College Cantina

description

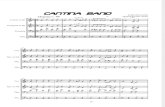

Transcript of College Cantina

College Cantina

Mike, Mario, Lauren, JT

Mission and Competitors

• Penetrate the already existing, but limited, Mexican food market, while providing a fun and friendly atmosphere to keep people coming back

Core Competencies and Processes

• Market Know-howo Being a part of the target market

• Facilitieso Location

• Place to hang out and stay for more than a meal• Customer Relationship

o What will differentiate ourselves• Order Fulfillment

o Restaurants need great order fulfillment

SWOT AnalysisStrengths

-Combination of successful markets

-Big target market in this area

Weaknesses-New player in the

market-Seasonal demand

Opportunities--Growth in college areas

Threats-Legal issues with

alcohol-Changes in consumer demand or preferences

Market Description• Limited direct competition• Differentiation from Chipotle and bars

o Atmosphere• Order Winners

Consistent QualityCustomizationLow Cost

Products & Services

Operations Strategy• Assemble to order

o Customization is keyo Make to order/make to stock

• Why?o Heavy customer involvement

• Flexible

Supplier Relationship• Local Farmers

o Qualityo Constant improvement

• Supplier Selectiono Sysco Foods

• Proven

ToolingEqupiment Price · Large grill (62 inch gas grill) $ 2,500

· deep fryer $ 620 · Tortilla press (tortilla steamer) $ 919 · Meat slicer $ 250 · Mixer $ 639 · Hot food table $ 2,500 · Refrigerators/Freezers x2 $ 2,500 · Eating utensils 500 sets (Alibaba) $ 1,500 · Napkins 3000 paper napkins $ 27 · Condiments Mayo/gal Ketchup/gal Mustard/gal $ 85 · Wet towels 1000 $ 17 · Beverage dispenser (8 beverages) $ 4,100 · Coffee Maker $ 270 · Shelves (66 inch 3 tier backlight display) $ 980

Quality Control• Lean System

o Overproductiono Inventory

• Employee Trainingo Non-utilized resources

• Implementation of Inspections

Quality Strategy• 5s Method• Sort• Straighten• Shine• Standardize• Sustain

Supply Chain Inventory Management

Local Farmers

Chaes Food Distributor

Philadelphia Wholesale Produce Market

Rosemont Beverage Center

Southern Wine and Spirits

Intend to maintain as largest food distributor

Meat distributor for when local farmers are not an option

Vegetable distributor when local farmers are not an option

Source of Beer including all domestic and foreign brands

Source of liquors and other hard alcohols

Maintain low cost and show interest in sustenance of area of business

Philadelphia distributor, local business for ease of access

Philadelphia distributor, local business for ease of access

Close proximity to store location in case of sudden spikes in demand

Relatively close to location of business for convenience

Forecasting Demand

Judgment methods • Salesforce estimates• Executive opinion • Market research

Quantitative forecasting• Time-series methods• Weighted moving average

Customer Demand

Product Demand & Inputs

Inputs Quanity (daily) Quantity (weekly)Chicken (lbs) 23 161Steak (lbs) 23 161Pork (lbs) 23 161Shrimp (lbs) 3 23White rice (cups) 35 245Brown rice (cups) 20 140Refried beans (cups) 10 70Black beans 18 123Red beans 18 123Salsa (cups) 20 140Sour cream (cups) 17 118Guacamole (cups) 16 114Lettuce (heads) 18 126Tomatoes 52 364Cheese (lbs) 33 231Peppers 13 88Onions 19 133Cooking oil (liters) 4 25Hard taco shells 25 175Soft taco shells 45 315Soft flour tortilla 150 1050

Pricing Decision• Start-up fixed costs = $265,000

o Cost for capital equipment = $100,000• Including; furniture, equipment, fixtures, and

computers/registers etc.o Administrative expenses = $150,000

• rent, utilities, legal and accounting fees, prepaid insurance, and pre-opening salaries

o Opening inventory = $15,000• Including all of the produce, Mexican food related inputs,

utensils, and napkins etc.

• Annual fixed cost = 75,000 o Including depreciation, insurance, interest expense, rent, and

utilities

• Monthly variable costs = $20,000 (will vary directly with output) o Comprised of the cost for direct materials, staff wages, production supplies, and credit card fees

Conclusion• Great opportunity in this area• Great place for fun and delicious food• Come and join us!