Conductivity of Rubber Cots

Transcript of Conductivity of Rubber Cots

8/6/2019 Conductivity of Rubber Cots

http://slidepdf.com/reader/full/conductivity-of-rubber-cots 1/4

01.11.2010

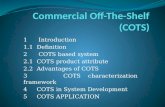

Principle of static charge generation & dissipation mechanism by rubber cot

Dissipative materials have a surface resistivity equal to or greater than 1 x 10 5 Ω/sq butless than 1 x 10 12 Ω/sq or a volume resistivity equal to or greater than 1 x 10 4 Ω-cm but lessthan 1 x 10 11 Ω-cm. 2 For these materials, the charges flow to ground more slowly and in asomewhat more controlled manner than with conductive materials.

Electrostatic shielding materials have a conductive layer with a surface resistivity of less

than 1 x 104

Ω/sq or a volume resistivity of less than 1 x 103

Ω-cm per millimeter of thickness. 2 For ESD-sensitive devices, these materials provide Faraday cage protectionfrom energy transfer.

Insulative materials are defined as those having a surface resistivity of at least 1 x 10 12

Ω/sq or a volume resistivity of at least 1 x 10 11 Ω-cm. 1 Insulative materials prevent or limit theflow of electrons across their surface or through their volume. Insulative materials have ahigh electrical resistance and are difficult to ground. Static charges remain in place on thesematerials for a very long time.

+ ++ +

+ + Rubber cots inner core (PVC OR Alu core)+ ++ + Static charges accumulated on cots surface+ +

+ + Rubber cot layer Material drafted

Steel bottom fluted roller

Static charges accumulated on cots surface+ + + + + + + + + + + + + ++ + + + + + + + + + + + + +

Core acting as a medium between metal to rubber andelectrical conductivity of this layer isVery important for charge neutralization

Charge neutralizationFibreStrands

Earth

Note that the static charges comes in either polarity + or -

+ - + - + - + - + - + - + -

+ - + - + - + - + - + - + -

+ - + - + - + -+ - + - + - + -

Bottom steelFluted roller

8/6/2019 Conductivity of Rubber Cots

http://slidepdf.com/reader/full/conductivity-of-rubber-cots 2/4

Conductive cots:

Any synthetic rubber cot which is used in front & back line positions of a spinning frame canbe said “Conductive” if it obeys the following rules.

1. The rubber cots (Any shore A hardness) should have a surface resistivity less than 1 x 10 5 Ω/sq or a volume resistivity less than 1 x 10 4 Ω-cm. 1 with a low electrical resistance,

2. From cots working surface to its inner core there should be “closed electrical path” sothat “static charges” build up on surface will be easily conducted by the rubber cot and dissipated.

3. The electrical resistance between inner layers of the cots to outer most layers should be “minimum” In other words cots surface resistivity should <1 x 10 5Ohm/ Sq. Areaand volumetric resistivity should be <1 x 10 4ohm /Cubic area

4. Most of the manufactures uses Nitrile rubber for making cots & aprons and surfaceresistivity of both soft & hard cots measures as high as 10 13 Ohm / Sq.Area which fallsin “insulative” range. So it’s clear that any synthetic rubber cots of any shorehardness can’t be conductive no matter what type of raw material they use &manufacturing technique they adopt ”Always a synthetic rubber cot will be non-conductive one!

The below table will shows the electrical properties of various material

Conductive cot characteristicsSurfaceresistance<1 x 10 5

Ohm/ Sq.Area

Volumetric resistivity should be

<1 x 10 4ohm /Cubic

8/6/2019 Conductivity of Rubber Cots

http://slidepdf.com/reader/full/conductivity-of-rubber-cots 3/4

Material Type Surface Resistivity(Ω/sq)

Volume Resistivity(Ω-cm)

Conductive <1 x 10 <1 x 10

Dissipative 1 x 10 5, <1 x 10 12 1 x 10 4, <1 x 10 11

Electrostatic shielding <1 x 10 <1 x 10

Insulative 1 x 10 12 or =1 x 10 11

A Synthetic rubber cot of any shore hardness of any manufactures measures “surfaceresistivity” above 10 13 (Ω/Sq.Area) which is “insulative in nature “, In order to make therubber cot “conductive” in nature a manufacturer must reduce the surface resistivity of cotby a factor 10 7! . For discussion sake even if they able bring down the surface resistivity levelfrom 10 13 (Ω/Sq.Area) to 10 5 (Ω/Sq.Area), it won’t be a rubber cot it will be a metal!

Salient features of “Conductive” cot should be

1. No static charge will be generated on cots surface during working.

2. Absence of static electricity on cots surface will directly results in “nil” fiber licking or“Zero” clearer cover waste. Because there won’t be any electro static attraction of fibers.

3. Even after end breaks, drafted strands of fibers will not be attracted by cots surfaceand it should go into suction tube for prolonged time.

4. Lapping should be “Nil” provided other parameters of cots are ok like surfacecharacteristics, Ra value, Diameter, Top arm pressure, EBR, fiber parameters &speeds & productivity.

5. Cots surface & Volumetric resistivity should be <1 x 10 5 ohm/Sq.Area & <1 x 10 4

ohm/Cubic. Area respectively.

8/6/2019 Conductivity of Rubber Cots

http://slidepdf.com/reader/full/conductivity-of-rubber-cots 4/4

Inarco stand on manufacturing / marketing “Conductive cot”

Even in theory it’s not practically possible to produce a “Conductive cot” whose electricalproperties should be as good as metals , in recent years we at Inarco focused on “How to

improve the electrical properties of synthetic rubber cot by making it more anti static” sothat cot can dissipate the static charges generated on its surface during working .

An antistatic agent is a compound used for treatment of materials or their surfaces in orderto reduce or eliminate buildup of static electricity generally caused by the tribo-electriceffect. Its role is to make the surface or the material itself slightly conductive, either bybeing conductive itself, or by absorbing moisture from the air, so some humectants can beused. The molecules of an antistatic agent often have both hydrophilic and hydrophobicareas, similar to those of a surfactant; the hydrophobic side interacts with the surface of thematerial, while the hydrophilic side interacts with the air moisture and binds the watermolecules

Sujai.BSenior manage – Process controlInarco Ltd