collection of data sheets for MPS PA - Festo · MPS® PA Data sheets. GRE-1/4 Exhaust flow control...

Transcript of collection of data sheets for MPS PA - Festo · MPS® PA Data sheets. GRE-1/4 Exhaust flow control...

-

MPS® PA

Data sheets

-

GRE-1/4Exhaust flow control valve

10352

Feature Data/description

Data sheet

Part no.:Page:1

Assembly position Any

Adjusting element Slotted head screw

Valve function Flow control – silencer function

Operating pressure 0 - 10 bar

Standard nominal flow rate in flow control direction 996 l/min

Operating medium Compressed air, filtered, unlubricatedFiltered, lubricated air

Medium temperature -10 - 70 °C

Ambient temperature -10 - 70 °C

Product weight 25 g

Mounting type Threaded

Pneumatic connection, port 1 G1/4

Materials information for screw-in stud Wrought Aluminium alloy

Materials information for seals NBR

Regulating screw material data Brass

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:58:46

-

I/O cable Description

D.MP-B-AN-KEAT Designation

034031 Order No.

034031

1/2

I/O cable

Data sheet Festo Didactic

-

Cable with 21 wires each of cross section of 0.34 mm2. 24 pin plug connectorsare fitted to both ends.

Construction

The I/O cable connects an I/O terminal (Order No. 034035) to a controlcabinet. 16 I/O signals can be transmitted. In addition, the cable conducts thesensor and actuator power supply.

Function

Technical data

Wire colours andpin allocations

01 Bit 0 Output word white 13 Bit 0 Input word grey-pink

02 Bit 1 Output word brown 14 Bit 1 Input word red-blue

03 Bit 2 Output word green 15 Bit 2 Input word white-green

04 Bit 3 Output word yellow 16 Bit 3 Input word brown-green

05 Bit 4 Output word grey 17 Bit 4 Input word white-yellow

06 Bit 5 Output word pink 18 Bit 5 Input word yellow-brown

07 Bit 6 Output word blue 19 Bit 6 Input word white-grey

08 Bit 7 Output word red 20 Bit 7 Input word grey-brown

09 24 V Power supply black 21 24 V Power supply white-pink

10 22

11 0 V Power supply pink-brown 23 0 V Power supply white-blue

12 0 V Power supply purple 24

034031

2/2

Wires per cableCross sectionPlug type

210.34 sq. mmAmphenol 24 pin

010203040506070809101112

131415161718192021222324

Data sheet Festo Didactic

-

034035

I/O terminal

© Festo Didactic GmbH & Co., 08/2001 Subject to change 1/2

The terminals for 8 inputs and 8 outputs are combined in a basic unit. In addition,distributor terminals are provided for 0 V and 24 V for the supply of sensors andactuators. The base unit can be clipped onto top-hat rails. All contact points and thecurrent supply are linked to the 24-pin plug. The I/O terminal is connected to thecontrol cabinet by means of an I/O cable, which is not part of the scope of delivery(Order No. 34031).

The I/O terminal provides 8 inputs and 8 outputs on screw terminals. 24 LEDs areavailable for status display to indicate the status of the I/Os.

Feature Value

Number of inputs with LED 8

Number of outputs with LED 8A

Number of terminals 0 V 22

Number of terminals 24 V 12

Connector Amphenol-Tuchel 24-pin, 57 GE series

Design

Function

Technical data

-

034035

I/O terminal

2/2 Subject to change © Festo Didactic GmbH & Co., 08/2001

1

13 24

12

X

0 VA0 VA

0 VA0 VB

0 VB

0 VB

0 VB

0 VB

0 VB

0 VB

0 VB

0 VB

0 VB

0 VA

0 VA

0 VA

0 VA

0 VA

0 VA

0 VA

0 VA

0 VA

24 VA

24 VA

24 VB

24 VB

24 VB

24 VB

24 VB

24 VB

24 VB

24 VB

24 VA

24 VA

O7 I7

I0

I1

I2

I3

I4

I5

I6

O1

O0

O2

O3

O4

O5

O6

PIN 1 O0PIN 2 O1PIN 3 O2PIN 4 O3PIN 5 O4PIN 6 O5PIN 7 O6PIN 8 O7PIN 9 24 VAPIN 10 24 VAPIN 11 0 VAPIN 12 0 VAPIN 13 I0PIN 14 I1PIN 15 I2PIN 16 I3PIN 17 I4PIN 18 I5PIN 19 I6PIN 20 I7PIN 21 24 VBPIN 22 24 VBPIN 23 0 VBPIN 24 0 VB

Pin assignment

The inputs of the I/O terminal can be switched for the connection of either positiveswitching (PNP) or negative switching (NPN) sensors via two slide switches.

Connection of negativeswitching sensors (NPN):both switches in NPN position

NPN

PNP

1212

24240 VA0 V

B

0 VB

0 VB

I 7

0 VA

24 VA

24 VA

24 VB

Connection of positiveswitching sensors (PNP):both switches in PNP position

NPN

PNP

1212

24240 VA0 V

B

0 VB

0 VB

I 7

0 VA

24 VA

24 VA

24 VB

Slide switch positions

Note

-

MSFG-24DC/42AC-ODSolenoid coil

34411

Feature Data/description

Data sheet

Part no.:Page:1

Assembly position Any

Min. pickup time 10 ms

Duty cycle 100%

Characteristic coil data 24V DC: 4,5W42V AC: 50/60Hz, AL7,5W,HL6W

Permissible voltage fluctuation +/- 10 %

Medium temperature -10 - 60 °C

Protection class IP65

Ambient temperature -5 - 40 °C

Product weight 65 g

Electrical connection Plug vanes for MSSD-F3-pin

Mounting type With knurled nutwith accessories

Materials information, housing PA

Materials information, plug Steel

Material information, coil Copper

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:49:18

-

150768

Starting current limiter

© Festo Didactic GmbH & Co., 08/2001 Subject to change 1/2

A relay and an electronic current limiter have been integrated on a circuit board. Thecircuit board can be fitted via the attachments on the reverse side. Electricalconnection is effected via screw terminals.

The device limits the surge current to a maximum of 2A the moment it is switchedon. Otherwise, the module operates in the same way as a relay.

This module must only be used to operate consuming devices with a maximum staticcurrent requirement of 1A. The current limiting effect must not be used for thecontinuous current limiting of a consuming device.

24 V

0 V

24 VIN 0 VOUT

0 V 0 V

A

SPS

M

Connection diagram

Design

Function

Note

-

150768

Starting current limiter

2/2 Subject to change © Festo Didactic GmbH & Co., 08/2001

Feature Value

Control voltage 24 V DC

Current 1 A

Current limitation 2 A

Max. limitation duration 50 ms

Max. switching frequency 1/s

Technical data

-

152894

Service unit with on/off valve

© Festo Didactic GmbH & Co., 04/2001 Subject to change 1/2

The filter regulator with pressure gauge, on/off valve, push-in fitting and quick

coupling plug is mounted on a swivelling retainer. The filter bowl is fitted with a

metal bowl guard. The unit is mounted on the profile plate by means of cheese head

screws and T-head nuts (mounting alternative “C”). Attached is a quick coupling

socket with threaded bush and connector nut for plastic tubing PUN 6 x 1.

The filter with water separator cleans the compressed air of dirt, pipe scale, rust and

condensate.

The pressure regulator adjusts the compressed air supplied to the set operating

pressure and compensates for pressure fluctuations. An arrow on the housing

indicates the direction of flow. The filter bowl is fitted with a filter drain screw. The

pressure gauge shows the preset pressure. The on/off valve exhausts the entire

control. The 3/2-way valve is actuated via the blue sliding sleeve.

When constructing a circuit, please ensure that the filter regulator is installed in the

vertical position. The pressure regulator is fitted with an adjusting knob, which can

be turned to set the required pressure. By sliding the adjusting knob towards the

housing, the setting can be locked.

Design

Function

Note

-

152894

Service unit with on/off valve

2/2 Subject to change © Festo Didactic GmbH & Co., 04/2001

Pneumatic

Medium Compressed air

Design Sintered filter with water separator, diaphragm control valve

Assembly position Vertical ±5°

Standard nominal flow rate * 750 l/min

Upstream pressure max. 1600 kPa (16 bar)

Operating pressure max. 1200 kPa (12 bar)

Connection Coupling plug fore coupling socket G 1/8

QS-plug fitting for plastic tubing PUN 6 x 1

* Upstream pressure: 1000 kPa (10 bar), Operating pressure: 600 kPa (6 bar),

Differential pressure: 100 kPa (1 bar).

Technical data

-

LRMA-QS-4Pressure regulator

153495

Feature Data/description

Data sheet

Part no.:Page:1

Actuator lock Knurled screw with lock nut

Assembly position Any

Design structure directly-controlled piston regulatorwith looped-through compressed air supply

Controller function with secondary exhaustOutput pressure constant

Pressure gauge with pressure gauge

Pressure control range 1 - 8 bar

Inlet pressure 1 0 - 9 bar

Standard nominal flow rate 50 l/min

Operating medium Filtered compressed air

Ambient temperature 0 - 60 °C

Product weight 45 g

Mounting type with through hole

Pneumatic connection, port 1 QS-4

Pneumatic connection, port 2 QS-4

Materials information for screw-in stud Nickel platedBrass

Materials information, housing PBT-reinforced

Materials information for thread seal PTFE

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 14:00:12

-

160236

Pressure vessel

© Festo Didactic GmbH & Co. KG, 02/2004 Subject to change 1/1

Pressure vessel

The pressure vessel is used for storage of pressurized media.

The pressure vessel is used for the storage of pressurized media.

Parameter Value

Medium Water

Design Welded vessel

Mounting Mounting bracket

Connection G ½“

Volume 2 l

Pressure range * -0,95 bar to 16 bar

Materials Steel (X 5 Cr Ni 18 10)

Weight 1,681 kg

Subject to change

* If ou use the pressure vessel within the pressure control station, the maximum

operating pressure must not exceed 0,5 bar!

