: LTR Paper Drawers 3 and 4: 13” x 19”, 12 5/8” x 17 11/16”, 12” x 18”, 11” x 17”,

LGL, LTR, LTRR, EXEC, STMTR, and Custom Size (5 1/2" x 7 1/8” to 13” x 19 1/4” (139.7 mm x 182 mm to 330.2 mm x 487.7 mm))

Multi-Purpose Tray: 13” x 19”, 12 5/8” x 17 11/16”, 12” x 18”, 11” x 17”,

LGL, LTR, LTRR, EXEC, STMTR, and Custom Size/Free Size (4” x 5 7/8” to 13” x 19 1/4” (100 mm x 148 mm to 330.2 mm x 487.7 mm))

Warm-Up Time

After Powering ON: Approximately 1 minute Returning from the Sleep mode: Approximately 1 minute Returning from the Energy Saver Mode: Approximately 20 seconds Activation time may vary, depending on the environment and conditions under which the machine is being used.

First Copy Output Time Approximately 2.7 seconds

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 37

Main Unit Table Continued

Item Specifications

Margin Top Margin: 1/8” (2.5 mm) Left and Right Margins: 1/8” (2.5 mm) Bottom Margin: 1/8” (2.5 mm)

Copy Speed (20 lb bond (80 g/m2)) (Except When Paper Is Fed from the Multi-Purpose Tray)

Direct (sheets/minute) Black-and-White 13” x 19” 43 12 5/8” x 17 11/16” 46 12” x 18” 45 11” x 17” 49 LGL 60 LTR 95 LTRR 73 EXEC 95 STMTR 95

Paper Feeding System/ Capacity

Paper Drawers 1 and 2: 1,500 sheets x 2 drawers (20 lb bond (80 g/m2)) Paper Drawers 3 and 4: 550 sheets x 2 cassettes (20 lb bond (80 g/m2)) Multi-Purpose Tray: 100 sheets (20 lb bond (80 g/m2))

Multiple Copies 1 to 9,999 sheets

Operating Noise Approximately 75 dB

Ozone Emissions Approximately 0.01 ppm (parts per million) (Initial Startup) Approximately 0.035 ppm (After a short break-in period) Memory 1.5 GB RAM (Standard), 2 GB RAM (Maximum)

Hard Disk 80 GB (Standard), 250 GB (Maximum)

Power Source 120 V AC, 60 HZ, 20 A

Maximum Power Consumption

Up to 1.92 kW When in the Sleep Mode: Up to 1 W When in the Energy Saver Mode: Up to 240 W (if ‘-10%’ is selected)

Dimensions (H x W x D) (To the Platen Glass) 41” x 25 3/8” x 30 3/8” (1,040 mm x 645 mm x 770 mm)

Dimensions (H x W x D) (With the Duplex Color Image Reader Unit-C1)

49 1/4”*1 x 53 3/8”*2 x 30 3/8” (1,252 mm x 1,481 mm x 770 mm) *1 To the top of the upright control panel in the standard position. *2 To the right edge of the upright control panel in the rightmost position.

Weight Approximately 534 lb (242 kg) (Includes the toner bottle, upright control panel, and Duplex Color Image Reader Unit-C1)

Installation Space (W x D)

93 3/4”*1 x 30 3/8” (2,382 mm x 770 mm) (When the optional Booklet Finisher-D1 is attached, and the multi-purpose tray and auxiliary tray are extended.) 100 1/4”*1 x 31 7/8” (2,546 mm x 810 mm) (When the optional Booklet Finisher-F1 PRO is attached, and the multi-purpose tray and auxiliary tray are extended.) *1 To the right edge of the upright control panel in the extended position.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 38

6.2 Duplex Color Image Reader Unit-C1

Item Specifications Original Feeding Mechanism Single Pass Duplex Automatic Document Feeder

Size and Weight of Originals

11” x 17”, LGL, LTR, LTRR, STMT, and STMTR 1-Sided Scanning: 13 lb bond to 80 lb cover (50 to 220 g/m2) 2-Sided Scanning: Black-and-White Original: 13 lb bond to 80 lb cover (50 to 220 g/m2) Color Original: 17 lb bond to 80 lb cover (64 to 220 g/m2)

