Concrete Box Culvert

Transcript of Concrete Box Culvert

PROJECT SHEET

NO.

TOTAL

SHEETS

STATE

OF

S.D.

DESIGNED BY DRAWN BY CHECKED BY APPROVED

BRIDGE ENGINEER

8

STR. NO. 60-129-235

FOR

S. D. DEPT. OF TRANSPORTATION

1 OF

( & ALT. )

HS 20-44

STA. 453+15.00

SEC. 34-T1 13N-R80W

PLANS BY :

OFFICE OF BRIDGE DESIGN, SOUTH DAKOTA DEPARTMENT OF TRANSPORTATION

Q d

A d

V d

Q F

Q 100

V

F

100

d

project based on 25 year frequency.

Q Computed discharge for the basin approaching proposed project

HYDRAULIC DATA

Q Designated peak discharge for the basin approaching proposed

=

=

=

max

V Maximum computed outlet velocity for the proposed culvert=max

25

Q Design discharge for the proposed culvert based on

based on a 100 year frequency.

1570 cfs

3488 cfs

year frequency. El. 1634. 5

=based on 100 year frequency. El. 1641. 5

13. 2 fps

16. 7 fps

LC

Box Culvert

Sta. 453 15. 00+

L Roadway

Top of Subgrade C

P. I.

+

V. C. 1200. 00’

=+P. I. Sta. 451 00

El. 1638. 00 (Subgr.)

=

OVER COW CREEK

PCN 6394

0 SKEW

1570 cfs

1 19 sq. ft.

-X028-

1’ - 0’’1’ - 0’’

LC

Rdwy

4’ - 0

’’

94’ - 0’’

22’ - 0’’ (Outlet)

6’’

8’’

8’’

8’’

8’’

Subgrade ShoulderSubgrade Shoulder

2 : 1

3 : 14 : 10. 02 ft./ft.0. 02 ft./ft.4 : 13 : 1

1 7’ - 0’’2 : 1 1 7’ - 0’’

F. L. Elev. 1626. 60

F. L. Elev. 1626. 81

F. L. Elev. 1626. 88

F. L. Elev. 1626. 38

F. L. Elev. 1626. 32

Sta. 453 28. 04

Sta. 453 01. 96

PLAN

1 7’ - 0’’ 1 7’ - 0’’

þÿ�1

�4�

þÿ�1

�5�

F. L. Elev. 1626. 60-0. 0030 ft./ft.

F. L. Grade

F. L. Elev. 1626. 32

F. L. Elev. 1626. 88

ELEVATION

1’

- 9’’

Subgrade

Elev. 1652. 1 7 Elev. 1651. 67Elev. 1651. 67

Subgrade ShoulderSubgrade Shoulder

Elev. 1647. 42 Elev. 1647. 42

H. W. Elev. 1641. 5

D. H. W. Elev. 1634. 5

Sta. 451 00. 00

P. C. P. T.

Sta. 457 00. 00+Sta. 445 00. 00+

4. 8858%

29’ - 0’’25’ - 0’’

Sta. 453 15. 00

25’ - 0’’31’ - 0’’

23

’ -

8’’

þÿ�1�8�6�’� �

24’ - 0

’’

þÿ�4

�7�’

� �-

�

12

’ -

0’’

12

’ -

0’’

10

’ -

0’’

25’ - 0’’ 25’ - 0’’

(100 yr.)

(25 yr.)

3’

- 0

’’

Class C Riprap

33

’ -

0’’

16

’ -

6’’

16

’ -

6’’

21’ - 0’’

Class C Riprap

4’ - 6

’’

(Typ.)

4’

- 0’’

Class C Riprap

Type B Drainage Fabric Type B Drainage Fabric

Type B Drainage Fabric

Class C Riprap

Type B Drainage Fabric

- 1. 041 7 %

3’

- 0’’

SITE 2

VERTICAL CURVE DATA

P 3804(16)256

þÿ�1

�2�

10

’ -

0’’

14’’

Construction Joint

Construction Joint

2’

- 0

’’

(Typ.)

3’

- 2’’

Construction Joint

Construction Joint

8’’ 1

2’

- 0

’’1

2’

- 0

’’

21’ - 0’’ 4’ - 0’’

30 (Typ.)

5’ - 8

’’

þÿ�2

�3�’

� �-

� þÿ�2

�3�’

� �-

�

þÿ�2�2�’� �-� �4� 9

28’ - 0’’30’ - 0’’

S3 42’ - 0’’S3 42’ - 0’’ S4 58’ - 0’’= = =

þÿ�9�2�’� �-

þÿ�8

� þÿ�8

�

þÿ�1

�4�’

� �-

�

þÿ�1

� �1

�’� �-

GENERAL DRAWING AND QUANTITIES

The elevations shown in these plans are based on the National Geodetic

Survey (NGS) North American Vertical Datum of 1988 (NAVD88).

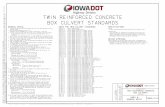

INDEX OF CULVERT SHEETS-

Sheet No. 1 - General Drawing and Quantities

Notes and Undercut DetailsSheet No. 2 -

Sheet No. 3 -

Sheet No. 4 -

Sheet No. 5 -

Sheet No. 6 -

Sheet No. 7 -

W. P.

TABLE OF WORKING POINTS

STATION OFFSET

‘‘A’’

‘‘B’’

‘‘C’’

‘‘D’’

‘‘E’’

‘‘F’’

‘‘G’’

‘‘H’’

Sheet No. 8 - Details of Standard Plate No. 620. 16

Details of Standard Plate No’s. 460. 02 and 460. 10

Standard S3 Barrel End Section Details

Standard S4 Barrel Interior Section Details

Standard Inlet Details

Standard Outlet Details

W. P. ‘‘D’’

W. P. ‘‘A’’

W. P. ‘‘B’’

W. P. ‘‘C’’

W. P. ‘‘E’’

W. P. ‘‘F’’

W. P. ‘‘G’’

W. P. ‘‘H’’

+453 03. 1 7

453 28. 00

453 02. 00

453 38. 99

453 28. 00

73. 00’ Lt.

73. 00’ Lt.

94. 00’ Lt.

94. 00’ Lt.

71. 00’ Rt.

71. 00’ Rt.

92. 37’ Rt.

92. 37’ Rt.

453 26. 83

453 02. 00

+++++++

12

3

4

5

1 23

45

I TEM UNI T QUANTI TY

Class A45 Concrete, Box Culvert

Reinforcing Steel

Structure Excavation, Box Culvert

Box Culvert Undercut

Cu. Yd.

Lb.

Cu. Yd.

Cu. Yd.

106188

Class C Riprap Ton

Type B Drainage Fabric Sq. Yd.

137. 7

used to convert Cu. Yds. to Tons.

For estimating purposes only a factor of 1. 4 tons/cu. yd. was

253

531. 6

NOVEMBER 2005

62’ - 0’’

LC

18’’ CMP

LC

18’’ CMP

49’ - 0’’

-X028-

ESTIMATED QUANTITIES

1 72

For payment, quantity is based on plan shown undercut dimensions

and will not be measured unless the Engineer orders a change.

