Comparing Parallel ERD and Oxidation Pilot Tests in a Low ...

Transcript of Comparing Parallel ERD and Oxidation Pilot Tests in a Low ...

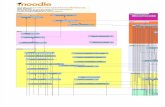

LAKE

B-190

B-189

B-1

95

B-191

"

INACTIVE POND

(COVERED)

B-1OX-1

OX-2OX-2'

B-2

OX-3

OX-5OX-4

OX-8OX-7

OX-7'OX-8' OX-6

MW45

RW03MW19

RW02

MW18R

MW54

LEGEND

INJECTION BORING

RESPONSE ACTION MONITOR WELL LOCATION & NUMBER

FENCELINE

FIGURE 2 - WESTERN INJECTION BORING LOCATIONS CORPUS CHRISTI TECHNICAL CENTERCELANESE, LTD.Project No.: 60339332

Issue Status: DRAFT

Fourth International Symposium on Bioremediation and Sustainable Environmental TechnologiesMay 22-25, 2017 | Miami, Florida

Groundwater impacts have been identified at a closed chemical research facility in the gulf coast of Texas. Two distinct plumes are present without comingling

Comparing Parallel ERD and Oxidation Pilot Tests in a Low Permeability AreaBryon Dahlgren P. E. (AECOM, Atlanta, GA) | Jing Zhou, PhD (AECOM Atlanta, GA)

www.aecom.com

Introduction Activities Results

• 22,400 pounds of persulfate activated ferric oxide compound was injected with 7,000 gallons of water

Direct push activities for chlorobenzene

• Targeted injections were completed in January 2016• Chemical oxidation was selected for treatment for chlorobenzene• Enhanced Reductive Dechlorination (ERD) was selected as treatment for

carbon tetrachloride• Direct push technology was used for each injection• Both activities were completed in a single mobilization• These activities allow direct comparison of reductive and oxidation processes

under otherwise identical field conditions

• Pre-remediation carbon tetrachloride

• Off-site concentrations recently identified above the standard of 0.5 mg/L

• Remediation was planned

• Pre-remediation chlorobenzene

• Off-site concentrations are below the standard of 10 mg/L

• Concentrations near boundary are close to limit and remediation was planned

The site geology is primarily silty sands with low hydraulic conductivity. The groundwater flow velocity is estimated to be less than one-half foot per year. Therefore, injection activities present a particular challenge. Two remediation pilot studies were completed to address separate plumes. Chemical oxidation was applied to a chlorobenzene plume and Enhanced Reductive Dechlorination (ERD) was applied to a carbon tetrachloride plume. The objectives of the pilot studies were:• Determine effectiveness of remedial

technologies under site conditions• Inform design of further remediation and/or

migration control measures• Eliminate highest concentrations

• 8,100 pounds of reductive agent was injected with approximately 3,000 gallons of water

• Reductive agent included primarily carbon source with zero valent iron, and proprietary enhancements

Direct push activities for carbon tetrachloride

Conclusions

• Consistent site conditions appear to have produced mirrored results for oxidative and reductive processes in this study

• Despite rapid increase in ORP, the chlorobenzene concentration did not change initially following injection. After a delay, concentrations improved significantly

• Carbon tetrachloride concentrations dropped immediately but rebounded quickly

• Contact is the key• Oxidation effectiveness was delayed by transport to

the right location• Reduction was immediately effective, but carbon

source did not persist long enough to address porespace diffusion

0

5

10

15

20

25

30

35

40

Oct‐12 May‐13 Nov‐13 Jun‐14 Dec‐14 Jul‐15 Jan‐16 Aug‐16 Mar‐17 Sep‐17

Concen

tration (m

g/L)

Date

Chlorobenzene at Target Well

Pre‐injectionInitial

post injection

recent results

0

0.5

1

1.5

2

2.5

Nov‐13 Jun‐14 Dec‐14 Jul‐15 Jan‐16 Aug‐16 Mar‐17 Sep‐17

Concen

tration (m

g/L)

Date

Carbon Tetrachloride at Target Well

Pre‐injection

Initial post injection

recent results

• Chlorobenzene results showed no change in target concentrations for several quarters

• Results fluctuated between 30 and 37 mg/L

• Then concentrations dropped significantly, meeting criteria

• Current concentrations are approximately 5 mg/L

• Carbon tetrachloride concentrations immediately dropped more than 75%.Rebound occurred shortly thereafter with a recovery to approximately 50% of initial concentrations

• Total organic carbon has dropped to approximately pre-injection levels

• Further remediation is not expected based on work completed

From Darcy's Law: average linear velocity =

Assumed parameter values:Minimum Maximum

gradient (ft/ft) 1.17E-03 1.70E-03hydraulic conductivity (cm/s) 5.35E-05 5.35E-05effective porosity 3.00E-01 2.50E-01

Minimum velocity:v = ( 1.17E-03 ) x ( 5.35E-05 ) = 2.09E-07 cm/s

7.09E-03 inches/day2.16E-01 ft/year

Maximum velocity:v = ( 1.70E-03 ) x ( 5.35E-05 ) = 3.64E-07 cm/s

1.24E-02 inches/day3.76E-01 ft/year

Notes:cm/s = centimeters per secondinches/day = inches per dayft/year = feet per yearHydraulic conductivity values based on October 2015 slug test on MW-64.Gradient values from November 2016 potentiometric surfaces.Porosity values from TWC-CME report 1986.

