Reinforced concrete box culvert Specification

Transcript of Reinforced concrete box culvert Specification

ICS 93.080.10

Reference number

DRS 62: 2021

© RSB 2021

RWANDA STANDARD

DRS

62

Third edition

2021-mm-dd

Reinforced concrete box culvert — Specification

DRS 62: 2021

©RSB 2021 - All rights reserved ii

In order to match with technological development and to keep continuous progress in industries, standards are subject to periodic review. Users shall ascertain that they are in possession of the latest edition

© RSB 2021

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm, without prior written permission from RSB.

Requests for permission to reproduce this document should be addressed to:

Rwanda Standards Board

P.O Box 7099 Kigali-Rwanda

KK 15 Rd, 49

Tel. +250 788303492

Toll Free: 3250

E-mail: [email protected]

Website: www.rsb.gov.rw

ePortal: www.portal.rsb.gov.rw

DRS 62: 2021

iii ©RSB 2021 - All rights reserved

Contents Page

Reinforced concrete box culvert — Specification ................................................................................. 1

1 Scope ............................................................................................................................................. 1

2 Normative references ................................................................................................................... 1

3 Terms and definitions .................................................................................................................. 1

4 Requirements ................................................................................................................................ 3 4.1 Types of culverts .......................................................................................................................... 3 4.2 Materials ........................................................................................................................................ 4 4.3 Structural design .......................................................................................................................... 6 4.4 Resistance to proof load.............................................................................................................. 7 4.5 Resistance to ultimate load ......................................................................................................... 7 4.6 Manufacture .................................................................................................................................. 7

5 Workmanship and finish ............................................................................................................ 10

6 Sampling and compliance ......................................................................................................... 10 6.1 General ........................................................................................................................................ 10 6.2 Sample for inspection ................................................................................................................ 10 6.3 Sample for testing ...................................................................................................................... 10 6.4 Sample for ultimate load testing ............................................................................................... 10 6.5 Criteria for compliance .............................................................................................................. 10

7 Inspection .................................................................................................................................... 11

8 Rejection ..................................................................................................................................... 11

9 Physical tests .............................................................................................................................. 11 9.1 Straightness test ........................................................................................................................ 11 9.2 Cover over reinforcement test .................................................................................................. 11 9.3 Squareness test at ends of section .......................................................................................... 12 9.4 Compression test ....................................................................................................................... 12 9.5 Proof load and ultimate load test .............................................................................................. 14 9.6 Water absorption test................................................................................................................. 15

10 Testing facilities ......................................................................................................................... 15

11 Cost of testing ............................................................................................................................ 15

12 Information to be supplied by the purchaser .......................................................................... 15

13 Information to be supplied by the manufacturer .................................................................... 15

14 Marking ........................................................................................................................................ 16

Annex A (normative) Box culvert load—Test method ........................................................................ 17 A.1 Apparatus .................................................................................................................................... 17 A.2 Positioning of culvert in testing machine ................................................................................ 18 A.3 Application and calculation of test load .................................................................................. 18

Annex B (normative) Water absorption — Test method .................................................................... 19 B.1 Method of test ............................................................................................................................. 19 B.2 Calculation .................................................................................................................................. 19

DRS 62: 2021

©RSB 2021 - All rights reserved iv

Foreword

Rwanda Standards are prepared by Technical Committees and approved by Rwanda Standards Board (RSB) Board of Directors in accordance with the procedures of RSB, in compliance with Annex 3 of the WTO/TBT agreement on the preparation, adoption and application of standards.

The main task of technical committees is to prepare national standards. Final Draft Rwanda Standards adopted by Technical committees are ratified by members of RSB Board of Directors for publication and gazettment as Rwanda Standards.

RS 62 was prepared by Technical Committee RSB/TC 009, Building materials and civil engineering.

In the preparation of this standard, reference was made to the following standards:

1) ASTM C1433M-20, Standard specification for precast reinforced concrete monolithic box sections for culverts, storm drains, and sewers (Metric)

2) ASTM C822-20, Standard terminology relating to concrete pipe and related products

3) SANS 986:2019, precast reinforced concrete culverts

The assistance derived from the above source is hereby acknowledged with thanks.

This third edition cancels and replaces the second edition (RS 62:2014), of which has been technically revised.

Committee membership

The following organizations were represented on the Technical Committee on Building materials and civil engineering (RSB/TC 009) in the preparation of this standard.