F. L. Elev. 1630. 50

18’’ CMP

F. L. Elev. 1630. 70

18’’ CMP

452 91 . 01

+

Bottom Limits of Undercut

(See Typical Section

Sheet No. 2 of 8.)

Top Limits of Undercut

(See Typical Section

Sheet No. 2 of 8.)

1 1

’ -

10’’

1 1

’ -

10’’

þÿ�1

�0�’

� �-

(Typ.)

(Typ.)

JKSKS/EO SKS/SJ

SULLY COUNTY

2 - 12’ X 10’ BOX CULVERT (C. I. P.)

236

ALTERNATE A

1

2

3

4

5

6

Hydraulic Data

Index of Sheets

7

8

9

10

Title Block

REQUIRED LIST

Project Block

Estimated Quantities

Plan View

Elevation View

Design Firm or Office

107

1

2

5

68

4

3

Survey Datum Box

11 Working Point Table

11

9

Reference

Box Culvert 01

Horiz.& Vert. Curve Data

12 North Arrow

12

SPECIFICATIONS

Specifications and/or Special Provisions as included in the Proposal.

2. Construction Specifications: South Dakota Standard Specifications for

GENERAL NOTES

1. Design Live Load: HS 20-44, Alternate Loading, and construction

load consisting of one axle with gross weight 95, 850 lbs. The

construction load shall not be applied until a minimum of 3 ft. of

fill has been placed over the Box Culvert. Other construction loads

in excess of legal load must be submitted thru proper channels to the

Office of Bridge Design for analysis.

2. The design of the barrel section is based on a minimum fill height of one

(1) foot and includes all subsequent fill heights up to and including the

Reinforcing Steel fs 24000 p.s.i.

on the wings.

3. Unit Stresses: Concrete fc 1800 p.s.i.

shall be incidental to the other contract items.

I. D. Numbers (see SDDOT Materials Manual).

=

Roads and Bridges, 2004 Edition and required Provisions, Supplemental

length shown in the PLAN view on the General Drawing ( for each S1, S2 etc.

barrel section, as applicable).

2002 Edition (Service Load).

1. Design Specifications: AASHTO Standard Specifications for Highway Bridges

specified and detailed on Standard Plate No. 460. 02

I TEM

and will not be measured unless the Engineer orders a change.

For payment, quantity is based on plan shown undercut dimensions

Box Culvert Undercut

UNI T QUANTI TY

Cu. Yd.

maximum fill height of 15 ft. (S3) and 20 ft. (S4).

4. All Concrete shall be Class A45.

5. All reinforcing steel shall conform to ASTM A615 Grade 60.

þÿ�6�.� � � � �A�l�l� � �e�x�p�o�s�e�d� �e�d�g�e�s� �

7. Use 1 inch clear cover on all reinforcing steel EXCEPT as shown.

8. The Contractor shall imprint on the structure the date of construction as

9. Care shall be taken to establish Working Points (W. P.) as shown

1 1. Cost of Preformed Expansion Joint Filler used in apron construction

12. Dimension ’’L’’ on the standard box culvert barrel sheet(s) is the barrel section

253

PROJECT SHEET

NO.

TOTAL

SHEETS

STATE

OF

S.D.

DESIGNED BY DRAWN BY CHECKED BY APPROVED

BRIDGE ENGINEER

8

STR. NO. 60-129-235

FOR

S. D. DEPT. OF TRANSPORTATION

2 OF

( & ALT. )

HS 20-44

STA. 453+15.00

SEC. 34-T1 13N-R80WOVER COW CREEK

0 SKEW

P 3804(16)256

(Bottom Dimensions)

TYPICAL SECTION(For Limits of Undercut)

UNDERCUT LAYOUT

31’ - 0’’

LC

Box Culvert

32’ - 0’’

16’ - 0’’ 16’ - 0’’

12

’’U

ndercut

and

Backfil

l

2

1

34

’ -

0’’

34

’ -

0’’

68

’ -

0’’

LC

Bo

x C

ulv

ert

19

’ -

6’’

19

’ -

6’’

39

’ -

0’’

LC

Rdwy

31

’ -

0’’

15

’ -

6’’

15

’ -

6’’

23’ - 9’’ 4’ - 0’’ 32’ - 0’’

4’

- 0’’

190’ - 3’’

68’ - 3’’ 62’ - 3’’

+.Sta 453 15. 00

NOVEMBER 2005

NOTES AND UNDERCUT DETAILS

10. Circled numbers in PLAN and ELEVATION views on the General Drawing are Section

ESTIMATED QUANTITIES

2 - 12’ X 10’ BOX CULVERT (C. I. P.)

SULLY COUNTY

SKS/EO JK SKS/SJ

(min

.)

=

=

SITE 2

ALTERNATE A

Backfilled to the top of the top slab.

13. The 18’’ CMP’s shall be installed by trenching them in after the box culvert has been

1

2

3

4

5

Title Block

REQUIRED LIST

Project Block

Plan Notes

Undercut and Backfill

Estimated Quantities

1

2

4

3

5

4

Reference

Box Culvert 02

PROJECT SHEET

NO.

TOTAL

SHEETS

STATE

OF

S.D.

DESIGNED BY DRAWN BY CHECKED BY APPROVED

BRIDGE ENGINEER

8

FOR

S. D. DEPT. OF TRANSPORTATION

3 OF

0 SKEW

NOVEMBER 2005

STANDARD INLET DETAILS

1’ - 15’ FILLS

9’’

( At Bottom Slab )

2 - b1

p6

e 12’’

W. P.

monolithic with Box Culvert.

NOTE:

ITEM

UNIT

O. F. W. W. - Outside Face of Wing Wall

I. F. W. W. - Inside Face of Wing Wall

LEGEND FOR PLACING RE-STEEL

Box Culvert

Structure

Box Culvert

Cu. Yd. Lb. Cu. Yd.

Class A45

Concrete, Excavation,

Inlet

Inlet Apron

Reinforcing

Steel

a1 6 Str.

b1 6 Str.

c1 5 Str.

c2 5 19B

d1 5 19B

e 4 S12

e1 4 S12A

f1 4 S6A

g0 5

g1 4

No. Size Length Type Bending Details

REINFORCING SCHEDULE

All dimensions are out to out of bars.NOTE:Type 19B

þÿ� � �6

12

Cut

(Typ.)

g1

g1

g1

Type

Type

S12

þÿ�5��

þÿ�5��

þÿ�6

� �

Type 19B

Type 19B

12

12

12

þÿ�6

c2d1

d1

c2

Cu

t

Type 1 7A

8’’

f1

Type S6A

k0

Cut

h0

h0

k0

S12A

e1

þÿ�9� �

4

1 7A

p6 6 Str.

p7 4 Str.

p8 4 Str.

p9 4 Str.

g2 4

1

15 c 1A

e

Type 1A

c

20’ - 0’’

20’ - 0’’ 5’ - 9’’

5’ - 9’’

þÿ�1

�0�

28’ - 9’’

27’ - 0’’

25’ - 6’’

25’ - 6’’

29’ - 9’’

26’ - 0’’

24’ - 3’’

25’ - 9’’

25

68

26

28

See cutting diagram.

Bend in field as necessary to fit.