Function

Design

Technical data

Note

-

162844

Pressure gauge

© Festo Didactic GmbH & Co. KG, 03/2004 Subject to change 1/2

Pressure gauge

This pressure gauge (to EN 837-1) is designed for pressure measurement and

display in controls.

The maximum pressure at continuous operation (dead load) is at ¾ of the full scale

value. The Pressure gauge is free of paint-wetting impairment substances.

Symbol

Description

-

162844

Pressure gauge

2/2 Subject to change © Festo Didactic GmbH & Co. KG, 03/2004

Parameter Value

Nominal diamenter 63 mm

Indicating range 0...1 bar

Operating pressure 0...0,7 bar

Medium Liquid and gaseous media (not permissible:

oxygen, acetylene)

Design Bourdon tube pressure gauge

Connection G1/4(Type MA-40-...-1/8-EN: R1/8)

Anschlusslage Rear side (centrically)

Temperaturbereich -20°C...+60°C

Measuring device class (DIN 16005/EN 837-1) 2,5

Vibration resistance (DIN IEC 68-2-6/EN 837-1) 5 m/s2 at 10 ... 150 Hz

Resistance to shocks

(DIN IEC 68-2-27/EN 837-1)

150 m/s2 at 11 ms

Protection class IP 43

Materials

Housing

Window shield

Dial

Labelling

Connection thread

PS, black

SAN

ABS white

black, blue

Brass

Subject to change

Technical data

-

SOEG-E-Q30-PS-S-2LReceiver

165323

Feature Data/description

Data sheet

Part no.:Page:1

Conforms to standard DIN EN 60947-5-2

Short circuit strength Pulsing

Type of light Infrared

Measurement method Through-beam sensorReceiver

Switching element function Dark switching

Polarity protected for all electrical connections

Upper limit of adjustment range 6 mm

Setting options Potentiometer

Operating reserve display Green LED

Operating status display Yellow LED

Max. switching frequency 1.000 Hz

Operating voltage DC 10 - 30 V

Idle current 30 mA

Max. output current 200 mA

Residual ripple 20 %

Switch output PNP

Voltage drop 2 V

CE Symbol In compliance with EU directive 89/336/EWG (EMV)

Corrosion resistance classification CRC 2

Protection class IP65

Ambient temperature -5 - 55 °C-25 - 55 °C

Product weight 18 g

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:56:31

-

SOEG-E-Q30-PS-S-2LReceiver

165323

Feature Data/description

Data sheet

Part no.:Page:2

Working range 0 - 6.000 mm

Electrical connection M8x1Plug3-pin

Mounting type with through hole

Materials note Copper and Teflon-free

Materials information, housing PBT-reinforced

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:56:31

-

SOEG-S-Q30-S-LTransmitter

165353

Feature Data/description

Data sheet

Part no.:Page:1

Conforms to standard DIN EN 60947-5-2

Type of light Infrared

Measurement method Through-beam sensorTransmitter

Polarity protected for all electrical connections

Upper limit of adjustment range 6 mm

Max. switching frequency 1.000 Hz

Operating voltage DC 10 - 30 V

Idle current 25 mA

Residual ripple 20 %

Voltage drop 2 V

CE Symbol In compliance with EU directive 89/336/EWG (EMV)

Corrosion resistance classification CRC 2

Protection class IP65

Ambient temperature -5 - 55 °C-25 - 55 °C

Product weight 18 g

Electrical connection M8x1Plug3-pin

Mounting type with through hole

Materials note Copper and Teflon-free

Materials information, housing PBT-reinforced

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:55:43

-

© Festo Didactic GmbH & Co. KG, 03/2009 Subject to change 1/2

170701, 170702, 170703, 170705, 304518, 690590

Pipe fittings

Piping of process engineering systems is quick, reliable and leak-proof using the

piping and push-fit connector system. The individual components of the piping

system are:

• Push-in L-connector 90° (see above) Order No. 170701 • Push-in T-connector (see above) Order No. 170702 • Hand lever valve (see above.) Order No. 170703 • Plug Order No. 170705 • Straight piping sections

available in different lengths Order No. 304518

• Push-in L-connector 90° (see above) Order No. 690590 • Pipe cutter Order No. 7658

The piping system consists of pipes and push-fit connectors made of plastic.

Parameter Value

Operating characteristics

Cold water system

Hot water system

Central heating system

20 °C/10 bar

65 °C/7 bar

82 °C/4 bar

Withdrawal force > 1200 N/20 °C

Bursting pressure > 40 bar/20 °C

Flow media Water, miscellaneous gases

Operating pressure Max. 6 bar at 80 °C

Material Plastic PEM (Polymerelectrolytmembranes)

Piping diameter, external 15 mm

Function

Design

Technical data

-

2/2 Subject to change © Festo Didactic GmbH & Co. KG, 03/2009

170701, 170702, 170703, 170705, 304518, 690590

Pipe fittings

• A pipe cutter is required to cut the piping to length. • Piping is assembled without the need for tools. • Assembly: – Simply cut the piping to length using plastic pipe cutters and ensure that the

pipe is free of sharp edges, longitudinal grooves or other damage.

– Prior to pushing-in, the fitting must be in the „unlocked“ position, whereby a narrow gap exists between the screw cap and the body of the fitting.

– Insert the piping past the O-ring up to the stop in the connector. The O ring in the support sleeve ensures additional sealing of the connection.

– Tighten the screw cap up to the stop on the housing. This presses the O-ring onto the piping, thereby securing the connector.

– Check the established connection by attempting to withdraw the piping.

Zweite Abdichtung = Second seal

Einsteckmarkierung = Plug-in mark

• Dismantling: – Unscrew the screw cap until a narrow gap is created and the two arrows snap

into the opposite position. Press back and hold the retaining element using your

fingers or with the help of releasing tool. The pre-fitted piping can now be pulled

out.

Assembly/dismantling

-

© Festo Didactic GmbH & Co. KG, 03/2009 Änderungen vorbehalten 1/2

170704

Double non-return valve

This valve has a shut-off function whereby flow is only possible in one direction.

The valve has an additional functional screw for manual exhausting.

The direction of the non-return function must be noted when installing the valve.

The valve must not be used for gas, heating oil or compressed air applications.

Attachments and piping must be kept clean and undamaged prior to usage.

Piping can be assembled without the need for tools.

Assembly: The piping is inserted into the push-in connector up to the stop.

Dismantling: To release the connection, release the collet on the push-in connector

and pull out the piping.

Function

Note

Assembly/dismantling

-

2/2 Subject to change © Festo Didactic GmbH & Co. KG, 03/2009

170704

Double non-return valve

Parameter Value

Operating characteristics

Cold water system

Hot water system

20 °C/10 bar

65 °C/6 bar

Flow medium Water

Material Polyacetal (POM)*

Plug-in connection for piping diameter, external 15 mm

– * Polyoxymethylene/polyacetal (POM) Structural formula:

Polyacetals (POM) are universal materials for functional components in precision

mechanics and in apparatus engineering. They offer excellent characteristics

such as low frictional resistance, excellent abrasion resistance, excellent spring

power, high fatigue resistance, excellent electrical characteristics, high dielectric

strength, low dielectric loss factor, good chemical resistance, particularly to

solvents and they are extremely resistant to stress crack formation.

Polyacetals (POM) are thermoplastics, which and have been on the market since

1959.

Technical data

-

170709

Temperature sensor

© Festo Didactic GmbH & Co. KG, 07/2006 Subject to change 1/4

The temperature sensor comprises a resistance thermometer made of platinum and with exchangeable measuring insert. The sensor consists of a shield tube, a connecting head and the measuring insert. When installing the sensor, make sure that the sensor accepts the temperature to be measured as accurately as possible. Heat absorption or heat supply through the sensor is to be avoided. The temperature sensor is screwed into the threaded hole of a container t. Resistance basic values of Pt 100 resistances as a function of temperature: Temperature [°C] −100.00 0.00 100.00 200.00 Basic value [W] 60.25 100.00 138,50 175.84

Characteristic line: Resistance curve of Pt 100 across temperature within a range of −100 °C to +200 °C

ϑ

Function

Design

-

170709 Temperature sensor

2/4 Subject to change © Festo Didactic GmbH & Co. KG, 07/2006

The permissible flow velocity is 3 m/s. In order to dismantle the sensor, it is not necessary to release the entire mounting on the container. It is sufficient to loosen both of the set screws (see fig. below). This then enables you to pull the thermoelement out of the protective sleeve.

1 Set screw (2x) 2 Protective sleeve 3 Thermoelement

Parameter Value

Design To DIN 43 763

Measuring range −50 °C – +150 °C

Measuring resistance Pt 100

Material Plastic

Tolerance

0 °C

100 °C

+/− 0.12 Ω +/− 0.30 Ω

Material:

Casing

Protective sleeve

Stainless steel

Stainless steel

Dimensions

Length

Measuring insert length

Screw-in thread

100 mm

145 mm

G ½“

Electrical connection Cable, 750 mm long

Note

Dismantling of the sensor

Technical data

-

170709

Temperature sensor

© Festo Didactic GmbH & Co. KG, 07/2006 Subject to change 3/4

ϑGnWs

The table below contains the digitalised measured value representation of the Simatic S7 for the standard temperature range of the generator.

Temperature range -

Standard PT 100 850°C

Decimal unit Hexadecimal unit Range

>1000.0 32767 7FFFH Overflow

1000.0

.

.

850.1

10000

.

.

8501

2710H

.

.

2135H

Overload range

850.0

.

.

−200.0

8500

.

.

−2000

2134H

.

.

F830H

Nominal range

−200.1

.

.

−243.0

−2001

.

.

−2430

F82FH

.

.