B. J Construction Ltd

Bridge to Prosperity

City of Kigali

Green Pact Africa

MASS Design

NPD Ltd

Rwanda Housing Authority (RHA)

Rwanda Inspectorate, Competition and Consumer Protection Authority (RICA)

University of Rwanda/College of Science and Technology (UR-CST)

Rwanda Standards Board (RSB) – Secretariat

DRS 62: 2021

1 ©RSB 2021 - All rights reserved

Reinforced concrete box culvert — Specification

1 Scope

This Draft Rwanda Standard specifies the requirements for reinforced concrete box culverts primarily intended for conveying water not under pressure, and for carrying highway vehicle loadings.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

RS EAS 12, Potable water — Specification

RS 142, Design of concrete structures — Code of practice

RS 373, Aggregates for concrete — Specification

RS EAS 18-1, Cement ─ Composition, specifications and conformity criteria for common cements

RS ISO 1920-1, Testing of concrete — Part 1: Sampling of fresh concrete

RS ISO 1920-4, Testing of concrete — Part 4: Strength of hardened concrete

RS ISO 6935-2, Specification for the reinforcement of concrete — Part 2: Ribbed bars

RS ISO 6935-3, Specification for the reinforcement of concrete — Part 3: Welded fabric

3 Terms and definitions

For the purposes of this standard, the following terms and definitions apply.

3.1

absorption

increase in weight of concrete resulting from the penetration of water into the concrete

3.2

absorption test

test made to determine the absorption of concrete

3.3

admixture

material other than water, aggregates, cement and fibre reinforcing used as an ingredient of concrete and added to the batch immediately before or during its mixture

3.4

batch

material from a single mix or, in the case of a continuous process, the material from a single day's production

©RSB 2021 - All rights reserved 2

3.5

box culvert

precast concrete unit with a clear opening of rectangular shape which may have internal splayed corners

3.6

box section

concrete pipe with a rectangular cross section

3.7

box section bottom slab

lower horizontal portion of a box section in the installed condition

3.8

box section top slab

upper horizontal portion of a box section in the installed condition

3.9

box section wall

vertical sides of a box section in the installed condition

3.10

cage

assembled unit of steel reinforcement consisting of circumferential and longitudinal bars or wires

3.11

circumferential reinforcement

reinforcement that is approximately perpendicular to the longitudinal axis of the concrete box culvert

3.12

compression test

test made on a concrete specimen to determine the compressive strength

3.13

compressive strength

maximum resistance of a concrete specimen to axial compressive loading; or the specified resistance used in design calculations

3.14

concrete

mixture of portland cement, fine aggregate, coarse aggregate, and water. The mixture may also contain admixtures, or other cementitious materials, or both

3.15

core

cylinder of concrete obtained from concrete by means of a core drill

DRS 62: 2021

3 ©RSB 2021 - All rights reserved

3.16

culvert

pipeline intended to convey water under a highway, railroad, canal, or similar facility

3.17

cylinder (test)

cast cylindrical specimen of concrete

3.18

joint

connection of two concrete box section ends, made either with or without the use of additional parts and/or materials

3.19

reinforcement

steel in the form of continuous wire, welded wire fabric, or bars embedded in concrete in such a manner that the above referenced concrete and steel act together to resist stresses

3.20

lot

assemblage of concrete products, all being of like size, material, and strength designation, manufactured by the same process.

4 Requirements

4.1 Types of culverts

The types of culvert covered by this standard are as follows:

a) double U: two U-shaped sections arranged to form a rectangle with horizontal joints at the mid-point of each wall;

b) single U: U-shaped section forming the invert slab and walls, with a separate deck slab;

c) inverted U: U-shaped section forming the deck, slab and walls, with a separate invert slab;

d) one-piece: A monolithic hollow rectangular section forming deck, walls and invert; and

e) sectional: Four separate sections forming walls, deck and invert slab.

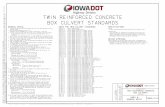

The dimensions of reinforced concrete box culverts are illustrated in figure 1.

©RSB 2021 - All rights reserved 4

Figure 1 — Section of a monolithic reinforced concrete box culvert

Key

TT: is the top slab thickness

TB: is the bottom slab thickness

TS: is the wall thickness

H: is the haunch

NOTE The haunch dimension H, is equal to the wall thickness TS.

4.2 Materials

4.2.1 General

The reinforced concrete shall consist of cementitious materials, mineral aggregates, admixtures if used and water, in which steel has been embedded in such a manner that the steel and concrete act together.

4.2.2 Cement

Cements used in the manufacture of the culverts shall comply, in all respects, with RS EAS 18-1.

4.2.3 Aggregate

4.2.3.1 Aggregates shall consist of crushed or uncrushed gravel, stone or rock, or a combination of any of these. The aggregates shall be hard, strong, inert and durable and shall be clean and free from clay films and

DRS 62: 2021

5 ©RSB 2021 - All rights reserved

other adherent coatings. No mica, shale, laminated particles or harmful material shall be present in sufficient quantity to affect adversely the quality of the concrete. Other requirements shall conform to RS 373.