4’ - 2’’

5’ - 0’’

2’

- 7’’

5’ - 0’’

2’

- 9

’’

e2

þÿ�1

�5�

þÿ�1

�8�

9

23’ - 9’’ g2

Cut

u2

u3

10

10

u2

u3

u3

h0

k0

Inlet Apron

u1

e2 45

23

47’ - 0’’

21’ - 0’’

Str.

Str.

Str.

10

10

5

4

4

4

4

4

7’ - 6’’

25’ - 0’’

68’ - 3’’

4

4

4

8

4

8

12

18

4

10

10

4

4

4’ - 6’’

7’ - 0’’

7’ - 9’’

26’ - 6’’

u2

u3

u4

Mk.

3136

1328

3’ - 0’’

2’ - 0

’’

7’ - 0’’

2’ - 0’’

B

B

5’ - 0’’

28

33. 4

g02’ - 6’’

Str.

4 Str.30’ - 6’’4p10

16

1 1’ - 3’’

5’ - 6’’

1 7A

2’

- 1

1 ’

’

7’’

5

5

þÿ�4�’� �-�

23’ - 2’’ 45’ - 1 ’’

3’ - 1 1 ’’

k0

h0

h0

k0

12’ - 7’’ 3’ - 2’’

3’ - 2’’ 12’ - 7’’

12’ - 7’’ 3’ - 2’’

3’ - 2’’ 12’ - 7’’

e

9’’

SEC. B - B

b1

þÿ�1� �

Cl.

Cl.

3’

- 2’’

14’’

2’

- 0’’

þÿ�2

�

9’’

12’’

SEC. A - A

a1f1

5’’

( At Top Slab )

LC

Box C

ulv

ert

Sym

. Abt.

5’

- 8

’’

6’’

4’

- 6

’’

1’ - 6’’

24’ - 0’’

8’’

HALF PLAN

4’ - 0’’

e1

cc2

30

2 - p8 2 - p9 2 - p10

2 - p7 2 - d1W. P.

W. P.

W. P.

2 - a1

f1 12’’

12’’

A

A

See DETAIL ’’X’’HALF PLAN

(Inlet Apron)

u2

u3

u1

e2

3 - u4

2 - u4

þÿ�2�1

�’� �-

3’’

þÿ�2�’�

�-�

þÿ�1� �’� �-�

þÿ�2�’� �-� �

þÿ�4�7

�’� �-� 12’’

ELEVATION

1’

- 9

’’14’’

2’

- 0

’’

p7

e1

g1

h0

k0g2

g1 9’’

3’’3’’3

’’

c

c2

g2

18

’’

8’’

4’’

3’’

c1

e1

d1

p7

O. F. W. W.

I. F. W. W.

1’ - 6’’

þÿ�1

�4�’

� �-

� �

1’ - 6’’

p10

15

’’

g0

=

=

=

=

=

=

=

6’’

h0

c c

6’’

p6

p6

k0

3’

- 8

’’

14’’

Opt. Constr. Jt.

2’

- 0

’’

4’ - 6’’

SEC. C - C

9’’

Opt. Constr. Jt.e1

2’’

Cl.

Cl.

2’’

Cl.

þÿ�1�

1’

- 8’’

g2

g1

g0 g0

g1

g1g1

c2

c1c1

c1 c1

p7

p7

p8 p9 p10

4’ - 1 1’’

5’ - 8’’

8’’

g0 g0

g1

g1

19B

19B

19B

S12

e2

9’’

SEC. E - E

u4

þÿ�1� �

Cl.

Cl.

3’

- 0

’’

þÿ�2

�

u4

u46’’

2’

- 6

’’

1’

- 6

’’

E

E

5

16

Apron shall Not be built

þÿ�4

�’� �-

�

1 7. 4

18. 3

1 7. 4

ESTIMATED QUANTITIES

Opt. Constr. Jt.

DETAIL ‘‘X’’

þÿ�1

�2�

þÿ�1

�’�

�-�

D

D

Constr. Jt. (Typ.)

+ -þÿ�2

��

u1 or u2

O. F. W

. W.

I. F. W

. W.

Op

t.

Co

nstr

. J

t.

Opt. Constr. Jt.

k0 ~ 27 Spaces 10’’ 22’ - 6’’

h0 ~ 15 Spaces 18’’ 22’ - 6’’

e1 ~ 30 Spaces 9’’ 22’ - 6’’=

f1 ~

25 S

paces 1

2’’ 2

5’ - 0

’’

6’’

u3 ~ 1

9 Spaces

12’’

1

9’ - 0

’’

u1 ~

1 1

Spaces 1

2’’ 1

1’ - 0

’’

u2 ~

9 S

paces 1

2’’ 9

’ - 0’’

e2 ~

22 S

paces 1

2’’ 2

2’ - 0

’’

þÿ ��’�’�,�

&�’�’� � �o�r� �

���’�’� �P�r�e�f�o�r�

2 - 12’ X 10’ BOX CULVERT (C. I. P.)

SKS/EO JK SKS/SJ

6’ - 0’’

1 7’ - 6’’

þÿ�3�3�’� �- þÿ�3�4�’� �-

Cut

þÿ�2�0�’� �-

u2 þÿ�2�0�’� �-þÿ�4�’� �-�

C

C

5’’

þÿ�1

�0�’

� �

6’’

24’ - 0’’

9’’ (Typ.)

SITE 2

ALTERNATE A

1

2

3

4

5

6

Standard Notes

7

8

9

10

Title Block

REQUIRED LIST

Project Block

Estimated Quantities

Plan View

Elevation View

Reinforcing Schedule

Legend

Detail "X"

Sections as Req’d.

10

VIEW D - D

Bev

el

9’’

( At Interior Wall )

9

5’’

þÿ�1

�2�

þÿ�1

�’�-

�

1

4

32

9

8

9

9

9

6

6

7

5

Reference

Box Culvert 03

PROJECT SHEET

NO.

TOTAL

SHEETS

STATE

OF

S.D.

DESIGNED BY DRAWN BY CHECKED BY APPROVED

BRIDGE ENGINEER

8

FOR

S. D. DEPT. OF TRANSPORTATION

4 OF

0 SKEW

NOVEMBER 2005

STANDARD OUTLET DETAILS

1’ - 15’ FILLS

All dimensions are out to out of bars.NOTE:

a1 4 6 Str.

6 Str.

4

5 Str. 8

5 19B

d2 8 19B

S12

S12A

f1 S6A

p6 6

4 Str.

4 Str.

4 Str.

Type

Cut

Cut

4

4

Type 19B12

c4

Bend in field as necessary to fit.

No. Size Length Type Bending Details

REINFORCING SCHEDULE

Cut

4 S12

4 Str.

4 Str.

þÿ�1

�0�

g3

c3

c4

e

e1

e2

1 7A

1 7A

10

d2

c4d2 12

1 7A

Str.

4

14

24

ITEM

UNIT

O. F. W. W. - Outside Face of Wing Wall

I. F. W. W. - Inside Face of Wing Wall

LEGEND FOR PLACING RE-STEEL

Cu. Yd.

Box Culvert

Concrete

Lb.

Structure

Excavation

Box Culvert

Cu. Yd.

, , Class A45

. .