Original Tray Capacity 300 sheets (20 lb bond (80 g/m2))

Original Scanning Speed

Copying: LTR in Black-and-White at 600 dpi:

1-sided scanning: 120 sheets/minute 2-sided scanning: 60 sheets (120 pages)/minute

LTR in Color at 600 dpi*1:

1-sided scanning: 51 sheets/minute 2-sided scanning: 25.5 sheets (51 pages)/minute

Scanning*2 LTR in Black-and-White at 300 dpi:

1-sided scanning: 120 sheets/minute 2-sided scanning: 100 sheets (200 pages)/minute

LTR in Color at 300 dpi:

1-sided scanning: 85 sheets/minute 2-sided scanning: 50 sheets (100 pages)/minute

*1 Requires the optional Additional Memory Type B (512 MB). *2 The scanning speed may vary, depending on the scanning mode and

original type. Resolution for Reading Up to 600 dpi x 600 dpi

Number of Gradations 256

Acceptable Originals Sheet, book, three dimensional objects (up to 4.4 lb (2 kg))

Magnification

Regular paper size: Direct Reduction 1:0.78 (LGL ➞ LTR) 1:0.73 (11” x 17” ➞ LGL, 11” x 15” ➞ LTR) 1:0.64 (11” x 17” ➞ LTR) 1:0.50 (11” x 17” ➞ STMT) 1:0.25

Enlargement 1:1.21 (LGL ➞11” x 17”) 1:1.29 (LTR ➞ 11” x 17”) 1:2.00 (STMT ➞ 11” x 17”) 1:4.00

Copy Ratio: 25 to 400% (in 1% increments) Power Source/ Consumption

From the main unit. Up to 180 W

Dimensions (H x W x D) 10” x 25” x 23 7/8” (253 mm x 635 mm x 605 mm)

Weight Approximately 86.9 lb (39.4 kg)

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 39

6.3 Paper Deck Unit-C1

Item Specifications

Paper Size/Weight/Type

Size: LTR Weight: 14 lb bond to 80 lb cover (52 to 220 g/m2)) Type: Thin, Plain, Heavy, Color, Recycled, and Pre-Punched

Paper Deck Capacity 3,500 sheets (20 lb bond (80 g/m2))

Power Source From the main unit.

Maximum Power Consumption Up to 44 W

Dimensions (H x W x D) 22 1/2” x 12 3/4” x 23” (570 mm x 323 mm x 583 mm)

Weight Approximately 81.6 lb (37 kg)

Installation Space Including the Main Unit (W x D)

93 3/4” x 31 1/8” (2,382 mm x 789 mm) (When the optional Booklet Finisher-D1 is attached, and the auxiliary tray is extended.) 100 1/4”*1 x 31 7/8” (2,546 mm x 810 mm) (When the optional Booklet Finisher-F1 PRO is attached, and the auxiliary tray is extended. *1 To the right edge of the upright control panel in the extended position.

6.4 POD Deck Lite-A1

Item Specifications

Paper Size/Weight/Type

Size: 13” x 19”, 12 5/8” x 17 11/16”, 12” x 18”, 11” x 17”, LGL, LTR, and LTRR

Weight: 14 lb bond to 140 lb index (52 to 256 g/m2)) Type: Thin, Plain, Heavy, Color, Recycled, Pre-Punched, Bond, Labels,

Transparency, and Letterhead

Paper Deck Capacity 3,500 sheets (20 lb bond (80 g/m2))

Power Source 120-127 V AC, 60 Hz, 5 A

Maximum Power Consumption Up to 288 W

Dimensions (H x W x D) 22 1/2” x 23 5/8” x 24 1/2” (570 mm x 601 mm x 621 mm)

Weight Approximately 110 lb (50 kg)

Installation Space Including the Main Unit (W x D)

93 3/4” x 31 1/8” (2,382 mm x 789 mm) (When the optional Booklet Finisher-D1 is attached, and the auxiliary tray is extended.) 100 1/4”*1 x 31 7/8” (2,546 mm x 810 mm) (When the optional Booklet Finisher-F1 PRO is attached, and the auxiliary tray is extended. *1 To the right edge of the upright control panel in the extended position.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 40