4.2.3.2 When required by the purchaser, a sample of the aggregate shall be submitted to him for approval.

NOTE Aggregates from all sources should be adequately tested to establish whether or not they are satisfactory.

4.2.4 Reinforcement

4.2.4.1 Reinforcement shall consist of reinforcing bars conforming to RS ISO 6935-2 or welded wire reinforcement conforming to RS ISO 6935-3 where relevant.

4.2.4.2 Steel used for reinforcement shall show no loose scale, oil or grease and shall be free from loose or heavy rusting.

4.2.4.3 The reinforcement shall be assembled into units so designed that they may readily be placed and held in proper positions within the casting mould during the manufacture of the culvert sections.

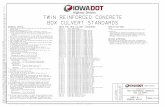

4.2.4.4 Arrangement of steel reinforcement in a monolithic reinforced concrete box culvert is illustrated in figure 2.

Figure 2 — Steel reinforcement in a monolithic reinforced concrete box culvert

4.2.5 Water

The water used in the mixing of the concrete shall conform to RS EAS 12.

4.2.6 Admixtures

The admixtures used shall not have any harmful effect on the properties of the concrete and shall comply with their respective standard requirements. Admixtures containing calcium chloride or rust-inhibiting admixtures shall not be used.

4.2.7 Spacers

Bar spacers shall be used to ensure correct cover and they shall be of adequate strength to resist loads imposed during manufacture. They shall be of concrete mortar (which may be fibre reinforced) to a specification compatible with the culvert concrete or, when used against vertical formwork only, they may be of plastic with

©RSB 2021 - All rights reserved 6

perforations of not less than 25 % of their area.

4.2.8 Concrete

4.2.8.1 General

The concrete shall be fully compacted and shall have:

a) minimum cement content of 350 kg/m3;

b) maximum free water/cement ratio of 0.5;

c) lowest grade of C25/30;

d) total chloride content expressed as a percentage of chloride ion by weight of cement not exceeding 0.1 %;

e) a total water-soluble sulphate content expressed as SO3 not exceeding 4 %; and

f) air content of ( 5 ± 1.5) % when air entrainment is specified and nominal maximum aggregate size is 20.

NOTE Other limits apply to higher grade concrete and to sulphate-resisting concrete.

4.2.8.2 Control of alkali silica reaction

In order to control the possibility of alkali silica reaction, either of the following conditions shall be met:

a) alkali content of the concrete shall not exceed 3.0 kg/m3; and

b) aggregates, both coarse and fine, shall be of a non-reactive nature.

4.3 Structural design

4.3.1 Box culverts shall be designed to resist the combination of vertical load acting on the roof and floor and horizontal load acting on the walls. This load combination is known as proof load (kN/m of length) and it shall be considered at maximum and minimum fill heights. Intermediate depths need not to be considered.

4.3.2 Design and detailing of sections to resist moments and shear forces shall be in accordance with RS 142.

4.3.3 It is recommended that the minimum fill height should be not less than 200 mm or one-fifteenth of the internal width of the box culvert for fill height greater than or equal to 600 mm.

4.3.4 Other requirements for structural arrangements are as follows:

a) top slab: cover over reinforcement shall be 25 mm for fill heights greater than or equal to 600 mm, 50 mm for fill heights lower than 600 mm;

b) slab thickness: for fill heights greater than 600 mm, 1/12 times inside span plus 25 mm up to 2 m span, 1/12 inside span above 2 m span;

c) side wall thickness: 1/12 times inside span plus 25 mm up to 2 m span;

d) haunch dimensions: vertical and horizontal dimensions both equal to wall thickness; and

e) Circumferential wire spacing: 100 mm.

DRS 62: 2021

7 ©RSB 2021 - All rights reserved

4.4 Resistance to proof load

A box culvert shall sustain the simultaneous application of the proof loads given in table 4, appropriate to the class of culvert required, without the development of cracks of 0.3 mm width such that the feeler gauge can enter to a depth of 2 mm or more over a continuous length of at least 300 mm.

4.5 Resistance to ultimate load

4.5.1 The ultimate load tests shall be conducted as in 8.5.1 with at least 1.25 times the proof loads and applied in the same manner.

4.5.2 When so required (see annex A), an ultimate load test shall be carried out. When a box culvert is tested, it shall sustain a load of at least 1.25 times the proof load without failure.

4.6 Manufacture

4.6.1 Mixture

4.6.1.1 The aggregates shall be sized, graded, proportioned, and mixed with such proportions of cementitious materials of such quality that the box culvert will conform to the test and design requirements of this specification. All concrete shall have a water-cementitious materials ratio not exceeding 0.53 by weight.

4.6.1.2 Cementitious materials shall be added to the mix in a proportion not less than 350 kg/m3 unless mix designs with lower cementitious materials content demonstrate that the quality and performance of the box culvert meet the requirements of this specification.