Outlet

Outlet Apron

Reinforcing

Steel

k

k

kk

h

h

h

h

4’ - 2’’

þÿ�5

þÿ�5

19’ - 5’’

c

Type 1A

3’ - 1 1’’

Type

Type

S12

þÿ�5��

þÿ�5��

þÿ�6

� �

S12A

e1

1

1

e

2’

- 7’’

5’ - 0’’

2’

- 9’’

e2

8’’

f1

Type S6A

þÿ�1

�8�

þÿ�1

�5�

u5

u6

c 4 5 4’ - 6’’ 1A

26

24

24

25’ - 9’’

24’ - 9’’

23’ - 3’’

25’ - 9’’

1 7’ - 9’’

24’ - 6’’

26’ - 9’’

2’ - 0’’

2871

841

Mk.

5’ - 0’’

7’ - 0’’

5’ - 6’’

5’ - 0’’

26’ - 3’’

22’ - 6’’

7’ - 0’’

23’ - 6’’

7’ - 6’’

20’ - 9’’

23’ - 3’’

4’

- 1 1

’’

30. 0

See cutting diagram.

b2

g0

g3

g4

Str.29’ - 0’’p14

p12

p1 1

p13

25

25

60

12

18

4

14

24

10

4 4

5

4

4

4

5

4

4

4

5

Str.

6’ - 0’’

7’ - 9’’

1 1’ - 3’’ 3’ - 5’’ 12’ - 7’’

þÿ�3�’� �-� þÿ�1�2�’� �-

6’ - 10’’

9

g3

2’

- 1 1

’’

þÿ�9� �

6’’

h

cc

6’’

p6

p6

k

3’

- 8’’

14

’’

Opt. Constr. Jt.

2’

- 0’’

4’ - 6’’

SEC. C - C

9’’

Opt. Constr. Jt.e1

2’’

Cl.

Cl.

2’’

Cl.

þÿ�1�

1’

- 8’’

g4

g3

g0g0

g3

g3 g3

c3 c3

c3c3

p14

4’ - 1 1’’

5’ - 8’’

8’’

g0g0

g3

g3

21’ - 0’’

1’ - 9’’

21’ - 0’’ 4’ - 0’’

1’

- 9’’

14’’

2’

- 0’’

6

’’

4’’

u6 ~ 19 Spaces 12’’ 19’ - 0’’ 3’’=

=u5 &

e2 ~

1 1

Spaces 1

2’’ 1 1

’ -

0’’

2 - u6

3 - u6

W. P.

( At Bottom Slab )

DETAIL ’’X’’

9’’

BB

(Typ.)

p6

2 - b2

3’ - 0’’

W. P.

e2

E E

u5

u6

LC

Bo

x C

ulv

ert

Sym

. A

bt.

LC

Bo

x C

ulv

ert

Sym

. A

bt.

HALF PLAN

O. F. W. W

.

I. F. W

. W.

þÿ�1

�4�’

� �-

�

ELEVATION

e1

e1

d2

h

g4

k

c3

c

c4

g4

p1 1

g3 9’’

p14

8’’4’’

3’’

Opt. Constr. Jt.

g3 9’’

p1 1

g0

3’’ 3

’’ 3’’

C

C

1’ - 6’’

1’ - 10’’ k ~ 23 Spaces 10’’ 19’ - 2’’=

h ~ 13 Spaces 18’’ 19’ - 6’’=

21’ - 0’’

O. F. W. W.

I. F. W. W. 9

’’

12’’

SEC. A - A

a1f1

e

9’’

SEC. B - B

b2

þÿ�1� �

Cl.

Cl.

3’

- 2’’

14’’

2’

- 0’’

þÿ�2

�

e2

9’’ SEC. E - E

u6

þÿ�1� �

Cl.

Cl.

3’

- 0

’’

þÿ�2

�

u5u6

u6 6’’

2’

- 6’’

1’

- 6

’’

1’ - 6’’

e1 ~ 26 Spaces 9’’ 19’ - 6’’=

9’’

( Typ. )

HALF PLAN

e1 2 - p12 2 - p13 2 - p14

W. P.6’’

5’

- 8

’’

8’’

4’

- 6

’’

= f

1 ~

25

Sp

aces

12

’’

2

5’ -

0’’

f1

AA

2 - a1

See DETAIL ’’X’’

c3

W. P.2 - d2

2 - p1 1

18

’’1

5’’

( At Top Slab )

p1 1

p1 1

p13 p12

þÿ�1

�2�

þÿ�1

�’�

�-�

Expansion Joint Filler

þÿ ��’�’�,� &�’�’�,� � �o�r

1 1

’ -

10’’

( Outlet Apron )

6’’

e 12’’

c4

19’ - 5’’ 6’ - 10’’ g3

k

h

3’ - 5’’12’ - 7’’

þÿ�3�’� �-�þÿ�1�2�’� �-

Str.

Str.

7’’

16. 4

10. 8 10. 8

Constr. Jt. (Typ.)

þÿ�2

� �

Opt. Constr. Jt.

Opt. Constr. Jt.

2 - 12’ X 10’ BOX CULVERT (C. I. P.)

6’’

SKS/EO JK SKS/SJ

Outlet Apron

ESTIMATED QUANTITIES

þÿ�1

�0�’

� �-

c

SITE 2

ALTERNATE A

1

2

3

4

5

6

Standard Notes

7

8

9

10

Title Block

REQUIRED LIST

Project Block

Estimated Quantities

Plan View

Elevation View

Reinforcing Schedule

Legend

Detail "X"

Sections as Req’d.

1

9

8

9

5

4

3 2

9

9

6

6

7

monolithic with Box Culvert.

NOTE: Apron shall Not be built

10

Reference

Box Culvert 04

PROJECT SHEET

NO.

TOTAL

SHEETS

STATE

OF

S.D.

DESIGNED BY DRAWN BY CHECKED BY APPROVED

BRIDGE ENGINEER

8

FOR

S. D. DEPT. OF TRANSPORTATION

5 OF

0 SKEW

NOVEMBER 2005

STANDARD S3 BARREL END SECTION DETAILS

Box Culvert

Structure

Box Culvert

ITEM

UNIT

Concrete, Excavation,

Class A45

Lb. Cu. Yd.Cu. Yd.

Reinforcing

Steel

See General Drawing for number of construction joints required.

S3 BARREL SECTION(15’ - 0’’ Maximum Fill)

LEGEND FOR PLACING RE-STEEL

T. T. S. - Top of Top Slab

B. T. S. - Bottom of Top Slab

T. B. S. - Top of Bottom Slab

B. B. S. - Bottom of Bottom Slab

O. F. O. W. - Outside Face of Outside Wall

M. W. - Middle Wall

I. F. O. W. - Inside Face of Outside Wall

Note: Contractor may form the optional full fillet,

with 2’’ Chamfer, as detailed. The cost of the

additional concrete shall be borne by the Contractor.

REINFORCING SCHEDULE

Mk. No. Size Length Type Bending Details

n3

j3

h3 4 1 7A

Str.

k3

Str. m3

1 7

Type 1 7

(E

xact)

k3

h312’’ w3

Type S1 1A

(Exact)

(E

xact)

Type 1 7A

Str.4 L 6’’

Str.

w3

5 Str.

2’

- 9

’’

min

. la

p

Typ.