F682H

Underload range

-

4/4 Subject to change © Festo Didactic GmbH & Co. KG, 07/2006

-

170712

Pump

© Festo Didactic GmbH & Co. KG, 06/2006 Subject to change 1/4

• Recirculating pump for water, antifreeze compounds in heating systems for

motor vehicles, boats, caravans, etc. • Recirculating pump for fresh water cooling in vehicles. • All-purpose pump for applications where self-priming is not required. These pumps are standard intake centrifugal pumps and must be filled with the pumping medium prior to commissioning. These pumps must not be operated dry. A brief period of dry operation does not damage the pump. Please note that if the pump is operated dry for more than 30 minutes, it will be rendered unusable. If run dry, a noise will become audible. Important: This pump must always operate in the specified direction of rotation. The pumps are designed for continuous operation and voltage fluctuations of ±20%. They must not be used for waste water containing coarse dirt particles. The pumps can be installed in any working position – horizontal or vertical. In order to avoid the formation of air pockets, the pump outlet should be turned upwards in the case of horizontal mounting or aligned so that it is positioned at the upper side of the pump.

Typical areas of application

Mounting instructions

-

170712 Pump

2/4 Subject to change © Festo Didactic GmbH & Co. KG, 06/2006

The pump is held within a clamping ring and is mounted onto a profile plate using two screws and T-head nuts.

Individual components of the pump: 1) Housing, ∅ 20 2) Impeller 3) O-ring 4) Screw 5) Clamping ring 6) Washer 7) Shaft 8) Seal 9) Magnet housing When in operation, note the polarity of the voltage applies. The cable connections are colour coded: Operating voltage Positive terminal red Negative terminal black The maximum cable length is 44 m at: Cable cross section: 1.0 mm2

Operating voltage: 24 V

Design

Note

-

170712

Pump

© Festo Didactic GmbH & Co. KG, 06/2006 Subject to change 3/4

Parameter Value

Pump housing Fibreglass reinforced plastic (PPA,

GF 30 %)

Shaft Stainless steel

Wearing plate Stainless steel

O-ring EPDM

Impeller Body: Fibreglass reinforced plastic (PPS, GF

40 %)

Magnet: Ferrite

Bearing: Resin-bound carbon

Magnet housing Fibreglass reinforced plastic (PSU,

GF 30 %)

Motor flange Fibreglass reinforced plastic (PA66,

GF 30 %)

Motor housing Steel, iron-zinc treated,

Motor cover Fibreglass reinforced plastic (PA 66,

GF 30 %)

Schrauben Steel, iron-zinc treated,

Motor Bearing mounted, permanent magnet motor

12/24 V

Motor bracket? Aluminium, varnished

Protection class IP 67 (DIN 40050)

Connection

Push-in connection for piping diameter, external

20 mm (¾“)

15 mm

Interference supressed EN 55014

Temperature range

Fluidt

Environment

−40°C – + 100°C −40°C – +70°C

Max. system pressure 2.5 bar

Operating voltage 24V DC

Power 26 W

Max. flow 10 l/min

Dimensions:

Length

Width

Height

170 mm

62 mm

75 mm

Weight 0.53 Kg

Technical data

-

170712 Pump

4/4 Subject to change © Festo Didactic GmbH & Co. KG, 06/2006

Pressure (bar) Delivery rate (l/min) Current at 24 V (A)

0.1 26 1.1

0.2 19,5 1.0

0.3 9,0 0.75

Measured values apply for a tubing connection of ¾“ (20 mm)

Pressure and performance

-

170713

Heating unit

The heating unit functions via a 230 V AC power supply. Two operating modes

facilitate strictly digital or analogue operation. If the digital operating mode is used,

the heater is switched on and off via a 24 V input.

Function

In the case of analogue operation, heating power can be infinitely adjusted via a 0 to

10 V signal.

An LED indicates the switching status and also any faults.

The heater is screwed into a 50 mm diameter hole in a container and retained via a

threaded sleeve.

Setup

The submersible heater must only be operated when entirely submersed in fluid.

Parameter Value

Heating power 1000 W / 230 V AC

Power supply 24 V DC / 100 mA

Digital input 24 V DC / 12 mA

Analogue input 0 to 10 V

Dimensions

Heater tube

Retaining thread

150 mm x 20 mm diameter

G 1• "

Materials (heater tube casing) Stainless steel

Connections

Heater

Control

Mains cable with plug, 2000 mm long

4-pin M8 plug

Technical data

• Festo Didactic GmbH & Co. KG, 06/2007 Subject to change without notice 1/

-

170713

Heating unit

Parameter Value

Digital operation:

24 V at digital input and

24 V at analogue input

0 V at digital input and

24 V at analogue input

Green on

continuously Heater on

Green off Heater off

Analogue operation:

24 V at digital input and

0 to 10 V at analogue input

Flashing green Heater

actuated

Excessively high temperature at heater tube:

Heater is shut down at TH > approx. 50˚ C, and is switched back on automatically at TH < 45˚ C

Red on continuously Heater off

Excessively high temperature at power section:

Heater is shut down at component temperature TC > 90˚ C, and is switched back on automatically at TC < 85˚ C

Flashing red Heater off

LED display

Parameter Value

24 V supply Plug pin 1 (brown)

0 V supply Plug pin 4 (blue)

24 V digital input Plug pin 3 (black)

0 to 10 V / 24 V analogue input Plug pin 2 (white)

Electrical pin allocations

The heating tube is subject to high temperatures – risk of burns!

2/ Subject to change without notice • Festo Didactic GmbH & Co. KG, 06/2007

-

170714

Proportional valve

© Festo Didactic GmbH & Co. KG, 03/2009 Änderungen vorbehalten 1/7

Proportional valve

The proportional valve facilitates flow control of neutral gases and fluids. It can be

used as a remote controllable final control element or in closed control loops.

The proportional valve is a directly actuated 2/2- way valve. The valve piston is lifted

of its seat as a function of the solenoid coil current and releases the flow from

connection 1 to connection 2. Once the valve is de-energised, it is closed via a reset

spring.

The control signal, which is transformed into a PMW-signal, lifts the piston of its

seat. The frequency of the PWM-signal could be changed. The value depends on

what kind of valve is used.

The proportional valve is mounted on an angle bracket and can be attached to an

MPS profile plate using a screw and T-head nut.

The maximum flow rate for water should not exceed 3 m/s.

Function

Design

Information

-

170714

Proportional valve

2/7 Änderungen vorbehalten © Festo Didactic GmbH & Co. KG, 03/2009

Parameter Value

Permissible operating voltage

(to be connected to control electronics)

24 V DC

Power consumption (solenoid) 8 W

Operation permanent

Degree of protection IP 65

Nominal size 7,1 mm

Operating pressure max. 1 bar pressure difference

Ambient operating temperature max. +75 °C

Response sensitivity < 2% of final value

Repetition accuracy < 3 % of final value

Flow media Neutral media

e.g. water, compressed air

Flow rate coefficient 15,0 l/min; 0,9 m³/h

Temperature of medium -10 °C to +90 °C

Materials

Housing

Internal valve parts

Seal

Brass

Stainless steel

FPM

Dimensions

Height with plugged in control electronics

Length

129,5 mm

40 mm

Pipe connection G 3/8

Electrical connection Contact box with 4 pins

Subject to change

Technical Data of

the valve

-

170714

Proportional valve

© Festo Didactic GmbH & Co. KG, 03/2009 Änderungen vorbehalten 3/7

Parameter Value

Permissible voltage supply 24 VDC +/- 10%

Residual ripple max. 10 %

Input signal 0 ... 10 V, 0 ... 20 mA, 4 ... 20 mA

Power consumption 0,8 W

Current consumption at approx.. 24V max. 1100 mA

Min. current Adjustable between 15 – 50% of the

max. current

Max. current Adjustable between 30 – 100 % of the

max. current

Time ramp optional ON/OFF, adjustable between 0,1 – 3s

Adjustable switching frequency 40 – 700 Hz

Ambient operating voltage -10 to + 75°C

Material (Housing) Plastic

Electrical connection Contact box with 4 pins

Subjects to change

Technical Data of

the control electronic

-

170714

Proportional valve

4/7 Änderungen vorbehalten © Festo Didactic GmbH & Co. KG, 03/2009

9

10

11

12

Pin assignment

1 gasket

2 connector

3 printed circuit

4 cap and gasket

5 screw

6 wire wound coil

7 wire wound coil

8 protection earth

9 supply 24V DC

10 control signal

11 neutral conductor 0 V

12 protection earth

Connecting instruction

6

7

8

-

170714

Proportional valve

© Festo Didactic GmbH & Co. KG, 03/2009 Änderungen vorbehalten 5/7

D

P1 minimum flow rate (point of origin)

P2 ramp time

P3 maximum flow rate

P4 switching frequency

D1 input signal

X1

The minimum control range can be adjusted by the potentiometer P1

X 2

The maximum control range can be adjusted by the potentiometer P3

Set potentiometer

Flow curve

-

170714

Proportional valve

6/7 Änderungen vorbehalten © Festo Didactic GmbH & Co. KG, 03/2009

Setup the input signal by using the switches D1. The graphic below shows, how the

switches has to be set. The factory-setting for the input signal is 0-10 V.

S1 control signal

S2 ramp ON/OFF

S3 control signal

S4 control signal

0-10 V DC: S1 OFF, S3 ON, S4 OFF

0-20 mA: S1 ON, S3 ON, S4 OFF

4-20 mA: S1 OFF, S3 OFF, S4 OFF

Activate the ramp function while (switching ON S3), to delay the flow rate at fast

signal changes. The ramp time can set with the potentiometer P2 in a range between

0.1 and 3 seconds. By using the proportional valve in the compact workstation, the

ramp function is not needed and could stay off. The factory setting for the ramp time

is ”no ramp”.

For commissioning the proportional valve, following criteria has to be fulfilled:

• The tank has to be filled to the lowest level (~4 l) • Open the relevant hand valves, so that the medium gets in a circle way through

the proportional valve back in the tank.

• Ramp function has to be off.