6.5 Document Insertion Unit-K1

Item Specifications

Paper Size/Weight/Type

Size: 13” x 19”, 12 5/8” x 17 11/16”, 12” x 18”, 11” x 17”, LGL, LTR, LTRR, EXEC, and Custom Size (7 1/8” x 7 1/8” to 13” x 19 1/4” (182 mm x 182 mm to 330.2 mm x 487.7 mm))

Weight: 14 lb bond to 140 lb index (52 to 256 g/m2) Type: Thin, Plain, Heavy, Recycled, Color, Pre-Punched, Bond, Tab,

Tracing, Letterhead, and Coated*1 *1 Coated paper can be loaded into the insertion unit only.

Paper Capacity

Upper Tray 200 sheets (20 lb bond (80 g/m2))

Lower Tray 200 sheets (20 lb bond (80 g/m2))

Power Source 100-240 V AC, 50/60 Hz, 1 A

Maximum Power Consumption

Up to 104 W*1 Up to 115 W*2 *1 When the optional Staple Finisher-D1/Booklet Finisher-D1 is attached. *2 When the optional Booklet Finisher-F1 PRO is attached.

Dimensions (H x W x D) 55 3/8” x 29 3/8” x 31 1/4” (1,407 mm x 746 mm x 793 mm)

Weight Approximately 134 lb (61 kg)

Installation Space Including the Main Unit (W x D)

107 1/4”*1 x 31 1/8” (2,723 mm*1 x 789 mm) (When the optional Booklet Finisher-D1 is attached, and the multi-purpose tray and the auxiliary tray are extended.) 113 5/8”*1 x 32 1/8” (2,887 mm x 817 mm) (When the optional Booklet Finisher-F1 PRO is attached, and the multi-purpose tray and the auxiliary tray are extended.) *1 To the right edge of the upright control panel in the extended position.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 41

6.6 Paper Folding Unit-H1

Item Specifications

Paper Size/Weight/Type

Staple Finisher-D1/Booklet Finisher-D1 is attached: Size:

Z-Fold: LTRR, LGL, 11” x 17” C-Fold: LTRR Accordion Z-Fold: LTRR Double Parallel-Fold*1 LGL, LTRR Half-Fold: LTRR

Weight:

Z-Fold: 14 to 28 lb bond (52 to 105 g/m2) C-Fold: 14 to 28 lb bond (52 to 105 g/m2) Accordion Z-Fold: 14 to 28 lb bond (52 to 105 g/m2) Double Parallel-Fold*1 14 to 24 lb bond (52 to 90 g/m2) Half-Fold: 14 to 24 lb bond (52 to 90 g/m2)

Booklet Finisher-F1 PRO is attached: Size:

Z-Fold: 11” x 17” C-Fold: LTRR Accordion Z-Fold: LTRR Double Parallel-Fold*1 LGL, LTRR

Weight:

Z-Fold: 14 to 28 lb bond (52 to 105 g/m2) C-Fold: 14 to 28 lb bond (52 to 105 g/m2) Accordion Z-Fold: 14 to 28 lb bond (52 to 105 g/m2) Double Parallel-Fold*1 14 to 24 lb bond (52 to 90 g/m2)

Type*2: Thin, Plain, Color, Recycled, Bond, and Coated*3 *1 If the machine has version 1 hardware, a firmware upgrade is required to

utilize this fold. *2 Select Plain paper if using 25 to 28 lb bond (91 to 105 g/m2) paper for

Z-Fold, C-Fold, Accordion Z-Fold, and Half-Fold. *3 Coated paper can be loaded into the insertion unit only.