þÿ�7

�’� �-

�

Contractor may use optional reinforcing steel splice, as shown.

The cost of the additional reinforcing steel shall be borne by

the Contractor.All dimensions are out to out of bars.

NOTE -

Request for additional reinforcing steel splices at points other

approval. If additional splices are approved, no payment will be

than those shown, must be submitted to the Engineer for prior

allowed for the added quantity of reinforcing steel.

construction joint.

OPTIONAL k3

SPLICE DETAIL

s3 2. 40L Str.

OPTIONAL FILLET DETAIL( At Bottom Slab)

6’’2’’

2’’

6’’

1 - Construction Joint+

+

ESTIMATED QUANTITIES

NOTE:

as shown on Standard Plate No. 460. 10.

Place z1 bars thru construction joint between barrels

The Bottom Slab may be poured continuously, at the option of

forming to the keyway dimensions and location as shown on

slab. Care shall be taken to maintain proper alignment of

the keyway during the pour sequence. All additional costs

of this option shall be borne by the Contractor.

OPTIONAL POUR - BOTTOM SLAB

the Contractor, with the use of a Preformed Metal keyway con-

the plans. The keyway length shall be full width of the bottom

p

z1

2. 40L

2. 00L

2. 40L

139

8

6

7

6

8

4

12’ - 6’’

24’ - 9’’

19’ - 0’’

26’ - 9’’

25’ - 9’’

5’ - 9’’

26’ - 3’’

3’ - 6’’þÿ�1� �1

6’’

þÿ�1

� �1

� �’

� �-

�

3’ - 6’’

3’ - 6’’

1 1

’ -

1 1

’’

1’- 8’’

4’’

27’ - 0’’

8’’

p

p

p

p

p

p

2’

- 5

’’

26’ - 0’’

Const. Jt. (Typ.)

Opt. Const. Jt. (Typ.)

14’’

þÿ�1

�2�

12’ - 0’’

6’’6’’1 1 Spaces at 12’’ 1 1’- 0’’

6’’

2’ - 2’’

6’’ 6’’1 1 Spaces at 12’’ 1 1’ - 0’’

10’

- 0’’

þÿ�2

�’�

�-�

�

1’ - 15’ FILLS

2’’

Cl.

Cl.

þÿ�1

� �

=

=

=

=

=

ELEVATION

2’’ x 3’’ Keyway (Typ.)

M.

W.

I. F. O

. W.

O. F. O

. W.

pp

p p ps3 10’’

j3 10’’

h3 1 1’’

j3 10’’

s3 10’’

m3 6’’

p 18’’

p 18’’

m3 6’’

þÿ�k�3� �

þÿ�k�3� �

þÿ�k�3� �

p

w3 12’’

n3 5’’ n3 5’’

Round number of bars up to nearest

whole number, except round h3, k3,

j3 and s3 up to nearest even whole

number.

650. 64L 206. 59

240. 93

barrel wall.

NOTE -

required to place 18’’ CMP thru

I. F. O. W.

ELEVATION( showing typ. steel revision at pipe location )

a3 - place bars in

inside and outside

for position and F. L.

Elev. of CMP.

face of wall at 18’’ CMP.

h3

k3

k3

m3

n3

See Sheet No. 1 of 8

Cut and bend h3, k3 and p bars asp bars

p bars

p bars

p

12’’‘‘L’’

3’’

8’’

2’’ x 3’’ Keyway (Typ.)

p p

s3 10’’

j3 10’’

m3 6’’

p 12’’

þÿ�k�3� �

p

w3 12’’

n3 5’’

þÿ�k�3� �

þÿ�k�3� �

s3 10’’

j3 10’’

p

p

p 12’’

h3 1 1’’

W. P.

B. T. S

.

T. T. S

.T. B

. S.

B. B. S

.p 12’’

LC

Bo

x C

ulv

ert

j3, m3, n3, k3, h3, and w3 bar spacing

s3 bar spacing

Sy

m.

Ab

t.

HALF PLAN

p

LC

Box Culvert

Sym. Abt.

1’

- 8

’’

þÿ�1

�2�’

� �-

�

10 Spaces at 12’’ 10’ - 0’’ 1’ - 4’’

1’ - 4’’ 10 Spaces at 12’’ 10’ - 0’’

5 ~

Spaces a

t 18’’ 7’ -

6’’

2 - 12’ X 10’ BOX CULVERT (C. I. P.)

SKS/EO JK SKS/SJ

s3 10’’j3 10’’

m3 6’’

w3 12’’

þÿ�k�3� �

h3 1 1’’

s3 10’’j3 10’’

n3 5’’

p

2. 18(L 1)

4. 36(L 1)

1. 00(L 1)

+

+

+

66 z1 bars required at each

1’ - 3’’

1

1 Type 19A

2’ - 9’’

a3

19A6’ - 9’’58a3

PIPE INLET

S1 1A

1 - Standard S3 Barrel End Section 2. 966L 1. 167L

SITE 2

ALTERNATE A

1

2

3

4

5

6

Standard Notes

7

8

9

10

Title Block

REQUIRED LIST

Project Block

Estimated Quantities

Plan View

Elevation View

Reinforcing Schedule

Legend

Typical Section

Optional Fillet Detail

6

10

2

3

4

9

1010

5

1

8

7

Reference

Box Culvert 05

PROJECT SHEET

NO.

TOTAL

SHEETS

STATE

OF

S.D.

DESIGNED BY DRAWN BY CHECKED BY APPROVED

BRIDGE ENGINEER

8

FOR

S. D. DEPT. OF TRANSPORTATION

6 OF

1’ - 20’ FILLS

NOVEMBER 2005

STANDARD S4 BARREL INTERIOR SECTION DETAILS

h4

j4

k4

m4

n4

5

Mk. No. Size

6’’

2’’

2’’

6’’

4

s4 8

8

Concrete

Box Culvert

Structure

Excavation

Box Culvert

ITEM

UNIT Cu. Yd. Lb. Cu. Yd.

1 7A

Str.

1 7

Str.

Str.

Str.

Str.

REINFORCING SCHEDULE

Length

Class A45 Reinforcing

Steel

L 3’’

Str.

____ ____

ELEVATIONS4 BARREL SECTION

( 20’- 0’’ Maximum Fill)

1 - Construction Joint

h4

(E

xact)

k4

Bending Details

2’

- 6

’’

w4

(Exact)

(E

xact)

12’’

2. 29L

-

2.00L

Type 1 7

(min

. la

p)

OPTIONAL k4 SPLICE DETAIL

S11A

LEGEND FOR PLACING RE- STEEL

T. T. S. - Top of Top Slab

B. T. S. - Bottom of Top Slab

T. B. S. - Top of Bottom Slab

B. B. S. - Bottom of Bottom Slab

OPTIONAL POUR - BOTTOM SLAB

the Contractor, with the use of a Preformed Metal keyway con-

forming to the keyway dimensions and location as shown on

the plans. The keyway length shall be full width of the bottom

slab. Care shall be taken to maintain proper alignment of

the keyway during the pour sequence. All additional costs

of this option shall be borne by the Contractor.