4.6.2 Form

The forms used in manufacture shall be sufficiently rigid and accurate to maintain the box section dimensions

within the permissible variations. All casting surfaces shall be of smooth nonporous material.

4.6.3 Curing

4.6.3.1 Exposed surfaces shall be protected from low humidity until the concrete has reached sufficient maturity for lifting and storage.

4.6.3.2 The box sections shall be cured for a sufficient length of time so that the concrete will develop the specified compressive strength in 28 days or less.

4.6.4 Reinforcement cages

Reinforcement shall be cut and/or bent, assembled into cages and fixed by tack welding or by using soft annealed iron or stainless steel tying wire.

4.6.5 Cover over the reinforcement

4.6.5.1 Nominal cover shall be provided to the steel as indicated in RS 142 where design to this standard

is specifically requested.

4.6.5.2 The concrete cover over reinforcement to the concrete surface on any culvert face shall not be less than 25 mm for at least 95 % of the reinforcing bars. In addition, under no circumstances shall any single bar have a cover over reinforcement to the concrete surface on any culvert face of less than 20 mm.

4.6.6 Lifting arrangements of precast reinforced concrete box culverts

Precast reinforced concrete box culverts shall be provided with lifting points such that they may be safely lifted

©RSB 2021 - All rights reserved 8

by crane.

4.6.7 Transport and Storage of precast reinforced concrete box culverts

4.6.7.1 Units shall not be transported from the precast yard within seven days after casting and the curing has been completed in accordance with Clause 4.6.3. Units shall be supported on timber bearers which are fitted with rubber strips on top. Rubber strips shall also be placed between units, both laterally and longitudinally. All tie down straps and chains shall have rubber protection strips over box culvert edges. The legs of all box culverts shall be adequately braced to prevent whipping and bending.

4.6.7.2 Precast reinforced concrete box culverts shall be stored in ambient temperature on a level surface and in a manner preventing damage to the members. Do not place any load on box culverts until design strength is reached and curing is completed.

4.6.8 Geometry

4.6.8.1 Nominal sizes

Box culverts shall be described by their nominal internal size expressed by their manufacturing dimensions in millimetres in the sequence of width and height of opening.

4.6.8.2 Joints

All faces of box culvert sections which are to adjoin when the culvert is assembled shall be of such form that the culvert can be laid to form a continuous conduit with a smooth and uniform interior surface.

4.6.9 Permissible deviations

4.6.9.1 Dimensions

4.6.9.1.1 Internal dimensions

The internal dimension shall not vary more than 1 % from the design dimensions. The haunch dimensions shall not vary more than 6 mm from the design dimensions.

4.6.9.1.2 Internal cross-sectional dimensions

4.6.8.1.2.1 The nominal internal cross-sectional dimensions of box culverts shall be one the combination given in table 1, as required. The actual dimensions shall not differ from the stated dimensions by more than:

a) spans or heights of up to and including 1 200 mm : 5 mm;

b) spans or heights that exceed 1 200 mm : 10 mm; and

c) length of unit : 12 mm

4.6.8.1.2.2 The slab and wall thickness shall not be less than that shown in the design by more than 5 % or 5 mm, whichever is greater. A thickness more than that required in the design shall not be a cause for rejection.

4.6.8.1.2.3 The actual internal cross-sectional area of a culvert shall be not less than 95 % of the nominal internal cross-sectional area given in table 1.

4.6.8.1.2.4 The cross-sectional area of haunches and similar features may be included in the stated internal cross-sectional area. However, the stated area shall not exceed the actual cross-sectional area available for flow of water by more than 5 %.

DRS 62: 2021

9 ©RSB 2021 - All rights reserved

Table 1 — Nominal internal cross-sectional dimensions of culvert

Height. H

mm

Nominal internal cross — Sectional area m2

Span. S mm

450 600 750 900 1 200 1 500 1 800 2 400 3 000 3 600

300 0.12 0.18 0.23 0.27 0.36 0.45 0.54 0.72 0.90 1.08

450 0.20 0.27 0.34 0.41 0.54 0.68 0.81 1.08 1.35 1.62

600 - 0.36 0.45 0.54 0.72 0.90 1.08 1.80 1.80 2.76

900 - - - 0.81 1.08 1.35 1.62 2.16 2.37 3.24

1 200 - - - - 1.44 1.80 2.16 2.86 3.60 4.32

1 500 - - - - - 2.25 2.70 3.60 4.50 5.40

1 600 - - - - - - 3.24 4.32 5.40 6.48

2 400 - - - - - - - 5.76 7.20 8.64

3 000 - - - - - - - - 9.00 10.8

4.6.9.1.3 Flatness

The maximum deviation from a 1 500-mm straight edge placed in any position on an internal surface shall not exceed 6 mm.