Setting the minimum and maximum flow rate

Switch on the pump and the proportional valve by activating them from the

controlling software. Setup the control value of the proportional valve to 1 V. Control

the pump digital, thus with maximum control value. Now setup the flow rate to

~0.25 l/min via the potentiometer P1.

In the next step, setup the proportional valve with 10 V, maximum control value.

Via the potentiometer P3, the maximum flow rate can be adjusted. Twist the

potentiometer until the flow rate has reached an value of ~2.7 l/min.

DIP-switches

Notes for Installation

-

170714

Proportional valve

© Festo Didactic GmbH & Co. KG, 03/2009 Änderungen vorbehalten 7/7

Information

The setup of the maximum flow rate affects the minimum flow rate marginally. Due

to a restart, the setup of the minimum flow solves the problem.

Some mounting conditions create unwanted vibrations. In this cases increase the

switching frequency via the potentiometer P4. The problem should be solved.

Factory setting is 300 Hz.

By changing the switching frequency a unwanted effect occurs. The minimum and

maximum flow rate also changes its value. Restart the mentioned steps above to

solve the problem.

-

170715

2/2 way solenoid valve DN10

© Festo Didactic GmbH & Co. KG, 02/2009 Subject to change 1/2

2/2 way solenoid valve

The 2/2-way solenoid valve is a direct controlled valve. If electrical current is not

flowing through the coil, the valve is closed by spring power. There is no pilot

pressure necessary to open the valve.

In normal position the armature with seal is pressed from spring power on the valve

seat.

The medium reinforces the seal effect. Engaging the selenoid coil the armature is

lifted from the valve seat whereby it is released. The medium is possible to flow

unchecked from P to A. Deactivating the selenoid coil the clip presses on the

armature whereby the valve is locked.

The 2/2-way solenoid valve is mounted with plug connectors into the piping.

Schaltzeichen

Function

Functional principle

Design

-

170715

2/2 way solenoid valve DN10

2/2 Subject to change © Festo Didactic GmbH & Co. KG, 02/2009

The assembly position of the valve is in any direction, preferably vertical position.

Neutral gases, liquids and steam.

Plug vanes to DIN 43650 A for a connector socket Type 2508.

For a firm attachment, a pipe clamp may be fitted in front and behind the valve.

Parameter Wert

Nominal diameter 10 mm (DN10)

Connection G 1/2

Pressure difference 0...0,3 bar

Static pressure max. 10 bar

Max. anbiant air temperature 50 °C

Body material Brass

Cores Stainless steel (1.4105)

Assembly position Arbitrary, preferably vertical position

Operating voltage 24 VDC ±10 %

Operating cycles max. 360/min.

Viscosity of usable media max. 21 mm2/s (3 °E)

Power consumption 8 W

Kv-Value (water, +20°C) 1,2 m3/h (measurement 1 bar valve input free

outlet

Protection class IP 54

Weight 0,415 kg

Subject to change

1

2

3

Assembly position

Medium

Electrical connection

Note

Technical data

Electrical pin assignment

1 24 V (black)

2 Ground (black)

3 PE (gn/ge)

-

170716

Ball valve

© Festo Didactic GmbH & Co. KG, 02/2004 Subject to change 1/1

Ball valve

Swivelling of the lever, causes the flow to be shut off completely in both directions. The ball valve is installed in the piping by means of quick push-pull connectors. The figure above shows the ball valve in closed position. If the lever is turned to 90° ball valve is opened completely.

Parameter Value

Connection 15 mm

Nominal size 15

Pressure range 0 ... 7 bar

Temperature range (with plastic connectors) 0 ... +65 °C

Actuating force 5 Nm

Weight Approx. 0,45 kg

Subject to change

Function

Design

Note

Technical data

-

GRLA-M5-QS-4-LF-COne-way flow control valve

175056

Feature Data/description

Data sheet

Part no.:Page:1

Assembly position Any

Adjusting element Slotted head screw

Valve function Exhaust-air one-way flow control valve

Operating pressure 0,2 - 10 bar

Standard flow rate in direction of flow control: 6 -> 0 bar

80 l/min

Standard flow rate in blocked direction: 6 -> 0 bar 100 - 150 l/min

Standard nominal flow rate in flow control direction 40 l/min

Standard nominal flow rate in non-return direction 50 - 75 l/min

Operating medium Filtered, unlubricated compressed air, 40 µm filtrationFiltered, lubricated compressed air, 40 µm filtration

Medium temperature -10 - 60 °C

Ambient temperature -10 - 60 °C

Max. tightening torque 1,5 Nm

Product weight 9 g

Mounting type Threaded

Pneumatic connection, port 1 M5

Pneumatic connection, port 2 QS-4

Materials information for screw-in stud Nickel platedBrass

Materials information for seals NBR

Materials information, housing Zinc die-casting

Release ring material data POM

Regulating screw material data Brass

Swivel joint material data Zinc die-casting

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:55:01

-

QSML-M7-6Push-in/threaded L-fitting

186353

Feature Data/description

Data sheet

Part no.:Page:1

Size Mini

Nominal size 4 mm

Type of seal on screw-in stud Sealing ring

Design structure Push/pull principle

Operating pressure -0,95 - 10 bar

Operating medium Filtered compressed air

Corrosion resistance classification CRC 2

Ambient temperature 0 - 60 °C

Max. tightening torque 2 Nm

Pneumatic connection M7for tubing, 6mm outside diameter

Materials information, housing PBT-reinforced

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:54:02

-

DRE-4-F05-Q10-FOSemi-rotary drive

189971

Feature Data/description

Data sheet

Part no.:Page:1

Size of actuator 4

Rotation angle adjustment range 90 deg

Flange hole pattern F05

Swivel angle 90 deg

Fitting connection conforms to standard ISO 5211

Cushioning none

Assembly position Any

Mode of operation single-acting

Design structure Rack and pinion

Position detection none

Closing direction Spring force, opening

Valve connection conforms to standard VDI/VDE 3845 (NAMUR)

Operating pressure 2 - 10 bar

Operating medium Dried compressed air, lubricated or unlubricated

Corrosion resistance classification CRC 3

Ambient temperature -20 - 80 °C

Torque at 6 bar 26,9 Nm

Spring return moment 10,3 Nm

Efficiency of actuator 80 %

Air consumption per cycle 0,3 l

Product weight 1.200 g

Shaft connection V14

Pneumatic connection G1/8

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:51:47

-

DRE-4-F05-Q10-FOSemi-rotary drive

189971

Feature Data/description

Data sheet

Part no.:Page:2

Sub-base

Materials note Contains PWIS substances

Materials information for drive shaft AluminiumAnodised

Materials information for cover PA

Materials information for seals NBR

Materials information, housing AluminiumAnodised

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:51:47

-

CPE10-M1BH-5L-M7Solenoid valve

196927

Feature Data/description

Data sheet

Part no.:Page:1

Nominal size 4 mm

Exhaust-air function throttleable

Type of actuation electrical

Sealing principle soft

Assembly position Any

Manual override resettingwith accessories, detenting

Design structure Piston slide

Type of reset Air spring

Type of piloting Piloted

Flow direction non reversible

Valve function 5/2monostable

Valve position identification Inscription label holder

Operating pressure range, external pilot air -0,9 - 10 bar

Operating pressure range, internal pilot air 3 - 8 bar

Control pressure characteristics (diagram) Diagram

b value 0,41

C value 1,43 l/sbar

Standard nominal flow rate 350 l/min

Switching time off 16 ms

Switching time on 16 ms

Operating pressure 3 - 8 bar

Duty cycle Kabelsteckdose KMYZ-9-...100% mit Haltestromabsenkung

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:50:45

-

CPE10-M1BH-5L-M7Solenoid valve

196927

Feature Data/description

Data sheet

Part no.:Page:2

Characteristic coil data 24V DC: 1W

Operating medium Dried filtered compressed air, TFDried, filtered and lubricated compressed air, TFGFiltered, unlubricated compressed air, 40 µm filtrationDried compressed air, lubricated or unlubricatedFiltered, lubricated compressed air, 40 µm filtration

Corrosion resistance classification CRC 2

Medium temperature -5 - 50 °C

Protection class IP65to IEC 60529with plug socket

Pilot medium Dried compressed air, lubricated or unlubricated

Ambient temperature -5 - 50 °C

Product weight 0,056 kg

Mounting type with through hole

Pilot exhaust port 82 M3

Pilot exhaust port 84 M3

Pilot air port 12 M3

Pilot air port 14 M3

Pneumatic connection, port 1 M7

Pneumatic connection, port 2 M7

Pneumatic connection, port 3 M7

Pneumatic connection, port 4 M7

Pneumatic connection, port 5 M7

Materials information for seals NBR

Materials information, housing Aluminium die cast

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:50:45

-

CPE10-M1BH-5L-M7Solenoid valve

196927

Feature Data/description

Data sheet

Part no.:Page:3

Authorisation c UL us - Recognized (OL)

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:50:45

-

304518

Piping

© Festo Didactic GmbH & Co. KG, 06/2006 Subject to change 1/2

This plastic piping made of polyethylene is used to establish all connections, with

the exception of piping with acrylic glass.

Parameter Value

Material Polyethylene (PE)**

Temperature and pressure

Hot water

Cold water

Periodic with interruptions *

6 bar at 65 °C

12 bar at 20 °C

114 °C

Expansion 1 % across the overall length (20 °C – 82 °C)

Medium Water

Light Protect against ultraviolet light (long term solar

irradiation, etc.)

Dimensions

Piping diameter, external

Piping length

15 mm

2 m

*Never use this piping in conjunction with an uncontrolled heat source!

**Lead-free and non-toxic. Long service life.

Function

Technical data

-

2/2 Subject to change © Festo Didactic GmbH & Co. KG, 06/2006

-

374134

Gear motor

© Festo Didactic GmbH & Co., 08/2001 Subject to change 1/2

The 24 V D.C. motor is permanently attached to a reversible worm gear. The motorshaft and drive shaft are positioned at right angles. The gear motor can be attachedvia the worm gear housing by means of three screws. The mounting holes are forselftapping screws M5. Electrical connection is by means of 2 flat.