The Bottom Slab may be poured continuously, at the option of

OPTIONAL FILLET DETAIL

( At Bottom Slab)

Note: Contractor may form the optional full fillet,

with 2’’ Chamfer, as detailed. The cost of the NOTE -

Place z1 bars thru construction joint between

barrel sections as shown on Standard Plate No.

460. 10.

All dimensions are out to out of bars.

Request for additional reinforcing steel splices at points other

approval. If additional splices are approved, no payment will be

than those shown, must be submitted to the Engineer for prior

allowed for the added quantity of reinforcing steel.

NOTES -

NOTE -

Maximum dimension (’’X’’) equal to one half of bar spacing.

Type 1 7A

ESTIMATED QUANTITIES

2. 18L

Type

additional concrete shall be borne by the Contractor.

k4

See General Drawing for number of construction joints required.

z1

w4

p4

2. 67L

4.00L

139

2. 67L

1. 00L

4

7

26’- 9’’

25’- 9’’

7

7

4

12’ - 9’’

5’ - 9’’

26’ - 9’’

3’- 6’’

19’- 6’’

24’- 9’’

12’’

12

’ -

2’’

6’’

12

’- 3

’’

þÿ�3�’� �-�

þÿ�7

�’� �-

�

þÿ�3�’� �-�

1’- 4’’

1’- 4’’

8’’

1’- 4’’

27’ - 1’’

5 ~

Sp

aces a

t 1

8’’

7

’- 6

’’

p4

p4p4

p4

p4

p4

p4

p4

p4p4 p4p4p4

p4

26’ - 1’’

Const. Jt. (Typ.)

Opt. Const. Jt. (Typ.)

þÿ�1

�4�

12’- 0’’ 12’- 0’’

6’’ 6’’

10 Spaces at 12’’ 10’-0’’ 10 Spaces at 12’’ 10’-0’’

10 Spaces at 12’’ 10’-0’’ 10 Spaces at 12’’ 10’-0’’

1 1 Spaces at 12’’ 1 1’- 0’’

6’’6’’ 1 1 Spaces at 12’’ 1 1’- 0’’ 6’’6’’

6’’

(T

yp

.)

6’’6’’1 1 Spaces at 12’’ 1 1’- 0’’

6’’ 6’’1 1 Spaces at 12’’ 1 1’- 0’’

10

’- 0

’’

1’- 4’’

þÿ�2

�’�-

� �5

2’’

Cl.

Cl.

þÿ�1

� �

=

=

=

=

==

==

=

þÿ�8� � þÿ�8� �

þÿ�1�’�-� � þÿ�1�’�-� �

12

’ -

6’’

þÿ�1

�5�

12

’ -

6’’

þÿ�2

�’�-

� �6

þÿ�2�’� �-� þÿ�2�’� �-�

M.

W.

I. F. O

. W.

O. F. O

. W.

p4p4

p4 p4 p4s4 9’’

j4 9’’

j4 9’’

s4 9’’

p4 18’’

p4 18’’

p4

w4 12’’

n4 6’’

2’’ x 3’’ Keyway (Typ.) k4 6’’

k4 6’’

þÿ�m�4� �

k4 6’’

T. T. S.

B. T. S.

T. B. S.B. B. S.

‘‘L’’

p4p4

s4 9’’

j4 9’’

p4 12’’

p4

w4 12’’

n4 6’’

s4 9’’

j4 9’’

p4

p4

p4 12’’

p4 12’’

‘‘X’’

þÿ�‘�‘�X�’�’�

þÿ�m�4� �

k4 6’’

k4 6’’

k4 6’’

2’’ x 3’’ Keyway (Typ.)

+

O. F. O. W. - Outside Face of Wall

I. F. O. W. - Inside Face of Wall

M. W. - Middle Wall

Round number of bars up to the

nearest whole number, except round

h4, j4, s4 and k4 bars up to nearest

even whole number.

3. 290L 731. 55L 23. 21

240. 93

-

66 - z1 bars required at each

construction joint.

Contractor may use optional reinforcing

steel splice, as shown. The cost of the

additional reinforcing shall be borne by

the Contractor.

þÿ�h�4� � �

LC

Box C

ulv

ert

j4, m4, n4, k4, h4, and w4 bar spacing

s4 bar spacing

HALF PLAN

þÿ�h�4� � �

Sy

m.

A

bt.

s4 9’’j4 9’’

þÿ�m�4� �

w4 12’’

þÿ�h�4� � �

k4 6’’

þÿ�h�4� � �

k4 6’’

n4 6’’

s4 9’’j4 9’’

þÿ�1

�’�-

� �9

SKS/EO JK SKS/SJ

2 - 12’ X 10’ BOX CULVERT (C. I. P.)

S1 1A

1. 296L

p4

1 - Standard S4 Barrel Interior Section

SITE 2

ALTERNATE A

1

2

3

4

5

6

Standard Notes

7

8

9

10

Title Block

REQUIRED LIST

Project Block

Estimated Quantities

Plan View

Elevation View

Reinforcing Schedule

Legend

Typical Section

Optional Fillet Detail

1

5

4

3

2

10

10

9

6

7

8

10

Reference

Box Culvert 06

PROJECT SHEET

NO.

TOTAL

SHEETS

STATE

OF

S.D.

87 OFNOVEMBER 2005

STR. NO. 60-129-235

2 - 12’ X 10’ BOX CULVERT (C. I. P.) SITE 2

ALTERNATE A

REQUIRED LIST

1

2

3Title Block

Project Block

Insert Required Standard

Plate Sheets as Needed

1

2

Box Culvert 07

Reference

460. 02

PLATE NUMBER

S

D

D

O

TSheet 1 of 1

YEAR PLATE DETAILS

PLACE

APPROPRIATE

NUMBER

HERE

PLACE

APPROPRIATE

NUMBER

HERE

1 7’’

þÿ��� 1’’ þÿ�2� � 1’’ þÿ�2� � 1’’ þÿ�2� � þÿ���

þÿ��

�þÿ

���

3’’

þÿ

���

þÿ��

�

6’’

YEAR PLATE DETAILS

NOTES:

and attached to the forms in such a manner that the finished imprint in the

the other contract items.

box culverts and bridges. The year plates shall be constructed in reverse

þÿ�1� � þÿ�1� �

1. Year plates of the general dimensions shown shall be constructed on all

þÿ�c�o�n�c�r�e�t�e� �d�o�e�s� �n�o�t� �e�x�c�e�e�d� �o

3. There will be no separate measurement or payment made for year plates

the upper sloped portion of the barrier approximately 5’- 6’’ from the end of

at each end of the bridge on opposite sides.

the bridge, or as designated by the Engineer. There shall be one year plate

endblocks, the year plate shall be centered vertically on the curb face approximately

bridges with ‘‘Jersey’’ shaped barrier endblocks, the year plate shall be centered on

six (6) inches from the end of the bridge, or as designated by the Engineer. On

b. On bridges with six (6) inch curbs or ‘‘Jersey’’ shaped barriers with no

End Brid

ge

End Bridge

Year Plate

Year Plate

End Bridge

Year Plate

JERSEY BARRIER TYPE B CURBJERSEY BARRIER

( With Endblock )

inches below the top of the upstream parapet wall and centered laterally on the

upstream face. On precast box culverts the year plate shall be centered laterally

with this location, the year plate shall be centered in an adjacent barrel.

on the upstream face of the top slab. Where an extended interior wall interferes

þÿ�a�.� � � � � �O�n� �c�a�s�t�-�i�n�-�p�l�a�c�e� �b�o�x� �c�u�l�v�e�r�t�s� �t�h�e� �y�e�a

5’- 6’’

Year Plate See Note 2 (c)

Year Plate See Note 2 (c)

6’’

Year Plate See Note 2 (c)

6’’

c. When the plans specify that both the original date of construction and the date of

reconstruction are to be shown, one date shall be placed as listed above and the

bridge on opposite sides.

other located adjacent to it. Both year plates shall be shown at each end of the

2. Year plates shall be located on structure (s) as follows:

þÿ�2� �

on box culverts and bridges. All costs for this work shall be incidental to

March 31, 2000 March 31, 2000

PLATE NUMBER

S

D

D

O

TSheet 1 of 1

LEGEND FOR PLACING RE-STEEL

RISE ’’ X ’’

2’’ x 3’’ Keyway (Typ.)