Table 6

0.30

0.25

Flow Velocity Calculations – November 2016Celanese Ltd. Corpus Christi Technical Center

gradient x hydraulic conductivityeffective porosity

1 of 1

S-29

STORES WAREHOUSEB-216

RAMP

HOUSEGUARDB-220

B-2

05

B-212

B-204

B-203B-180

B-133B-129 B-107

B-163

B-132

LAYDOWN YARD

Avenue "E"

(COVERED)

(COVERED)

B-150

B-215

POND #10INACTIVE

CONTROL BLDG.B-206

B-1

83

B-211

BLDG

B-217

B-190

B-189

B-1

59

B-1

68

B-2

01

BLDGSTAGING

TOTE

B-225

B-207B-161

B-200

B-148 B-112

B-2

02

B-111

B-1

85

B-1

13

B-199

B-182

B-147

B-1

87 B-160

B-188

B-156

B-157

B-198 B-194

B-1

95

B-213

B-149

B-114

B-210

B-1

58

B-223

B-166

BLDGANALYZER

B-214

B-1

45

B-167

TOWERCOOLING

B-130

B-191

"90"

STR

EE

T

Avenue "S"

(COVERED)CLOSED

BURN PIT

"100

" STR

EE

T

Avenue "P"

Avenue "M"

Avenue "U"

"70"

STR

EE

T

"50"

STR

EE

T

"60"

STR

EE

T

"50"

STR

EE

T

Avenue "S"

Avenue "W"

B-184

B-144

"80"

STR

EE

T

(COVERED)

POND #6INACTIVE

B-155

B-146

LAKE

Bld

g.S

tora

geTe

mpo

rary

Bldg.Storage

Temporary

FLARE

SUMP

drainstorm

Sto

rage

Tem

pora

ry

Temporary Storage

Bldg.Storage

Temporary

Bldg.Storage

Temporary

Bldg.Storage

Temporary

S-28

1.0

10.0

1.0

1.0

CELANESE, LTD.CORPUS CHRISTI TECHNICAL CENTER

FIGURE 13CHLOROBENZENE

JUNE 2016CONCENTRATIONS IN GROUNDWATER

LEGEND

MONITORING WELL

CHLOROBENZENE CONCENTRATION IN GROUNDWATER (mg/L)

CHLOROBENZENE ISOCONTOUR (mg/L) (DASHED WHERE INFERRED)

NOT DETECTED AT OR ABOVE THE LABORATORY REPORTING LIMIT

PROTECTIVE CONCENTRATION LEVEL = 10 mg/L

MW-61

0.4

1.0

<

S-29

STORES WAREHOUSEB-216

RAMP

HOUSEGUARDB-220

B-2

05

B-212

B-204

B-203B-180

B-133B-129 B-107

B-163

B-132

LAYDOWN YARD

Avenue "E"

(COVERED)

(COVERED)

B-150

B-215

POND #10INACTIVE

CONTROL BLDG.B-206

B-1

83

B-211

BLDG

B-217

B-190

B-189

B-1

59

B-1

68

B-2

01

BLDGSTAGING

TOTE

B-225

B-207B-161

B-200

B-148 B-112

B-2

02

B-111

B-1

85

B-1

13

B-199

B-182

B-147

B-1

87 B-160

B-188

B-156

B-157

B-198 B-194

B-1

95

B-213

B-149

B-114

B-210

B-1

58

B-223

B-166

BLDGANALYZER

B-214

B-1

45

B-167

TOWERCOOLING

B-130

B-191

"90"

STR

EE

T

Avenue "S"

(COVERED)CLOSED

BURN PIT

"100

" STR

EE

T

Avenue "P"

Avenue "M"

Avenue "U"

"70"

STR

EE

T

"50"

STR

EE

T

"60"

STR

EE

T

"50"

STR

EE

T

Avenue "S"

B-184

B-144

"80"

STR

EE

T

(COVERED)

POND #6INACTIVE

B-155

B-146

LAKE

Bld

g.S

tora

geTe

mpo

rary

Bldg.Storage

Temporary

FLARE

SUMP

drainstorm

Sto

rage

Tem

pora

ry

Temporary Storage

Bldg.Storage

Temporary

Bldg.Storage

Temporary

Bldg.Storage

Temporary

S-28

0.5

0.05

0.05

0.5

0.5

5.0

5.00.5

0.05

0.05

CELANESE, LTD.CORPUS CHRISTI TECHNICAL CENTER

FIGURE 10CARBON TETRACHLORIDE

NOVEMBER 2016CONCENTRATIONS IN GROUNDWATER

LEGEND

MONITORING WELL

CARBON TETRACHLORIDE CONCENTRATION IN GROUNDWATER (mg/L)

CARBON TETRACHLORIDE ISOCONTOUR (mg/L) (DASHED WHERE INFERRED)

NOT DETECTED AT OR ABOVE THE LABORATORY REPORTING LIMIT

PROTECTIVE CONCENTRATION LEVEL = 0.50 mg/L

MW-61

0.16

0.05

<

Carbon TetrachlorideNovember 2016

ChlorobenzeneNovember 2016

Avenue "W"

MW57

IR-1IR-1'IR-2

IR-3IR-4

IR-2'

MW46MW56

LEGEND

INJECTION BORING

RESPONSE ACTION MONITOR WELL LOCATION & NUMBER

FENCELINE

FIGURE 1 - EASTERN INJECTION BORING LOCATIONS CORPUS CHRISTI TECHNICAL CENTERCELANESE, LTD.Project No.: 60339332

Issue Status: DRAFT