The gear motor serves as a drive for the various conveyors.

Feature Value

Nominal voltage 24 V

Nominal current 1,5 A

Nominal speed of drive shaft 65 r.p.m

Reduction stages 1

Nominal torque 1 Nm

Reversible yes

Starting torque 7 Nm

Connection 2 flat pins

Weight 450 g

Design

Function

Technical data

-

373134

Gear motor

2/2 Subject to change © Festo Didactic GmbH & Co., 08/2001

0 1 2 3 4 5 6 7 8 Nm 100 0

5

10

15

20

25

30

35

40

50

I1

0

110

220

330

440

550

660

770

8 n180

10100

Torque M

Curr

ent I

Rota

tiona

l spe

ed n

A

Effic

ienc

y η

r.p.m

η1

%

Characteristic curve

-

526213

Analogue terminal

© Festo Didactic GmbH & Co. KG, 06/20065 Subject to change 1/2

1...

9 10 11 12 13 14 15

8

The analogue terminal is an optimised terminal strip for the connection of analogue sensors and actuators to a control unit (PLC, EasyPortDA, Simu-Box etc.) via 15 pin Sub-D interfaces. A 15-pin cable (not included) with a core cross-section of 0.25 mm2 connects the analogue terminal parallel to the control unit. 4 analogue input signals and 2 analogue output signals can be connected. The analogue terminal is to be mounted on an H-rail.

Parameter Value

Number of analogue inputs 4

Number of analogue outputs 2

Number of earth for inputs and outputs 2

Nominal voltage VN 125 V

Max. Current-carrying capacity per branch 2.5 A

Number of pins 15

Dimensions

Length

Width

Height

45 mm

65 mm

42 mm

Ambient temperature (operation) -20 °C – 50 °C

The function of the terminals is described in general in the allocation list and subject to the function scope of the industrial controller. Therefore please observe the notes regarding the connection procedure of the controller.

Function

Design

Technical data

-

526213 Analogue terminal

2/2 Subject to change © Festo Didactic GmbH & Co. KG, 06/20065

PIN allocation Analogue terminal

Analogue Function Terminal

OUT VO1 1

VO2 2

AGNDO 3

IN II2 4

II1 5

AGNDI 6

VI2 7

VI1 8

OUT IO2 9

IO1 10

IN II4 12

II3 13

VI4 14

VI3 15

U = Voltage I = Current E = Input A = Output GND = Earth

Pin allocation

-

526214

Analogue comparator 0 - 10 V

© Festo Didactic GmbH & Co., 06/2003 Subject to change 1/2

4

GN

DG

ND

+10

V

+24

V

AIn

GN

D

Erro

r

LEVEL1 LEVEL2

0-10 V AnalogComparator

7 5

2

6

8 3

1 (low)1 (mid)

1 (high)

9

1 Digital outputs 2 Display of output error 3 Potentiometer LEVEL2 (upper threshold) 4 Analogue input 5 Reference voltage linear displacement sensor 6 Display of external operating voltage 7 External operating voltage 8 Potentiometer LEVEL1 (lower threshold) 9 Display of switching status of the outputs

UrefUinGND

24 V DC

0 V

-

526214 Analogue comparator 0 - 10 V

2/2 Subject to change © Festo Didactic GmbH & Co., 06/2003

The comparator is mounted onto top-hat rails. The electrical connection is effected by means of screw terminals. The comparator converts the analogue output signal of the linear displacement sensor in a digital output signal. 3 digital outputs are available: • 1: Measured value lower than threshold 1 • 2: Measured value between threshold 1 and threshold 2 • 3: Measured value higher than threshold 2 The thresholds are adjustable by means of two potentiometers LEVEL1 and LEVEL2. The active output is displayed by a LED.

UHyst.

UHyst.

Digitaloutputs

AnaloginputLevel 1 Level 2 +10 V

low

mid

high

Hysteresis of the switching outputs

Electrical

Operating voltage 20 – 28 V DC

Current consumption up to 200 mA

Switching outputs 3, PNP, normally open

Maximum switching current 50 mA per channel

Output URef 10 V DC (max. 50 mA)

Analogue input 0 – 10 V

Hysteresis UHyst. 80 mV

Degree of protection IP 20

Elektrical connection Screw terminals for cable with max. 0.75 mm ²

Design

Function

Technical data

-

Data sheet - Proximity Sensor SME-8-SL-LED-24 - 526622

Function

Feature values

Operating voltage range DC 10 - 30 V

Operating voltage range AC 10 - 30 V

Switch output with contact, bipolar

Switching element function Normally open contact

Max. output current 500 mA

Electrical connection Plug

M8x1

3-pin

Design for T-slot

Conforms to standard DIN EN 60947-5-2

Short circuit strength No

Measuring principle Reed magnetic

Polarity protected No

Operating status display Yellow LED

Switch-off time 0.05 ms

Switch-on time

-

Feature values

Tightening torque 0.2 Nm

Product weight 5 g

Reproducibility of switching value +/- 0,1 mm

Connector exit direction axial

Mounting type Clamped in T-slot

Insertable into slot lengthwise

Materials note Free of copper and PTFE

Conforms to RoHS

Materials information, housing Epoxy resin

PC

PET

High alloy steel, non-corrosive

Materials information, cable sheaths PUR

2 / 209.03.2009 - Subject to change Festo AG & Co. KG

-

529141

Analog-cable, parallel

© Festo Didactic GmbH & Co. KG, 03/2009 Subject to change 1/1

Analog-cable, parallel

The analog data cable is 15-pole cable with diameter of 0.25 mm². It connects an

analog terminal parallel to a controller (SPS, Easyport; etc.). It is possible to transfer

4 analog output signals and 2 analog input signals. In addition the ground is routed

in the cable.

Connection designation

Analog data cable

Analog Function 15-pole Sub D Colour

code

OUT UA1 1 WH

UA2 2 BN

AGNDA 3 GN

IN IE2 4 YE

IE1 5 GY

AGNDE 6 PK

UE2 7 BU

UE1 8 RD

OUT IA2 9 BK

IA1 10 GYPK

IN IE4 12 RDBU

IE3 13 WHGY

UE4 14 BNGN

UE3 15 WHYE

Analog data cable – Pin assignment

Function

Pin-assignment

Analog data cable

-

HPV-14-20-AFeed separator

529351

Feature Data/description

Data sheet

Part no.:Page:1

Stroke 20 mm

Piston diameter 14 mm

Max. replacement accuracy 0,3 mm

Max. stem backlash Sx 0,05 mm

Max. stem backlash Sz 0,03 mm

Max. angular gripper jaw backlash ax 0,12 deg

Max. angular gripper jaw backlash ay 0,2 deg

Max. angular gripper jaw backlash az 0,175 deg

Mounting of external fingers Through-hole

Cushioning none

Assembly position Any

Mode of operation double-acting

Design structure twin pistonPiston rodStopperNon-rotating

Position detection with proximity sensor

Variants Single-ended piston rod

Protection against torque/guide Square guide

Operating pressure 3 - 8 bar

Advancing time 25 ms

Return-stroke time 25 ms

Repetition accuracy

-

HPV-14-20-AFeed separator

529351

Feature Data/description

Data sheet

Part no.:Page:2

Corrosion resistance classification CRC 2

Ambient temperature 5 - 60 °C

Max. force on finger Fz static 100 N

Max. torque at finger Mx static 5 Nm

Max. torque at finger My static 5 Nm

Theoretical force at 6 bar, return stroke 75 N

Theoretical force at 6 bar, advance stroke 90 N

Twisting torque Mz (graph) 5 Nm

Product weight 290 g

Mounting type OptionalInternal thread and centring sleeveWith through-hole and centring sleeve

Pneumatic connection M5

Materials note Copper and Teflon-free

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:47:44

-

SDE1-D10-G2-H18-C-PU-M8Pressure sensor

529955

Feature Data/description

Data sheet

Part no.:Page:1

Assembly position Any

Short circuit strength Pulsing

Measured variable Relative pressure

Measurement method Piezoresistive pressure sensor with display

Polarity protected for all electrical connections

Threshold setting range 0,2 - 9,98 bar

Hysteresis adjustment range [bar] 0 - 9 bar

Operating pressure 0 - 10 bar

Analogue output 0 - 10 V

Operating voltage DC 15 - 30 V

Max. output current 150 mA

Switch output PNP

Operating medium Filtered, unlubricated compressed air, 40 µm filtrationFiltered, lubricated compressed air, 40 µm filtration

CE Symbol In compliance with EU directive 89/336/EWG (EMV)

Corrosion resistance classification CRC 2

Medium temperature 0 - 50 °C

Protection class IP65

Ambient temperature 0 - 50 °C

Product weight 70 g

Pressure measuring range 0 - 10 bar

Accuracy, FS 2 %

Electrical connection M8x1Plugto EN 60947-5-2

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:46:26

-

SDE1-D10-G2-H18-C-PU-M8Pressure sensor

529955

Feature Data/description

Data sheet

Part no.:Page:2

Round design4-pin

Mounting type with top-hat rail

Pneumatic connection G1/8

Materials information, housing POM-reinforcedPA

Festo AG & Co. KGPostfach73734 EsslingenPrinted:10.07.2006 13:46:26

-

2005/04 – Subject to change – Products 2004/2005 7 / 1.2-1

Quarter turn actuators DAPSKey features

-T- Size0015 ... 1920

The quarter turn actuators DAPS are

specially tailored to the requirements

of the process industry. The torque is

generated via a scotch-yoke

� Compact design

� Torque characteristics adjusted to

the process valves

� For the same housing size, the

� Port pattern to Namur VDI/

VDE 3845 for attaching solenoid

valves

-L- Torque15 ... 1,920 Nm

-Y- Swivel angel0 … 90°

g y

mechanism. This is advantageous for

overcoming the valve’s high break-

away torques.