1’- 9’’

p bars 18’’

I. F. W

.

ELEVATION

6’’

( T

yp

. ) ( Typ. )

( Typ. )

I. F. W. - Inside Face Wall

p

p

TYPICAL SINGLE BARREL VIEW A - A

TYPICAL MULTIPLE BARREL VIEW A - A

z1 bars spaced 12’’

( T

yp

.

Ou

tsid

e W

all

s )

9’’

6’’

3’’

9’’

6’’

3’’

9’’

6’’

3’’

’’X

’’

RIS

E

’’X

’’

6’’

6’’

6’’

6’’

’’X

’’

’’X

’’

2. Drainage Fabric Protection shall be

placed in accordance with Section 422,

middle of the 2’’ X 3’’ keyway in

NOTES:

shall be lapped with the longitudinal

for outside walls and in either face for

z1 bars s

paced 1

8’’ I. F

. W

. z1 bars spaced 12’’

z1 bars s

paced 1

8’’ e

ither f

ace

( T

yp. In

teri

or

Wall

s )

6’’

( T

yp

. ) ( Typ. )

( Typ. )

z1 bars spaced 12’’

( T

yp. O

uts

ide W

all

s )

’’X

’’

RIS

E

’’X

’’

6’’

6’’

6’’

6’’

z1 bars s

paced 1

8’’ I. F

. W

. z1 bars spaced 12’’

z1 18’’ ( I. F. W. )

z1

z1

4’- 0’’

5’- 0’’

6’- 0’’

7’- 0’’

8’- 0’’

9’- 0’’

10’- 0’’

1 1’- 0’’

12’- 0’’

the top and bottom slabs. z1 bars

p bars in the inside face of the wall

1. z1 bars shall be placed in the

interior walls. z1 bars are listed and

3’- 0’’ 3’’

1’- 9’’

included elsewhere in plans.

or Section 560, whichever is applicable.

A

A

BOX CULVERT BARREL TIE REINFORCEMENT460. 10

3

Published Date: 4th Qtr. 2008 Published Date: 4th Qtr. 2008

INDEX OF CULVERT SHEETS-

Sheet No. 1 - General Drawing and Quantities

Notes and Undercut DetailsSheet No. 2 -

Sheet No. 3 -

Sheet No. 4 -

Details Of Standard Plate No. 460. 02

and No. 560. 01

Details of Standard Plate No. 560. 20

and No. 620. 16

PROJECT SHEET

NO.

TOTAL

SHEETS

STATE

OF

S.D.

DESIGNED BY DRAWN BY CHECKED BY APPROVED

BRIDGE ENGINEER

4

STR. NO. 60-129-235

FOR

S. D. DEPT. OF TRANSPORTATION

1 OF

( & ALT. )

HS 20-44

STA. 453+15.00

SEC. 34-T1 13N-R80WOVER COW CREEK

PCN 6394

0 SKEW

-X028-

PLANS BY :

OFFICE OF BRIDGE DESIGN, SOUTH DAKOTA DEPARTMENT OF TRANSPORTATION

LC

Box Culvert

Sta. 453 15. 00+

L Roadway

Top of Subgrade C

P. I.

+

V. C. 1200. 00’

=P. I. Sta. 451 00

El. 1638. 00 (Subgr.)

=

Sta. 451 00. 00

P. C. P. T.

Sta. 457 00. 00+Sta. 445 00. 00+

4. 8858%- 1. 041 7 %

+

Q d

A d

V d

Q F

Q 100

V

F

100

d

project based on 25 year frequency.

Q Computed discharge for the basin approaching proposed project

HYDRAULIC DATA

Q Designated peak discharge for the basin approaching proposed

=

=

=

max

V Maximum computed outlet velocity for the proposed culvert=max

25

Q Design discharge for the proposed culvert based on

based on a 100 year frequency.

1570 cfs

3488 cfs

year frequency. El. 1634. 4

=based on 100 year frequency. El. 1641. 3

12. 9 fps

16. 3 fps

1570 cfs

122 sq. ft.

2 - 14’ X 10’ BOX CULVERT (PRECAST)

LC

Rdwy

LC

Box C

ulv

ert

FLOW

N

74’ - 0’’ 72’ - 0’’

142’ - 0’’ Precast Box Culvert20’ - 0’’ 20’ - 0’’

(Outlet) (Inlet)

92’ - 0’’ 90’ - 0’’

182’ - 0’’

21’ - 0’’

37

’ -

0’’

18

’ -

6’’

18

’ -

6’’

F. L. Elev. 1626. 32 F. L. Elev. 1626. 60

Sta. 453 15. 00+

Sta. 453 30. 00+

Sta. 453 00. 00+

W

14

’ -

0’’

W 14’ -

0’’

==

Ts

Ts

Tm

Tt

Tb

H

10

’ -

0’’

-0. 0030 ft./ft.F. L. Elev. 1626. 32 F. L. Elev. 1626. 60

25’ - 0’’ 25’ - 0’’1 7’ - 0’’ 1 7’ - 0’’

0. 02 ft./ft.0. 02 ft./ft.4 : 1 4 : 1

32’ - 0’’

3 : 1

30’ - 0’’

3 : 1

2 : 12 : 1

25’ - 0’’ 1 7’ - 0’’1 7’ - 0’’ 25’ - 0’’

SubgradeCL

Elev. 1652. 1 7

Subgrade Shoulder

Elev. 1651. 67

Elev. 1647. 42

Subgrade Shoulder

Elev. 1651. 67

Elev. 1647. 42

4’

- 0’’

4’

- 0’’

F. L. Elev. 1626. 87

F. L. Elev. 1626. 87

Class C Riprap

Type B Drainage Fabric

3’

- 0’’

Class C Riprap

Type B Drainage Fabric

2’

- 0

’’

(Typ.)

3’

- 0

’’

=

F. L. Grade

H. W. Elev. 1641. 3

(100 yr.)

D. H. W. Elev. 1634. 4

(25 yr.)

Subgrade Shoulder Subgrade Shoulder

Dimension may vary with fabricator. See Shop Plans for actual installation length.

Minimum distance to satisfy fill slope.

Based on dimensions shown.