Power Source From the finisher. Maximum Power Consumption Up to 165 W

Dimensions (H x W x D) 46 7/8” x 13 1/4” x 31 1/4" (1,190 mm x 336 mm x 793 mm) Weight Approximately 157 lb (71 kg)

Installation Space Including the Main Unit (W x D)

107 1/4”*1 x 32 1/8” (2,723 mm*1 x 817 mm) (When the optional Booklet Finisher-D1 is attached, and the multi-purpose tray and auxiliary tray are extended.) 113 5/8”*1 x 32 1/8” (2,887 mm x 817 mm) When the optional Booklet Finisher-F1 PRO is attached, and the multi-purpose tray and the auxiliary tray are extended.) *1 To the right edge of the upright control panel in the extended position.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 42

6.7 Staple Finisher-D1

Item Specifications

Paper Size/Weight/Type

Size: 13” x 19”, 12 5/8” x 17 11/16”, 12” x 18”, 11” x 17”, LGL, LTR, LTRR, STMTR, EXEC, and Custom/Free Size (4” x 5 7/8” to 13” x 19 1/4” (100 mm x 148 mm to 330.2 mm x 487.7 mm))

Weight:

Tray A and C: 14 lb bond to 140 lb index (52 to 256 g/m2)

(The Collate mode cannot be set for paper that weighs less than 16 lb bond (60 g/m2).)

Tray B: 14 lb bond to 140 lb index (52 to 256 g/m2)

Type: Thin, Plain, Heavy, Recycled, Color, Pre-Punched, Bond, Tracing,

Labels, Tab, Transparency, Letterhead, and Coated*1 *1 Coated paper can be loaded into the insertion unit only.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 43

Staple Finisher-D1 Table Continued

Item Specifications

Capacity Per Tray

No Collating

Tray A:

LTR, STMTR, EXEC: 1,500 sheets (or 7 3/4” (195 mm) in height)*1 13” x 19”, 12” x 18”, 11” x 17”, LGL, LTRR: 750 sheets (or 3 7/8” (97 mm) in height)

Tray B:

LTR, STMTR, EXEC: 250 sheets (or 1 1/4” (32 mm) in height) 13” x 19”, 12” x 18”, 11” x 17”, LGL, LTRR: 125 sheets (or 5/8” (16 mm) in height)

Tray C:

LTR: 2,500 sheets (or 12 3/4” (325 mm) in height)*1 STMT, EXEC: 1,500 sheets (or 7 3/4” (195 mm) in height)*1 13” x 19”, 12” x 18”, 11” x 17”, LGL, LTRR: 750 sheets (or 3 7/8” (97 mm) in height)

Collate and Group Modes Tray A and C:

LTR, EXEC: 1,500 sheets (or 7 3/4” (195 mm) in height)*1 13” x 19”, 12” x 18”, 11” x 17”, LGL, LTRR: 750 sheets (or 3 7/8” (97 mm) in height)

Staple Mode Tray A and C:

LTR, EXEC: 1,500 sheets/100 sets (or 7 3/4” (195 mm) in height)*1 11” x 17”, LGL, LTRR: 750 sheets/50 sets (or 3 7/8” (97 mm) in height)

No Collating Mode with Different Paper Sizes Tray A: 750 sheets (or 3 7/8” (97 mm) in height) Tray B: 11” x 17”, LGL, LTRR, LTR, STMTR, EXEC: 125 sheets (or 5/8” (16 mm) in height)*2

Tray C: 750 sheets (or 3 7/8” (97 mm) in height) Collate, Group, and Staple Modes with Different Paper Sizes Tray A and C: 750 sheets (or 3 7/8” (97 mm) in height) *1 Up to 1,200 sheets (or 3 7/8” (97 mm) in height) when thin paper or custom

paper (lighter than 16 lb bond (59 g/m2)) is selected. *2 Up to 30 sheets when printing on mixed paper sizes including 13” x 19”,

12 5/8” x 17 11/16”, and 12” x 18” paper.

-

Version 4 imageRUNNER ADVANCE 8095 Customer Expectations Document Page 44

Staple Finisher-D1 Table Continued

Item Specifications

Capacity Per Tray Continued

Z-Fold Mode (When the Paper Folding Unit-H1 Is Attached) Tray A, C: 11” x 17”: 30 sheets LTRR, LGL: 10 sheets Tray B: 11” x 17”, LGL, LTRR: 10 sheets Half Fold Mode (When the Paper Folding Unit-H1 Is Attached) Tray A, B, C: LTRR: 10 sheets

Max. Stapling Capacity/Available Staple Size

When the Standard Staple Cartridge Is Attached: (The maximum stapling capacity may vary, depending on the paper type and weight.) LTR, EXEC: 100 sheets (20 lb bond (80 g/m2)) or Heavy paper stacked to a