Given their robustness and graduated

torques, the DAPS quarter turn actua-

tors are predominantly used to control

valves through which various media

flow and whose angle of rotation is

limited to 90° e g ball valves and

g ,

single-acting drive has half the

torque of the double-acting drive

� Low wearing thanks to the simple

and robust mechanical system

� Adjustable swivel angle

� Selected types according to ATEX

directive for explosive atmospheres

� www.festo.com/en/ex

limited to 90°, e.g. ball valves and

butterfly valves.

Actuators

Quarterturnactuators

1.2

-

Products 2004/2005 – Subject to change – 2005/047 / 1.2-2

Quarter turn actuators DAPS, double-actingProduct range overview

Flange hole pattern - Connection dimensions to DIN ISO 5211 and Namur VDI/VDE 3845

Connection F03 F04 F04 F05 F05 F07 F07 F10 F10 F12 F12 F14 F14 F16 Shaft

Square V11 V11 V14 V14 V17 V22 V27 V36 V36 V46 V46 height

DAPS-0015-…-F03 � – – – – – – – – – – – – – 20

DAPS-0015-…-F04 – � – – – – – – – – – – – – 20

DAPS-0030-…-F03 � – – – – – – – – – – – – – 20

DAPS-0030-…-F04 – � – – – – – – – – – – – – 20

DAPS-0060-…-F04 – – � – – – – – – – – – – – 20

DAPS-0060-…-F05 – – – � – – – – – – – – – – 20

DAPS-0106-…-F0507 – – – – � � – – – – – – – – 20

DAPS-0180-…-F0710 – – – – – – � � – – – – – – 30

DAPS-0240-…-F0710 – – – – – – � � – – – – – – 30

DAPS-0360-…-F0710 – – – – – – � � – – – – – – 30

DAPS-0480-…-F1012 – – – – – – – – � � – – – – 30

DAPS-0960-…-F12 – – – – – – – – – – � – – – 30

DAPS-0960-…-F14 – – – – – – – – – – – � – – 30

DAPS-1920-…-F14 – – – – – – – – – – – – � – 30

DAPS-1920-…-F16 – – – – – – – – – – – – – � 30

Hole pattern for Namur 30 30 30 30 30 30 30 30 30 30 30 30 30 30p

accessories 80 80 80 80 80 80 80 80 80 80 80 80 80 80

Actuators

Quarterturnactuators

1.2

-

2005/04 – Subject to change – Products 2004/2005 7 / 1.2-3

Quarter turn actuators DAPS, single-actingProduct range overview

Flange hole pattern - Connection dimensions to DIN ISO 5211 and Namur VDI/VDE 3845

Connection F03 F04 F04 F05 F05 F07 F07 F10 F10 F12 F12 F14 F14 F16 Shaft

Square V11 V11 V14 V14 V17 V22 V27 V36 V36 V46 V46 height

DAPS-0015-…-F03 � – – – – – – – – – – – – – 20

DAPS-0015-…-F04 – � – – – – – – – – – – – – 20

DAPS-0030-…-F04 – – � – – – – – – – – – – – 20

DAPS-0030-…-F05 – – – � – – – – – – – – – – 20

DAPS-0053-…-F0507 – – – – � � – – – – – – – – 20

DAPS-0090-…-F0710 – – – – – – � � – – – – – – 30

DAPS-0120-…-F0710 – – – – – – � � – – – – – – 30

DAPS-0180-…-F0710 – – – – – – � � – – – – – – 30

DAPS-0240-…-F1012 – – – – – – – – � � – – – – 30

DAPS-0480-…-F12 – – – – – – – – – – � – – – 30

DAPS-0480-…-F14 – – – – – – – – – – – � – – 30

DAPS-0960-…-F14 – – – – – – – – – – – – � – 30

DAPS-0960-…-F16 – – – – – – – – – – – – – � 30

Hole pattern for Namur 30 30 30 30 30 30 30 30 30 30 30 30 30 30p

accessories 80 80 80 80 80 80 80 80 80 80 80 80 80 80

Actuators

Quarterturnactuators

1.2

-

Products 2004/2005 – Subject to change – 2005/047 / 1.2-4

Quarter turn actuators DAPSPeripherals overview

1

3

2

4

5

6

7

Mounting attachments and accessories

Brief description � Page

1 Limit switch attachment

QH-DR-E

Square design

pneumatic, electrical or inductive sensing

7 / 1.2-61

2 Limit switch attachment

DAPZ

Square design

electrical, electrically explosion-proof or inductive sensing

7 / 1.2-54

3 Limit switch attachment

DAPZ

Round design, variant AR

electrical, inductive or inductively explosion-proof sensing

7 / 1.2-58

4 Limit switch attachment

DAPZ

Round design, variant RO

electrical, inductive or inductive Namur sensing

7 / 1.2-56

5 Solenoid valve

MFH

Basic valve with pilot control valve for F solenoid coil 7 / 2.1-10

Solenoid valve

MN1H

Basic valve with pilot control valve for N1 solenoid coil 7 / 2.1-10

Solenoid valve

MGTBH

Basic valve with pilot control valve, solenoid coil and socket 7 / 2.1-10

6 Solenoid valve

NVF3

For F solenoid coil and explosion-proof F solenoid coil 7 / 2.1-4

7 Ball valve

VAPB

Brass or stainless steel, corrosion-resistant 7 / 2.2-2

Actuators

Quarterturnactuators

1.2

-

2005/04 – Subject to change – Products 2004/2005 7 / 1.2-5

Quarter turn actuators DAPSType codes

DAPS — 0240 — 090 — R S 4 — F1012

Type

DAPS Quarter turn actuator

Size

0015 Nominal torque 15 Nm

0030 Nominal torque 30 Nm

0053 Nominal torque 53 Nm

0060 Nominal torque 60 Nm

0106 Nominal torque 106 Nm

0180 Nominal torque 180 Nm

0240 Nominal torque 240 Nm

0360 Nominal torque 360 Nm

0480 Nominal torque 480 Nm

0960 Nominal torque 960 Nm

1920 Nominal torque 1,920 Nm

Swivel angle

090 90°

Closing direction

R Closes to right

Mode of operation

Double-acting

S Single-acting

Spring strength

Omitted for double-acting

1 For connection pressure 2.8 bar

2 For connection pressure 3.5 bar

3 For connection pressure 4.2 bar

4 For connection pressure 5.6 bar

Flange hole pattern

F03 Flange hole pattern F03

F04 Flange hole pattern F04

F05 Flange hole pattern F05

F07 Flange hole pattern F07

F10 Flange hole pattern F10

F12 Flange hole pattern F12

F14 Flange hole pattern F14

F16 Flange hole pattern F16

Actuators

Quarterturnactuators

1.2

-

Products 2004/2005 – Subject to change – 2005/047 / 1.2-6

Quarter turn actuators DAPS, double-actingTechnical data

Function

-T- Size0015 ... 1920

-L- Torque15 ... 1,920 Nm

-Y- Swivel angel0 … 90°

General technical data

Size 0015 … 0360 0480 … 1920

Pneumatic connection G� G�

Design Scotch yoke system, double-acting

Assembly position Any

Swivel angle [°] 90

End-position adjusting range

at 90 °

[°] ±5

Closing direction Closes to right

Operating and environmental conditions

Size 0015 … 1920

Operating pressure1) [bar] 1 … 8.4

Operating medium Dried compressed air, lubricated or unlubricated

Ambient temperature [°C] –20 … +80

Corrosion resistance class CRC2) 3

1) Minimum operating pressures vary for single-acting quarter turn actuators depending upon spring quantity.

2) Corrosion resistance class 3 according to Festo standard 940 070

Components requiring higher corrosion resistance. External visible parts in direct contact with industrial atmospheres or media such as solvents and cleaning agents, with a predominantly functional requirement for

the surface.

Air consumption [l/cycle] at 6 bar

Size Size

DAPS-0015 0.72 DAPS-0240 12

DAPS-0030 1.44 DAPS-0360 17.4

DAPS-0060 3 DAPS-0480 24

DAPS-0106 5.04 DAPS-0960 48

DAPS-0180 8.64 DAPS-1920 96

Weight [g]

Size Size

DAPS-0015 750 DAPS-0240 5,200

DAPS-0030 1,000 DAPS-0360 6,200

DAPS-0060 1,900 DAPS-0480 8,200

DAPS-0106 2,300 DAPS-0960 17,400

DAPS-0180 4,100 DAPS-1920 30,700

Actuators

Quarterturnactuators

1.2

-

2005/04 – Subject to change – Products 2004/2005 7 / 1.2-7

Quarter turn actuators DAPS, double-actingTechnical data

Actual torque [Nm] as a function of operating pressure [bar] and swivel angle [°]