4.6.9.1.4 Squareness

The side of the opening shall not vary in its distance from the perpendicular to the top or bottom so that the difference between the greatest and shortest dimensions exceeds:

a) 6 mm for heights up to 1 200 mm;

b) 9 mm for heights from 1 200 mm - 1 800 mm; and

c) 12 mm for heights over 1 800 mm

The ends of the culvert shall be square within the greater of 5 mm or 0.5 % of the length of the culvert.

4.6.9.1.5 Twist

Any corner shall not be more than 12 mm from the plane containing the other three corners.

4.6.9.1.6 Straightness

When the inner surfaces of the culvert are measured in accordance with 8.1 they shall not at any point deviate from straightness by the lesser of 12 mm and 5 mm per metre length of the culvert

©RSB 2021 - All rights reserved 10

5 Workmanship and finish

The interior and exterior surfaces of the sections shall be substantially free from roughness voids, honey combing, chipped edges laitance and other imperfections which would impair the serviceability of the culvert.

The sections shall be free from cracks other than craze cracks i.e cracks occurring superficially and usually of irregular pattern and shall be free from defects resulting from faulty materials or faulty methods of manufacture.

6 Sampling and compliance

6.1 General

Samples of concrete shall be taken at a rate of one per 20 m3 or one per 20 batches whichever is the lesser. Other requirements for sampling fresh concrete shall be in compliance with RS ISO 1920-1. Cubes from these samples shall be prepared and tested for compressive strength in accordance with RS ISO 1920-4.

A prescribed sampling procedure shall be followed to determine whether a lot complies with the standard and the samples so taken shall be deemed to represent the lot. Samples shall be taken in accordance with the procedures given in 6.2 and 6.3.

6.2 Sample for inspection

From the lot take at random the number of specimens shown in column 2 of table 2 relative to the appropriate lot size shown in column 1.

Table 2 — Sample sizes for inspection and testing and permissible number of defectives

Lot size

(L)

Inspection Testing

Sample size Permissible

number of

defective

Sample size Permissible

number of

defective

10 ≤ L ≤ 20 All 0 3 0

21 ≤ L ≤ 100 20 0 3 0

101 ≤ L ≤ 300 30 1 5 0

301 ≤ L ≤ 500 45 1 7 0

6.3 Sample for testing

From the lot take at random the number of specimens shown in column 4 of table 2 relative to the appropriate lot size shown in column 1.

6.4 Sample for ultimate load testing

The ultimate load test shall be conducted on one sample from a lot of 500 unless otherwise dictated by the manufacturer's quality system.

6.5 Criteria for compliance

6.5.1 Acceptance

6.5.1.1 Acceptability of the box sections produced in accordance with 4.3 shall be determined by the results

DRS 62: 2021

11 ©RSB 2021 - All rights reserved

of the concrete compressive strength tests described in 8.2 by the material requirements described in clause 4 and by inspection of the finished box sections.

6.5.1.2 Box sections shall be considered ready for acceptance when they conform to the requirements of this specification.

6.5.1.3 The lot shall comply with the following relevant requirements:

a) on inspection of the sample drawn in accordance with 6.2 with regard to the properties given in 4.6. the number of defectives found does not exceed the relevant permissible number of defectives given in column 3 of table 2;

b) on testing of the sample drawn in accordance with 6.3 for compliance with the requirements given in 4.3.

c) no defective is found (see column 5 of table 2); and

d) sample subjected to the ultimate load does not collapse.

7 Inspection

The quality of materials, the process of manufacture and the finished box sections shall be subject to inspection by the purchaser.

8 Rejection

8.1 Box sections shall be subject to rejection on account of failure to conform to any of the specification requirements.

8.2 Individual box sections shall be allowed to be rejected because of any of the following:

Fractures or cracks passing through the wall, except for a single end crack that does not exceed the depth of the joint,

Defects that indicate mixing and moulding not in compliance with 4.6.1, or honeycombed or open texture that would adversely affect the function of the box sections, and

Damaged ends, where such damage would prevent making a satisfactory joint.

Any continuous crack having a surface width of 0.3 mm or more and extending for a length of 300 mm or more, regardless of position in the wall of the box culvert, for box culvert not installed or under load.

9 Physical tests

9.1 Straightness test

Take a straight-edge of length at least equal to that of the culvert under test and so lay it on an inner face of the culvert that the straight-edge is parallel to the longitudinal axis of the culvert. Measure to the nearest 2 mm. any deviation of the culvert surface from the straight-edge. Repeat the test on each of the other inner faces of the culvert and check the results for compliance with 4.6.8.1.6.

9.2 Cover over reinforcement test

Using a calibrated electronic cover meter measure the concrete cover over reinforcement. Conduct at least twenty spot tests per face of the culvert. Check for compliance with 4.6.5.