LEGEND

W

H

Tt

Tb

Ts

===

=

Width of Opening

Height of Opening

Thickness of Top Slab

Thickness of Side Wall=

Thickness of Bottom Slab

Tm = Thickness of Middle Wall

ELEVATION

PLAN

VERTICAL CURVE DATA

P 3804(16)256

Based on 8’’ Walls.

NOVEMBER 2005

GENERAL DRAWINGS AND QUANTITIES

I TEM UNI T QUANTI TY

Structure Excavation, Box Culvert Cu. Yd.

Cu. Yd.

For estimating purposes only a factor

Type B Drainage Fabric

Box Culvert Undercut

of 1. 4 tons/cu. yd. was

Ton

Sq. Yd.

used to convert Cu. Yds. to Tons.

Quantity is based on an 8’’ bottom slab and 8’’ walls

Ft.

Ft.

Each

Each

2

2

Class C Riprap

Type B Drainage Fabric

-X028-

Class C Riprap

Type B Drainage Fabric

2 - 14’ x 10’ Precast Concrete Box Culvert, Furnish

2 - 14’ x 10’ Precast Concrete Box Culvert, Install

2 - 14’ x 10’ Precast Concrete Box Culvert End Section, Furnish

2 - 14’ x 10’ Precast Concrete Box Culvert End Section, Install

ESTIMATED QUANTITIES

183

142

142

Class C Riprap

49’ - 0’’ 62’ - 0’’

F. L. Elev. 1630. 50

F. L. Elev. 1630. 70

LC

18’’ CMP

LC

18’’ CMP

18’’ CMP 18’’ CMP

Top Limits of Undercut

(See Typical Section

Sheet No. 2 of 4.)

Bottom Limits of Undercut

(See Typical Section

Sheet No. 2 of 4.)

SKS/EO JK SKS/SJ

The elevations shown in these plans are based on the National Geodetic

Survey (NGS) North American Vertical Datum of 1988 (NAVD88).

135

238

151

+

SULLY COUNTY

SITE 2

ALTERNATE B

1

2

3

4

5

6

Hydraulic Data

Index of Sheets

7

8

9

10

Title Block

REQUIRED LIST

Project Block

Estimated Quantities

Plan View

Elevation View

Design Firm or Office

Survey Datum Box

11

3

1

10

8

4

6

5

7

9

2

Dimension Legend

11

11

Reference

Box Culvert 08

Horiz.& Vert. Curve Data

12

12 North Arrow

PROJECT SHEET

NO.

TOTAL

SHEETS

STATE

OF

S.D.

43 OFNOVEMBER 2005

STR. NO. 60-129-235

2 - 14’ X 10’ BOX CULVERT (PRECAST) SITE 2

ALTERNATE B

REQUIRED LIST

1

2

3Title Block

Project Block

Insert Required Standard

Plate Sheets as Needed

1

2

Box Culvert 10

Reference

460. 02

PLATE NUMBER

S

D

D

O

TSheet 1 of 1

YEAR PLATE DETAILS

PLACE

APPROPRIATE

NUMBER

HERE

PLACE

APPROPRIATE

NUMBER

HERE

1 7’’

þÿ��� 1’’ þÿ�2� � 1’’ þÿ�2� � 1’’ þÿ�2� � þÿ���

þÿ��

�þÿ

���

3’’

þÿ

���

þÿ��

�

6’’

YEAR PLATE DETAILS

NOTES:

and attached to the forms in such a manner that the finished imprint in the

the other contract items.

box culverts and bridges. The year plates shall be constructed in reverse

þÿ�1� � þÿ�1� �

1. Year plates of the general dimensions shown shall be constructed on all

þÿ�c�o�n�c�r�e�t�e� �d�o�e�s� �n�o�t� �e�x�c�e�e�d� �o

3. There will be no separate measurement or payment made for year plates

the upper sloped portion of the barrier approximately 5’- 6’’ from the end of

at each end of the bridge on opposite sides.

the bridge, or as designated by the Engineer. There shall be one year plate

endblocks, the year plate shall be centered vertically on the curb face approximately

bridges with ‘‘Jersey’’ shaped barrier endblocks, the year plate shall be centered on

six (6) inches from the end of the bridge, or as designated by the Engineer. On

b. On bridges with six (6) inch curbs or ‘‘Jersey’’ shaped barriers with no

End Brid

ge

End Bridge

Year Plate

Year Plate

End Bridge

Year Plate

JERSEY BARRIER TYPE B CURBJERSEY BARRIER

( With Endblock )

inches below the top of the upstream parapet wall and centered laterally on the

upstream face. On precast box culverts the year plate shall be centered laterally

with this location, the year plate shall be centered in an adjacent barrel.

on the upstream face of the top slab. Where an extended interior wall interferes

þÿ�a�.� � � � � �O�n� �c�a�s�t�-�i�n�-�p�l�a�c�e� �b�o�x� �c�u�l�v�e�r�t�s� �t�h�e� �y�e�a

5’- 6’’

Year Plate See Note 2 (c)

Year Plate See Note 2 (c)

6’’

Year Plate See Note 2 (c)

6’’

c. When the plans specify that both the original date of construction and the date of

reconstruction are to be shown, one date shall be placed as listed above and the

bridge on opposite sides.

other located adjacent to it. Both year plates shall be shown at each end of the

2. Year plates shall be located on structure (s) as follows:

þÿ�2� �

on box culverts and bridges. All costs for this work shall be incidental to

March 31, 2000

PLATE NUMBER

S

D

D

O

TSheet 1 of 1

Hole Hole

16’’

Edge of

Outside Joint

Washer

þÿ�3�2�’�’� � �(�A�d�j�.� � �

þÿ�2�’�’� � �l�o�n�g� �1� � ���’�’� � � � � � � �(� �n

extra strong pipe sleeve or approved equal. ( Typ. )

Typ.þÿ

16’’

2’’

max

.

(Typ.)

TIE BOLT ASSEMBLY

(Typ.)

Nuts shall be heavy hex in conformance with ASTM A563. Washers

CLCL

-+

1. All holes for tie bolts shall be cast-in-place, 16 in. from

2. Ties shall be 1’’ and conform to the requirements of ASTM A36.

shall conform to ASTM F436, Type 1. The welded pipe sleeve

shall conform to ASTM A53, Grade B.

3. Welding and weld inspection shall be in conformance with

4. Tie Bolt Assembly shall be galvanized in accordance with ASTM A153.

5. Tie Bolt Assembly details may vary from that shown, but alternate

tie bolt assemblies are subject to testing to demonstrate equal

strength. Submit details, thru proper channels, to the Office

of Bridge Design for approval.

shall be made of a corrosion resistant material.

outside edge of joint. Cast in inserts or sleeves, if used,

AWS/ANSI D1. 1-(Current Year) Structural Welding Code - Steel.

PRECAST BOX CULVERT

TIE BOLT ASSEMBLY DETAILS560. 01

GENERAL NOTES:

6. All costs for furnishing and installing the precast box culvert tie

bolt assembly shall be incidental to the contract unit price per Foot

for "Precast Concrete Box Culvert, Furnish".

April 25, 2006

33

Published Date: 4th Qtr. 2008 Published Date: 4th Qtr. 2008