Size Swivel angle Operating pressure [bar]g

[°] 2.5 3 4 5 5.6 6 7 8

DAPS-0015 0 6.7 8 10.7 13.4 15 16.1 18.8 21.45

50 3.3 4 5.4 6.7 7.5 8 9.4 10.7

90 5 6 8.1 10.1 11.3 12.1 14.1 16.1

DAPS-0030 0 13.4 16.1 21.4 26.8 30 32.1 37.5 42.93

50 6.7 8 10.7 13.4 15 16.1 18.8 21.4

90 10 12 16.1 20.1 22.5 24.1 28.1 32.1

DAPS-0060 0 26.8 32.1 42.9 53.6 60 64.3 75 85.7

50 13.4 16.1 21.4 26.8 30 32.1 37.5 42.9

90 20.1 24.1 32.1 40.2 45 48.2 56.3 64.3

DAPS-0106 0 47.5 57 76 95 106 114 133 151

50 23.5 28 38 47 53 57 66 76

90 35.5 43 57 71 80 86 100 114

DAPS-0180 0 80.4 96 128.4 160.8 180 193.2 225.6 264.8

50 40.2 48 64.8 80.4 90 96 112.8 128.4

90 60.6 72 97.2 121.2 135 145.2 169.2 193.2

DAPS-0240 0 107.1 128.6 171.4 214.3 240 257.1 300 342.9

50 53.5 64.3 85.7 107.1 120 128.6 150 171.4

90 80.3 96.4 128.6 160.7 180 192.9 225 257.1

DAPS-0360 0 160.8 192 256.8 321.6 360 386.4 451.2 513.63

50 80.4 96 129.6 160.8 180 192 225.6 264.8

90 121.2 144 194.4 242.4 270 290.4 338.4 386.4

DAPS-0480 0 214.3 257.1 342.9 428.6 480 514.3 600 685.7

50 107.1 128.6 171.4 214.3 240 257.1 300 342.9

90 160.7 192.9 257.1 321.4 360 358.7 450 514.3

DAPS-0960 0 428.6 514.3 685.7 857.1 960 1,028.6 1,200 1,371.49

50 214.3 257.1 342.9 428.6 480 514.3 600 685.7

90 321.4 385.7 514.3 642.9 720 771.4 900 1,028.6

DAPS-1920 0 857.1 1,028.6 1,371.4 1,714.3 1,920 2,057.1 2,400 2,742.99

50 428.6 514.3 685.8 857.1 960 1,028.6 1,200 1,371.4

90 642.9 771.4 1,028.6 1,285.7 1,440 1,542.9 1,800 2,057.13

Torque for size at 5.6 bar and swivel angle 0°

Materials

Quarter turn actuators

Housing Wrought aluminium alloy

Cover Wrought aluminium alloy

Shaft Stainless steel

External screws Stainless steel

Seals Nitrile rubber

Actuators

Quarterturnactuators

1.2

-

Products 2004/2005 – Subject to change – 2005/047 / 1.2-8

Quarter turn actuators DAPS, double-actingTechnical data

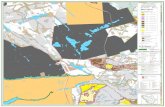

Dimensions Download CAD data� www.festo.com/en/engineering

Size 0015 … 0360

Actuators

Quarterturnactuators

1.2

-

2005/04 – Subject to change – Products 2004/2005 7 / 1.2-9

Quarter turn actuators DAPS, double-actingTechnical data

Size B1 B2 B3 D1

∅

D2

∅

D3 D4 D6

∅

D7

∅

H1 H2

DAPS-0015-…-F0352 2 24 2 28

36– –

M59 2 13 72 2 28

DAPS-0015-…-F0452.2 24.2 28

42– –

M59.2 13 72.2 28

DAPS-0030-…-F0359 2 27 7 31 5

36– –

M510 9 13 79 2 31 5

DAPS-0030-…-F0459.2 27.7 31.5

42– –

M510.9 13 79.2 31.5

DAPS-0060-…-F0470 4 32 7 37 7

42– –

M514 5 13 90 4 37 7

DAPS-0060-…-F0570.4 32.7 37.7

50– –

M614.5 13 90.4 37.7

DAPS-0106-…-F0507 83.3 38.5 44.8 50 70 M8 M6 16.2 17 103.3 44.8

DAPS-0180-…-F0710 107.5 51 56.5 70 102 M10 M8 20.2 22 137.5 56.5

DAPS-0240-…-F0710 111.1 51 60.1 70 102 M10 M8 22.5 22 141.1 60.1

DAPS-0360-…-F0710 118 56 62 70 102 M10 M8 25.5 22 148 62

Size H3 H5 H6 L1 T1 T2 T3 T4 � 1 � 2

DAPS-0015-…-F0320 0 8 3 2 159 –

810 13 2 11 8

DAPS-0015-…-F0420 0.8 3.2 159 –

810 13.2 11 8

DAPS-0030-…-F0320 0 8 3 2 174 –

810 13 2 11 9

DAPS-0030-…-F0420 0.8 3.2 174 –

810 13.2 11 9

DAPS-0060-…-F0420 – 4 198 –

813 16 5 14 10

DAPS-0060-…-F0520 – 4 198 –

913 16.5 14 10

DAPS-0106-…-F0507 20 – 4 236.5 9 12 13 19.3 17 12

DAPS-0180-…-F0710 30 – 4 289.9 12 15 16 24.8 22 15

DAPS-0240-…-F0710 30 – 4 313.6 12 15 17 24.8 22 15

DAPS-0360-…-F0710 30 – 4 339.3 12 15 19 24.3 22 19

Actuators

Quarterturnactuators

1.2

-

Products 2004/2005 – Subject to change – 2005/047 / 1.2-10

Quarter turn actuators DAPS, double-actingTechnical data

Dimensions Download CAD data� www.festo.com/en/engineering

Size 0480 … 1920

Actuators

Quarterturnactuators

1.2

-

2005/04 – Subject to change – Products 2004/2005 7 / 1.2-11

Quarter turn actuators DAPS, double-actingTechnical data

Size B1 B2 B3 D1

∅

D2

∅

D3 D4 D6

∅

D7

∅

H1

DAPS-0480-…-F1012 134.9 62 72.9 102 125 M12 M10 29 27 164.9

DAPS-0960-…-F12168 74 5 93 5

125– –

M1236 5 27 198

DAPS-0960-…-F14168 74.5 93.5

140– –

M1636.5 27 198

DAPS-1920-…-F14207 7 93 114 7

140– –

M1646 36 237 7

DAPS-1920-…-F16207.7 93 114.7

165– –

M2046 36 237.7

Size H2 H3 L1 T1 T2 T3 T4 � 1 � 2

DAPS-0480-…-F1012 72.9 30 387.7 15 18 19 29.5 27 19

DAPS-0960-…-F1293 5 30 479 4 –

1819 5 38 5 36 24

DAPS-0960-…-F1493.5 30 479.4 –

2419.5 38.5 36 24

DAPS-1920-…-F14114 7 30 601 –

2418 5 48 5 46 32

DAPS-1920-…-F16114.7 30 601 –

3018.5 48.5 46 32

Actuators

Quarterturnactuators

1.2

-

Products 2004/2005 – Subject to change – 2005/047 / 1.2-12

Quarter turn actuators DAPS, double-actingTechnical data

Ordering data – Actuators

Part No. Type Part No. Type

Size 0015 Size 0240

533 417 DAPS-0015-090-R-F03 533 422 DAPS-0240-090-R-F0710

533 475 DAPS-0015-090-R-F04

Size 0360

Size 0030 533 423 DAPS-0360-090-R-F0710

533 418 DAPS-0030-090-R-F03

533 476 DAPS-0030-090-R-F04 Size 0480

533 424 DAPS-0480-090-R-F1012

Size 0060

533 419 DAPS-0060-090-R-F04 Size 0960

533 477 DAPS-0060-090-R-F05 533 425 DAPS-0960-090-R-F12

533 478 DAPS-0960-090-R-F14

Size 0106

533 420 DAPS-0106-090-R-F0507 Size 1920

533 426 DAPS-1920-090-R-F14

Size 0180 533 479 DAPS-1920-090-R-F16

533 421 DAPS-0180-090-R-F0710

Ordering data – Wearing parts kits

Part No. Type Part No. Type

Size 0015 Size 0240

397 470 DAPS-0015 397 475 DAPS-0240/S0120

Size 0030 Size 0360

397 471 DAPS-0030/S0015 397 476 DAPS-0360/S0180

Size 0060 Size 0480

397 472 DAPS-0060/S0030 397 477 DAPS-0480/S0240

Size 0106 Size 0960

397 473 DAPS-0106/S0053 397 478 DAPS-0960/S0480

Size 0180 Size 1920

397 474 DAPS-0180/S0090 397 479 DAPS-1920/S0960

Actuators

Quarterturnactuators

1.2

-

2005/04 – Subject to change – Products 2004/2005 7 / 1.2-13

Quarter turn actuators DAPS, single-actingTechnical data

Function

-T- Size0015 ... 0960

-L- Torque15 ... 960 Nm

-Y- Swivel angel0 … 90°

General technical data

Size 0015 … 0180 0240 … 0960

Pneumatic connection G� G�

Design Scotch yoke system, single-acting

Assembly position Any

Swivel angle [°] 90

End position adjusting range

at 90 °

[°] ±5

Closing direction Closes to right

Operating and environmental conditions

Size 0015 … 0960

Operating pressure1) [bar] 1 … 8.4

Operating medium Dried compressed air, lubricated or unlubricated

Ambient temperature [°C] –20 … +80

Corrosion resistance class CRC2) 3

1) Minimum operating pressures vary for single-acting quarter turn actuators depending upon spring quantity.

2) Corrosion resistance class 3 according to Festo standard 940 070

Components requiring higher corrosion resistance. External visible parts in direct contact with industrial atmospheres or media such as solvents and cleaning agents, with a predominantly functional requirement for

the surface.