The exposure of the ends of spacers which have been used to position the reinforcement during the placement of concrete shall not be a cause of rejection.

©RSB 2021 - All rights reserved 12

9.3 Squareness test at ends of section

When tested by means of a try-square. The ends of the culvert shall be square within 3 mm.

9.4 Compression test

9.4.1 Type of test specimen

Compression tests for determining concrete compressive strength shall be allowed to be made on either standard rodded concrete cylinders or concrete cylinders compacted and cured in like manner as the box

sections or on cores drilled from the box section.

9.4.2 Compression testing of cylinders

Cylinders shall be obtained and tested for compressive strength.

9.4.2.1 Apparatus

9.4.2.1.1 Moulds

Moulds for specimens or fastenings thereto in contact with the concrete shall be made of steel cast iron or other non-absorbent material nonreactive with concrete containing portland or other hydraulic cements. Moulds shall hold their dimensions and shape under all conditions of use and shall be watertight during use as judged by their ability to hold water poured into them. A suitable sealant such as heavy grease modeling clay or microcrystalline wax shall be used where necessary to prevent leakage through the joints. Positive means shall be provided to hold base plates firmly to the moulds. Reusable molds shall be lightly coated with mineral oil or

a suitable nonreactive form release material before use.

9.4.2.1.2 Tamping rod

A round smooth straight steel rod with a diameter conforming to the requirements in Table 3 shall be used. The length of the tamping rod shall be at least 100 mm greater than the depth of the mold in which rodding is being performed but not greater than 600 mm in overall length. A rod of 400 mm - 600 mm should be suitable. The rod shall have the tamping end or both ends rounded to a hemispherical tip of the same diameter as the rod.

Table 3 — Tampering rod length

Diameter of cylinder Rod length

< 150 mm 10 ± 2 mm

≥ 150 mm 16 ± 2 mm

9.4.2.1.3 Vibrators

8.4.2.1.3.1 Internal vibrators shall be used. The vibrator frequency shall be at least 9 000 vibrations per minute (150 Hz) while the vibrator is operating in the concrete. The diameter of a round vibrator shall be no more than one-fourth the diameter of the cylinder mould or one-fourth the width of the beam mould.

8.4.2.1.3.2 Other shaped vibrators shall have a perimeter equivalent to the circumference of an appropriate round vibrator. The combined length of the vibrator shaft and vibrating element shall exceed the depth of the section being vibrated by at least 75 mm. The vibrator frequency shall be checked periodically with a vibrating-reed tachometer or other suitable device.

9.4.2.1.4 Mallet

A mallet with a rubber or rawhide head weighing 0.6 kg ± 0.2 kg shall be used.

DRS 62: 2021

13 ©RSB 2021 - All rights reserved

9.4.2.1.5 Scoop

A scoop shall be used to place concrete in a cylinder mould.

9.4.2.2 Testing requirements

9.4.2.2.1 Cylindrical specimens

8.4.2.2.1.1 Compressive or splitting tensile strength specimens shall be cylinders cast and allowed to set in an upright position. The number and size of cylinders cast shall be as directed by the specifier of the tests. In addition, the length shall be twice the diameter and the cylinder diameter shall be at least 3 times the nominal maximum size of the coarse aggregate. When the nominal maximum size of the coarse aggregate exceeds 50 mm. the concrete sample shall be treated by wet sieving through a 50 mm sieve as described. For acceptance testing for specified compressive strength cylinders shall be 150 mm by 300 mm or 100 mm by 200 mm.

8.4.2.2.1.2 Cylindrical specimens of sizes other than 150 mm by 300 mm may be used provided all other requirements of moulds are met. If the concrete is of a consistency too stiff for compaction by rodding or internal vibration Cylinders shall be exposed to the same curing conditions as the manufactured box sections and shall remain with the sections until tested.

8.4.2.2.1.3 Prepare not less than three test cylinders from each concrete mix used within a group (one day’s production) of box sections.

9.4.2.2.2 Acceptability on the basis of cylinder test results

When the average compressive strength of all cylinders tested is equal to or greater than the design concrete strength not more than 10 % of the cylinders tested have a compressive strength less than the design concrete strength and no cylinder tested has a compressive strength less than 80 % of the design concrete strength the lot shall be accepted.

9.4.3 Compression testing of cores

Cores shall be obtained and tested for compressive strength. Three cores shall be cut from a section selected at random from each group of 15 box sections or fraction thereof of a single size from each continuous production run.

9.4.3.1 Acceptability by core tests

8.4.3.1.1 The compressive strength of the concrete in each group of box sections is acceptable when concrete compressive strength defined as the average of three cores taken at random from the subject group is equal to or greater than 85 % of the required strength of the concrete with no one core less than 75 % of the required strength.