Air consumption [l/cycle] at 6 bar

Size Size

DAPS-0015 0.36 DAPS-0180 4.32

DAPS-0030 0.72 DAPS-0240 6

DAPS-0053 1.08 DAPS-0480 12

DAPS-0090 2.16 DAPS-0960 24

DAPS-0120 3

Weight [g]

Size Size

DAPS-0015 1,300 DAPS-0180 8,700

DAPS-0030 2,200 DAPS-0240 11,000

DAPS-0053 3,200 DAPS-0480 23,300

DAPS-0090 5,400 DAPS-0960 41,400

DAPS-0120 6,900

Materials

Quarter turn actuators

Housing Wrought aluminium alloy

Cover Wrought aluminium alloy

Shaft Stainless steel

External screws Stainless steel

Seals Nitrile rubber

Actuators

Quarterturnactuators

1.2

-

Products 2004/2005 – Subject to change – 2005/047 / 1.2-14

Quarter turn actuators DAPS, single-actingTechnical data

Actual torque [Nm] as a function of operating pressure [bar], spring strength and swivel angle [°]

Spring Spring torque Operating pressure [bar]p g

strength

p g q

[Nm] 2.5 2.8 3 3.5 4.2g

0° 50° 90° 0° 50° 90° 0° 50° 90° 0° 50° 90° 0° 50° 90° 0° 50° 90°

DAPS-0015

1 5.0 3.7 7.5 6.2 2.9 3.7 7.5 3.7 5 8.4 4.2 5.9 10.6 5.6 8.1 13.8 7.4 11.3

2 6.3 4.7 9.4 – – 7.2 3.3 4 9.4 4.7 6.3 12.6 6.5 9.4

3 7.5 5.6 11.3 – – – 8.2 3.7 4.4 11.3 5.6 7.5

4 10.0 7.5 15 – – – – –

DAPS-0030

1 10.0 7.5 15 12.3 5.9 7.3 15 7.5 10 16.8 8.6 11.8 21.3 11.3 16.3 27.5 15 22.5

2 12.5 9.4 18.8 – – 14.3 6.7 8 18.8 9.4 12.5 25.1 13.2 18.8

3 15.0 11.3 22.5 – – – 16.3 7.5 8.8 22.5 11.3 15

4 20.0 15 30 – – – – –

DAPS-0053

1 17.5 13 26.5 21.8 10.2 12.8 26.5 13 17.5 29.6 14.9 20.6 37.5 19.5 28.5 48.5 26 39.5

2 22 16.5 33 – – 25.1 11.8 14.1 33 16.5 22 44 23.1 33

3 26 19.5 40 – – – 29 13 15 40 19.5 26

4 35 26 53 – – – – –

DAPS-0090

1 30 22.5 45 37 17.7 22 45 22.5 30 50.4 25.7 35.4 63.8 33.8 48.8 82.5 45 67.5

2 37.5 28.1 56.3 – – 42.9 20.1 24.1 56.3 28.1 37.5 75.1 39.4 56.3

3 45 33.9 67.5 – – – 48.8 22.6 26.3 67.5 33.9 45

4 60 45 90 – – – – –

DAPS-0120

1 40 30 60 49.3 23.6 29.3 60 30 40 67.1 34.3 47.1 85 45 65 110 60 90

2 50 37.5 75 – – 57.1 26.8 32.1 75 37.5 50 100 52.5 75

3 60 45 90 – – – 65 30 35 90 45 60

4 80 60 120 – – – – –

DAPS-0180

1 60 45 90 73.9 35.4 43.9 90 45 60 100.7 51.4 70.7 127.5 67.5 97.5 165 90 135

2 75 56.3 112.5 – – 85.7 40.2 48.2 112.5 56.3 75 150 78.8 112.5

3 90 67.5 135 – – – 97.5 45 52.5 135 67.5 90

4 120 90 180 – – – – –

DAPS-0240

1 80 60 120 98.6 47.1 58.6 120 60 80 134.3 68.6 94.3 170 90 130 220 120 180

2 100 75 150 – – 114.3 53.6 64.3 150 75 100 200 105 105

3 120 90 180 – – – 130 60 70 180 90 120

4 160 120 240 – – – – –

DAPS-0480

1 160 120 240 197.1 94.3 117.1 240 120 160 268.6 137.1 188.6 340 180 260 440 240 360

2 200 150 300 – – 228.6 107.1 128.6 300 150 200 400 210 300

3 240 180 360 – – – 260 120 140 360 180 240

4 320 240 480 – – – – –

DAPS-0960

1 320 240 480 394.3 188.6 234.3 480 240 320 537.1 274.3 377.1 680 360 520 880 480 720

2 400 300 600 – – 457.1 214.3 257.1 600 300 400 800 420 600

3 480 360 720 – – – 520 240 280 720 360 480

4 640 480 960 – – – – –3

Actuators

Quarterturnactuators

1.2

-

2005/04 – Subject to change – Products 2004/2005 7 / 1.2-15

Quarter turn actuators DAPS, single-actingTechnical data

Actual torque [Nm] as a function of operating pressure [bar], spring strength and swivel angle [°]

Spring Operating pressure [bar]p g

strength 5 5.6 6 7 8

0° 50° 90° 0° 50° 90° 0° 50° 90° 0° 50° 90° 0° 50° 90°

DAPS-0015

1 – – – – –

2 16.1 8.7 13 18.8 10.3 15.7 – – –

3 14.9 7.7 11.1 17.6 9.3 13.8 19.4 10.4 15.6 23.8 13.1 20 28.3 15.7 24.5

4 12.3 5.9 7.3 15 7.5 10 16.8 8.6 11.8 21.3 11.3 16.3 25.7 13.9 20.7

DAPS-0030

1 – – – – –

2 32.2 17.5 25.9 37.6 20.7 31.3 – – –

3 29.6 15.6 22.1 35 18.8 27.5 38.6 21 31.1 47.5 26.4 40 56.4 31.7 48.9

4 24.6 11.8 14.6 30 15 20 33.6 17.1 23.6 42.5 22.5 32.5 51.4 27.9 41.4

DAPS-0053

1 – – – – –

2 56.6 30.6 45.6 66 36.3 55 – – –

3 52.6 26.9 38.6 62 32.5 48 68.3 36.2 54.3 84 45.5 70 99.7 54.8 85.7

4 43.6 20.4 25.6 53 26 35 59.3 29.7 41.3 75 39 57 90 48.3 72.7

DAPS-0090

1 – – – – –

2 96.5 52.2 77.7 112.6 61.9 93.8 – – –

3 88.9 46.8 66.4 105 56.5 82.5 115.7 63 93.2 142.5 79.1 120 169.3 95.2 146.8

4 73.9 35.4 43.9 90 45 60 100.7 51.4 70.7 127.5 67.5 97.5 154.3 83.6 124.3

DAPS-0120

1 – – – – –

2 128.6 69.6 130.6 150 82.5 125 – – –

3 118.6 62.1 88.6 140 75 110 154.3 83.6 124.3 190 105 160 225.7 126.4 195.7

4 86.7 40 46.7 106.7 52 66.7 120 60 80 153.3 80 113.3 186.7 100 146.7

DAPS-0180

1 – – – – –

2 192.9 104.5 155.4 225 123.8 187.5 – – –

3 177.9 93.2 132.9 210 112.5 165 231.4 125.4 186.4 285 157.5 240 338.6 189.6 293.6

4 147.9 707.7 87.9 180 90 120 201.4 102.9 141.4 255 135 195 308.6 167.6 284.6

DAPS-0240

1 – – – – –

2 257.1 139.3 207.1 300 165 250 – – –

3 237.1 124.3 177.1 280 150 220 308.6 167.1 248.6 380 210 320 451.4 252.9 391.4

4 197.1 94.3 117.1 240 120 160 268.6 137.1 188.6 340 180 260 411.4 222.9 331.4

DAPS-0480

1 – – – – –

2 514.3 278.6 414.3 600 330 500 – – –

3 474.3 248.6 354.3 560 300 440 617.1 334.3 497.1 760 420 640 902.9 505.7 782.9

4 394.3 118.6 234.3 480 240 320 537.1 274.3 377.1 680 360 250 822.9 445.7 662.9

DAPS-0960

1 – – – – –

2 1,028.6 557.1 828.6 1,200 660 1,000 – – –

3 948.6 497.1 708.6 1,120 600 880 1,234.3 668.6 994.3 1,520 840 1,280 1,805.7 1,011.4 1,565.7

4 788.6 377.1 468.6 960 480 640 1,074.3 548.6 754.3 1,360 720 1,040 1,645.7 891.4 1,325.73

Torque for size at 5.6 bar and swivel angle 0°

Actuators

Quarterturnactuators

1.2

-

Products 2004/2005 – Subject to change – 2005/047 / 1.2-16

Quarter turn actuators DAPS, single-actingTechnical data

Dimensions Download CAD data� www.festo.com/en/engineering

Size 0015 … 0180

Actuators

Quarterturnactuators

1.2

-

2005/04 – Subject to change – Products 2004/2005 7 / 1.2-17

Quarter turn actuators DAPS, single-actingTechnical data

Size B1 B2 B3 D1

∅

D2

∅

D3 D4 D6

∅

D7

∅

H1 H2

DAPS-0015-…-F0359 2 27 7 31 5

36– –

M510 9 13 79 2 31 5

DAPS-0015-…-F0459.2 27.7 31.5

42– –

M510.9 13 79.2 31.5

DAPS-0030-…-F0470 4 32 7 37 7

42– –

M514 5 13 90 4 37 7

DAPS-0030-…-F0570.4 32.7 37.7

50– –

M614.5 13 90.4 37.7

DAPS-0053-…-F0507 83.3 38.5 44.8 50 70 M8 M6 16.2 17 103.3 44.8

DAPS-0090-…-F0710 107.5 51 56.5 70 102 M10 M8 20.2 22 137.5 56.5

DAPS-0120-…-F0710 111.1 51 60.1 70 102 M10 M8 22.5 22 141.1 60.1

DAPS-0180-…-F0710 118 56 62 70 102 M10 M8 25.5 22 148 62

Size H3 H5 H6 L1 T1 T2 T3 T4 � 1 � 2

DAPS-0015-…-F0320 0 8 3 2 233 3 –

810 13 2 11 9

DAPS-0015-…-F0420 0.8 3.2 233.3 –

810 13.2 11 9

DAPS-0030-…-F0420 – 4 259 –

813 16 5 14 10

DAPS-0030-…-F0520 – 4 259 –

913 16.5 14 10

DAPS-0053-…-F0507 20 – 4 303.5 9 12 13 19.3 17 12

DAPS-0090-…-F0710 30 – 4 393.7 12 15 16 24.8 22 15

DAPS-0120-…-F0710 30 – 4 409.6 12 15 17 24.8 22 15

DAPS-0180-…-F0710 30 – 4 474 12 15 19 24.3 22 19

Actuators

Quarterturnactuators

1.2

-

Products 2004/2005 – Subject to change – 2005/047 / 1.2-18

Quarter turn actuators DAPS, single-actingTechnical data

Dimensions Download CAD data� www.festo.com/en/engineering

Size 0240 … 0960

Size B1 B2 B3 D1

∅

D2

∅

D3 D4 D6

∅

D7

∅