8.4.3.1.2 If the compressive strength of the three cores does not meet the stated requirements the sections from which the cores were taken shall be rejected. Two box sections from the remainder of the group shall be selected at random and one core shall be taken from each. If both cores have strength equal to or greater than 85 % of the required strength of the concrete the remainder of the group is acceptable. If the compressive strength of either of the two cores tested is less than 85 % of the required strength of the concrete the remainder of the group of box section shall be rejected or at the option of the manufacturer each box section of the entire group shall be cored and accepted individually and any of these box sections that have cores with less than 85 % of the required strength of the concrete shall be rejected.

9.4.3.2 Plugging core holes

The core holes shall be plugged and sealed by the manufacturer in a manner such that the box section will meet all of the test requirements of this specification. Box sections so sealed shall be considered as satisfactory for use.

©RSB 2021 - All rights reserved 14

9.4.3.3 Test equipment

Every manufacturer furnishing box sections under this specification shall furnish all facilities and personnel

necessary to carry out the tests required.

9.4.4 Transportation of specimens to laboratory

8.4.4.1 Prior to transporting cure and protect specimens as specimens shall not be transported until at least 8 h after final set. During transporting protect the specimens with suitable cushioning material to prevent damage from jarring. During cold weather protect the specimens from freezing with suitable insulation material.

8.4.4.2 Prevent moisture loss during transportation by wrapping the specimens in plastic wet burlap by surrounding them with wet sand or tight fitting plastic caps on plastic moulds. Transportation time shall not exceed 4 h.

9.5 Proof load and ultimate load test

9.5.1 Proof load test

8.5.1.1 From each 20 or part of 20 culvert lengths of each size ordered the purchaser may select one length for proof load testing by the method given in Annex A.

8.5.1.2 When so tested the culvert length shall sustain a proof load as set out in Table 4 without developing a clearly visible crack and on removal of the load minor cracks caused by the load shall close.

8.5.1.3 Additional vertical proof loads may be used to designate additional proof loads but in all cases the

horizontal load should be 30 kN/m.

NOTE 1 A clearly visible crack is one into which the point of crack-measuring gauge conforming to the details given in

Annex B may be inserted at close intervals over a length of at least 300 mm to a depth of 1.5 mm.

NOTE 2 Cracks smaller than a clearly visible, crack are considered minor crack.

Table 4 — Proof loads for commonly available culverts

Span. S Proof loads kN/m

Vertical. Pv Horizontal. pH

30

Culvert class

75S 100 S 150 S 175 S 200 S

450 - - - - 90

600 - - - - 120

750 - - - 31.25 -

900 - - - 157.50 -

1 200 - - 180 - -

1 500 - 150 - - -

1 800 135 - - - -

2 100 157.5 - - - -

DRS 62: 2021

15 ©RSB 2021 - All rights reserved

2 400 180 - - - -

300 225 - - - -

3 600 270 - - -

NOTE S is the nominal span in meter

9.5.2 Ultimate load test

Where so specified by the purchaser up to 1 % or 1 length whichever is the greater of the total number of culvert lengths in the order shall be subjected to an ultimate load test by the method described in Annex A. When so tested each culvert length shall sustain a load of not less than the appropriate load set out in Table 4 before increased deformation occurs without any increase in load.

9.6 Water absorption test

Where so specified by the purchaser the water absorption of the concrete in the culverts shall be determined using the test pieces cut from culvert lengths that have been subjected to and have complied with the cracking or ultimate load tests (see Annex B).

10 Testing facilities

Unless otherwise agreed between the purchaser and the manufacturer the manufacturer shall supply all facilities for measuring inspecting and testing the culverts in accordance with this specification.

11 Cost of testing

The cost of the ultimate load test and the water absorption test shall be borne by the purchaser. The cost of all other testing shall be borne by the manufacturer.

12 Information to be supplied by the purchaser

The purchaser shall supply the following information to the manufacturer:

a) the type of culvert required;

b) the preferred internal dimensions for the culvert;

c) the length of culvert sections if the recommended length is not desired;

d) whether the ultimate load test is required and. if the test is required. the number of culvert lengths to be so tested; and

e) whether the water absorption test is required and. if the test is required the number of test pieces required and the number of culvert lengths from which the test pieces are to be obtained.

13 Information to be supplied by the manufacturer

When requested by the purchaser, the manufacturer shall supply the following information:

a) drawings showing the proposed internal dimensions of the culverts and the proposed thickness of the sections; and

b) the approximate weights of the individual culvert lengths or sections.

©RSB 2021 - All rights reserved 16

14 Marking

Each culvert (or each component of a culvert) shall bear the following information legibly impressed (during moulding) or indelibly marked in another manner on the inner face of a leg and in such a position that it cannot be covered by a joint. The following information shall be supplied:

a) manufacturer’s name, trade name or trade mark and location of the factory;

b) nominal internal cross-sectional dimensions;

c) class of the culvert;

d) date of manufacture;

e) any additional project-specific requirements; and

f) box section span, rise and the minimum design earth cover.

DRS 62: 2021

17 ©RSB 2021 - All rights reserved

Annex A (normative)

Box culvert load—Test method

A.1 Apparatus

A.1.1 Testing machine

A machine capable of applying the loads specified in 8.5 to a length of culvert without undue deformation or yielding of the machine. The machine shall be mounted over a sand bed as specified below.

A.1.2 Bearing block

An unyielding bearing block of a length at least as long as the culvert under test and 152 mm wide having a rubber packing piece 152 mm wide and 25 mm thick between the bearer and the culvert. The rubber packing

shall have a hardness of 70 2 BS Hardness Degrees.

A.1.3 Sand bed

A sand bed of sufficient area to accommodate the length of the culvert under test orientated as required below. The sand shall not be less than 76 mm deep and the base of the bed shall be level.

A.1.4 Crack-measuring gauge

A crack-measuring gauge 0.25 mm thick and 10 mm wide tapering at one end over a length of 22 mm to a width of 1.6 mm as shown in Figure A.1.

©RSB 2021 - All rights reserved 18

Figure A.1 — Crack-measuring gauge

A.2 Positioning of culvert in testing machine

One piece type culvert lengths shall be placed on the sand bed under the testing machine. Other types of culvert shall be assembled on the sand bed so that the component sections are in the relationship intended in use and the culvert length is under the testing machine. Mortar not more than 6.0 mm thick or bituminous felt may be used in the longitudinal joints between the sections to reduce any damage to the concrete surfaces during the application of the test load. The orientation of the culvert length shall be such that the line of application of the load will be on the centre line for the full length of the culvert.

A.3 Application and calculation of test load

The test load shall be applied vertically along the centre line for the full length of the culvert through the bearing block as shown in Figure A.3. The rate of loading shall be uniform and the total load shall be applied in five minutes. The test load shall be maintained no longer than is necessary to observe and record the load and examine the culvert. The load per unit length shall be calculated by dividing the total recorded load by the length

of the culvert.

Figure A.2 — Positioning of culvert for testing

DRS 62: 2021

19 ©RSB 2021 - All rights reserved

Annex B (normative)

Water absorption — Test method

B.1 Method of test

B.1.1 From the culvert lengths selected for testing in accordance with 8.6 test pieces having the full thickness of the culvert shall be taken.

B.1.2 Each test piece shall be as nearly square as possible and shall have an area of between 103 cm2 and 105 cm² measured on one surface. Edges may be broken cut or ground but two faces of the specimen shall be the original inner and outer surfaces of the culvert and shall be free from cracks other than craze cracks. The specimen shall not be taken within 152 mm of the end of the culvert.

B.1.3 The specimen shall be dried in a well-ventilated drying oven at a temperature not exceeding 100 °C for a period of four days. The drying shall be continued until two successive weighing at intervals of not less than 2 h and not more than 24 h show an increment of loss not greater than 0.1 % of the original weight of the specimen.

B.1.4 The dried specimen shall be placed in a suitable receptacle and covered with distilled or rain water (tap water may be used if it is known that its use will not affect the results) raised to boiling point and boiled for five hours. At the end of this time, the specimen shall be allowed to cool in water to normal room temperature.

B.1.5 When cool the specimen shall be allowed to drain for not more than one minute and the superficial water then removed by means of absorbent paper or cloth; the specimen shall then be weighed immediately.

B.1.6 If the specimen contains reinforcing wire. The wet specimen shall then be broken up and the wire recovered and weighed.

B.1.7 The balance used shall be sensitive to 0.5 g when loaded with 1 kg.

B.2 Calculation

The absorption shall not exceed 8 %.

Percentage absorption= 𝐵−𝐴

𝐴× 100

where

A is the weight of specimen dried to a constant weight; and

B is the weight in air of specimen as saturated with water after boiling.

©RSB 2021 - All rights reserved 20

Bibliography

[1] RS 62: 2014, Precast reinforced box culvert — Specification

[2] ASTM C76 − 12a, Standard Specification for Reinforced Concrete Culvert. Storm Drain. and Sewer

Pipe

[3] ASTM C31/C31M – 12, Standard Practice for Making and Curing Concrete Test Specimens in the

Field

[4] C1577 − 13b, Standard Specification for Precast Reinforced Concrete Monolithic Box Sections for Culverts. Storm Drains. and Sewers Designed According to AASHTO LRFD

[5] OPSS 1821, Material specification for precast reinforced concrete box culverts and box sew

DRS 62: 2021

Price based on 19 pages

©RSB 2021 - All rights reserved